文章信息

- 杨斌, 李云龙, 王世杰, 聂瑞, 王照智

- YANG Bin, LI Yun-long, WANG Shi-jie, NIE Rui, WANG Zhao-zhi

- 拉应力下碳纳米管增强高分子基复合材料的应力分布

- Stress distribution of carbon nanotube reinforced polymer matrix composites under tensile stress

- 材料工程, 2020, 48(2): 79-86

- Journal of Materials Engineering, 2020, 48(2): 79-86.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2019.000332

-

文章历史

- 收稿日期: 2019-04-08

- 修订日期: 2019-09-10

2. 汕头大学 工学院, 广东 汕头 515063

2. College of Engineering, Shantou University, Shantou 515063, Guangdong, China

在复合材料工业中, 凭借超强的表面吸附作用,碳纳米管(CNT)作为纳米补强剂受到了广泛的关注和研究[1-2]。CNT具有高长径比和中空的圆柱形结构,其长度从几十纳米延伸到几微米,外径在2.5 nm到30 nm之间[3]。作为一维材料,CNT具有优异的力学、电学、化学等特性[4-6]。通过将CNT引入橡胶、尼龙、聚甲基丙烯酸甲酯和环氧树脂等材料中,可有效地提升其基体的刚度、强度和硬度等力学性能[7]。以CNT增强高分子复合材料的力学性能一直是理论和实验的重要研究课题。

在CNT增强的高分子复合材料中,应力从基体传递到CNT的外层,并通过范德华力从最外层传递到最内层。因此,CNT各层的应力分布不同于连续体中的应力分布。为了探究CNT内的应力分布情况,国内外学者通过理论、实验和计算机模拟对此作了一系列相关研究。何才启等[8]从理论的角度计算了CNT增强弹性基体复合材料中界面层厚度对应力场、CNT纤维饱和应力和应力传递效率等的影响。Zalamea等[9]利用连续介质力学中的两种方法计算了多壁碳纳米管(MWCNT)结构中多个壳层之间的界面相互作用,并且认为MWCNT能否有效地将应力从基质传递到其内部在复合材料应用中起到至关重要的作用。Viet等[10]研究也表明,从基体到CNT的载荷转移在提高复合材料的力学性能方面起着重要作用。为了研究CNT/高分子复合材料的力学性能,许多研究人员提出了不同的理论模型。Gao等[11]提出了由CNT增强的聚合物复合材料的剪切滞后模型,并使用多尺度方法研究从聚合物基体到CNT最内层的载荷转移以及影响载荷传递的因素。Tsai等[3]将三壁CNT增强复合材料的离散几何结构转变为等效连续几何结构,使用剪切滞后模型研究了从基体到CNT内层的载荷传递。基于现有理论和模型,许多学者进行了进一步的扩展研究。Spanos等[12]应用细观力学混合有限元方法研究了单壁碳纳米管(SWCNT)增强复合材料的应力传递,并详细分析了SWCNT体积分数,界面刚度和基体弹性模量对应力传递的影响。Viet等[13]利用剪切滞后模型,研究了CNT/环氧树脂复合材料在拉力下的载荷传递,他们发现环氧树脂基体和CNT外层之间的杨氏模量和界面剪切模量对载荷传递和饱和应力长度的影响并不明显。高江姗等[14]通过实验研究了在碳纳米管和炭黑协同作用下对天然橡胶/顺丁橡胶复合材料的力学性能、加工性能、耐磨性和动态力学性能的影响,并给出了不同性能填料的最佳质量分数。张勇[15]采用分子动力学模拟的方法从微观上研究了混杂结构/聚合物复合材料中在轴向载荷下的力学响应以及界面力学增强机理。然而,目前对于理论计算和计算机仿真的结合研究还不够充分和完备,同时缺少对CNT在不同高分子复合材料内受力情况的对比研究,对CNT实际取用原则的宏观理论解释也鲜有涉及。

本工作建立了CNT/高分子复合材料的代表性体积元(RVE)模型,采用了剪切滞后模型对CNT增强高分子复合材料中CNT内各层在基体受固定拉伸载荷下的应力分布进行了计算与分析,并通过有限元法(FEM)进行仿真模拟,将计算和模拟结果进行了对比与分析。研究了CNT的长径比、层数、CNT含量和不同基体材料对CNT各层的应力分布的影响。为不失一般性,CNT的层数选择为1, 2, 4, 8层。

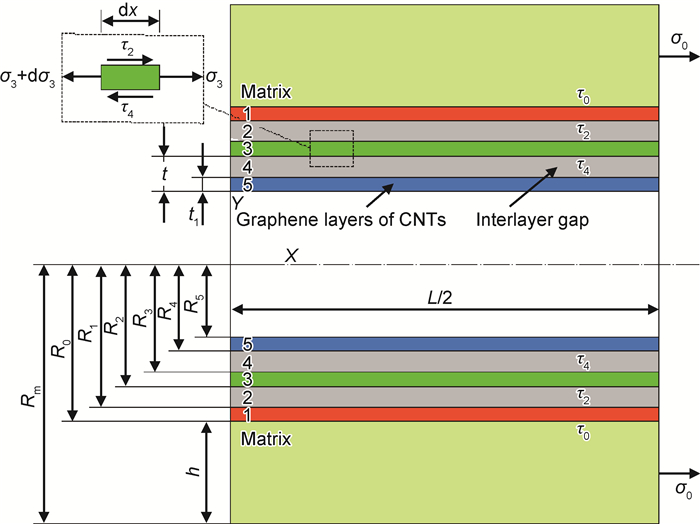

1 模型构建与计算仿真 1.1 构建模型CNT的微观结构并不连续,可看作由若干卷曲的石墨烯层组成,层与层之间依靠范德华力结合,故CNT内部各层之间存在间隙。根据分子模拟和实验观测,其间隙大小t=0.34 nm[16-17]。为了便于研究,在本工作中将CNT的离散结构简化为等效的连续体结构,如图 1所示。在该连续体模型中,两个相邻的石墨烯层之间的间隙被假定为由范德华力控制的实体,其厚度为t2。而石墨烯层的厚度假定为碳原子的直径,其值t1取为0.14 nm,t=t1+t2。假设CNT和环氧树脂之间完美结合,其界面间的厚度忽略不计。

|

图 1 碳纳米管几何模型 (a)离散分子模型;(b)等效连续模型 Fig. 1 Geometry model of carbon nanotube (a)discrete molecular model; (b)equivalent continuous model |

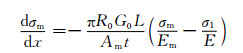

为更好地研究CNT/高分子复合材料的应力分布,选取了一个代表性体积元,将其离散的结构转化为连续模型,并采用剪切滞后模型进行了数值计算与分析。在剪切滞后模型中考虑了CNT各层轴向上的应力,而忽略了径向应力的变化,计算中使用的参数如图 2所示。CNT的几何结构关于x和y坐标轴对称。为简单起见,RVE的三维(3D)模型被简化为二维(2D)模型,且取模型的一半进行分析。2D模型的所有材料属性设置与3D模型中相同。其中,Rm和R0分别表示基体材料的外半径和内半径,R1,R2,R3,R4和R5分别表示模型的第1,2,3,4,5层的内半径。h表示基体的厚度。L表示RVE模型的长度,也代表CNT的长度。在RVE模型末端的基体层均匀施加拉伸应力σ0。为进一步探究CNT长度对应力分布的影响,研究了长径比从1到1000的RVE模型。

|

图 2 碳纳米管复合材料剪切滞后模型图 Fig. 2 Shear lag model of carbon nanotube composite |

该模型中,CNT内两个相邻层之间的间隙也被视为实体,其剪切模量大小由范德华力决定,用G来表示,在此取值为4.2 GPa [18],间隙层的弹性模量由Ein=2G(1+μ)给出。模型各组分的材料属性被视为各向同性。在图 2中,基于剪切滞后模型在CNT的第2层提取了尺寸为dx的一个无穷小元素,并在该元素上进行了力平衡分析。对于其他层的计算亦采用相同的手法。基体和CNT的第1,2,3层的轴向应力分别表示为σm,σ1和σ5。图 2中的3层模型可以扩展到更多层数。

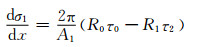

根据平衡关系,基体层的方程可表示为:

|

(1) |

式中:Am表示基体层的横截面积;τ0表示基体与CNT之间界面的剪切应力。CNT最外层的应力表示为:

|

(2) |

式中:A1表示模型第1层的横截面积;τ2表示模型由于第1层和第3层的相互作用而在第2层产生的剪切应力。对于其他CNT内部的层,根据力平衡可以得到:

|

(3) |

式中:σi,Ai和Ri分别表示第i层的轴向拉伸应力、截面面积和内半径。在本模型中,编号为奇数的层代表组成CNT的石墨烯层,其变形受两侧剪切应力τi-1和τi+1的影响。最内层只有一侧存在剪切应力,因此其表达式为:

|

(4) |

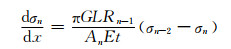

其中n表示CNT的层数。假设组成CNT的两层之间的剪切应力与相邻两层的切应变成比例,根据公式τ=G·γ和ε=σ/E可得i层的剪切应力为:

|

(5) |

式中:τi和Gi分别表示第i层的剪切应力和剪切模量;Ei-1和Ei+1分别表示i层相邻两层的弹性模量;σi-1和σi+1分别表示i层相邻两层的轴向应力。为便于计算,现假设基体与CNT之间存在一薄层,其剪切模量G0=10 GPa[13]。将式(5)代入式(1)~(4)中,得到:

|

(6) |

|

(7) |

|

(8) |

|

(9) |

其中Em表示基体层的弹性模量。根据实际情况,其边界条件设定为:

|

(10) |

为了计算层中的应力分布,数值计算中采用了4阶龙格库塔-算法(RK-4)。CNT的外径选为9 nm,通过连续地增加最内层,可以获得具有不同CNT层数的其他RVE模型。假设CNT中各层的弹性模量E为1 TPa [19]。初始拉应力σ0定义为常应力。

本工作还定义了有效长度(Lss),它是表示CNT/高分子复合材料中的载荷传递的重要参数之一,表示饱和应力长度所占的比例,其表达式为:

|

(11) |

式中:xs表示饱和应力的长度;LCNT表示CNT的长度。

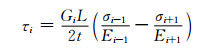

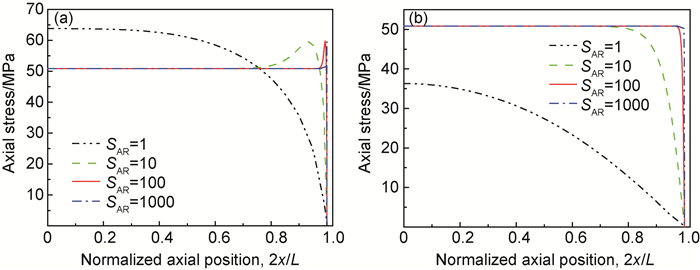

1.3 有限元分析采用有限元方法进行仿真验证,软件选择为ANSYS。因为模型既在x和y方向是轴对称结构,也是圆周对称,因此在建模中采用二维有限元模型进行仿真,简化计算,模型见图 3。

|

图 3 代表性体积元(RVE)的有限元模型(FEM) Fig. 3 Finite element model(FEM) of representative volume element(RVE) |

在ANSYS模拟中,所有参数,如半径、长度、边界条件、材料属性和弹性模量等与剪切滞后模型中的参数相同。选泊松比μ=0.006[16]。材料属性设定为各向同性。采用Solid183单元,CNT各层的弹性模量取为E=1000 GPa,首选基体为尼龙,其弹性模量取为Enylon=8.3 GPa[20],由范德华力控制的层的剪切模量G取为4.2 GPa[18],弹性模量由Em=2G(1+μ)获得。模型左侧施加轴向约束,基体上施加的应力为一常应力,在本次仿真中取为10 MPa。基体层厚度h初步选为3 nm。

2 结果与分析首先采用了有限元仿真与基于剪切滞后模型的数值计算相互验证的方法。图 4显示了长径比SAR=10时,在数值计算和有限元模型中得到的4层CNT/尼龙复合材料代表性体积元的层内轴向应力分布,表 1中则列举了一些主要数据。图中的层编号1,3,5,7是RVE模型中的编号,代表的是实际中CNT的第1,2,3,4层。结合表 1并比较图 4(a),(b)可知,两种分析方法中的层内轴向应力值是比较一致的。在剪切滞后计算模型里,饱和应力值为施加在基体层上的常应力值σ0的5.3倍,是基体层饱和应力的108.3倍;在有限元分析里,这两个值分别为5.08倍和110.5倍,这两组数据的有限元分析和理论计算误差分别为4.15%和1.99%。由此可以看出,由剪切滞后效应引起的CNT的层内应力远远大于施加在基体层上的常应力值和饱和应力值。就基体自身而言,其内部的应力减小到初始施加应力σ0的4.6%和4.9%,可见CNT的加入极大地改善了高分子基体的受力情况。在应力的变化趋势上可以看出,由于剪切滞后效应的存在,在CNT的最外层,其应力分布并不平顺,在接近末端时存在一个应力的高峰,这个应力峰在剪切滞后模型中表现更为平缓。其他各层的应力变化趋势则是由饱和应力逐渐减小为0,这是由边界条件决定,是考虑了大部分CNT最外层都带有圆帽,因此内层的边缘部分基本不受力的情况。由于应力传递的衰减,层数越靠里,饱和应力下降越快,趋势也表现得更平缓。由图 4还可得出,作为表示CNT/高分子复合材料中的载荷传递的重要参数,剪切滞后模型中计算的有效长度为0.54,有限元仿真中计算的有效长度为0.6。由此可知理论计算中的CNT有效长度更小一些。

|

图 4 四层碳纳米管的各层轴向应力分布图(SAR=10) (a)剪切滞后模型结果; (b) FEM仿真结果 Fig. 4 Axial stress distribution in each layer of four-walled carbon nanotubes(SAR=10) (a)shear lag model results; (b)FEM simulation results |

| Layer | Saturation stress/MPa | Maximum stress/MPa | |||

| Theoretical | ANSYS | Theoretical | ANSYS | ||

| Matrix | 0.49 | 0.46 | 10.00 | 10.00 | |

| 1 | 53.07 | 50.84 | 61.97 | 59.58 | |

| 4 | 53.07 | 50.84 | 53.07 | 50.84 | |

对于理论结果与计算结果的应力值的差异,作者认为是由于建模方式的不同所致。因为在剪切滞后模型中,只是考虑了界面剪切力和相邻层之间的间隙的理想状况,而在有限元的建模中,由于模型是基于连续力学模型构建的,实际的分析中还受其他应力的影响,而且会有部分负载分布到界面层中,从而导致了仿真结果的应力值偏小。

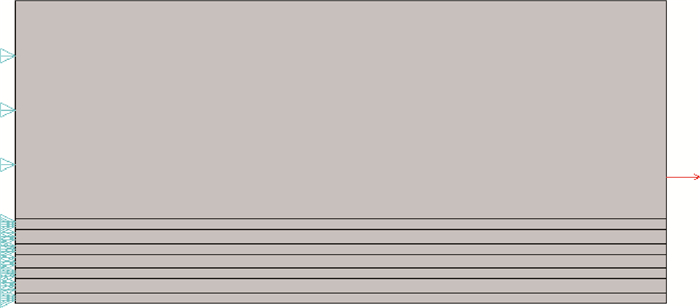

在有限元仿真和剪切滞后模型的相互验证之后,又研究了CNT长径比相同时,高分子复合材料中不同层数CNT的应力分布情况。在本研究中,CNT的层数n选了1,2,4,8。定义CNT的利用率为CNT的实际所受应力与其自身的拉伸强度的比值。如图 5(a), (b)所示,对比CNT第1层和第2层的应力分布情况可以看出,CNT内各层的应力分布受其层数的影响很大。在相同的受力下,SWCNT内部的应力最大,达到了施加应力的18.2倍。随着CNT层数的增加,饱和应力不断降低,CNT的层数n=2时为初始应力的9.8倍,层数n=4时为5.1倍,层数n=8时只有2.6倍。由此可知,在复合材料内,相较于自身的拉伸强度,对CNT的利用率随层数增加而呈线性降低的趋势,且SWCNT利用率最高,这也印证了文献[21]的观点。对于这种现象,合理的解释是CNT的层与层之间靠范德华力相互作用,但这种相互作用力并不强,从而导致了内部各层的利用率的降低。但MWCNT相较SWCNT更有利于复合材料承担较大的载荷。因此在实际选材中,承载较大的材料最好选取MWCNT来填充。CNT的层数对于其有效长度也有影响,SWCNT和双层CNT的Lss值为0.64,n=4时为0.6,n=8时为0.51。说明饱和应力长度随着CNT层数的增加在减小。对比图 5(a), (b)可以发现,层数较少的CNT不存在靠近末端的应力峰,而存在应力峰的CNT,应力峰值与饱和应力的比值大小则随层数的增大而扩大,在n=4时为饱和应力的1.16倍,n=4时为1.96倍。而且层数较多的CNT,应力峰不仅存在于最外层。

|

图 5 RVE中不同层数的碳纳米管的轴向应力分布(SAR=10) (a)第1层;(b)第2层 Fig. 5 Axial stress distribution in carbon nanotubes of different layers in RVE (SAR=10) (a)layer 1;(b)layer 2 |

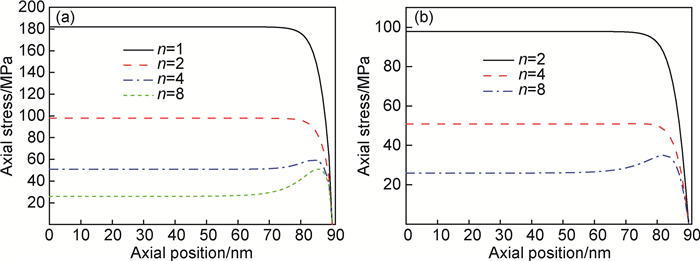

本研究还探索了长径比对复合材料中4层CNT的内应力分布的影响,其结果在图 6(a), (b)中示出。选取了4层CNT的第1层和第3层进行了比较。为了方便观察,对数据的横坐标进行了归一化处理。通过对比发现,当长径比大于一定的数值之后,对于层数一定的CNT,其饱和应力值不随长径比的变化而改变,应力峰的峰值亦相同。但其有效长度差距较大,长径比SAR=10时为0.6,SAR=100时为0.947,SAR=1000时则达到了0.995,具有极高的利用率,因此在实际使用中,应选用较大长径比的CNT,这也印证了文献[22]的结论。对比图 6(a), (b)可以发现,当长径比较小,如SAR=1时,CNT甚至没有达到应力饱和状态,其层内应力从一开始便从64 MPa一直下降,每一层的最大应力亦一直减小。由于长径比太小,没有达到饱和应力,因此CNT内部各层的利用率较低,导致了其第1层的最大应力大于正常的饱和应力。

|

图 6 RVE中不同长径比碳纳米管的轴向应力分布 (a)第1层;(b)第3层 Fig. 6 Axial stress distribution in carbon nanotubes with different aspect ratios in RVE (a)layer 1;(b)layer 3 |

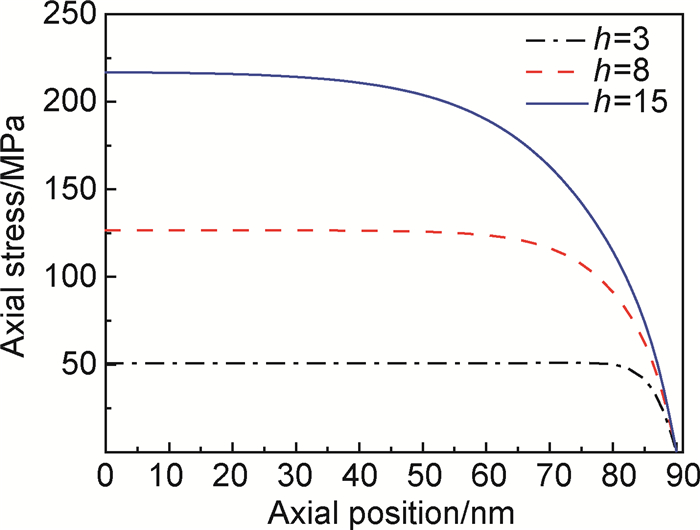

为了探究CNT在基体中的含量对其轴向应力的影响,设定了3,8,15 nm 3种RVE模型基体厚度进行分析,其结果如图 7所示。在图 7中,对RVE模型的第3层结果进行了比较。结果发现,随着CNT含量的减少,其饱和应力呈增大趋势,其值在基体层厚度为3 nm时为初始应力σ0的5.1倍,8 nm时为σ0的12.7倍,15 nm时为σ0的21.7倍。有效长度的值也随着CNT含量的减少而减少,其值分别为0.6,0.4,0.16。在实际的操作中,CNT的含量远远低于本次计算中的数值,所以实际的饱和应力要比初始应力大更多。因此,为了提升CNT的利用率,实际中应选用具有少量层数的大长径比的CNT,该结果同时验证了图 5和图 6所得出的结果。

|

图 7 不同碳纳米管含量对4层碳纳米管轴向应力分布的影响(SAR=10) Fig. 7 Axial stress distribution of four layer carbon nanotubes with different contents in RVE (SAR=10) |

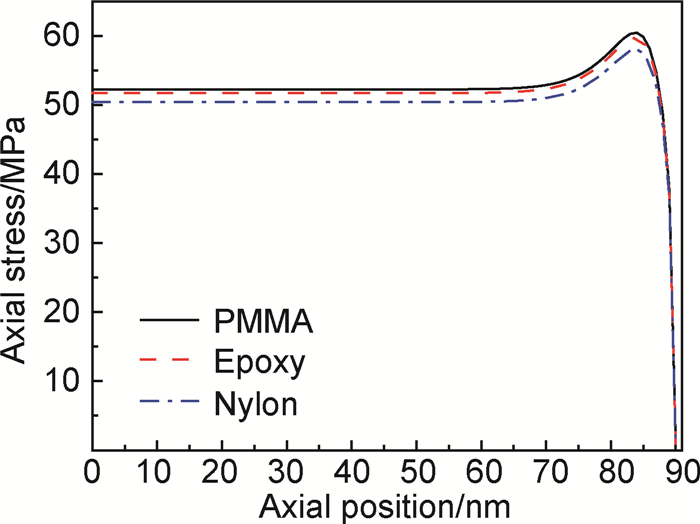

最后,本工作研究了不同基体材料对于CNT应力分布的影响,对4层CNT的最外层应力分布进行了分析,其中CNT的长径比为10,基体材料选取了环氧树脂、尼龙和聚甲基丙烯酸甲酯(PMMA)。高分子复合材料的弹性模量并不固定,在本研究中其值分别取为EPMMA=3 GPa,Eepoxy=5 GPa,Enylon=10 GPa[20],结果如图 8所示。通过比较发现,对于不同的基体材料,虽然其弹性模量不同,但对于CNT的应力分布的影响并不明显。首先是饱和应力值会随着材料弹性模量的增加而减小,PMMA基体中CNT饱和应力是初始应力σ0的5.23倍,环氧树脂中是σ0的5.17倍,尼龙中是σ0的5.04倍。有效长度则随着材料弹性模量的增加而略有增加,PMMA基体中CNT的有效长度为0.58,环氧树脂中为0.59,尼龙中则是0.61,增加并不明显。应力峰值与其自身饱和应力的比值随基体弹性模量增加而减小,但变化并不显著,这一比值在PMMA基体中是1.157倍,在环氧树脂中也是1.155倍,在尼龙中是1.151倍。因此可以知道,不同高分子复合材料对碳纳米管的应力分布影响并不明显,若要获得较高的CNT利用率,即材料性能提升较大时的最小CNT用量,不同的高分子复合材料相差不大。

|

图 8 不同基体材料对4层碳纳米管轴向应力分布的影响(SAR=10) Fig. 8 Axial stress distribution of four layer carbon nanotubes in different matrix materials (SAR=10) |

(1) 当复合材料承受固定载荷时,碳纳米管(CNT)内部各层的应力分布趋势并不相同,在最外层或近最外层,其轴向应力会在靠近末端时出现一个应力峰值,其他各层则在靠近末端的地方从饱和应力逐步下降为0。CNT的饱和应力一般为初始应力的数倍甚至几十倍,CNT的加入大大改善了基体的受力情况。

(2) 长径比对CNT内部应力分布的影响主要体现在有效长度上。当长径比很大时,其有效长度迅速增加到0.99以上,这也是CNT高长径比的优势所在。但当CNT的长径比过小时,CNT甚至达不到应力饱和状态,这严重削弱了CNT利用效率。

(3) CNT的层数对其内部应力的影响主要体现在饱和应力值上。饱和应力值会随着CNT层数的增加而降低,这一现象在层数较少时尤为明显。由此也可以看出,SWCNT对自身性能具有最高的利用率。层数的增加对有效长度也有影响,其值会随层数增加而略有降低。另外随着层数的增加,其在末端的应力峰值与饱和应力的比值也逐渐增大。

(4) CNT的含量对于饱和应力值和有效长度都有较大影响。随着CNT含量的降低,饱和应力值迅速增加,有效长度迅速减小。不同高分子基体对CNT本身的应力分布影响较小。随着高分子基体弹性模量的增加,CNT的饱和应力值略有下降。理论上讲,不同的高分子复合材料基体性能提升较大时的最小CNT用量相差不大。

| [1] |

JACKSON E M, LAIBINIS P E, COLLINS W E, et al. Development and thermal properties of carbon nanotube-polymer composites[J]. Composites: Part B, 2016, 89: 362-373. DOI:10.1016/j.compositesb.2015.12.018 |

| [2] |

曾少华, 申明霞, 段鹏鹏, 等. 碳纳米管-玻璃纤维织物增强环氧复合材料的结构与性能[J]. 材料工程, 2017, 45(9): 38-44. ZENG S H, SHEN M X, DUAN P P, et al. Structure and property of carbon nanotubes attached glass fabric reinforced epoxy composites[J]. Journal of Materials Engineering, 2017, 45(9): 38-44. |

| [3] |

TSAI J L, LU T C. Investigating the load transfer efficiency in carbon nanotubes reinforced nano-composites[J]. Composite Structures, 2009, 90(2): 172-179. DOI:10.1016/j.compstruct.2009.03.004 |

| [4] |

胡芳芳, 聂小安. 碳纳米管增强环氧树脂基复合材料研究进展[J]. 热固性树脂, 2019, 34(1): 60-65. HU F F, NIE X A. Research progress on carbon nanotubes reinforced epoxy composites[J]. Thermosetting Resin, 2019, 34(1): 60-65. |

| [5] |

LI Y, WANG S, HE E, et al. The effect of sliding velocity on the tribological properties of polymer/carbon nanotube composites[J]. Carbon, 2016, 106: 106-109. DOI:10.1016/j.carbon.2016.04.077 |

| [6] |

王程成, 贺德龙, 崔溢. 结构-导电复合材料研究进展[J]. 材料工程, 2018, 46(9): 1-13. WANG C C, HE D L, CUI Y. Research progress in electrically conductive structural composites[J]. Journal of Materials Engineering, 2018, 46(9): 1-13. |

| [7] |

RAFIEE R, MOGHADAM R M. On the modeling of carbon nanotubes: a critical review[J]. Composites: Part B, 2014, 56: 435-449. DOI:10.1016/j.compositesb.2013.08.037 |

| [8] |

何才启, 张俊乾. 碳纳米管复合材料的应力分析[J]. 复合材料学报, 2008, 25(5): 120-124. HE C Q, ZHANG J Q. Stress analysis of carbon nanotubes reinforced composites[J]. Acta Materiae Compositae Sinica, 2008, 25(5): 120-124. DOI:10.3321/j.issn:1000-3851.2008.05.020 |

| [9] |

ZALAMEA L, KIM H, PIPES R B. Stress transfer in multi-walled carbon nanotubes[J]. Composites Science & Technology, 2007, 67(15): 3425-3433. |

| [10] |

VIET N V, KUO W S. Shear transfer in fractured carbon nanotubes under torsion[J]. Materials Science and Engineering: A, 2012, 536: 256-264. DOI:10.1016/j.msea.2012.01.009 |

| [11] |

GAO X L, LI K. A shear-lag model for carbon nanotube-reinforced polymer composites[J]. International Journal of Solids and Structures, 2005, 42(5/6): 1649-1667. |

| [12] |

SPANOS K N, GEORGANTZINOS S K, ANIFANTIS N K. Investigation of stress transfer in carbon nanotube reinforced composites using a multi-scale finite element approach[J]. Composites: Part B, 2014, 63: 85-93. DOI:10.1016/j.compositesb.2014.03.020 |

| [13] |

VIET N V, WANG Q, KUO W S. A studying on load transfer in carbon nanotube/epoxy composites under tension[J]. Journal of Modeling in Mechanics & Materials, 2017, 1(1): 20160153. |

| [14] |

高江姗, 何燕, 徐瑾, 等. 碳纳米管/炭黑协同效应对天然橡胶/顺丁橡胶复合材料性能的影响[J]. 材料研究学报, 2017, 31(10): 758-764. GAO J S, HE Y, XU J, et al. Influence of synergistic effect of carbon nanotubes/carbon black on properties of natural rubber/butadiene rubber composites[J]. Chinese Journal of Materials Research, 2017, 31(10): 758-764. DOI:10.11901/1005.3093.2016.444 |

| [15] |

张勇.碳纳米管-石墨烯混杂复合材料力学增强机理研究[D].哈尔滨: 哈尔滨工业大学, 2016. ZHANG Y. Study on molecular enhancement mechanisms of carbon nanotube-graphene hybrid reinforced composites [D]. Harbin: Harbin Institute of Technology, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10213-1016913380.htm |

| [16] |

CHO J, LUO J J, DANIEL I M. Mechanical characterization of graphite/epoxy nanocomposites by multi-scale analysis[J]. Composites Science and Technology, 2007, 67(11/12): 2399-2407. |

| [17] |

ZHENG Q, LIU J Z, JIANG Q. Excess van der Waals interaction energy of a multiwalled carbon nanotube with an extruded core and the induced core oscillation[J]. Physical Review:B, 2002, 65(24): 245409. DOI:10.1103/PhysRevB.65.245409 |

| [18] |

DOLLING G, BROCKHOUSE B N. Lattice vibrations in pyrolitic graphite[J]. Physical Review, 1962, 128(3): 1120-1123. DOI:10.1103/PhysRev.128.1120 |

| [19] |

KASHYAP K T, PATIL R G. On Young's modulus of multi-walled carbon nanotubes[J]. Bulletin of Materials Science, 2008, 31(2): 185-187. DOI:10.1007/s12034-008-0032-2 |

| [20] |

MARK J E. Polymer data handbook[M]. London: Oxford University Press, 1999.

|

| [21] |

QIAN D, LIU W K, RUOFF R S. Load transfer mechanism in carbon nanotube ropes[J]. Composites Science and Technology, 2003, 63(11): 1561-1569. DOI:10.1016/S0266-3538(03)00064-2 |

| [22] |

SHOKRIEH M M, RAFIEE R. Investigation of nanotube length effect on the reinforcement efficiency in carbon nanotube based composites[J]. Composite Structures, 2010, 92(10): 2415-2420. DOI:10.1016/j.compstruct.2010.02.018 |

2020, Vol. 48

2020, Vol. 48