文章信息

- 谭耀红, 刘呈坤, 毛雪, 刘佳

- TAN Yao-hong, LIU Cheng-kun, MAO Xue, LIU Jia

- 压电式纳米发电机及其混合器件的研究进展

- Research progress of piezoelectric nanogenerators and their hybrid devices

- 材料工程, 2019, 47(10): 10-21

- Journal of Materials Engineering, 2019, 47(10): 10-21.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2018.000665

-

文章历史

- 收稿日期: 2018-06-01

- 修订日期: 2019-07-05

经过了十几年的发展,电子设备在微型化、便携化、可穿戴化等方面取得了不少进步,手机、智能眼镜、智能手表等一系列电子产品都已经进入寻常百姓家,为人们生活带来了极大的便利,正是由于这些电子设备在人们生活中扮演的角色极为重要,随之而来的续航问题也尤为突出。而更为紧迫的是,由于化石能源的过度开采和使用,能源危机、全球变暖、环境污染等字眼时刻提醒着我们,促使我们寻求一种绿色的、可持续的和可再生的能源[1-3]。在我们所处的环境中,可收集和利用的能源种类非常多,如:太阳能、机械能、热能、化学和生物能等[4],因此,从环境中进行能量收集和转化的概念引起了研究人员的极大兴趣[5-7]。纳米材料作为现代电子学中一种新兴的组成材料,具有一系列独特的性能和形貌,为提高各种能量器件的性能提供了广阔的窗口,利用纳米材料和纳米技术从环境中获取能量,作为可持续、自给自足的能源,构成了纳米能源的新兴领域,可用于为电子设备提供持续能源[8]。2006年,王中林等[9]利用氧化锌(ZnO)纳米线阵列的偏转所产生的压电效应,首次实现了纳米尺度上的机械能到电能的转化,并提出了纳米发电机(nanogenerator,NG)的概念,这种纳米发电机能达到17%~30%的发电效率,为自发电的纳米器件奠定了理论基础[10]。随着NG的不断发展,相关理论研究也不断完善和深入,从原理上可以将NG分为3类:摩擦式纳米发电机(triboelectric nanogenerator,TENG)、热释电式纳米发电机(pyroelectric nanogenerator,PNG)和压电式纳米发电机(piezoelectric nanogenerator,PENG)。其中TENG和PENG都能实现机械能到电能的转化,TENG的工作原理是通过两种材料之间的摩擦,产生电子转移,并对产生的电能进行收集,具有输出电压高、绿色环保、安全性好、体积质量小、成本低等优点,但相对的电流较小和受环境影响较大在一定程度上限制了其应用[11-12]。PENG则依赖于材料本身的压电效应,因此压电材料的选择是PENG性能的重要支撑,同时由于PENG工作时受环境影响较小,使用寿命较长,输出相对稳定等优点得到广大研究人员的关注[13]。本文将从PENG的材料、制备工艺、结构、输出功率等方面进行概述,对比不同材料、结构PENG的性能特点,并结合PENG混合型器件的研究现状,探讨PENG的发展趋势。

1 压电式纳米发电机材料是否具有压电效应是制备PENG的重要条件。许多材料都表现出压电性能,例如:锆钛酸铅(PZT)、钛酸钡(BTO)、纤锌矿结构半导体、石英、聚偏氟乙烯(PVDF)和过渡金属二硫化物(TMDs)等,这些材料的机械变形导致正负电荷中心相对于彼此产生位移,使正负电荷在相对表面上聚集,而整个材料保持电中性[14-15]。从本质上讲,晶体是否具有压电效应是由构成晶体的原子和离子的空间排列方式决定的,压电效应可由图 1表示[11]。基于这种特性,通过在压电材料上施加应变,能够实现机械能向电能的转化。

自从十多年前具有里程碑意义的ZnO纳米线NG问世以来,压电半导体在从周围环境中获取机械能并将其转化为电能,为电子和光电纳米器件提供动力方面引起了极大的关注。其中应用较多的是一些纤锌矿晶体结构的半导体材料,如ZnO,ZnS,CdS,GaN等,由于其机电耦合系数较大,同时兼有半导体、光电性能和压电性质,是制备压电纳米器件的合适材料[16-18]。

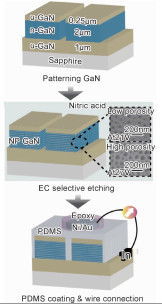

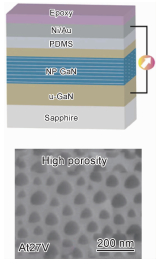

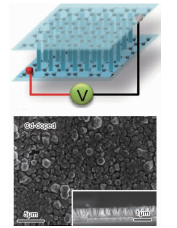

Kang等[19]采用电化学刻蚀方法,研究了一种高效纳米多孔氮化镓(GaN)基PENG,电化学刻蚀法可以很容易地制备出纳米孔结构,和其他纳米结构相比具有很大优势。随着孔隙率的增加,PENG的输出明显增强,这是由于存在费米能级钉扎效应,耗尽了纳米多孔GaN薄壁中的自由载流子,从而降低了自由载流子对压电电荷的内部屏蔽。当平均壁厚小于30nm时,PENG的输出随壁厚的减小而显著增加。这是由于压电和机械尺寸效应,即通过增加压电系数和减小纳米结构的弹性系数来增强压电极化。当微电子器件与充电电容器和整流电路相结合时,PENG的能量收集能力足以满足微电子器件的工作需要。

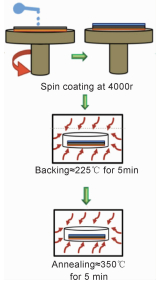

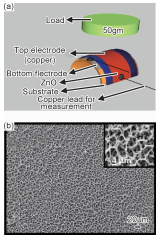

相比上述的GaN和常用的氮化铝(AlN)等半导体材料,ZnO具有较高的压电系数,同时,ZnO基压电材料具有成本低、能够进行大面积覆盖的特点,以及优良的生物相容性和光电特性使其得到广泛应用,如紫外线(UV)传感器、环境传感器、气体传感器,以及能量收集装置等[20-22]。然而和其他铁电材料相比,ZnO的压电性能仍然较差,少数金属元素的掺杂能够提高ZnO的压电活性。Rajagopalan等[23]通过溶胶-凝胶自旋涂层法掺杂Cu,制备出了具备高压电性能的柔性材料,采用层层相叠加的结构装置,能够同时用于风能收集和重力感应,掺杂了Cu的ZnO薄膜自然地弯曲放置在基板上,上下各放置一个电极,与未掺杂的ZnO相比,其压电性能提升了5~6倍,输出电流由原来的5nA提升到30nA。Son等[24]利用纳米压印技术和溶胶-凝胶法制备了聚对苯二甲酸乙二醇酯(PET)/聚二甲基硅氧烷(PDMS)/石墨烯/ZnO薄膜作为电极,而后采用水热合成法在两层薄膜之间生长ZnO纳米棒,制备了透明的PENG,弯曲产生电能,其输出功率取决于纳米棒的形貌,掺杂镉(Cd)的ZnO纳米棒,其体积功率密度为00531m·W-3,与市面上的普通储能器件相当。为比较各种制备方法之间的优缺点,表 1对上述几种方法进行了总结和对比。

| Preparation | Model & microstructure | Semiconductor | Comment | References |

|

|

GaN | 1D porous nanostructure can improve the piezoelectric efficiency of GaN greatly, and this PENG can be used in the field of Internet of Things (IoT). | [19] |

|

|

ZnO | ZnO membrane doped with Cd integrated sensors and energy collection, can collect wind energy while sensing the flow of air around. | [23] |

|

|

ZnO | The structure of ZnO nanorods doped with Cd can enhance the power of PENG greatly, and the transparent structure also widens its application field. | [24] |

压电陶瓷是具有压电效应的陶瓷材料,通常由几种氧化物和碳酸盐通过一定的烧结过程制得。烧结得到的陶瓷体是多晶体,主要成分是铁电体,故又称铁电陶瓷。相对于压电半导体而言,压电陶瓷具有更高的压电常数,因此,采用压电陶瓷来制备NG往往具有更高的输出效率[25]。长期以来,以PbTiO3-PbZrO3(PZT)为基体的PZT基压电陶瓷,由于其优良的压电性能而被广泛使用,但是随着绿色可持续发展理念的深入,含铅材料对人体及环境的不利影响日益受到关注,开发出环境友好型的铁电材料成为发展的重要方向[26]。

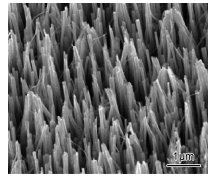

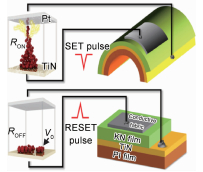

碱金属铌酸盐系陶瓷材料铌酸钾钠(K1-xNaxNbO3, KNN)、铌酸钾(KNbO3,KN)等,以其压电性能高、介电常数小、频率常数大和密度小等特点一直深受关注。Jin等[27]以Nb:SrTiO3单晶为衬底,通过水热反应合成了无铅KNN纳米棒阵列。测试结果表明,所有样品均有富k正交晶系结构,衍射峰向较高的方向移动,同时,随着反应时间的增加抑制了KNN纳米棒表面的氧空位,这些成分和晶体结构的变化,使纳米棒的压电响应明显增强,压电常数由19 pm/V增加到了64 pm/V。KN是一种ABO3型钙钛矿结构铁电材料,具有优良的压电和非线性光学性能,以及高的光学透光性,在可见光范围内具有较大的折射率,是一种很有前景的电子器件材料[28-29]。尤其是,当居里温度较高的时候KN陶瓷能够在电场的诱导下产生较大应变,这也使得研究人员对KN陶瓷在无铅压电层叠致动器中的应用越来越感兴趣[30]。常用的制备KN的方法有:水热合成法、溶胶-凝胶法、聚合前驱法等,但合成的KN单晶尺寸并不理想。基于此,在低温(≤350℃)条件下,Lee等[31]在TiN/聚酰亚胺(PI)/PET底衬上生长了尺寸良好的KN纳米晶,制备了PENG,具有2.5V的开路输出电压和70nA的短路电流。在TiN-Si薄膜上生长KN,不仅可以用作PENG,还可用于制备可变电阻式随机存取存储器(ReRAM),并具有良好的阻性开关特性。

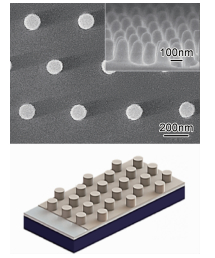

钙钛矿型BaTiO3(BTO)也是一种常用无铅、压电性能优良的材料,Shin等[32]制备了Fe掺杂的BTO纳米柱阵列,采用PDMS纳米压印软板,将BTO纳米粒子均匀压印在溶胶-凝胶包覆的PET上,实现了压电输出性能的可伸缩和增强,通过进一步的UV处理有助于进一步提高BTO层的结晶度。结果表明,在0.3MPa的作用力下,柱间距为400nm(有效面积:1cm2)的PENG输出电压和电流密度分别超过10V和1.2μA·cm-2,比无压印和后续处理的PENG输出电压高2个数量级,输出电流密度高6倍。表 2对上述几种制备方法进行了总结,对比了不同制备方法之间的优劣和差异。

| Preparation | Model & microstructure | Ceramic | Comment | References |

| Hydrothermal synthesis |

|

KNN | The KNN nanorod arrays were synthesized on the Nb-doped STO substrate through the hydrothermal process, and the piezoelectric activity of the material can be improved effectively with the normal increase of reaction time. | [27] |

| Low-temperature-grown method |

|

KN | The KN film grown at 350℃ exhibited a bipolar resistive switching behavior and good reliability characteristics. It is an ideal biomedical device with a good biocompatibility. | [31] |

| Nanoimprint & sol-gel method |

|

BTO | The preparation method is simple and the piezoelectric properties have been improved greatly. | [32] |

除了半导体和陶瓷等无机材料,一些高聚物也具有压电性能。表 3提供了一组常用压电材料的相关材料特性对比。可以看出,陶瓷材料相比于聚合物具有更大的压电系数,但也具有更高的弹性模量,因此比聚合物更硬,这使得陶瓷材料对小的振动不敏感,也更容易发生应力破坏[33]。与无机纳米材料相比,压电聚合物具有极大的柔性,并且由于其质量轻、力学性能好以及良好的加工性和生物相容性等特点,成为制造可穿戴设备、传感器和自供电植入装置的理想材料[34-35]。

| Parameter | Value | |||||

| PbTi0.48Zr0.52O3 (ceramic) |

BaTiO3 (single crystal) |

BaTiO3 (ceramic) |

ZnObr (single crystal) | PVDF | P(VDF-TrFE) 78-22 |

|

| Y/GPa | 58 | 64 | 112 | 139 | 2.1 | 3.1 |

| v | 0.34 | 0.33 | 0.31 | 0.33 | 0.44 | |

| d33/pC·N-1 | 233 | 85.6 | 191 | 12.3 | -35 | -39 |

| d31/pC·N-1 | -93.5 | -34.5 | -79 | -5.12 | 28 | 15-30 |

| k33 | 0.67 | 0.56 | 0.49 | 0.466 | ||

| k31 | 0.1 | 0.2 | ||||

| ρ/kg·m-3 | 7500 | 6020 | 5720 | 5704 | 1800 | 1900 |

| Tc/℃ | 386 | 130 | 130 | 80 | 70 | |

| Z0/MRayl | 20.8 | 19.5 | 27.0 | 27.9 | 3.2 | 2.4 |

| ε | 1180 | 4600 | 2000 | 11.26 | 10-15 | 15-20 |

| ft/MHz | 24 | 27 | 35 | 40 | 15 | 10 |

| Note: Parameters at room temperature-Young’s modulus Y, Poisson’s ratio v, piezoelectric matrix elements d33and d31, electromechanical coupling factors k33 and k31, density ρ, Curie temperature Tc, acoustic impedance Z0, dielectric constant ε and thickness-mode resonance frequency ft. | ||||||

目前已知的压电性较强的压电聚合物主要有PVDF及其共聚物、聚氟乙烯(PVF)、聚氯乙烯(PVC)、聚碳酸酯(PC)及尼龙-11等材料。其中,PVDF及其共聚物具有结构灵活、易于加工、耐溶剂、耐酸碱、耐机械强度等优点,成为目前应用最广泛的压电聚合物[36-38]。PVDF具有5种晶型,其中,电活性β相赋予了最高的偶极矩,从而产生了较高的压电性,在一定的温度下,通过拉伸、复合拉伸和极化等方法可以提高聚合物的β相含量。

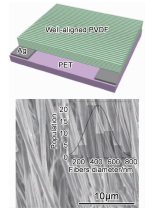

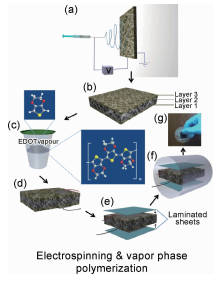

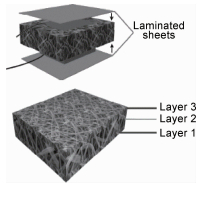

静电纺丝法是制备聚合物基PENG的常用方法,纺丝过程中的强电场对聚合物单轴有一定的拉伸作用,可以增强纳米纤维和纳米线的压电性能[13]。Liu等[39]介绍了一种以氧化石墨烯(GO)薄片化学包覆PVDF纳米纤维的核壳结构(PVDF/GO纳米纤维),通过机械拉伸、高压定向和化学的协同作用,得到了β相含量高达88.5%的纳米纤维。超高的β相含量以及其单轴取向对压电性能的提高有重要贡献,压电常数d33=-93.75pm/V(GO含量为1%(质量分数)时)。除了一维的纳米纤维,通过适当设计收集装置,静电纺丝法可以实现多种形式的纤维排列,如:随机排列的纤维膜、定向纳米纤维膜以及纳米纤维纱线等。Kang等[40]通过静电纺丝法,利用一个凹槽装置,制备了定向的PVDF纳米纤维,由于周围平台的存在,对纤维有一定的拉伸作用,聚合物纳米纤维受到拉伸和高电场作用,导致自然极化,使非极性相转变为极性β相,提高定向纳米纤维膜的压电性能。此外,作者还研究了PVDF定向纳米纤维的输出特征与薄膜厚度的关系,验证了定向纳米纤维的堆积效应,即随着薄膜厚度的增加,含有定向纳米纤维阵列的器件的输出性能急剧增加(与随机分布的纳米纤维相比),当厚度达到100μm时输出电压能够达到2V。Maity等[41]制备了一种全有机材料组成的3维PENG。首先采用静电纺丝法制备3层结构的PVDF纳米纤维垫,而后采用气相聚合法使上下表面层的PVDF纳米纤维包裹上聚3, 4-乙烯二氧噻吩(PEDOT),由于PEDOT具有合成简单、导电性好、柔韧性好、生物相容性好等优点,外层包覆有PEDOT的纳米纤维被用作电极,而内部的PVDF纳米纤维用作压电活性组分。这种与兼容电极集成的多层网络化三维结构表现出了更高的输出电压和电流(在外加应力为8.3kPa时,开路电压达到48V,短路电流达到6μA),与单片器件相比,其压电能量转换效率提高了66%。

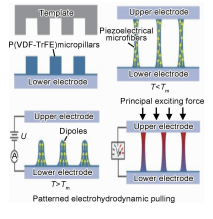

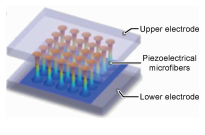

Chen等[42]采用电流体牵引技术制备P(VDF-TrFE)垂直阵列。首先,将P(VDF-TrFE)薄膜涂覆在平面导电基板上,在实验中作为下电极,然后,另一个平面导体作为上电极放置在预先形成的微柱阵列之上,具有适当的空气间隙,形成一个类似电容器的装置。在该过程中,麦克斯韦力对聚合物微柱有向上的拉力,从而拉到上电极。这项技术的主要优点是:不需要进一步加工制造设备,因为形成支柱的相同电极将构成最终装置的电极,P(VDF-TrFE)纤维阵列与上下两电极接触面之间黏着性较高,为PENG提供了更好的性能。

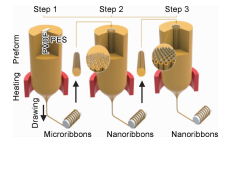

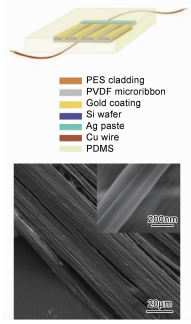

考虑到纳米线宽高比、均匀性、几何控制和产率等因素,上述方法并不能在所有方面都具有优势。另一种能够生产压电聚合物的方法是热拉伸法,热拉伸法不需要溶剂,就能够生产不同截面形状的超长长丝,而且不需要额外电极化。Kanik等[43]采用热拉伸技术,制备了4m长的平行PVDF纳米带,由于热拉伸过程中使用了较高的应力和温度,不需要电极化过程就能得到自发极性的γ相PVDF纳米带,用压电评价系统和原子力显微镜测得PVDF纳米带的平均有效压电常数为58.5pm/V。PVDF纳米带具有独特的几何形状和较长的长度、高的极性β相含量、高的热稳定性、高的压电系数等优点,是一种很有发展前途的新型结构。为了直观反映上述几种聚合物基PENG的制备方法之间的差异,采用表格的方法对其进行了总结,详见表 4。

| Preparation | Model & microstructure | Polymer | Comment | References |

| Electrospinning |

|

PVDF | With the influence of high voltage electric field and GO, the β phase content has been greatly increased, which is of great significance for the preparation and application of ultra high piezoelectric activity mate-rials. | [39] |

|

|

PVDF | Stacking effect of aligned nanofibers has been veri-fied, and the piezoelectric properties increase shar-ply with the increase of film thickness. | [40] |

|

|

PVDF | All organic and 3D multilayer structure has greatly improved the piezoelectric performance and flexibility, and suit-able for wearable electronic devices. | [41] |

|

|

P(VDF-TrFE) | No further processing is needed to fabricate the device since the same electrodes used to form the pillars will then constitute the electrodes of the final device. | [42] |

|

|

PVDF | Nanorod produced by iterative thermal size red-uction technique can be kilometer-long, and polar γ has been obtained spon-taneously. It can be used as efficient energy collection devices, large area pressure sensors and arti-ficial muscles. | [43] |

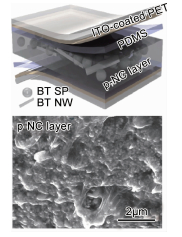

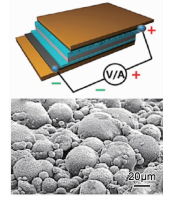

2012年,Park等[44]首次提出了一种名为纳米复合发电机(nanocomposite generator,NCG)的压电式能量收集装置,将添加有石墨化碳(单壁碳纳米管、多壁碳纳米管、还原石墨烯氧化物)的压电纳米BaTiO3纳米微球分散在PDMS弹性体中,用作压电纳米复合材料的简单自旋涂层,而后叠加形成PENG,该方法制备简单、成本低,开创了纳米复合发电机的先河。而后很多学者开发出了无铅、高产量、大面积的NCG装置,为了避免压电纳米粒子聚集在聚合物基体中,通常会添加一些一维结构材料,如碳纳米管、Cu纳米棒和Ag纳米线等,这些非压电添加剂具有多种用途,但其对生物体的毒性一直是实现柔性能源生物友好化的一个障碍。为了克服这一问题,Baek等[45]选择无毒的BaTiO3作为替代,并采用水热合成法制备了BaTiO3纳米微粒和BaTiO3纳米线,并找到了最佳的质量配比,使NCG器件的输出性能达到最大。除此之外,将聚合物与无机体系、二维材料混合制成的复合材料已被证明是改善压电性能的有效方法[46-47]。Shin等[48]报道了一种基于半球聚集BaTiO3纳米微粒和聚偏氟乙烯-共六氟丙烯P (VDF-HFP)的复合薄膜的高性能柔性PENG,利用自旋涂层溶液的蒸发实现了半球状BTO-P (VDF-HFP)的团簇,极大地提高了压电发电能力。在垂直于表面的作用力下,柔性PENG表现出高达75V和15μA的高电输出。表 5对上述几种复合材料基PENG的制备方法和结构进行了总结,能够清晰反映上述方法之间的差异及优缺点。

| Preparation | Model & microstructure | Nanocomposite | Comment | References |

| Hydrothermal reaction |

|

BaTiO3/PDMS | BaTiO3 is used as both additive and piezoelectric active mat-erials, which make NCG more environment-friendly and bio-compatible. | [45] |

| Spin coating & solvent evaporation |

|

BaTiO3/P (VDF-HFP) | The method is simple, econo-mical and practical, and can be produced in large scale. It can exhibit higher flexibility and piezoelectric performance. | [48] |

在日常生活中,一种能量往往伴随着其他一种或几种能量,例如:压电式纳米发电机在受到外界的挤压或者折叠时产生电能,不可避免地会和其他材料发生接触和摩擦,而摩擦产生的能量并没有被有效收集,因此,单一的压电式能量收集装置并不能适用于多种能量的收集,混合器件的研究也显得尤为重要[49-50]。到目前为止,压电式、摩擦电式、热释电式、电磁式、太阳能光电式等能量收集装置之间的二元/多元混合,无论是串联还是并联,在复杂的环境中依然能保持较高的输出功率,被广泛地用于高功耗电子设备。

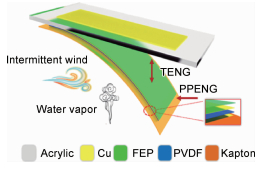

Zheng等[51]设计了一种混合纳米发电机,可以同时或独立地收集来自水蒸气的热能和从底部吹来的间歇性风的机械能,该装置包括2个部分:风力驱动的TENG和热释电-压电纳米发电机(PPENG)。在固定的丙烯酸板上沉积了一层铜膜,作为表面电极和摩擦表面。下方是一个可活动的多层结构,顶层为氟化乙丙烯(FEP)薄膜,用作另一摩擦表面,在间歇风驱动下,FEP膜与顶部的铜电极接触-分离,通过摩擦带电与静电感应耦合的方法,可以获得周期性交流电输出。由于PVDF既具有良好的压电性能,又具有热释电性能,FEP膜的下方放置一个PVDF薄膜,利用热释电效应和压电效应分别获取温度变化带来的热能和材料弯曲产生的扭转应变能[52]。该压电-摩擦-热释电混合器件,相比PENG或者PPENG具有更好的充电性能,充电速率能够提高了近3倍,当风速达到18m·s-1时,输出功率高达5mW,该装置已被用于口罩中,在可穿戴领域极具潜力。

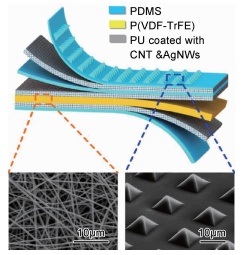

机械能是日常生活中最丰富、最易获取的能源之一,随着人造电子皮肤和智能贴片等可穿戴电子产品的迅速发展,通过采集生物运动时所产生的机械能实现自供电传感,对于可持续、高效的电子设备的发展至关重要。Chen等[53]采用电纺纳米纤维膜为基础,研究了一种柔性薄膜结构的复合纳米发电机,可以很好地贴合手上柔软的皮肤,并收集接触时产生的能量。该器件采用涂覆有导电材料的纳米纤维作为电极,P(VDF-TrFE)纳米纤维作为压电活性层,PDMS作为保护层和摩擦层,通过将TENG和PENG垂直集成在一起,既能在接触-分离过程中产生电能,又能在连续变形过程中产生电能,其中TENG产生的峰值功率为84μW/cm2,PENG产生的峰值功率为0.11μW/cm2,从而提高了能量的收集效率,扩大了应用领域。利用压电纳米材料的高灵敏度,还可将该装置安装在人体不同部位,实时监测人体呼吸和桡动脉脉冲等生理信号,在人造电子皮肤和医疗监护系统中具有潜在的应用价值。

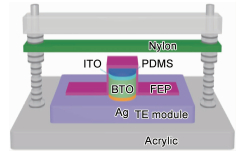

混合式的压电器件多为堆叠的三明治形式,Ji等[54]报道了一种单一结构的BaTiO3基多效应耦合纳米发电机,能够同时收集热能、太阳能和机械能。沉积的氧化铟锡(ITO)和Ag薄膜作为顶部和底部电极,铁电BaTiO3用作压电、热释电和光电材料,尼龙薄片振动用来提供外部应力并与FEP薄膜摩擦,该装置结合了热释电效应、摩擦起电效应、压电效应和光伏效应(photovoltaic effect,PVE),成功实现了多效应相互作用并提高输出功率,峰值电流达到1.5A、峰值电压为7V。表 6对上述3种混合器件式纳米发电机的结构及使用的主要材料进行了总结,能够直观反映出混合式纳米发电机之间的差异。

| Model of hybrid nanogenerator | Primary materials | Comment | References |

|

PVDF/Cu/FEP/Kapton | This work will promote an important step toward hybridized energy harvesting in these situations where the airflow and temperature variations concurrently exist, such as human respiration, heating pipe, or boilers. | [51] |

|

PDMS/P(VDF-TrFE) | It has good flexibility, high output power and sensitive sensing function, and has a great potential application value in the wearable medical monitoring system. | [53] |

|

PDMS/Ag/FEP/Nylon/ITO/BaTiO 3 | Compared with the traditional hybrid nanogenerator with a stacked structure, the multi-effect coupling based on single structure is smaller, simpler and cheaper. So it has a broad application prospect in practical applications and represents a new trend of multi-directional energy collection. | [54] |

近年来,研究者们通过对材料选择和后续加工,如:进行金属元素的掺杂,多种材料进行复合等,以及对材料形貌结构的设计与控制,如:纳米阵列的生长,定向纳米纤维的制备等,都明显地提高了PENG的输出功率和稳定性,同时也进一步向柔性、生物相容性等方向发展。但是作为一个新兴的研究领域,同样还面临很多挑战:PENG大多是实验室制备的,大规模的商业化前景尚不明朗;开发高效的集转能、整流、储能于一体的集成系统;具有良好的机械稳定性和耐久性,能长期使用。相信通过不断发展,一种自供电式的自给自足的PENG能够从根源上改变人们对能源的认知,使人们的生活更加便捷。

| [1] | SUN Y, LIU N, CUI Y. Promises and challenges of nanomaterials for lithium-based rechargeable batteries[J]. Nature Energy, 2016, 1 (7): 16071-1–16071-12. DOI: 10.1038/nenergy.2016.71 |

| [2] | KIM Y, COOK S, TULADHAR S M, et al. A strong regioregularity effect in self-organizing conjugated polymer films and high-efficiency polythiophene:fullerene solar cells[J]. Nat-ure Materials, 2006, 5 (3): 197–203. DOI: 10.1038/nmat1574 |

| [3] | CHAN C K, PENG H, LIU G, et al. High-performance lithium battery anodes using silicon nanowires[J]. Nature Nano-technology, 2008, 3 (1): 31–35. DOI: 10.1038/nnano.2007.411 |

| [4] | LEE M, CHEN C Y, WANG S, et al. A hybrid piezoelectric structure for wearable nanogenerators[J]. Advanced Materials, 2012, 24 (13): 1759–1764. DOI: 10.1002/adma.201200150 |

| [5] | HU Y, ZHANG Y, XU C, et al. High-output nanogenerator by rational unipolar assembly of conical nanowires and its application for driving a small liquid crystal display[J]. Nano Letters, 2010, 10 (12): 5025–5031. DOI: 10.1021/nl103203u |

| [6] | QI Y, KIM J, NGUYEN T D, et al. Enhanced piezoelectricity and stretchability in energy harvesting devices fabricated from buckled PZT ribbons[J]. Nano Letters, 2011, 11 (3): 1331–1336. DOI: 10.1021/nl104412b |

| [7] | QIU Y, LEI J, YANG D, et al. Enhanced performance of wearable piezoelectric nanogenerator fabricated by two-step hydrothermal process[J]. Applied Physics Letters, 2014, 104 (11): 113903-1–113903-4. DOI: 10.1063/1.4869118 |

| [8] | HUANG L B, XU W, HAO J. Energy device applications of synthesized 1D polymer nanomaterials[J]. Small, 2017, 13 (43): 1701820-1–1701820-3. DOI: 10.1002/smll.201701820 |

| [9] | WANG Z L, SONG J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays[J]. Science, 2006, 312 (5771): 242–246. DOI: 10.1126/science.1124005 |

| [10] |

王中林. 压电式纳米发电机的原理和潜在应用[J].

物理, 2006, 35 (11): 897–903.

WANG Z L. Piezoelectric nanogenerators-their principle and potential applications[J]. Physics, 2006, 35 (11): 897–903. DOI: 10.3321/j.issn:0379-4148.2006.11.002 |

| [11] |

黄涛.聚偏氟乙烯静电纺纳米发电机的制备、性能及应用研究[D].上海: 东华大学, 2016. HUANG T.The preparation, performance and application of electrospun PVDF based nanogenerators[D]. Shanghai: Donghua University, 2016. |

| [12] |

郭隐犇, 张青红, 李耀刚, 等. 可穿戴摩擦纳米发电机的研究进展[J].

中国材料进展, 2016, 35 (2): 91–100.

GUO Y B, ZHANG Q H, LI Y G, et al. Progress of the research on wearable triboelectric nanogenerator[J]. Materials China, 2016, 35 (2): 91–100. |

| [13] | WANG A C, WU C, PISIGNANO D, et al. Polymer nanogenerators:opportunities and challenges for large-scale applications[J]. Journal of Applied Polymer Science, 2017, 135 (24): 45674-1–45674-17. |

| [14] | ZHANG Y, ZHAI J, WANG Z L. Piezo-phototronic matrix via a nanowire array[J]. Small, 2017, 13 (46): 1702377-1–1702377-20. DOI: 10.1002/smll.201702377 |

| [15] | SOHN J I, CHA S N, SONG B G, et al. Engineering of efficiency limiting free carriers and an interfacial energy barrier for an enhancing piezoelectric generation[J]. Energy & Environmental Science, 2013, 6 (1): 97–104. |

| [16] | HUANG C T, SONG J, LEE W F, et al. GaN nanowire arrays for high-output nanogenerators[J]. Journal of the American Chemical Society, 2010, 132 (13): 4766–4771. DOI: 10.1021/ja909863a |

| [17] | LIN Y F, SONG J, DING Y, et al. Alternating the output of a CdS nanowire nanogenerator by a white-light-stimulated optoelectronic effect[J]. Advanced Materials, 2008, 20 (16): 3127–3130. DOI: 10.1002/adma.200703236 |

| [18] | LU M Y, SONG J, LU M P, et al. ZnO-ZnS heterojunction and ZnS nanowire arrays for electricity generation[J]. ACS Nano, 2009, 3 (2): 357–362. DOI: 10.1021/nn800804r |

| [19] | KANG J H, JEONG D K, HA J S, et al. Enhanced performance of a GaN piezoelectric nanogenerator with an embedded nanoporous layer via the suppressed carrier screening effect[J]. Semiconductor Science Technology, 2017, 32 (2): 025001-1–025001-6. DOI: 10.1088/1361-6641/32/2/025001 |

| [20] | GMHU B, PARK I K. Flexible ZnO nanorod-based piezoelectric nanogenerators on carbon papers[J]. Nanotechnology, 2017, 28 (44): 445402-1–445402-19. DOI: 10.1088/1361-6528/aa865d |

| [21] | ZHU G, WANG A C, LIU Y, et al. Functional electrical stimulation by nanogenerator with 58V output voltage[J]. Nano Letters, 2012, 12 (6): 3086–3090. DOI: 10.1021/nl300972f |

| [22] | XIAO J, HERNG T S, DING J, et al. Polarization rotation in copper doped zinc oxide (ZnO:Cu) thin films studied by Piezoresponse Force Microscopy (PFM) techniques[J]. Acta Materialia, 2017, 123 : 394–403. DOI: 10.1016/j.actamat.2016.10.051 |

| [23] | RAJAGOPALAN P, SINGH V, PALANI I A. Enhancement of ZnO based flexible nano generators via sol gel technique for sensing and energy harvesting applications[J]. Nanotechn-ology, 2018, 29 (10): 105406-1–105406-34. |

| [24] | SON M, JANG H, LEE M S, et al. Flexible transparent nanogenerators utilizing shape-modulated ZnO nanorod arrays on graphene electrodes[J]. Advanced Materials Technologies, 2018, 3 (4): 1700355–1. DOI: 10.1002/admt.201700355 |

| [25] | PRAMANICK A, PREWITT A D, FORRESTER J S, et al. Domains, domain walls and defects in perovskite ferroelectric oxides:a review of present understanding and recent contr-ibutions[J]. Critical Reviews in Solid State & Materials Sciences, 2012, 37 (4): 243–275. |

| [26] |

朱秀, 许桂生, 刘锦峰. 无铅压电材料的研究进展[J].

中国材料进展, 2017, 36 (4): 279–288.

ZHU X, XU G S, LIU J F. Research progress of lead-free piezoelectric materials[J]. Materials China, 2017, 36 (4): 279–288. |

| [27] | JIN W, WANG Z, LI M, et al. Evolution of the composition, structure, and piezoelectric performance of (K1-xNax) NbO3 nanorod arrays with hydrothermal reaction time[J]. Applied Physics Letters, 2018, 112 (14): 142904-1–142904-5. DOI: 10.1063/1.5021378 |

| [28] | GE H, HOU Y, RAO X, et al. The investigation of depoling mechanism of densified KNbO3 piezoelectric ceramic[J]. Applied Physics Letters, 2011, 99 (3): 032905-1–032905-3. DOI: 10.1063/1.3614541 |

| [29] | KIM D H, JOUNG M R, SEO I T, et al. Influence of sintering conditions on piezoelectric properties of KNbO3 ceramics[J]. Journal of the European Ceramic Society, 2014, 34 (16): 4193–4200. DOI: 10.1016/j.jeurceramsoc.2014.06.028 |

| [30] | KIM J H, KIM D H, LEE T H, et al. Large electrostrain in K(Nb1-xMnx)O3 lead-free piezoelectric ceramics[J]. Journal of the American Ceramic Society, 2016, 99 (12): 4031–4038. DOI: 10.1111/jace.14469 |

| [31] | LEE T H, HWANG H G, JANG S, et al. Low temperature-grown KNbO3 thin films and their application to piezoelectric nanogenerators and self-powered ReRAM device[J]. ACS Appl Mater Interfaces, 2017, 9 (49): 43220–43229. DOI: 10.1021/acsami.7b11519 |

| [32] | SHIN S H, CHOI S Y, LEE M H, et al. High-performance piezoelectric nanogenerators via imprinted sol-gel BaTiO3 nanopillar array[J]. ACS Applied Materials & Interfaces, 2017, 9 (47): 41099–41103. |

| [33] | CROSSLEY S, WHITER R A, KARNARAYAN S. Polymer-based nanopiezoelectric generators for energy harvesting applications[J]. Materials Science & Technology, 2014, 30 (13): 1613–1624. |

| [34] | KARAN S K, MANDAL D, KHATUA B B. Self-powered flexible Fe-doped RGO/PVDF nanocomposite:an excellent material for a piezoelectric energy harvester[J]. Nanoscale, 2015, 7 (24): 10655–10666. DOI: 10.1039/C5NR02067K |

| [35] | SONG J, LU H, LI S, et al. Fabrication of ferroelectric polymer nanostructures on flexible substrates by soft-mold reverse nanoimprint lithography[J]. Nanotechnology, 2016, 27 (1): 015302-1–015302-9. DOI: 10.1088/0957-4484/27/1/015302 |

| [36] | WU W, WEN X, WANG Z L. Taxel-addressable matrix of vertical-nanowire piezotronic transistors for active and adaptive tactile imaging[J]. Science, 2013, 340 (6135): 952–957. DOI: 10.1126/science.1234855 |

| [37] | CORREIA H M G, RAMOS M M D. Quantum modelling of poly(vinylidene fluoride)[J]. Computational Materials Science, 2005, 33 (1): 224–229. |

| [38] | WANG X, SUN F, YIN G, et al. Tactile-sensing based on flexible PVDF nanofibers via electrospinning:a review[J]. Sensors, 2018, 18 (2): 330–346. DOI: 10.3390/s18020330 |

| [39] | LIU X, MA J, WU X M, et al. Polymeric nanofibers with ultrahigh piezoelectricity via self-orientation of nanocrystals[J]. ACS Nano, 2017, 11 (2): 1901–1910. DOI: 10.1021/acsnano.6b07961 |

| [40] | KANG S B, WON S H, IM M J, et al. Enhanced piezoresponse of highly aligned electrospun poly(vinylidene fluoride) nanofi-bers[J]. Nanotechnology, 2017, 28 (39): 395402-1–395402-11. DOI: 10.1088/1361-6528/aa7f6b |

| [41] | MAITY K, MANDAL D. All organic high performance piezoelectric nanogenerator with multilayer assembled electr-ospun nanofibers mats for self-powered multifunctional sensor[J]. ACS applied materials & interfaces, 2018, 10 (21): 18257–18269. |

| [42] | CHEN X, TIAN H, LI X, et al. A high performance P(VDF-TrFE) nanogenerator with self-connected and vertically integrated fibers by patterned EHD pulling[J]. Nanoscale, 2015, 7 (27): 11536–11544. DOI: 10.1039/C5NR01746G |

| [43] | KANIK M, AKTAS O, SEN H S, et al. Spontaneous high piezoelectricity in poly(vinylidene fluoride) nanoribbons prod-uced by iterative thermal size reduction technique[J]. ACS Nano, 2014, 8 (9): 9311–9323. DOI: 10.1021/nn503269b |

| [44] | PARK K I, LEE M, LIU Y, et al. Flexible nanocomposite generator made of BaTiO3 nanoparticles and graphitic carbons[J]. Advanced Materials, 2012, 24 (22): 2999–3004. DOI: 10.1002/adma.201200105 |

| [45] | BAEK C, YUN J H, WANG H S, et al. Enhanced output performance of a lead-free nanocomposite generator using BaTiO3 nanoparticles and nanowires filler[J]. Applied Surface Science, 2018, 429 : 164–170. DOI: 10.1016/j.apsusc.2017.06.109 |

| [46] | PARK J, KIM M, LEE Y, et al. Fingertip skin-inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli[J]. Science advances, 2015, 1 (9): e1500661-1–e1500661-13. |

| [47] | TONG W, ZHANG Y, ZHANG Q, et al. An all-solid-state flexible piezoelectric high-k film functioning as both a generator and in situ storage unit[J]. Advanced Functional Materials, 2015, 25 (45): 7029–7037. DOI: 10.1002/adfm.201503514 |

| [48] | SHIN S H, KIM Y H, LEE M H, et al. Hemispherically aggregated BaTiO3 nanoparticle composite thin film for high-performance flexible piezoelectric nanogenerator[J]. ACS nano, 2014, 8 (3): 2766–2773. DOI: 10.1021/nn406481k |

| [49] | HAN M, ZHANG X S, MENG B, et al. r-shaped hybrid nanogenerator with enhanced piezoelectricity[J]. ACS nano, 2013, 7 (10): 8554–8560. DOI: 10.1021/nn404023v |

| [50] | JUNG W S, KANG M G, MOON H G, et al. High output piezo/triboelectric hybrid generator[J]. Scientific Reports, 2015, 5 : 9309-1–9309-6. DOI: 10.1038/srep09309 |

| [51] | ZHENG H, ZI Y, HE X, et al. Concurrent harvesting ambient energy by hybrid nanogenerators for wearable self-powered systems and active remote sensing[J]. ACS Applied Materials & Interfaces, 2018, 10 (17): 14708–14715. |

| [52] | GAO F, LI W, WANG X, et al. A self-sustaining pyroelectric nanogenerator driven by water vapor[J]. Nano Energy, 2016, 22 : 19–26. DOI: 10.1016/j.nanoen.2016.02.011 |

| [53] | CHEN X, SONG Y, SU Z, et al. Flexible fiber-based hybrid nanogenerator for biomechanical energy harvesting and physiological monitoring[J]. Nano Energy, 2017, 38 : 43–50. DOI: 10.1016/j.nanoen.2017.05.047 |

| [54] | JI Y, ZHANG K, YANG Y. A one-structure-based multieffects coupled nanogenerator for simultaneously scavenging thermal, solar, and mechanical energies[J]. Advanced Science, 2018, 5 (2): 1700622-1–1700622-8. DOI: 10.1002/advs.201700622 |

2019, Vol. 47

2019, Vol. 47