文章信息

- 高晔, 焦健

- GAO Ye, JIAO Jian

- NITE工艺制备SiCf/SiC复合材料的研究进展

- Research progress on NITE process for fabricating SiCf/SiC composites

- 材料工程, 2019, 47(8): 33-39

- Journal of Materials Engineering, 2019, 47(8): 33-39.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2019.000048

-

文章历史

- 收稿日期: 2019-01-15

- 修订日期: 2019-04-10

碳化硅纤维增强碳化硅基(SiCf/SiC)复合材料因其具备质轻、抗氧化、抗热震、抗辐射、耐高温性能优异等特点,被广泛应用于航空、航天、汽车和核反应等领域[1-2]。目前,经过多年的发展,制备SiCf/SiC复合材料的工艺技术主要有化学气相渗透法(CVI)、前驱体裂解法(PIP)及熔渗法(MI)。CVI工艺将先驱体通入反应炉内,在多孔纤维织物预制体内部连续、多次沉积某种物质来制备复合材料,其制备的陶瓷基体纯度高、晶型完整,但该工艺周期长,成本高,制备的SiCf/SiC复合材料孔隙率高。PIP工艺在一定的温度和压力下,将适当理论原子比的液态聚合物(如聚碳硅烷、聚硅烷等)浸渗到多孔纤维织物预制体中,在惰性气体保护下进行交联固化,然后高温热解处理使先驱体聚合物转化为陶瓷基体,由于热解过程中伴随着小分子逸出形成的气孔和基体热解后的体积收缩,需要多次反复进行浸渍-固化-热解,但制备的SiCf/SiC复合材料仍具有较大的孔隙率。MI工艺通过在高温下将熔融Si渗入碳化硅纤维增强的多孔体制备出SiC基复合材料,与前两种工艺相比,制备的复合材料致密性较高、孔隙率显著降低,但由于复合材料中存在一定含量的游离硅,在高温下可能会发生反应或挥发使材料的强度降低,不利于在高温下(>1400℃)长时间使用[3-5]。

NITE工艺通过纳米SiC粉末浸渍SiC纤维后进行热压烧结,从而制备高致密、高性能SiCf/SiC复合材料。由于碳化硅基体所需烧结温度(>1800℃)及压力(>15MPa)较高[6],该工艺通常需基于耐温性能更加优异的第三代高结晶程度的SiC纤维。本文将从基本概念、工艺流程、制备的SiCf/SiC复合材料和构件考核验证及前景展望对NITE工艺进行综合阐述。

1 NITE工艺基本概念NITE工艺于21世纪初起源于日本[7],该工艺主要流程为将含界面层(通常为裂解炭)的SiC纤维浸渍到由纳米SiC颗粒与氧化烧结助剂混合制成的料浆后,在惰性气体下(通常为氩气)进行热压烧结,以制备SiC基复合材料。与其他制备SiCf/SiC复合材料的工艺相比,由于直接采用了SiC粉末制备复合材料基体,陶瓷本征性能显著,因此NITE工艺制备出的复合材料具备孔隙率低、热导率高、基体致密、结晶程度高、不含残余Si等诸多优点,适合高温环境下长时使用。同时,采用的纳米SiC粉末比表面积大,反应活性高,有利于提高纤维束之间的浸渍效果和基体的致密化程度,降低烧结助剂的用量以及烧结温度,并减少热压烧结过程中对纤维造成的损伤[8-9]。

目前主要开展NITE工艺的国家以日本与美国为主,在日本CREST(core research for evolutional science and technology)项目[7]、日/美联合项目JUPITER[10](Japan US program of irradiation test for energy research:Ⅰ期1995~2000;Ⅱ期2000~2005)、日/欧盟联合项目IFMIF/EVEDA[11](international fusion materials irradiation facility/engineering validation and engineering design activities project)等面向核用材料研究计划的支持下,日本京都大学、美国橡树岭国家实验室等最早开展了NITE工艺的探索研究,经过十几年的发展,国外已基本实现SiCf/SiC复合材料的工业化生产,在以核能源工业为首的诸多领域已有广泛的应用[12]。

2 NITE工艺发展历程作为基于液相烧结制备高性能SiCf/SiC复合材料的新工艺[13],NITE工艺涉及混合料浆的流变学特性、烧结助剂的优化以及纤维防护等多项技术,研制难度较大[14]。由于采用的原料通常为具备大比表面积的纳米SiC粉末(≈110m2·g-1),导致料浆黏性会明显提高,使用传统的束丝缠绕技术难以配置相应的料浆[15];而且工艺过程中的烧结温度、压力均较高,可能对SiC纤维产生损伤。其工艺流程经历了以下发展阶段:

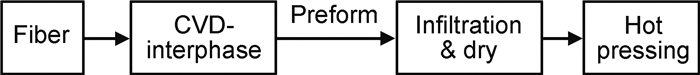

(1) 在工艺研制初期,普遍采用PIP+热压烧结(HP)的方法,工艺流程大致可分为4个工序(见图 1)[15-19]:首先通过化学气相沉积(chemical vapor deposition,CVD)工艺在纤维束表面沉积界面层,其次将纤维束在含聚合物先驱体(通常为PCS)、纳米SiC粉、烧结助剂的料浆中浸渍后高温裂解,形成预制体,该步骤即为PIP工艺,然后裁剪预制体,在含纳米SiC粉末、烧结助剂的料浆中浸渍、干燥(如有必要,该过程需反复进行),最后在石墨模具中将预制体裁剪、叠层后进行热压烧结(温度>1700℃,压力>15MPa)。

|

图 1 早期NITE工艺路线 Fig. 1 Initial routing of NITE process |

(2) 在后续的工艺研制中,实验结果表明有无PCS料浆制备的复合材料性能差异不大[20],因此可将NITE工艺流程进行简化,即取消PIP工艺,简化的工艺路线如图 2所示[21]:通过CVD工艺在纤维束表面沉积界面层后,将纤维束在料浆中浸渍后干燥,形成预制体并裁剪,叠层后进行热压烧结。Shimoda等[22-23]基于该简化的NITE工艺制备了两种不同体积分数的SiCf/SiC复合材料(分别对应高韧性复合材料、高强度复合材料),研究了在1000~1500℃热暴露前后的性能变化;同时还研究不同PyC界面层厚度对性能的影响,结果表明,当PyC界面层厚度适中时(500nm)制备的复合材料强度及韧性均较好[24]。

|

图 2 简化的NITE工艺路线 Fig. 2 Simplified NITE process route |

(3) 早期NITE工艺由于普遍采用水性料浆,可操作性较差,且在制备最终构件过程中难以维持预制体的形状,导致复合材料成品率较低[25-26]。为此,日本室兰工业大学于2010年成立了OASIS(organization of advanced sustainability initiative for energy system/materials)中心,其目的之一就是改进NITE工艺流程,提高生产效率,实现基于NITE工艺的SiCf/SiC复合材料工程化生产。为此,开发了新的Cera-NITE工艺,即采用非液态的SiC素坯及SiC纤维预浸料作为中间产物,以提高工艺的稳定性、可控性等,其基本工艺路线如图 3所示[13, 25-26]。

|

图 3 新型NITE工艺路线 Fig. 3 New NITE process route |

目前,日本已基本实现了NITE工艺的商用级应用,可批量生产性能稳定可控的Cera-NITE SiCf/SiC复合材料产品[25]。基于该工艺制备的复合材料基体致密,仅存在少量的微型孔洞及残余氧化烧结助剂[25]。然而,由于NITE工艺需采用成本高昂的高结晶程度的SiC纤维,导致工程化难度较大。为了降低SiC纤维原料的成本,日本室兰工业大学、京都大学与IEST公司合作开发了IC-NITE工艺,通过在无定型SiC纤维表层覆盖酚醛树脂,在通过NITE工艺制备复合材料的过程中同步实现纤维的原位化结晶[26]。

近年来,随着NITE工艺的稳定,国外在该领域的研究已向着更加细化的方面发展,对其制备的SiCf/SiC复合材料、碳化硅基体的氧化行为和辐射行为等均开展了较为广泛的研究[27-29]。如Park等[17, 30]对不同氧分压环境下的复合材料氧化行为进行了研究,发现在高温有氧条件下,复合材料中的残余烧结助剂会形成软化的玻璃相,与碳化硅基体反应后气化。Terrani等[31]对NITE碳化硅基体在400~700℃,2~10dpa辐射环境前后的膨胀率、拉伸强度和热导率进行了对比,发现碳化硅基体性能几乎不变,具备良好的抗辐射性能。Hino等[32-33]通过气密性测量装置对PIP,PIP+MI,NITE工艺制备的SiCf/SiC复合材料板件及管形试件的He气密性进行了测试,结果表明,NITE工艺比其他工艺制备的复合材料气密性低出2~5个数量级。

与国外相比,我国在NITE工艺制备SiCf/SiC复合材料方面开展的研究十分有限,这主要是由于在NITE工艺过程中需对碳化硅基体进行热压烧结,处理温度通常高于1700℃。因此,我国学者以碳纤维为增强体对NITE工艺的机理及工艺路线开展了早期的探索研究,如国防科技大学[34-36]、浙江大学[37]、上海硅酸盐研究所[19]、湖南大学[38]等开展了热压烧结工艺的系列研究,对热压烧结过程中的致密化机理、不同烧结助剂对复合材料性能的影响等均有了一定的认识,为NITE工艺制备SiCf/SiC复合材料的机理、原料的制备、工艺参数的控制等提供了参考。上海硅酸盐研究所于21世纪初采用日本Ube公司提供的Tyranno SA纤维制备了SiCf/SiC复合材料,初步探索了烧结温度、压力等对复合材料性能的影响[39]。

3 NITE工艺制备的SiCf/SiC复合材料性能与CVI,PIP等工艺相比,NITE工艺制备的SiCf/SiC复合材料致密程度高,且不含残余Si,因此导热性能与气密性优异,适用于高温氧化环境下长时工作。目前国外开展的NITE工艺研究大多针对核能工业领域,因此,通常采用不含B元素的PyC界面层体系,其制备的复合材料基本性能如表 1所示。

| Parameter | Kyoto | OAK | Muroran | Shanghai institute of ceramics | |||

| Fiber type | TyrannoTM-SA 3rd | TyrannoTM-SA 3rd | Cef-NITETM | Tyranno-SA | |||

| Fiber form | Long fiber | Woven | - | Woven | Shot fiber | Woven | |

| Fiber volume fraction/% | ≈30 | ≈50 | 35-40 | ≈40 | 45 | 45 | ≈30 |

| Density/(g·cm-3) | 2.94-3.06 | 2.81-3.11 | 2.73-2.96 | ≈3.0 | 3.05 | 2.76-2.94 | 2.85-2.93 |

| Porosity/% | 1.1-2.1 | 0.6-6.2 | 3.7-13.9 | ≈5.0 | 5 | - | - |

| Elastic modulus/GPa | 289-311 | 277-354 | 59-117 | ≈300 | - | - | 275.2-286.1 |

| Proportional limit/MPa | - | - | 142-365 | ≈180 | 142 | - | - |

| Tensile strength/MPa | 350-380 | 322-358 | 160-238 | ≈400 | 344 | - | 335.3-369.6 |

| Flexural strength/MPa | 517-690 | 375-860 | 152-497 | - | - | 96-135 | - |

| Fracture strain/% | 0.145-0.286 | 0.127-0.176 | - | ≈0.3 | - | - | - |

| Thermal conductivity/ (W·m-1·K-1) |

32-19 (20-1000)℃ |

21-15 (20-1000)℃ |

14-21 | 20-35 | - | - | - |

近年来,NITE工艺制备的复合材料孔隙率较低(< 5%),因此材料的热导率较高、He的气密性较低,被广泛应用于核聚变反应的热交换部件[40]。由于NITE工艺制备的复合材料中不可避免地存在残余氧化烧结助剂,在辐射环境下比碳化硅基体的膨胀率大,因此需通过严格控制工艺流程中的氧化助剂用量及比例,减少其对复合材料抗辐射性能的影响[41]。

需要指出的是,NITE工艺制备的SiCf/SiC复合材料的性能、微观结构等与烧结助剂种类、烧结助剂用量、热压烧结温度、热压烧结压力等参数的选取密切相关。Konishia等[41]研究了Al2O3,Y2O3,YAG,AYC(Al2O3+Y2O3+CaO)不同种类烧结助剂制备的SiCf/SiC复合材料在核辐射之后的性能变化,发现烧结助剂为YAG的复合材料膨胀率最大,且辐射后材料内部含有大量微裂纹。Parisha等[42]通过对YA(Al2O3+Y2O3),CZA(CeO2+ZrO2+Al2O3),YZA(Al2O3+Y2O3+ZrO2)烧结助剂制备的NITE-SiC进行热液腐蚀实验发现,YZA制备的复合材料抗辐射性能最优。Koyanagi等[43]对YA烧结助剂质量分数分别为6%,9%时的辐射性能进行研究,结果表明, 烧结助剂含量较高的复合材料受辐射后膨胀率较高,而残余的Y元素受辐射后膨胀率较高是导致该现象的主要原因。Abe等[44]基于NITE新工艺采用3种不同类型的SiC素坯制备了SiCf/SiC复合材料,并对其电导率进行了测试。

由此可知,根据材料的使用条件,可通过更换工艺、原料或修改工艺参数对制备的复合材料进行设计。如美国橡树岭国家实验室与GE公司[42]基于ZrO2抗辐射性能良好且水溶性差的特性,将其作为NITE工艺的烧结助剂来制备轻水反应堆的容器。此外,董绍明等[45]对热压烧结后的SiCf/SiC复合材料的后处理工艺进行了研究,通过在N2气氛中对复合材料进行高温热处理,使碳化硅基体与N2发生反应,在材料表面形成氮化层,以进一步消除材料内部残余孔隙及缺陷,调整相组成及显微结构,改善材料性能。

4 考核验证情况及前景展望在核能工业领域,超高温反应炉、核聚变反应炉等结构材料长时服役在高温、高辐射等恶劣工作环境下,同时氦气通常作为设备的冷却介质,若产生泄漏将明显降低核反应效率,因此对结构材料的耐高温、耐辐射性能、气密性等提出了苛刻的要求[8, 33, 46]。SiCf/SiC复合材料因其优异的性能被视为核能工业设备结构材料的首选,但由于PIP,MI工艺制备的碳化硅基体为非近化学计量比,在中子辐射环境下稳定性较差;CVI工艺制备的复合材料孔隙率较高,严重影响结构的热导率和力学性能,大量实验结果表明,NITE工艺制备的复合材料可成功应用于核能工业领域[7]。Idris等[4]研究发现,尽管存在残余的氧化助剂,NITE工艺制备的SiCf/SiC复合材料仍具备优异的抗辐射性能。许多专家学者基于NITE工艺制备了不同的核用构件,如Noborio等[47]针对高温气体反应装置制备了复合材料热交换器,并在LiPb-He双回路结合处进行了测试;Satori等[48]制备了多层复合材料隔热板,研究了不同孔结构对热导率的影响;Kishimoto等[11, 44]制备了复合材料加热器,发现在0~1000℃范围内,复合材料热导率几乎不受温度影响,且通过添加W丝可显著提高结构的热导率。

在航空发动机领域,随着对推重比及效率等需求的不断提高,燃烧室、涡轮等热端部件的材料只能诉求于耐温性能优异的陶瓷基复合材料[3]。目前,有关NITE工艺在航空发动机领域的研究鲜见报道,仅美国橡树岭国家实验室开展了相关实验,NITE工艺制备的燃烧室衬套经20~1350℃热震加载100个循环后,性能无衰减且组织结构无损伤[7],表明NITE工艺在航空发动机领域热端部件具有十分可观的应用前景。此外,通过NITE工艺制备高性能SiC纤维[25]、多孔炭材料[49],基于NITE工艺的SiCf/SiC复合材料连接技术[50]也展现出了日益广泛的应用前景。

尽管NITE工艺制备SiCf/SiC复合材料构件已取得了一定的应用基础,但目前可制备的构件结构形状仍较为简单,以规则的板件或管形构件为主。其中,板状构件可通过普通HP工艺制备;管形构件则通过“伪热等静压工艺”(pseudo-hot isostatic pressing, P-HIP)进行制备,该工艺将复合材料预浸料铺层到石墨模具中,利用碳粉作为传递压力的介质,以实现管形复合材料构件的近净成形。然而,如何通过热压烧结制备形状更加复杂的构件,如具备复杂型面结构的航空发动机涡轮叶片等,同时保持材料性能不产生损耗、微观结构不产生损伤,仍是目前NITE工艺仍需解决的难题之一。

5 结束语目前SiC纤维增强碳化硅基体复合材料在核能源、航空、航天等领域已开展了一定程度的应用,但随着新技术的发展,特别是核能工业及航空发动机对材料耐高温等性能需求的不断升高,制备SiCf/SiC复合材料的工艺也在不断发展。NITE工艺作为一种制备SiCf/SiC复合材料的液相烧结新工艺,兼有碳化硅基体近化学计量比、基体致密、制备周期短等优点,展现出了巨大的应用前景。目前国外基于已稳定批量生产的第三代SiC纤维已开展了大量NITE工艺研究,并利用该工艺制备的复合材料成功应用于核能工业领域,并在航空发动机领域开展了较为深入的研究。目前,国外正在研制可长时工作在1500~1650℃, 100MPa下的SiCf/SiC复合材料,NITE工艺无疑是制备该材料的首选。与国外相比,国内在NITE工艺方面的研究存在较大的差距,但随着国内第三代SiC纤维关键技术的突破,国内需加大在该领域的研究力度,以赶上发达国家的步伐,提升科技实力,为我国核能源及下一代先进航空发动机等领域的发展奠定基础。

| [1] |

刘虎, 杨金华, 周怡然, 等. 国外航空发动机用SiCf/SiC复合材料的材料级性能测试研究进展[J].

材料工程, 2018, 46 (11): 1–12.

LIU H, YANG J H, ZHOU Y R, et al. Progress in coupon tests of SiCf/SiC ceramic matrix composites used for aero engines[J]. Journal of Materials Engineering, 2018, 46 (11): 1–12. DOI: 10.11868/j.issn.1001-4381.2018.000503 |

| [2] |

刘海韬, 杨玲伟, 韩爽. 连续纤维增强陶瓷基复合材料微观力学研究进展[J].

无机材料学报, 2018, 33 (7): 711–720.

LIU H T, YANG L W, HAN S. Research progress on micro-mechanical property of continuous fiber-reinforced ceramic matrix composites[J]. Journal of Inorganic Materials, 2018, 33 (7): 711–720. |

| [3] |

焦健, 杨金华, 李宝伟. 熔渗法制备陶瓷基复合材料的研究进展[J].

航空制造技术, 2015 (增刊2): 1–6.

JIAO J, YANG J H, LI B W. Progress in ceramic matrix composites fabricated by melt infiltration process[J]. Aeron-autical Manufacturing Technology, 2015 (Suppl 2): 1–6. |

| [4] | IDRIS M I, YAMAZAKI S, YOSHIDA K, et al. Defects anni-hilation behavior of neutron-irradiated SiC ceramics densified by liquid-phase-assisted method after post-irradiation annealing[J]. Nuclear Materials and Energy, 2016, 9 : 199–206. DOI: 10.1016/j.nme.2016.05.014 |

| [5] |

王洪达, 周海军, 董绍明, 等. SiCf/SiC复合材料耐高温氟熔盐腐蚀性能研究[J].

无机材料学报, 2017, 32 (11): 1133–1140.

WANG H D, ZHOU H J, DONG S M, et al. Corrosion behavior of SiCf/SiC composites in high temperature fluoride salt environment[J]. Journal of Inorganic Materials, 2017, 32 (11): 1133–1140. |

| [6] |

朱丹, 李玉凤, 高明霞, 等. SiCf/SiC陶瓷基复合材料制备技术与性能研究进展[J].

材料导报, 2008, 22 (3): 55–59.

ZHU D, LI M F, GAO M X, et al. Research development of fabrication techniques and properties of SiCf/SiC ceramic matrix composite[J]. Materials Review, 2008, 22 (3): 55–59. DOI: 10.3321/j.issn:1005-023X.2008.03.014 |

| [7] | KATOH Y, KOHYAMA A, NOZAWA T, et al. SiC/SiC comp-osites through transient eutectic-phase route for fusion applications[J]. Journal of Nuclear Materials, 2004, 329/333 : 587–591. DOI: 10.1016/j.jnucmat.2004.04.157 |

| [8] | HIROHATA Y, JINUSHI T, YAMAUCHI Y, et al. Gas perm-eability of SiC/SiC composites as fusion reactor material[J]. Fusion Engineering and Design, 2002, 61/62 : 699–704. DOI: 10.1016/S0920-3796(02)00153-9 |

| [9] | KATOH Y, DONG S M, KOHYAMA A. Thermo-mechanical properties and microstructure of silicon carbide composites fabricated by nano-infiltrated transient eutectoid process[J]. Fusion Engineering and Design, 2002, 61/62 : 723–731. DOI: 10.1016/S0920-3796(02)00180-1 |

| [10] | KOHYAMA A. The present status of SiC/SiC R & D for nuclear application in Japan[J]. IOP Conference Series:Materials Science and Engineering, 2011, 18 : 162002. DOI: 10.1088/1757-899X/18/16/162002 |

| [11] | KISHIMOTO H, ABE T, PARK J S, et al. SiC/SiC and W/SiC/SiC composite heater by NITE-method for IFMIF and fission reactor irradiation rigs[J]. IOP Conference Series:Materials Science and Engineering, 2011, 18 : 162018. DOI: 10.1088/1757-899X/18/16/162018 |

| [12] |

赵爽, 周新贵, 余金山. SiC/SiC复合材料的制备与性能研究进展[J].

材料导报, 2013, 27 (1): 66–70.

ZHAO S, ZHOU X G, YU J S. Research and development in fabrication and properties of SiC/SiC composites[J]. Materials Review, 2013, 27 (1): 66–70. DOI: 10.3969/j.issn.1005-023X.2013.01.012 |

| [13] | PARK J S, JUNG H C, OOI Y, et al. Fabrication of enviro-nmentally resistant NITE-SiC/SiC composites[J]. IOP Conf-erence Series:Materials Science and Engineering, 2011, 18 : 202012. DOI: 10.1088/1757-899X/18/20/202012 |

| [14] | PARK J, KOHYAMA A, HINOKI T, et al. Efforts on large scale production of NITE-SiC/SiC composites[J]. Journal of Nuclear Materials, 2007, 367/370 : 719–724. DOI: 10.1016/j.jnucmat.2007.03.053 |

| [15] | DONG S, KATOH Y, KOHYAMA A. Processing optimization and mechanical evaluation of hot pressed 2D Tyranno-SA/SiC composites[J]. Journal of the European Ceramic Society, 2003, 23 (8): 1223–1231. DOI: 10.1016/S0955-2219(02)00298-4 |

| [16] | DONG S, KATOH Y, KOHYAMA A. Preparation of SiC/SiC composites by hot pressing, using Tyranno-SA fiber as reinforc-ement[J]. Journal of the American Ceramic Society, 2003, 86 (1): 26–32. DOI: 10.1111/j.1151-2916.2003.tb03272.x |

| [17] | PARK J S, KATOH Y, KOHYAMA A, et al. Tailoring the microstructure of hot-pressed SiC by heat treatment[J]. Journal of Nuclear Materials, 2004, 329/333 : 558–561. DOI: 10.1016/j.jnucmat.2004.04.117 |

| [18] |

董绍明, 丁玉生, 江东亮, 等. 制备工艺对热压烧结SiC/SiC复合材料结构与性能的影响[J].

无机材料学报, 2005, 20 (4): 883–888.

DONG S M, DING Y S, JIANG D S, et al. Effects of preparation conditions on the microstructure and properties of hot pressed SiC/SiC composites[J]. Journal of Inorganic Materials, 2005, 20 (4): 883–888. DOI: 10.3321/j.issn:1000-324X.2005.04.019 |

| [19] |

丁玉生, 董绍明, 高乐, 等. 烧结温度对Cf/SiC复合材料结构及性能的影响[J].

无机材料学报, 2008, 23 (6): 1151–1154.

DING Y S, DONG S M, GAO L, et al. Effect of sintering temperature on microstructure and properties of Cf/SiC composites[J]. Journal of Inorganic Materials, 2008, 23 (6): 1151–1154. DOI: 10.3321/j.issn:1000-324X.2008.06.013 |

| [20] | SHIMODA K, HINOKI T, KATOH Y, et al. Development of the tailored SiC/SiC composites by the combined fabrication process of ICVI and NITE methods[J]. Journal of Nuclear Materials, 2009, 384 (2): 103–108. DOI: 10.1016/j.jnucmat.2008.10.025 |

| [21] | NAKAZATO N, KISHIMOTO H, SHIMODA K, et al. Effects of preform densification on near-net shaping of NITE-SiC/SiC composites[J]. IOP Conference Series:Materials Science and Engineering, 2011, 18 : 202011. DOI: 10.1088/1757-899X/18/20/202011 |

| [22] | SHIMODA K, KOHYAMA A, HINOKI T. High mechanical performance SiC/SiC composites by NITE process with tailoring of appropriate fabrication temperature to fiber volume fraction[J]. Composites Science and Technology, 2009, 69 (10): 1623–1628. DOI: 10.1016/j.compscitech.2009.03.011 |

| [23] | SHIMODA K, PARK J S, HINOKI T, et al. Microstructural optimization of high-temperature SiC/SiC composites by NITE process[J]. Journal of Nuclear Materials, 2009, 386/388 : 634–638. DOI: 10.1016/j.jnucmat.2008.12.234 |

| [24] | SHIMODA K, PARK J, HINOKI T, et al. Influence of pyrol-ytic carbon interface thickness on microstructure and mechanical properties of SiC/SiC composites by NITE process[J]. Composites Science and Technology, 2008, 68 (1): 98–105. DOI: 10.1016/j.compscitech.2007.05.037 |

| [25] | KOHYAMA A, PARK J, JUNG H. Advanced SiC fibers and SiC/SiC composites toward industrialization[J]. Journal of Nuclear Materials, 2011, 417 (1/3): 340–343. |

| [26] | KOHYAMA A, KOHNO Y, KISHIMOTO H, et al. Indust-rialization of advanced SiC/SiC composites and SiC based composites; intensive activities at muroran institute of technology under OASIS[J]. IOP Conference Series:Materials Science and Engineering, 2011, 18 : 202002. DOI: 10.1088/1757-899X/18/20/202002 |

| [27] | HAYASAKAA D, PARK J, KISHIMOTO H, et al. Gas leak tightness of SiC/SiC composites at elevated temperature[J]. Fusion Science and Technology, 2016, 109/111 : 1498–1501. |

| [28] | IDRISA M I, KONISHIB H, IMAIB M, et al. Neutron irrad-iation swelling of SiC and SiCf/SiC for advanced nuclear applications[J]. Energy Procedia, 2015, 71 : 328–336. DOI: 10.1016/j.egypro.2014.11.886 |

| [29] | NOZAWA T, OZAWA K, ASAKURA Y, et al. Evaluation of damage accumulation behavior and strength anisotropy of NITE SiC/SiC composites by acoustic emission, digital image correlation and electrical resistivity monitoring[J]. Journal of Nuclear Materials, 2014, 455 (1/3): 549–553. |

| [30] | PARK J S, KIM J, NAKAZATO N, et al. Oxidation resistance of NITE-SiC/SiC composites with/without CVD-SiC environ-mental barrier coating[J]. Ceramics International, 2018, 44 (14): 17319–17325. DOI: 10.1016/j.ceramint.2018.06.194 |

| [31] | TERRANI K A, ANG C, SNEAD L L, et al. Irradiation stability and thermo-mechanical properties of NITE-SiC irradiated to 10dpa[J]. Journal of Nuclear Materials, 2018, 499 : 242–247. DOI: 10.1016/j.jnucmat.2017.11.040 |

| [32] | HINO T, HAYASHISHITA E, KOHYAMA A, et al. Helium gas permeability of SiC/SiC composite after heat cycles[J]. Journal of Nuclear Materials, 2007, 367/370 : 736–741. DOI: 10.1016/j.jnucmat.2007.03.089 |

| [33] | HINO T, HAYASHISHITA E, YAMAUCHI Y, et al. Helium gas permeability of SiC/SiC composite used for in-vessel components of nuclear fusion reactor[J]. Fusion Engineering and Design, 2005, 73 (1): 51–56. |

| [34] |

周新贵, 张长瑞, 何新波, 等. 热解碳涂层碳纤维增强碳化硅复合材料热压工艺研究[J].

材料工程, 2000 (3): 39–41.

ZHOU X G, ZHANG C R, HE X B, et al. A study on the hot press of pyrolysised carbon coated carbon fiber reinforced silicon carbide composite[J]. Journal of Materials Engineering, 2000 (3): 39–41. |

| [35] |

张新明, 何新波, 张长瑞, 等. 热压烧结Cf/SiC复合材料的力学性能[J].

硅酸盐学报, 1999, 27 (5): 611–617.

ZHANG X M, HE X B, ZHANG C R, et al. Mechanical properties of hot-pressed carbon fiber reinforced silicon carbide composites[J]. Journal of The Chinese Ceramic Society, 1999, 27 (5): 611–617. DOI: 10.3321/j.issn:0454-5648.1999.05.018 |

| [36] |

曹英斌, 张长瑞, 周新贵, 等. 热压烧结法制备Cf/SiC陶瓷基复合材料研究[J].

宇航材料工艺, 1998 (6): 35–37.

CAO Y B, ZHANG C R, ZHOU X G, et al. The study of Cf/SiC ceramic matrix composites fabricated by hot pressing sintering method[J]. Aerospace Materials & Technology, 1998 (6): 35–37. |

| [37] |

何新波, 张长瑞, 周新贵, 等. 先驱体转化-热压烧结碳纤维增韧碳化硅复合材料的显微结构[J].

航空材料学报, 1999, 19 (3): 43–50.

HE X B, ZHANG C R, ZHOU X G, et al. Microstructure of the Cf/SiC composites by precursor conversion-hot pressing sintering[J]. Journal of Aeronautical Materials, 1999, 19 (3): 43–50. DOI: 10.3969/j.issn.1005-5053.1999.03.008 |

| [38] |

周松青, 唐绍裘, 肖汉宁, 等. 碳化硅及其复合材料的烧结[J].

陶瓷学报, 1999 (1): 41–48.

ZHOU S Q, TANG S Q, SHAO H N, et al. Sintering on SiC and its composite material[J]. Journal of Ceramics, 1999 (1): 41–48. |

| [39] |

丁玉生, 冯债, 曹伟, 等.热压烧结制备短切SiC/SiC复合材料[C]//2004年材料科学与工程新进展论文集.北京: 中国材料研究学会, 2004: 887-891. DING Y S, FENG Z, CAO W, et al. Fabrication of short chop SiC/SiC composites by hot-pressing[C]//2004 Material Science and Engineering. Beijing: Chinese Materials Research Society, 2004: 887-891. |

| [40] | HINO T, HAYASHISHITA E, YAMADAA T, et al. Progress of plasma surface interaction study on low activation materials[J]. Fusion Engineering and Design, 2006, 81 (1/7): 181–186. |

| [41] | KONISHIA H, IDRIS M I, IMAI M, et al. Neutron irradiation effects of oxide sintering additives for SiCf/SiC composites[J]. Energy Procedia, 2015, 71 : 306–312. DOI: 10.1016/j.egypro.2014.11.883 |

| [42] | PARISHA C M, TERRANI K A, KIM Y, et al. Microstru-cture and hydrothermal corrosion behavior of NITE-SiC with various sintering additives in LWR coolant environments[J]. Journal of the European Ceramic Society, 2017, 37 : 1261–1279. DOI: 10.1016/j.jeurceramsoc.2016.11.033 |

| [43] | KOYANAGI T, KONDO S, HINOKI T. The influence of sintering additives on the irradiation resistance of NITE SiC[J]. Journal of Nuclear Materials, 2011, 417 (1/3): 435–439. |

| [44] | ABE T, KISHIMOTO H, NAKAZATO N, et al. SiC/SiC composite heater for IFMIF[J]. Fusion Engineering and Design, 2012, 87 (7/8): 1258–1260. |

| [45] |

董绍明, 陈忠明, 谭寿洪, 等. 高温等静压后处理液相烧结SiC陶瓷的强化与增韧机理[J].

硅酸盐学报, 1998, 12 (6): 754–761.

DONG S M, CHEN Z M, TAN S H, et al. Strengthening and toughening mechanism of post-hot isostatic pressing of liquid phase sintered SiC[J]. Journal of The Chinese Ceramic Society, 1998, 12 (6): 754–761. DOI: 10.3321/j.issn:0454-5648.1998.06.012 |

| [46] | KATOH Y, SNEAD L L, JR. HENAGER C H, et al. Current status and recent research achievements in SiC/SiC composites[J]. Journal of Nuclear Materials, 2014, 455 (1/3): 387–397. |

| [47] | NOBORIO K, YAMAMOTO Y, TAKEUCHI Y, et al. Develo-pment of high temperature SiC/SiC composite intermediate heat exchanger He and LiPb[C]//23rd IEEE/NPSS Symposium on Fusion Engineering, San Diego: IEEE, 2009. |

| [48] | SATORI K, KISHIMOTO H, PARK J S, et al. Thermal insulator of porous SiC/SiC composites for fusion blanket system[J]. IOP Conference Series:Materials Science and Engineering, 2011, 18 : 162019. DOI: 10.1088/1757-899X/18/16/162019 |

| [49] | PARK Y, HINOKI T, KOHYAMA A. Development of multi-functional NITE-porous SiC for ceramic insulators[J]. Journal of Nuclear Materials, 2009, 386/388 : 1014–1017. DOI: 10.1016/j.jnucmat.2008.12.202 |

| [50] | NOZAWA T, HINOKI T, HASEGAWA A, et al. Recent advances and issues in development of silicon carbide composites for fusion applications[J]. Journal of Nuclear Materials, 2009, 386/388 : 622–627. DOI: 10.1016/j.jnucmat.2008.12.305 |

2019, Vol. 47

2019, Vol. 47