文章信息

- 张颖, 王宁, 杜艺, 石鑫, 王伟超, 张军战

- ZHANG Ying, WANG Ning, DU Yi, SHI Xin, WANG Wei-chao, ZHANG Jun-zhan

- 冷冻浇注制备多孔陶瓷的研究进展

- Research progress in porous ceramics prepared by freeze casting

- 材料工程, 2019, 47(7): 26-34

- Journal of Materials Engineering, 2019, 47(7): 26-34.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2018.000053

-

文章历史

- 收稿日期: 2018-01-06

- 修订日期: 2018-07-10

多孔陶瓷是一种具有较多气孔并利用材料中的孔洞结构和高的比表面积,结合材料本身性质,达到所需的热、电、磁、声、光等物理和化学性能,用作过滤、分离、隔热、换热、储能、载体及生物工程等用途的材料[1]。目前,多孔陶瓷的典型制备方法包括:添加造孔剂法、直接发泡法、有机泡沫浸渍法、溶胶-凝胶法和凝胶注模法等[2-5]。这些制备方法均有其自身的优点,但也存在一些问题,如:添加造孔剂法气孔分布不均匀;发泡法工艺条件较难控制;有机泡沫浸渍法制品强度较低,且孔结构依赖于模板;溶胶-凝胶法生产效率低;凝胶注模法使用的单体有毒等[5-6]。因此,根据实际需要,如何有效控制多孔陶瓷的孔结构以及选择合适的制备工艺就显得尤为重要。

近年来,利用简单的物理升华原理制备多孔陶瓷的冷冻浇注工艺由于其环境友好、材料适用性强、经济高效等特点引起了各国学者的广泛关注[7-11]。本文结合近年来国内外冻浇注制备多孔陶瓷的研究现状,介绍了冷冻浇注的工艺原理及孔结构形成机理,详细阐述了冷冻浇注工艺过程中液相介质和冷冻条件对孔结构的影响,并提出了目前存在的问题及展望,以期为综合性能优良的多孔陶瓷的环保型制备工艺提供参考与借鉴。

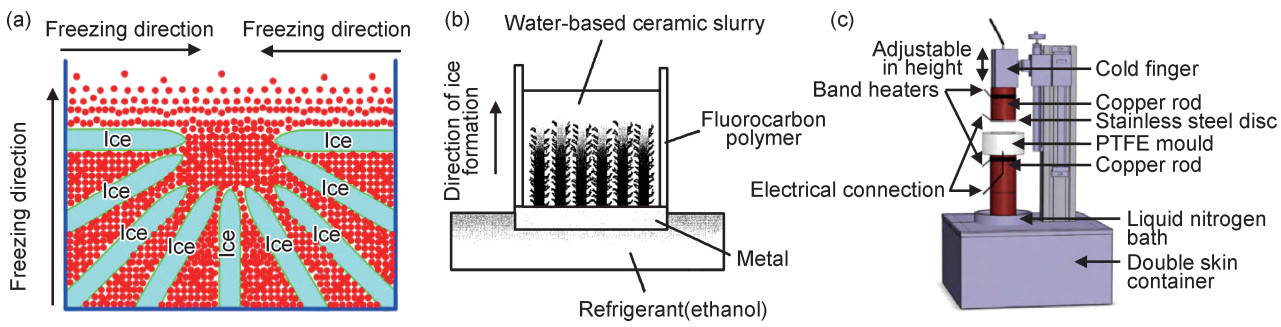

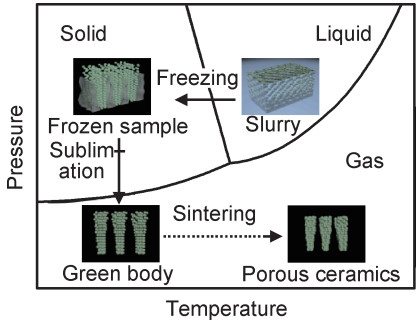

1 冷冻浇注制备多孔陶瓷的工艺原理冷冻浇注是将浆料冷冻、低压升华以及烧结致密化等技术结合起来的一种多孔陶瓷的新型制备工艺。冷冻浇注制备多孔陶瓷通常分为以下四步(见图 1):首先,制备具有良好稳定性且分散均匀的陶瓷浆料。在制备浆料时,一般需加入分散剂并进行球磨以增强分散效果;此外,还需加入黏结剂以提高液相介质升华后多孔陶瓷坯体的强度。其次,浆料倒入模具中,通过均匀或定向冷冻使温度降低到液相介质的凝固点以下,液相介质成核、长大,最终浆料冷冻固化。然后,在适当的温度及低压条件下,使凝固的液相介质升华排除,从而产生具有定向孔道分布的多孔坯体。最后,对多孔坯体进行烧结致密化使强度提高,从而得到结构功能一体化的多孔陶瓷。

|

图 1 冷冻浇注的基本原理示意图 Fig. 1 Schematic diagram of the basic principle of freezing casting |

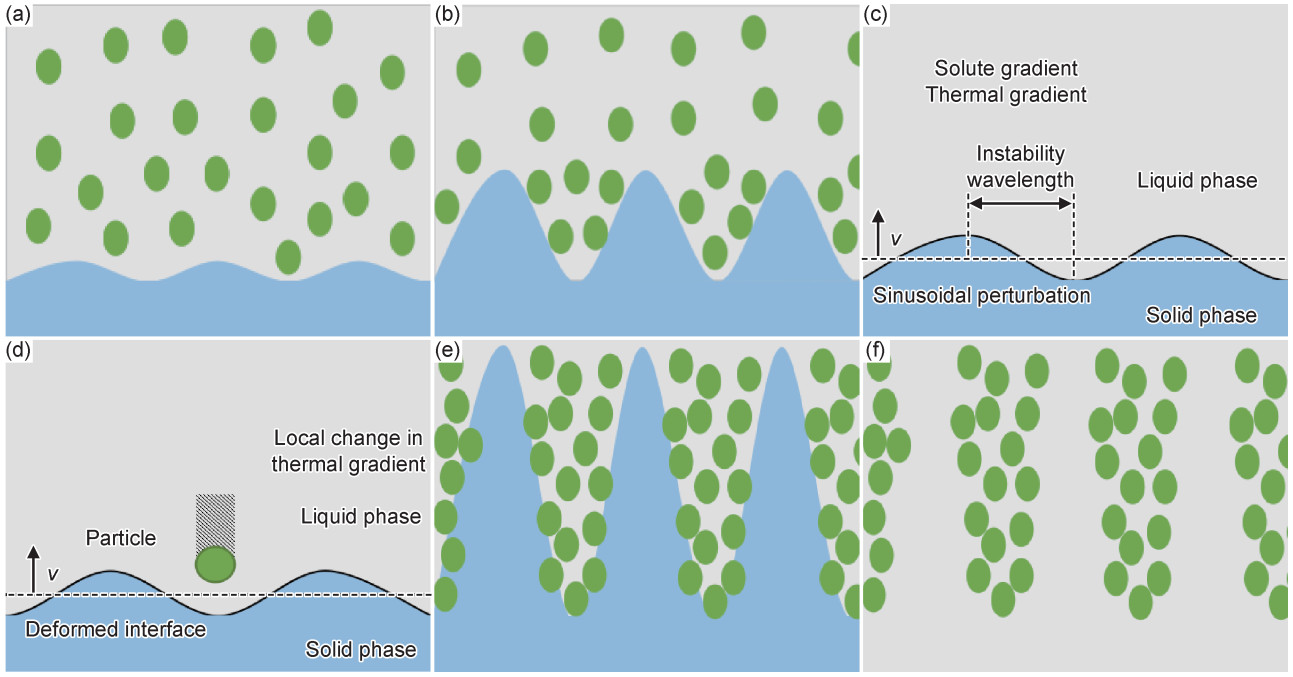

图 2为冷冻浇注制备多孔陶瓷的成孔及基体颗粒重新分布机理示意图。冷冻浇注过程中,当温度降低到液相介质的凝固点以下时,浆料中的液相介质首先在过冷条件下成核,并随着液体分子向固化晶体生长界面的输运而不断长大(图 2(a))。浆料中稳定悬浮的陶瓷基体颗粒则被移动的固化晶体生长界面前沿排挤、推移至相邻的晶体间隙(图 2(b))。其中,固化晶体生长界面需采用非平面界面结构,这是由于界面的热力学不稳定性(即Mullins-Sekerka不稳定性)形成的[12]。由于陶瓷基体颗粒相互聚集使得浆料形成浓度差,不断上升的浓度差导致凝固点降低,形成组分过冷区。在组分过冷区,平界面不稳定,干扰将在组分过冷层中迅速长大。组分过冷层有一定的厚度,故干扰发展到一定大小后,将出现新的定态形状的界面,即平面界面必须转变成非平面界面,如胞状,薄层状,甚至更复杂的枝晶状[13](图 2(c))。这种不稳定性受浆料中基体颗粒浓度梯度和冷冻过程中温度梯度的影响。另外,由基体颗粒引起的局部温度梯度改变也可能引起界面扰动[12](图 2(d))。随着固化速率的增加,液相介质层厚度逐渐减小,基体颗粒聚集,从而形成较为致密的孔壁结构(图 2(e))。随后,经过真空或常压环境下升华干燥,可以得到完全复制固化晶体形貌的多孔结构(图 2(f))。因此,冷冻浇注制备多孔陶瓷的孔结构的形成依赖于移动的固化晶体界面前沿对基体颗粒的排斥、固化晶体前沿的非平面形态转变以及陷入相邻固化晶体之间的颗粒浓度。

|

图 2 冷冻浇注制备多孔陶瓷的成孔及基体颗粒重新分布机理示意图 (a)液相介质成核; (b)陶瓷颗粒被排挤; (c)界面的热力学不稳定性[12]; (d)温度梯度引起界面扰动[12]; (e)形成孔壁; (f)形成多孔结构 Fig. 2 Schematic diagram of pore forming and redistribution of matrix particles mechanism of porous ceramics prepared by freeze casting (a)nucleation of liquid medium; (b)excluded ceramic particles; (c)thermodynamic instability of the interface[12]; (d)interface disturbance caused by temperature gradient[12]; (e)formation of wall; (f)formation of porous structure |

此外,除了固化晶体升华留下的大孔结构外,在孔壁上由于小的固化晶体的升华、颗粒的堆积以及添加剂的去除会形成微孔结构。因此,冷冻浇注制备多孔陶瓷的孔隙是具有大孔和微孔的多尺度复合孔结构。

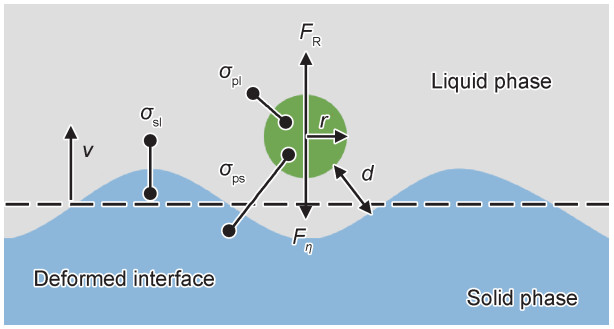

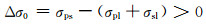

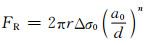

2.2 成孔的热力学与动力学条件浆料在低温下产生固化晶体结构需要满足一定的热力学条件。只有系统自由能Δσ0为正值,即颗粒与固化晶体间的界面自由能σps大于颗粒与液相介质间的界面自由能σpl和固化晶体与液相介质间的界面自由能σsl的总和,如式(1),基体颗粒才会受固化晶体界面排斥,进而加快固化晶体成核生长[14]。

|

(1) |

式中:Δσ0是系统自由能;σps是颗粒与固化晶体间的界面自由能;σpl是颗粒与液相介质间的界面自由能;σsl是固化晶体与液相介质间的界面自由能。

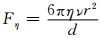

除了热力学条件,孔结构形成还需满足一定的动力学条件。基体颗粒接近固化晶体界面时,主要受到由于颗粒在固化晶体界面上的范德瓦尔斯相互作用而产生的排斥力FR和由于颗粒之间的黏性阻力而产生的吸引力Fη[14]:

|

(2) |

|

(3) |

式中:Δσ0是系统自由能;r是颗粒半径;a0是颗粒间的平均距离;d为颗粒到固化晶体界面的距离;n为常数(取1~4);ν为固化速率;η为浆料黏度。

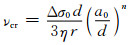

根据颗粒受力情况,当排斥力和吸引力达到平衡时,可建立液相介质的临界固化速率方程[15]:

|

(4) |

只有当固化速率低于临界固化速率(ν<νcr),颗粒才会被排斥从而形成固化晶体结构。因此,固化晶体结构的形成与颗粒之间距离、颗粒半径、浆料黏度以及系统自由能等诸多因素有关。如图 3所示[15]。

完全凝固的固化晶体经过升华,其所占据的空间形成多孔结构,即坯体内部的多孔结构是对固化晶体结构的完全复制。升华过程同样需要满足一定的条件。

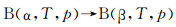

设纯物质B的固相α和气相β在温度T、压强p时处于平衡状态:

|

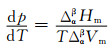

根据克拉佩龙方程,固化晶体升华时,温度和压强应满足单组分系统相变热力学[16]:

|

(5) |

式中:ΔαβHm为升华焓变;ΔαβVm为升华时的体积变化;T为温度。

3 影响孔结构的典型因素冷冻浇注制备多孔陶瓷过程中,影响孔结构的因素很多,包括液相介质、固相含量、添加剂、冷冻条件、烧结工艺等。其中,浆料制备过程与烧结工艺对孔结构的影响与其他制备多孔陶瓷的方法类似,故在此不再赘述。但值得注意的是,冷冻浇注中,固相含量过高时,浆料黏度大,使得临界固化速率降低,造成吞噬现象[14]。

3.1 液相介质冷冻浇注制备多孔陶瓷的孔结构实质上是对固化晶体结构的完全复制,因而液相介质结晶形成的固化晶体对多孔陶瓷的孔结构起着决定性作用。冷冻浇注过程中,使用的液相介质不同,晶体的固化温度、体积变化以及成核生长速率不同,因此形成不同形貌的孔结构。一般情况下,适合于冷冻浇注的液相介质应具有适当的凝固点(接近室温)和较高的蒸气压(容易升华)。总体上,冷冻浇注常用的液相介质可以划分为水、有机溶剂及复合溶剂三大类,如表 1所示[15, 17]。

| Liquid medium | Solidification temperature/℃ | Slurry preparation temperature/℃ | Sublimation condition | Vapor pressure/kPa | Viscosity/(mPa·s) |

| Water | 0 | Room temperature | -18--196℃, Low pressure | 2.2(20℃) | 1.78(0℃) |

| Camphene | 44 | 60 | Room temperature, atmospheric pressure | 2(55℃) | 1.4(47℃) |

| Tert-butyl alcohol | 25 | Room temperature | -50℃, atmospheric pressure | 6.4(40℃) | 3.35(30℃) |

| Naphthalene Camphor | Naphthalene:80 Camphor:180 | 60 | Room temperature, atmospheric pressure | Naphthalene:0.13(52℃) Camphor:0.13(41℃) | Naphthalene:0.91(80℃) Camphor:0.63(180℃) |

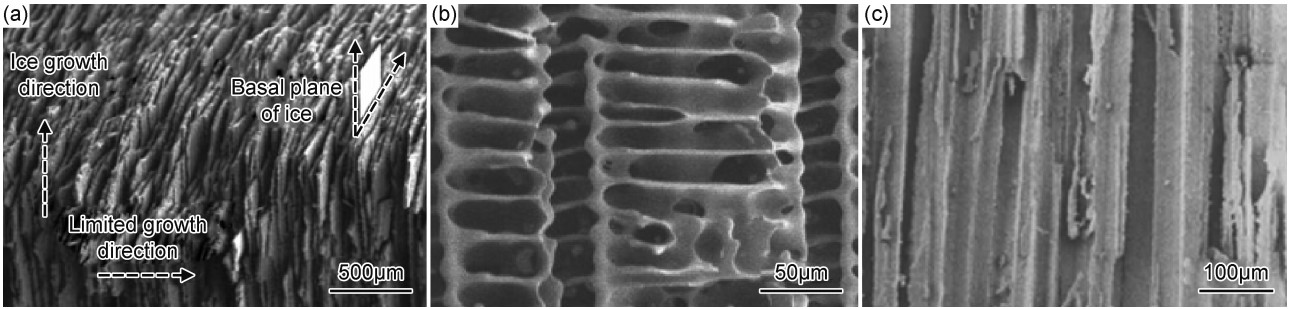

当水基浆料在特定温度梯度下冷冻时,水定向凝固,冰晶成核并逐渐长大,而后在低温低压条件下升华。根据冰晶成核长大过程中的动力学关系,冰晶平行于温度梯度方向上的生长速率是其法向方向上的102~ 103倍。冰晶这种很强的各向异性,有效控制了多孔陶瓷的片层状孔结构[18],如图 4(a)所示。

Yan等[19],Wu等[20],Michael等[21]分别以水为液相介质,采用冷冻浇注制备了具有定向孔结构的多孔钛、WS2以及Al2O3支架,作为骨组织支架材料在生物工程中有着非常好的应用前景。程喆等[22]以水为液相介质,并加入H2O2为造孔剂,采用冷冻浇注法制备了具有层状孔和球形孔复合孔结构的HA支架,通过改变浆料中H2O2的含量有效控制了孔形貌。Zhang等[23]通过水基冷冻浇注制备了具有层状和微孔复合孔结构的多孔Yb2SiO5陶瓷,该多孔陶瓷具有低线收缩率、高孔隙率、高耐压强度、低介电常数以及低热导率等特点,作为超高温结构材料和热绝缘材料有着广泛的应用前景。

水成本低廉、无污染,是冷冻浇注法最常用的液相介质。但是,水也有自身的缺点和局限:一是片层状孔结构孔径较大,导致素坯强度较差;二是水在固化过程中发生较大的体积膨胀,烧结过程中容易产生裂纹,影响多孔陶瓷的力学性能;三是固化温度在0℃以下,不易于工业化生产。

3.1.2 有机溶剂常用的有机溶剂有莰烯和叔丁醇。莰烯是一种晶态小分子有机物,其分子式为C10H16,天然无毒,具有室温凝固、体积收缩率小、在熔点附近黏度低等特点。在合适的温度梯度下,莰烯在固化过程中会发生“交联现象”,从而形成孔隙分布均匀、孔径相近、孔壁结构致密的树枝状结构[24]。

Yoon等[24-25]通过冷冻浇注莰烯/聚碳硅烷溶液制备了高度有序的多孔SiC陶瓷,分别在平行和垂直冷冻方向上形成了长直的孔结构和短细的孔结构,如图 4(b)所示,这种孔形貌与骨组织的内部结构非常类似,因此在生物陶瓷制备,特别是组织工程领域具有良好的应用前景。

相对于水基浆料,以莰烯为液相介质制备的多孔陶瓷具有更小的孔径和更细腻的微观结构,因而成为冷冻浇注成型工艺一个重要的研究方向。但是,由于莰烯在室温下为固体,因此需要在其熔点(44℃)以上制备浆料。

叔丁醇(TBA)的分子式为C4H10O,是一种具有较强极性的有机溶剂,结晶时分子之间通过氢键键合形成六聚体,六聚体经过堆积成为具有很大长径比的柱状晶体,由此制备的多孔陶瓷更接近真正意义上的蜂窝陶瓷[26-27],如图 4(c)所示。Li等[28]以叔丁醇为液相介质,采用冷冻浇注制备了具有直通孔结构的多孔Al2O3陶瓷,当浆料的固相体积分数为10%时,可以获得82%的高孔隙率。Xu等[29]同样采用叔丁醇为液相介质,通过冷冻浇注制备的多孔PZT陶瓷不仅具有单向排列的直通孔结构,而且具有非常高的压电常数,且压电常数与多孔结构密切相关。

叔丁醇作为液相介质,具有室温凝固的特点。但是,叔丁醇与其他丁醇相比有较高的毒性和麻醉性,且在熔点以上极易挥发,对人体健康有一定危害。

3.1.3 复合溶剂复合溶剂主要有叔丁醇-水和萘-樟体系。叔丁醇与水可以完全互溶,少量的叔丁醇加入到水中,冷冻时可以改变水的结晶形态,形成针状结晶。固化晶体升华时,坯体中形成大量针状孔道,使升华气体流动阻力明显减小,升华速率显著提高。

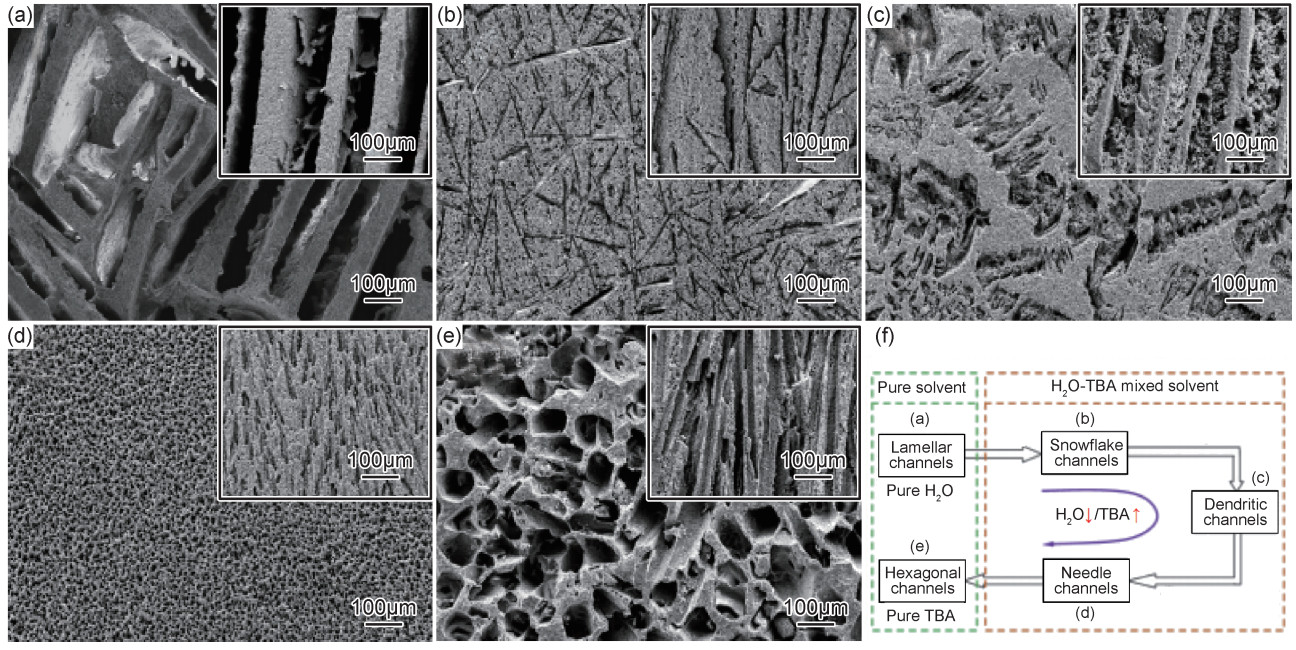

Tang等[30]以TBA-H2O为液相介质制备了具有不同结构的多孔Al2O3陶瓷。研究发现,随着Al2O3浆料中TBA质量分数从0%增加到100%,孔结构由水典型的层状结构逐渐转变为雪花状、树枝状、针状以及叔丁醇典型的六方柱状,如图 5所示。纯TBA为液相介质得到的具有六方柱状孔结构的多孔Al2O3陶瓷的耐压强度最高。Dong等[31]同样以TBA-H2O为液相介质,制备了具有不同孔结构的多孔硅酸盐水泥支架,随着TBA含量的增加,其孔结构变化规律与Tang等研究结果相似。通过改变叔丁醇与水的比例,可以显著改变孔结构以及多孔陶瓷的性能,极大地扩大多孔陶瓷的应用领域。

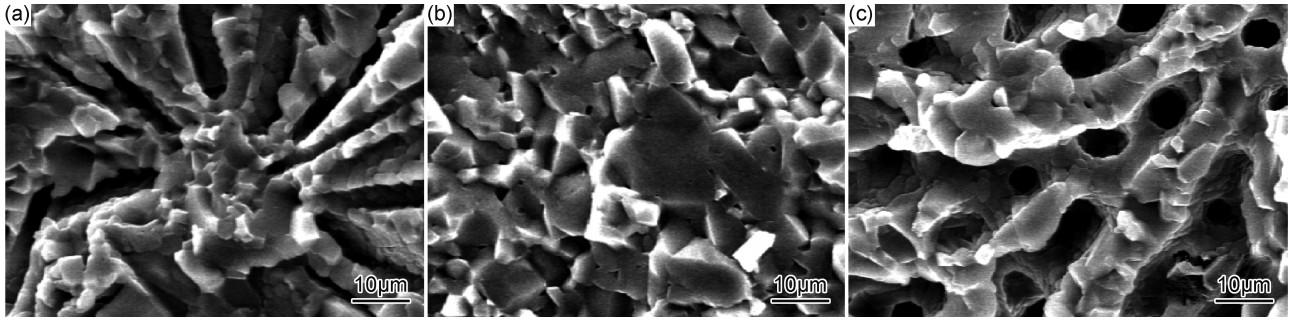

萘-樟体系的结晶形态为放射状结构,具有黏度低、可制备高固相含量浆料以及烧结收缩小等优点。但是,萘无色有毒、易升华并有特殊气味,固化时体积膨胀,熔化时伴随有害的烟雾,对人体危害较大,樟脑对环境有一定污染,因此目前研究较少。Halloran等[32]以萘-樟为液相介质,在其低共熔温度(31℃)下制备了多孔Al2O3陶瓷。结果发现,共熔体系制备的多孔陶瓷具有细小的片层状结构;而在亚共熔和过共熔体系中,由于富萘相和富樟相对浆料中颗粒的排斥,分别形成了形状独特的长板状孔和扭曲的枝晶状孔结构,如图 6所示。

冷冻过程是冷冻浇注制备多孔陶瓷的关键环节,其中冷冻条件(冷冻温度、速率以及方式)对固化晶体的成核与长大有着重要作用,从而影响多孔陶瓷的孔径、气孔率及孔分布状况。

3.2.1 冷冻温度冷冻温度较高时,过冷度小,固化晶体的生长速率大于其成核速率,更有利于固化晶体的生长,从而多孔陶瓷的孔径较大;冷冻温度较低时易于形成小孔径的结构[33-34]。此外,Hu等[27]研究还发现,不同冷冻温度下多孔YSZ陶瓷的气孔率也发生了变化,随着冷冻温度的降低,气孔率从77.9%下降到75.1%。

3.2.2 冷冻速率由结晶学理论可知,快速降温时,得到的晶体小而均匀,经过升华干燥,形成的孔径较小;降温速率慢时,固化晶体充分长大,固化晶体去除后留下了大孔结构[35]。根据赵康等[36]的研究,冷冻速率为1.3℃/min和11℃/min时,羟基磷灰石多孔支架的孔径分别为100μm和500μm,冷冻速率较低时的孔径明显大于冷冻速率较高时的孔径。

3.2.3 冷冻方式在冷冻过程中,可以采取均匀冷冻与定向冷冻等不同的冷冻方式,如图 7所示[37-39]。均匀冷冻时,由于液相介质结晶方向的多样化,因而多孔陶瓷的孔结构杂乱无章[40]。单面定向冷冻仅在一端提供冷源,随着固化晶体高度的增加,过冷度逐渐减小,此时更有利于固化晶体的生长,以水为液相介质时,沿高度方向,片层间距逐渐增大[41]。双面定向冷冻在模具的顶端和底端同时提供冷源,浆料两端过冷度差别不大,多孔陶瓷具有更为有序的孔结构[39]。一般研究中较多采用定向冷冻的方式。

目前,冷冻浇注研究最多的是Al2O3,ZrO2,TiO2等氧化物材料体系,其中以Al2O3多孔陶瓷为代表。氧化物多孔陶瓷因为具有较高的孔隙率和比表面积以及生物相容性,在骨植入支架、固体氧化物燃料电池(SOFC)、吸附分离等方面有着良好的应用前景[42-44]。

冷冻浇注制备非氧化物多孔陶瓷的研究主要集中在SiC与Si3N4多孔陶瓷上,其孔隙率高、高温力学性能优异、热震稳定性好、耐磨耐腐蚀能力强等优点,使得其在高温气体、熔体过滤,催化剂载体等领域得到广泛应用[45-47]。

复相多孔陶瓷是当前颇具应用潜力的先进材料,集组成相的优异性能于一身,其一般具有高的高温强度、低热膨胀率、高渗透性等[48]。目前研究较多的有Al2O3/ZrO2,Al2O3/莫来石以及SiC/Si3N4多孔陶瓷等。

对于不同的材料体系,冷冻浇注的工艺因素不尽相同,表 2列举了冷冻浇注制备不同体系多孔陶瓷的典型工艺条件。

| Material | Liquid medium | Freezing temperature/℃ | Sublimation condition | Sintering temperature/℃ | Porosity/ % | Pore size/ μm |

| Al2O3[49] | Water | -196 | 24h | 1550(2h) | >60 | 30 |

| Al2O3[50] | Camphene | 0, 25, -196 | 24h | 1400(3h) | - | 50 |

| Al2O3[51] | TBA | <0 | 0℃, 12h | 1500(2h) | 65-82 | 50 |

| ZrO2[52] | Water | -9 | Vacuum, <0℃, 12h | 1600(2h) | - | 115 |

| TiO2[53] | Water | -18 | Vacuum, 15h | 1000(1h) | 60 | 0.3-2.6 |

| SiC[54] | Water | -10--70 | Vacuum, 10℃, 24h | 1800(Ar, 2h) | 86 | 34-147 |

| Si3N4[55] | Water | -18 | 5Pa, 12h | 1680(N2, 2h) | 72 | 35 |

| HA[56] | Camphene | 4, 20, 30 | 25℃, 20h | 1280(4h) | 72 | 150 |

| Al2O3/ZrO2[57] | TBA | -196 | Vacuum | 1400(2h) | 64 | 40-140 |

| Al2O3/Mullite[58] | Camphene | -196 | - | 1300-1500(2h) | 31-80 | 15-25 |

冷冻浇注作为一种环保、经济、可控的制备多孔陶瓷的新方法,近年来成为国内外学者的研究热点。冷冻浇注可获得多尺度(微米至纳米)孔结构,实现对污水、高温气体或熔融金属的有效过滤[59-61];同时可获得复合(片层和微孔)孔结构,极大提高催化剂的分散度,从而提髙催化剂的利用率及其催化效果,在汽车尾气净化[62]和化工领域[63]具有广阔的应用前景。另外,该法为梯度多孔结构的设计提供了可能,在骨组织工程方面具有较高的潜在应用价值。

采用冷冻浇注制备多孔陶瓷的关键技术有:(1)如何实现冷冻过程中浆料的定向固化,形成可控孔结构。(2)升华时,固化介质如何高效快速脱离坯体,获得以气孔为主相的多孔陶瓷。因此,解决好这两个问题是制备出满足各种应用领域要求的多孔陶瓷的前提,也是今后的主要研究方向。通过优化工艺参数、采用特殊的冷冻工艺以及在冷冻过程中施加电场或磁场等可以有效增加孔结构有序程度。此外,大量的新型功能化多孔陶瓷还亟待开发,例如,具有梯度多孔结构的电极材料、高温下使用的多孔半导体材料、电磁响应灵敏的复相多孔材料及仿生智能材料等。相信随着对冷冻浇注工艺研究的进一步深入,会有越来越多的新型多孔陶瓷被开发出来以满足各种领域的需求。

| [1] |

罗民华.

多孔陶瓷实用技术[M]. 北京: 中国建材工业出版社, 2006: 11-16.

LUO M H. The practical technology of porous ceramics[M]. Beijing: China Building Materials Industry Press, 2006: 11-16. |

| [2] |

杨阳, 赵宏生, 刘中国, 等. 成型温度对多孔SiC陶瓷性能的影响[J].

材料工程, 2011 (5): 58–61.

YANG Y, ZHAO H S, LIU Z G, et al. Effects of molding temperature on properties of porous SiC ceramics[J]. Journal of Materials Engineering, 2011 (5): 58–61. DOI: 10.3969/j.issn.1001-4381.2011.05.013 |

| [3] | EOM J H, KIM Y W, RAJU S. Processing and properties of macroporous silicon carbide ceramics:a review[J]. Journal of Asian Ceramic Societies, 2013, 1 (3): 220–242. DOI: 10.1016/j.jascer.2013.07.003 |

| [4] | OHJI T, FUKUSHIMA M. Macro-porous ceramics:processing and properties[J]. International Materials Reviews, 2012, 57 (2): 115–131. DOI: 10.1179/1743280411Y.0000000006 |

| [5] | STUDART A R, GONZENBACH U T, TERVOORT E, et al. Processing routes to macroporous ceramics:a review[J]. Journal of the American Ceramic Society, 2006, 89 (6): 1771–1789. DOI: 10.1111/jace.2006.89.issue-6 |

| [6] | YANG J, YU J, HUANG Y. Recent developments in gelcasting of ceramics[J]. Journal of the European Ceramic Society, 2011, 31 (14): 2569–2591. DOI: 10.1016/j.jeurceramsoc.2010.12.035 |

| [7] |

彭美华, 程西云, 周彪, 等. CNTs-Al2O3多孔陶瓷复合材料的制备与性能[J].

材料工程, 2016, 44 (6): 117–122.

PENG M H, CHENG X Y, ZHOU B, et al. Preparation and properities of CNTs-Al2O3 porous ceramic composites[J]. Journal of Materials Engineering, 2016, 44 (6): 117–122. |

| [8] | LIU T, CHEN Y, FANG S, et al. A dual-phase bilayer oxygen permeable membrane with hierarchically porous structure fabricated by freeze-drying tape-casting method[J]. Journal of Membrane Science, 2016, 520 : 354–363. DOI: 10.1016/j.memsci.2016.07.046 |

| [9] | AQEEL A A A, MOHSEN A Z, SAMI A A, et al. Effects of SiC, SiO2 and CNTs nanoadditives on the properties of porous alumina-zirconia ceramics produced by a hybrid freeze casting-space holder method[J]. Journal of the European Ceramic Society, 2017, 37 (4): 1635–1642. DOI: 10.1016/j.jeurceramsoc.2016.10.035 |

| [10] | NAVIROJ M, WANG M M, JOHNSON M T, et al. Nucleation-controlled freeze casting of preceramic polymers for uniaxial pores in Si-based ceramics[J]. Scripta Materialia, 2017, 130 : 32–36. DOI: 10.1016/j.scriptamat.2016.10.038 |

| [11] | XU T T, WANG C A. Effect of two-step sintering on micro-honeycomb BaTiO3 ceramics prepared by freeze-casting process[J]. Journal of the European Ceramic Society, 2016, 36 (10): 2647–2652. DOI: 10.1016/j.jeurceramsoc.2016.03.032 |

| [12] | DEVILLE S. Freeze-casting of porous ceramics:a review of current achievements and issues[J]. Advanced Engineering Materials, 2008, 10 (3): 155–169. DOI: 10.1002/(ISSN)1527-2648 |

| [13] |

闵乃本. 晶体生长过程中的形态稳定性[J].

人工晶体学报, 1981 (2): 83–111.

MIN N B. Morphological stability in the process of crystal growth[J]. Journal of Artificial Crystal, 1981 (2): 83–111. |

| [14] | ULRIKE G K W, MATTHEW S, AMALIE E D, et al. Biomaterials by freeze casting[J]. Philosophical Transactions of the Royal Society A, 2010, 368 (1917): 2099–2121. DOI: 10.1098/rsta.2010.0014 |

| [15] | QIAN L, ZHANG H F. Controlled freezing and freeze drying:a versatile route for porous and micro-/nano-structured materials[J]. Journal of Chemical Technology and Biotechnology, 2011, 86 (2): 172–184. DOI: 10.1002/jctb.v86.2 |

| [16] |

天津大学物理化学教研室.

物理化学[M]. 北京: 高等教育出版社, 1997.

Department of Physical Chemistry of Tianjin University. Physical chemistry[M]. Beijing: Higher Education Press, 1997. |

| [17] | CHEN R F, WANG C A, HUANG Y, et al. Ceramics with special porous structures fabricated by freeze-gelcasting:using tert-butyl alcohol as a template[J]. Journal of the American Ceramic Society, 2007, 90 (11): 3478–3484. DOI: 10.1111/jace.2007.90.issue-11 |

| [18] | LI K L, WALZ J Y. Freeze casting of porous materials:review of critical factors in microstructure evolution[J]. International Materials Reviews, 2012, 57 (1): 37–60. DOI: 10.1179/1743280411Y.0000000011 |

| [19] | YAN L M, WU J S, ZHANG L, et al. Pore structures and mechanical properties of porous titanium scaffolds by bidirectional freeze casting[J]. Materials Science and Engineering:C, 2017, 75 : 335–340. DOI: 10.1016/j.msec.2016.12.044 |

| [20] | WU J S, LIU X L, YAN L M, et al. Long-range order and preferred orientation in WS2 scaffold created by freeze casting[J]. Materials Letters, 2017, 196 : 414–418. DOI: 10.1016/j.matlet.2017.03.031 |

| [21] | MICHAEL B F, STEVEN E N, TSUK H, et al. Stiff, porous scaffolds from magnetized alumina particles aligned by magnetic freeze casting[J]. Materials Science and Engineering C, 2017, 77 : 484–492. DOI: 10.1016/j.msec.2017.03.246 |

| [22] |

程喆, 赵康, 张伟, 等. 过氧化氢/蒸馏水溶液冷冻干燥制备多孔羟基磷灰石陶瓷[J].

硅酸盐学报, 2014, 42 (5): 672–676.

CHENG Z, ZHAO K, ZHANG W, et al. Preparation of hydroxyapatite scaffolds via freeze-casting using hydrogen peroxide/distilled water[J]. Journal of the Chinese Ceramic Society, 2014, 42 (5): 672–676. |

| [23] | ZHANG R, HAN B, FANG D. New multifunctional porous Yb2SiO5 ceramics prepared by freeze casting[J]. Ceramics International, 2016, 42 (5): 6046–6053. DOI: 10.1016/j.ceramint.2015.12.161 |

| [24] | YOON B H, CHOI W Y, KIM H E, et al. Aligned porous alumina ceramics with high compressive strengths for bone tissue engineering[J]. Scripta Materialia, 2008, 58 (7): 537–540. DOI: 10.1016/j.scriptamat.2007.11.006 |

| [25] | YOON B H, LEE E J, KIM H E, et al. Highly aligned porous silicon carbide ceramics by freezing polycarbosilane/camphene solution[J]. Journal of the American Ceramic Society, 2007, 90 (6): 1753–1759. DOI: 10.1111/jace.2007.90.issue-6 |

| [26] | KENNEDY M W, ZHANG K, FRITZSCH R, et al. Characterization of ceramic foam filters used for liquid metal filtration[J]. Metallurgical and Materials Transactions B, 2013, 44 (3): 671–690. DOI: 10.1007/s11663-013-9799-7 |

| [27] | HU L F, WANG C A, HUANG Y, et al. Control of pore channel size during freeze casting of porous YSZ ceramics with unidirectionally aligned channels using different freezing temperatures[J]. Journal of the European Ceramic Society, 2010, 30 (16): 3389–3396. DOI: 10.1016/j.jeurceramsoc.2010.07.032 |

| [28] | LI D Y, LI M S. Preparation of porous alumina ceramic with ultra-high porosity and long straight pores by freeze casting[J]. Journal of Porous Materials, 2012, 19 (3): 345–349. DOI: 10.1007/s10934-011-9480-y |

| [29] | XU T T, WANG C A. Control of pore size and wall thickness of 3-1 type porous PZT ceramics during freeze-casting process[J]. Materials and Design, 2016, 91 : 242–247. DOI: 10.1016/j.matdes.2015.11.101 |

| [30] | TANG Y, QIU S, WU C, et al. Freeze cast fabrication of porous ceramics using tert-butyl alcohol-water crystals as template[J]. Journal of the European Ceramic Society, 2016, 36 (6): 1513–1518. DOI: 10.1016/j.jeurceramsoc.2015.12.047 |

| [31] | DONG S J, WANG L Y, GAO X L, et al. Freeze casting of novel porous silicate cement supports using tert-butyl alcohol-water binary crystals as template:microstructure, strength and permeability[J]. Journal of Membrane Science, 2017, 541 : 143–152. DOI: 10.1016/j.memsci.2017.06.067 |

| [32] | ARAKI K, HALLORAN J W. Room-temperature freeze-casting for ceramics with nonaqueous sublimable vehicles in the naphthalene-camphor eutectic system[J]. Journal of the American Ceramic Society, 2004, 87 (11): 2014–2019. |

| [33] |

韩沈丹, 赵康, 汤玉斐, 等. 多层低温流延法制备片状氧化铝多孔陶瓷[J].

硅酸盐学报, 2013, 41 (2): 140–144.

HAN S D, ZHAO K, TANG Y F, et al. Fabrication of alumina porous ceramics substrate by multilayer freeze-tape-casting process[J]. Journal of the Chinese Ceramic Society, 2013, 41 (2): 140–144. |

| [34] |

胡利明, 唐婕, 陈玉峰, 等. 水基料浆冷冻浇注成型多孔陶瓷孔结构研究[J].

人工晶体学报, 2009, 38 (2): 515–518.

HU L M, TANG J, CHEN Y F, et al. Study on pores structure of freeze-casting formed porous ceramics from water-based slurry[J]. Journal of Synthetic Crystals, 2009, 38 (2): 515–518. DOI: 10.3969/j.issn.1000-985X.2009.02.048 |

| [35] |

邹景良, 张跃. 冷冻干燥法工艺条件对多孔氧化铝陶瓷的影响[J].

稀有金属材料与工程, 2009, 38 (增刊2): 161–163.

ZOU J L, ZHANG Y. Synthesis of porous α-Al2O3 ceramics by freeze-casting processing[J]. Rare Metal Materials and Engin-eering, 2009, 38 (Suppl 2): 161–163. |

| [36] |

赵康, 魏俊琪, 罗德福, 等. 冷冻干燥法制备羟基磷灰石多孔支架[J].

硅酸盐学报, 2009, 37 (3): 432–435.

ZHAO K, WEI J Q, LUO D F, et al. Fabrication of hydroxyapatite porous scaffolds by freeze drying[J]. Journal of the Chinese Ceramic Society, 2009, 37 (3): 432–435. DOI: 10.3321/j.issn:0454-5648.2009.03.019 |

| [37] | ZHANG R B, HAN B Y, FANG D N, et al. Porous Y2SiO5 ceramics with a centrosymmetric structure produced by freeze casting[J]. Ceramics International, 2015, 41 (9): 11517–11522. DOI: 10.1016/j.ceramint.2015.05.099 |

| [38] | FUKASAWA T, DENG Z Y, ANDO M. Synthesis of porous silicon nitride with unidirectionally aligned channels using freeze-drying process[J]. Journal of the American Ceramic Society, 2002, 85 (9): 2151–2155. DOI: 10.1111/jace.2002.85.issue-9 |

| [39] | PREISS A, SU B, COLLINS S, et al. Tailored graded pore structure in zirconia toughened alumina ceramics using double-side cooling freeze casting[J]. Journal of the European Ceramic Society, 2012, 32 (8): 1575–1583. DOI: 10.1016/j.jeurceramsoc.2011.12.031 |

| [40] | WANG F, YIN J W, YAO D X, et al. Porous SiC ceramics fabricated by quick freeze casting and solid state sintering[J]. Progress in Natural Science:Materials International, 2017, 27 (3): 380–384. DOI: 10.1016/j.pnsc.2017.04.006 |

| [41] | DEVILLE S, SAIZ E, TOMSIA A P. Ice-templated porous alumina structures[J]. Acta Materialia, 2007, 55 (6): 1965–1974. DOI: 10.1016/j.actamat.2006.11.003 |

| [42] | HONG C Q, DU J C, LIANG J, et al. Functionally graded porous ceramics with dense surface layer produced by freeze-casting[J]. Ceramics International, 2011, 37 (8): 3717–3722. DOI: 10.1016/j.ceramint.2011.04.119 |

| [43] | XIA Y F, ZENG Y P, JIANG D L. Microstructure and mechanical properties of porous Si3N4 ceramics prepared by freeze-casting[J]. Materials and Design, 2012, 33 (1): 98–103. |

| [44] | SOUZA D F, NUNES E H M, PIMENTA D S, et al. Synthesis and structural evaluation of freeze-cast porous alumina[J]. Materials Characterization, 2014, 96 (8): 183–195. |

| [45] | NAGLIERI V, BALE H A, GLUDOVATZ B, et al. On the development of ice-templated silicon carbide scaffolds for nature-inspired structural materials[J]. Acta Materialia, 2013, 61 (18): 6948–6957. DOI: 10.1016/j.actamat.2013.08.006 |

| [46] | CZAPSKI M, STORA T, TARDIVAT C, et al. Porous silicon carbide and aluminum oxide with unidirectional open porosity as model target materials for radioisotope beam production[J]. Nuclear Instruments and Methods in Physics Research B, 2013, 317 (Part B): 385–388. |

| [47] | HAN J C, HU L Y, ZHANG Y M, et al. Fabrication of ceramics with complex porous structures by the impregnate-freeze-casting process[J]. Journal of the European Ceramic Society, 2009, 92 (9): 2165–2167. DOI: 10.1111/jace.2009.92.issue-9 |

| [48] | LIU Q, YE F, HOU Z P, et al. A new approach for the net-shape fabrication of porous Si3N4 bonded SiC ceramics with high strength[J]. Journal of the European Ceramic Society, 2013, 33 (13/14): 2421–2427. |

| [49] | SHI G, WU Z, JIANG C, et al. Porous alumina ceramics produced by physical vapor deposition assisted freeze-casting method[J]. Materials Letters, 2015, 161 : 580–582. DOI: 10.1016/j.matlet.2015.09.037 |

| [50] | HONG C Q, DU J C, LIANG J, et al. Functionally graded porous ceramics with dense surface layer produced by freeze-casting[J]. Ceramics International, 2011, 37 (8): 3717–3722. DOI: 10.1016/j.ceramint.2011.04.119 |

| [51] | LI D Y, L M S. Preparation of porous alumina ceramic with ultra-high porosity and long straight pores by freeze casting[J]. Journal of Porous Materials, 2012, 19 (3): 345–349. DOI: 10.1007/s10934-011-9480-y |

| [52] | PREISS A, SU B, COLLINS S, et al. Tailored graded pore structure in zirconia toughened alumina ceramics using double-side cooling freeze casting[J]. Journal of the European Ceramic Society, 2012, 32 (8): 1575–1583. DOI: 10.1016/j.jeurceramsoc.2011.12.031 |

| [53] | REN L L, ZENG Y P, JIANG D L. Preparation of porous TiO2 by a novel freeze casting[J]. Ceramics International, 2009, 35 (3): 1267–1270. DOI: 10.1016/j.ceramint.2008.04.009 |

| [54] | FUKUSHIMA M, NAKATA M, ZHOU Y, et al. Fabrication and properties of ultra highly porous silicon carbide by the gelation-freezing method[J]. Journal of the European Ceramic Society, 2010, 30 (14): 2889–2896. DOI: 10.1016/j.jeurceramsoc.2010.03.018 |

| [55] | YAO D X, XIA Y F, ZENG Y P, et al. Fabrication porous Si3N4 ceramics via starch consolidation-freeze drying process[J]. Materials Letters, 2011, 68 (1): 75–77. |

| [56] | MACCHETTA A, TURNER I G, BOWEN C R. Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphene-based freeze-casting method[J]. Acta Biomaterialia, 2009, 5 (4): 1319–1327. DOI: 10.1016/j.actbio.2008.11.009 |

| [57] | CHOI H J, YANG T Y, YOON S Y, et al. Porous alumina/zirconia layered composites with unidirectional pore channels processed using a tertiary-butyl alcohol-based freeze casting[J]. Materials Chemistry and Physics, 2012, 133 (1): 16–20. DOI: 10.1016/j.matchemphys.2011.12.055 |

| [58] | KYU H K, SEOG Y Y, HONG C P. Recycling of coal fly ash for the fabrication of porous mullite/alumina composites[J]. Materials, 2014, 7 (8): 5982–5991. DOI: 10.3390/ma7085982 |

| [59] | REN D, COLOSI L M, SMITH J A. Evaluating the sustainability of ceramic filters for point-of-use drinking water treatment[J]. Environmental Science and Technology, 2013, 47 (19): 11206–11213. DOI: 10.1021/es4026084 |

| [60] | HEIDENREICH S. Hot gas filtration-a review[J]. Fuel, 2013, 104 (2): 83–94. |

| [61] | DAMOAH L N W, ZHANG L. Removal of inclusions from aluminum through filtration[J]. Metallurgical and Materials Transactions B, 2010, 41 (4): 886–907. DOI: 10.1007/s11663-010-9367-3 |

| [62] | LI L, SHEN X, WANG P, et al. Soot capture and combustion for perovskite La-Mn-O based catalysts coated on honeycomb ceramic in practical diesel exhaust[J]. Applied Surface Science, 2011, 257 (22): 9519–9524. DOI: 10.1016/j.apsusc.2011.06.050 |

| [63] | JULBE A, FARRUSSENG D, GUIZARD C. Porous ceramic membranes for catalytic reactors overview and new ideas[J]. Journal of Membrane Science, 2001, 181 (1): 3–20. DOI: 10.1016/S0376-7388(00)00375-6 |

2019, Vol. 47

2019, Vol. 47