文章信息

- 党赏, 李艳国, 邹芹, 王明智, 熊建超, 罗文奇

- DANG Shang, LI Yan-guo, ZOU Qin, WANG Ming-zhi, XIONG Jian-chao, LUO Wen-qi

- 机械合金化和粉末冶金法制备Fe-Mn-Si基形状记忆合金的研究进展

- Progress in Fe-Mn-Si based shape memory alloys prepared by mechanical alloying and powder metallurgy

- 材料工程, 2019, 47(5): 18-25

- Journal of Materials Engineering, 2019, 47(5): 18-25.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2018.001162

-

文章历史

- 收稿日期: 2018-10-06

- 修订日期: 2019-01-23

2. 燕山大学 亚稳材料制备技术与科学国家重点实验室, 河北 秦皇岛 066004

2. State Key Laboratory of Metastable Materials Science and Technology, Yanshan University, Qinhuangdao 066004, Hebei, China

形状记忆合金(shape memory alloys, SMA)是变形后经加热能够恢复到初始形状的功能材料[1]。目前商用SMA主要有3种类型,即Cu基(主要是Cu-Al-Ni和Cu-Zn-Al)、Ni-Ti基和Fe基(如Fe-Mn-Si,Fe-Ni-C和Fe-Ni-Co-Ti)[2]。与Ni-Ti基和Cu基合金相比,Fe基形状记忆合金自问世以来因其价格低廉、加工性能优良、可焊接性好等特点,倍受人们青睐,尤其是Fe-Mn-Si SMA被认为是具有发展前景的新型形状记忆材料[3-4]。在Fe-Mn-Si基SMA中,“执行”相是应力诱发的ε(密排六方,hcp)马氏体,其在加热后转变为γ(面心立方,fcc)奥氏体,从而产生自由恢复形状记忆效应(shape memory effect,SME)[5-6]。Sato等首次报道关于Fe-Mn-Si SMA单晶之后[7],Murakami等成功地获得了具有接近完全的SME的多晶Fe-(28~34)Mn-(4~6.5)Si(质量分数/%,下同)[8]。Otsuka等通过添加Cr和Ni提高三元Fe-Mn-Si SMA耐腐蚀性和热塑性,开发了具有商业应用价值的Fe-28Mn-6Si-5Cr[9]和Fe-14Mn-6Si-9Cr-5Ni[10] SMAs。随后的研究结果表明Cr,Ni都可以降低合金的Ms点、增加合金的层错能[11],但是在增加Cr,Ni含量的同时,应该降低Mn的含量,而当Mn含量小于18%时[4, 12], 合金中存在热诱发ε马氏体并在应力诱发ε马氏体片的交叉处易产生α′马氏体,恶化SME。李建忱等[13]从层错能角度出发研究了Fe-Mn-Si系合金的设计,确定了具有最佳SME时合金的成分含量:Mn 14.98%,Si 6%,Cr 7.174%,Ni 4.22%。先前的研究表明,多晶Fe-Mn-Si基SMA通过固溶处理后具有较低的回复应变(2%~3%)[14-15],而单晶Fe-Mn-Si基SMA的回复应变可达9%[7]。成分设计和显微组织设计是多晶Fe-Mn-Si基SMA可以实现较大回复应变(>6%)的两个基本条件。合金的成分设计主要遵循3个准则:(1)5%≤Si≤6%;(2)20%≤Mn≤32%;(3)其他元素的添加可以强化奥氏体基体[16]。显微组织设计[17]包括粗化奥氏体晶粒以及尽可能减少孪晶界,同时引入高密度的堆垛断层和强化奥氏体的第二相,这是因为退火孪晶的存在细化了奥氏体晶粒,但是奥氏体晶粒较大,晶界较少,可以降低晶界对应力诱发ε马氏体相变的抑制作用,还有利于引入单取向ε马氏体,特别是当变形应变较大时可以减少不同马氏体群体之间的碰撞,避免产生α′马氏体。减少退火孪晶界可以抑制其造成的奥氏体晶粒的细化。上述研究合金样品的制备主要是通过铸造冶金工艺获得的,包括熔融铸造、多次重熔以实现目标化学成分,延长热处理时间使得化学成分均化。传统冶金工艺制备Fe-Mn-Si基SMA很难克服成分偏析[18]、熔体中难以掺入Si[19]、不锈钢在熔炼和热处理过程中Mn的损失[20]、耗时的化学成分均匀化[21]、凝固过程中冷却收缩引起的裂纹强化以及淬火[22]等问题。

机械合金化(MA)作为一种成熟的粉末生产技术,关键参数包括球磨介质、转速、球磨时间、球料比、球磨气氛和过程控制剂[23-24]。粉末冶金(PM)是通过机械合金化和强烈热压共同控制化学成分和晶粒尺寸,实现零件的近终成形。与铸造冶金相比,MA/PM能够生产所需形状的合金,最大限度地减少二次加工和产生的废料量[25-26]。但与其他合金体系相比[27](如NiTi基[28]或Cu基[29]SMA),关于MA/PM工艺制备Fe-Mn-Si基SMA的文献报道很少。与常规铸造相比,虽然PM制造的合金存在着孔隙引起的脆性[30],但仍能精确地控制合金的化学成分[31],而MA可以在固态条件下得到合金元素和Fe基合金的均匀混合物[32],消除具有均匀结构的Fe-Mn-Si-Cr-Ni SMA晶粒细化过程中存在的缺陷,增加合金元素在Fe基质中的固态溶解度[33],避免了氧化物的形成[34]。MA/PM工艺使制备的Fe-Mn-Si合金微观组织更加精细,同时增加了合金的致密度并防止烧结体中产生可降低力学性能而不需要的相。在MA过程中Fe,Mn,Si(Cr,Ni)粉末被击碎并冷焊在一起,产生预合金结构,可在较低温度和较短烧结时间下进行烧结,获得具有更好力学性能和良好SME的Fe-Mn-Si合金[35-36]。

本文主要综述近年来MA/PM工艺在研究Fe-Mn-Si基SMA所取得的成果,并简单介绍了Fe-Mn-Si基SMA在新领域的应用,文末对MA/PM工艺在Fe基形状记忆合金以后的研究发展方向予以展望。

1 MA/PM对Fe-Mn-Si基SMA相变的影响在低层错能Fe-Mn-Si基合金中,主要发生γ(fcc)→ε(hcp),γ(fcc)→α′(bcc)以及ε(hcp)→α′(bcc)的相变。其SME的机理是通过加热将应力诱发的ε(hcp)马氏体逆转为γ(fcc)奥氏体。合金中的应力诱导的ε(hcp)马氏体应尽可能窄,具有单一的变化取向,彼此不相互作用,也不与预先存在的热诱导马氏体相互作用[37]。否则除产生ε-hcp外,在低Mn含量或高变形程度下可以由热或应力诱导形成α′体心立方(bcc)马氏体相[38]。

在MA过程中研磨时间对Fe-Mn-Si-Cr-Ni SMA中马氏体的形成起着决定的作用。Arslan等[39]的研究结果表明Fe-20Mn-6Si-9Cr粉末在球磨初期,主要是Fe,Mn,Si,Cr的固溶体,随着球磨时间的增加所形成的固溶体逐渐消失,晶格应变逐渐增大,晶粒尺寸逐渐减小,在球磨20h后粉末尺寸迅速减小约0.1μm,并产生了大量的ε(hcp),这是因为MA过程中所提供的能量使晶格从具有高应变γ(fcc)转变为低应变的ε(hcp)。

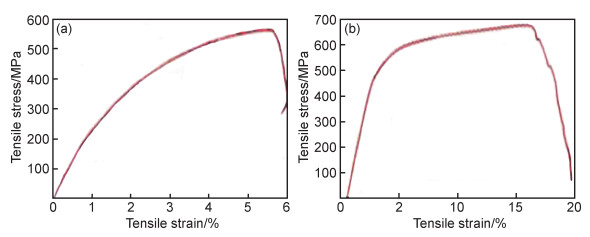

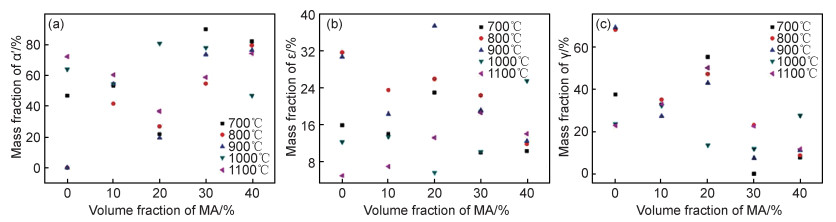

Fe-Mn-Si-Cr-Ni SMA中随着热处理温度的升高[40]和机械循环次数(最大应变为4%)的增加[41],热诱导γ-fcc奥氏体向应力诱发α′-bcc转变[42]的含量有增加的趋势。同时,由于MA/PM粉末混合物中无定形区域的存在[43]以及热诱导马氏体形成的增强[44],使MA粉末代替一部分混合粉末有助于减少表面氧化[45]。如图 1所示,Mocanu等[46]对MA+PM所得的Fe-14Mn-6Si-9Cr-5Ni SMA样品进行固溶处理后,发现以MA粉末取代部分混合粉末的样品经固溶处理后(ST),能够热诱导形成α′-bcc和ε-hcp马氏体(质量分数分别高达90%和38%),并且随着MA粉末体积分数的增加,α′-bcc马氏体总体呈上升趋势,ε-hcp马氏体和γ-fcc马氏体分别呈下降趋势,这与Pricop等[47]的研究结果相一致:MA不会改变热轧状态下合金的相结构,但能够在固溶状态下使对SME不利的α′马氏体含量增加。Amini等[48]对Fe-32Mn-6Si进行MA,发现在球磨过程中发生α→γ相转变,非晶相含量显著增加,在球磨48h达到最大值(84%);足够的研磨时间(96h和192h)之后,由于非晶相的机械结晶,其质量分数从84%减少至39%,此过程还产生大量的ε相(最大为47%)。

|

图 1 MA含量和固溶处理温度与Fe-14Mn-6Si-9Cr-5Ni SMA相含量的函数关系图[46] (a)α′-bcc马氏体; (b)ε-hcp马氏体; (c)γ-fcc奥氏体 Fig. 1 Relationship between MA content and solution treatment temperature as a function of Fe-14Mn-6Si-9Cr-5Ni SMA phase content[46] (a)α′-bcc martensite amount; (b)ε-hcp martensite amount; (c)γ-fcc austenite amount |

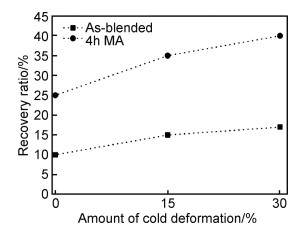

MA对合金中与SME相关的γ(fcc)相的失稳起着至关重要的作用,这对于由马氏体相变控制的SME是必不可少的,MA过程中形成γ相有两种可能:MA过程中温度可以达到900℃以上或MA过程中其他一些因素控制着γ相的形成,因此,MA+后续烧结具有生产Fe-Mn-Si形状记忆合金的潜力[35]。通过选择合适的MA粉末分数及相应的热机械训练[46]、热轧温度[49]和固溶处理[50],在已开发的Fe-14Mn-6Si-9Cr-5Ni SMA中观察到形状恢复程度的增加。在相同条件下,MA粉末所得的样品比原始混合粉末样品表现出更好的SME(如图 2所示),这是由于冷变形增强了MA样品微观结构中ε马氏体的形成[51]。

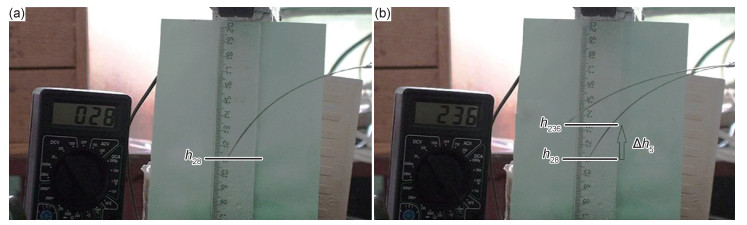

Mocanu等[46]对含有最少α′-bcc的Fe-14Mn-6Si-9Cr-5Ni片状样品进行5次热机械“训练”。如图 3所示,在第5次热机械训练中,温度加热到236℃时,14s内总位移Δh5为24×10-3m,平均位移量为1.71×10-3m/s。这表明α′-bcc马氏体虽然不利于形状记忆效应,但可以通过后续相应的热机械训练进一步提高SME。

MA和随后的烧结可能有利于提高Fe-Mn-Si基SMA合金的力学性能,通过PM工艺生产的Fe-30Mn-6Si,晶粒尺寸为2~3μm,屈服强度为500MPa,明显优于铸造生产的此类合金[35]。但是,Xu等[30]的研究表明,锻造的Fe-Mn-Si合金的断裂应变可在13.6%~40.4%范围内变化,PM烧结合金由于孔隙的存在拉伸强度非常低,断裂应变一般 < 4.2%。电化学测量结果表明PM烧结合金的腐蚀速率随Si含量的增加而降低,锻造合金则相反。这主要归因于PM烧结和锻造合金中γ奥氏体、ε马氏体以及孔隙率的存在[30]。而在添加MA的样品中,由于晶粒细小存在无定形区域,样品表现出更好的耐腐蚀性[52]。

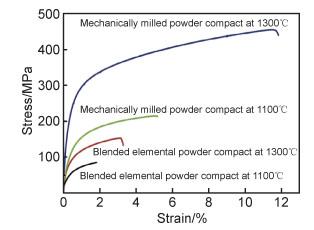

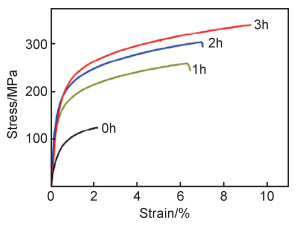

徐飞等[53]利用PM方法制备Fe-17Mn-6Si-0.03C铁基SMA,研究结果表明,实验合金压坯适宜的压制压力为400~500MPa,最佳的烧结温度为1150~1200℃,在此温度范围内烧结后可获得成分分布较均匀的合金组织。表 1为PM制备的Fe-14Mn-6Si-9Cr-5Ni SMA拉伸实验数据,结果表明试样的屈服应变和屈服应力相当稳定,不受热处理温度的影响[40]。烧结温度不同于热处理温度,对Fe-Mn-Si基合金的拉伸性能影响显著。Xu等[36]对MA Fe-28Mn-3Si粉末和未经MA的原始混合粉末进行烧结,发现合金力学性能是由原始粒度和烧结温度共同决定的,合金的力学性能随着烧结温度的升高而提高,而且前者比后者表现出更好的强度和延展性(如图 4所示)。此后[54],又对不同烧结时间的MA粉末样品进行研究,发现等温保温时间对提高烧结Fe-Mn-Si压块的拉伸性能起着重要作用,没有等温保温的样品经等温保温1h后的抗拉强度、伸长率和弹性模量从125MPa,2.1%和52GPa急剧增加至258MPa,6.4%和69GPa(如图 5所示)。

| Heat treatment temperature/℃ | Failure strain/% | Modulus/ MPa | Failure strength/ MPa | Yield stress (0.2%)/MPa | Yield strain (0.2%)/% |

| 700 | 2.10 | 56445 | - | 390 | 1.06 |

| 800 | 3.26 | 48651 | - | 408 | 1.19 |

| 900 | 3.36 | 47109 | - | 395 | 1.14 |

| 1000 | 4.16 | 47863 | 529 | 368 | 1.00 |

| 1100 | 3.81 | 51835 | - | 408 | 0.99 |

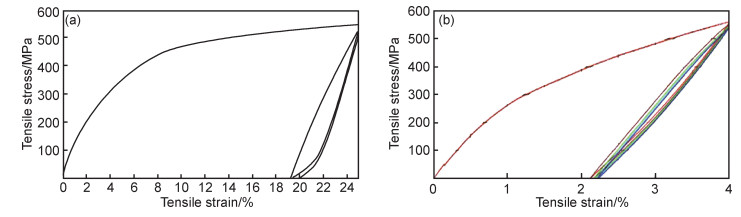

Pricop等[41]通过PM制备出添加硬脂酸锌黏合剂的Fe-18Mn-3Si-7Cr-4Ni粉末样品(PM-Zn),结果表明比不添加黏合剂的Fe-18Mn-3Si-7Cr-4Ni粉末(PM-MA)样品具有更好的断裂应变(如图 6所示)。Bujoreanu等[42]通过研究由传统冶金和粉末冶金所得Fe-18Mn-3Si-7Cr-4Ni SMA的拉伸应力-应变曲线,表明第一次加载主要是相变诱发塑性,而后续加载过程主要是滑移诱发塑性,卸载时都伴随着由伪弹性引起的回弹,如图 7所示,传统冶金所得样品的延展性较强,其应变率高达25%,而粉末冶金样品的应变率可达6%。与传统冶金相比粉末冶金样品所表现出的伪弹性特征较弱,这可能受MA的影响,在低Mn铁基合金中,由于脆性α′马氏体的形成,增强了变形硬化[55]。

|

图 7 Fe-18Mn-3Si-7Cr-4Ni SMA在拉伸加载-卸载实验中记录的应力-应变曲线[42] (a)传统冶金试样施加25%的总应变循环2次; (b)粉末冶金试样施加4%的总应变循环5次 Fig. 7 Stress-strain curves recorded during tensile loading-unloading tests of Fe-18Mn-3Si-7Cr-4Ni SMA[42] (a)specimen obtained by classical metallurgy with 25% total strain; (b)specimen obtained by powder metallurgy with 4% total strain |

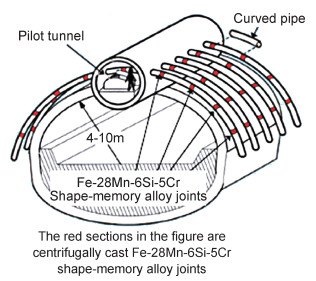

Fe-Mn-Si基SMA是应用最成功的铁基形状记忆合金。主要应用于[46]:自行车车架管的锁环、粉末喷嘴保护管、大块超导体增强防水树脂涂覆环、地下隧道挖掘钢管的肋状排连接段(如图 8所示)、起重机轨道连接板、混凝土预应变杆、用于控制混凝土梁弯曲梁和2t-抗震减震器等领域。Fe-Mn-Si基SMA由于具有较宽的相变滞后、高的弹性强度、良好的耐腐蚀性和可焊接性,因此Fe-Mn-Si基SMA管接头不必进行低温扩管处理,克服了在进行传统焊接和法兰连接时由焊接应力引起的应力腐蚀,而且占用空间少、易操作和抗压强度高。后续研究中[56],又通过添加Co使这类合金的耐腐蚀性能得到了进一步的提高,开发了一系列不锈钢铁基形状记忆合金。这些不锈钢形状记忆合金预期在反坦克导弹、炮射导弹和末制导炮弹的自动控制方面有应用前景,并可用于炮弹引信远距离解脱机构或弹药的保险机构等[57]。

近年来,具有细小析出物的新型Fe-Mn-Si合金[58],无须进行热机械训练即可实现高回复应力,使得Fe-Mn-Si基SMA加强筋在修复现有结构或加固新结构方面表现出良好的应用前景[59]。据报道[60],大约3000个Fe-Mn-Si基SMA起重机轨道接头板已经投入使用,并已安全使用了10年之久。最近,据报道Fe-Mn-Si合金由于其高细胞活力,良好的力学性能和合理的降解速率而成为可降解生物材料有希望的候选物[61-62]。Fe-Mn-Si记忆合金还可作为激光涂层,熔覆层内残余应力驱动诱发了γ→ε马氏体相变,通过相变变形(膨胀)来松弛熔覆层中的残余应力,解决熔覆层裂纹及工件变形问题并提高其疲劳强度[63]。

5 结束语在过去的几十年中,对Fe-Mn-Si基SMA的研究主要集中在通过成分设计、热机械训练和沉淀强化来改善其形状记忆性能。但是热机械训练相应地增加了成本,而且对于复杂的零部件难以实施。近年来,由于机械合金化在合金的许多研究中提高了其力学性能,因此MA/PM工艺对Fe-Mn-Si基SMA的研究成为此类合金研究的热点。但存在以下主要问题:

(1) MA/PM工艺相关的参数(例如:孔隙率,烧结气氛和添加剂)还没有进行系统的研究。

(2) PM工艺制备Fe-Mn-Si-Cr-Ni SMA中,由于晶粒细化和集聚,使应力诱发马氏体的产生呈现出一系列的特殊性,此过程中有关的定量相演变和相转变机理尚无系统研究。

(3) 有关MA/PM工艺获得Fe-Mn-Si基SMA的回复应力和低温应力松弛的研究鲜有报道,而对SME的研究目前大都是在理想状态下的研究。

为了更好地理解这种材料,仍需要大量的研究。机械合金化法可使合金元素分布均匀、灵活控制固溶或第二相添加以及产物的晶粒尺寸。利用MA/PM制备Fe基SMA,可精确控制其成分,细化晶粒,这为此类合金的制备提供了一种新的方法。

| [1] | MA J, KARAMAN I. Expanding the repertoire of shape memory alloys[J]. Science, 2010, 327 (5972): 1468–1469. DOI: 10.1126/science.1186766 |

| [2] | SUN L, HUANG W M, DING Z, et al. Stimulus-responsive shape memory materials:a review[J]. Materials & Design, 2012, 33 (1): 577–640. |

| [3] | LEE W J, WEBER B, LEINENBACH C. Recovery stress form-ation in a restrained Fe-Mn-Si-based shape memory alloy used for prestressing or mechanical joining[J]. Construction & Building Materials, 2015, 95 : 600–610. |

| [4] |

林成新, 徐凯池, 张佳琪. Fe-Mn-Si基形状记忆合金记忆效应的研究现状[J].

材料保护, 2016 (增刊1): 143–147.

LIN C X, XU K C, ZHANG J Q. Research status of memory effect of Fe-Mn-Si based shape memory alloy[J]. Materials Protection, 2016 (Suppl 1): 143–147. |

| [5] | JANI J M, LEARY M, SUBIC A, et al. A review of shape mem-ory alloy research, applications and opportunities[J]. Materials & Design, 2014, 56 (4): 1078–1113. |

| [6] | RAO A, SRINIVASA A R, REDDY J N. Design of shape mem-ory alloy (SMA) actuators[M]. Heidelberg: Springer, 2015. |

| [7] | SATO A, CHISHIMA E, SOMA K, et al. Shape memory effect in γ→ε transformation in Fe-30Mn-1Si alloy single crystals[J]. Acta Metallurgica, 1982, 30 (6): 1177–1183. DOI: 10.1016/0001-6160(82)90011-6 |

| [8] | MURAKAMI M, OTSUKA H, SUZUKI H, et al. Effect of alloying content, phase and magnetic transformation on shape memory effect of Fe-Mn-Si alloys[J]. Transactions of the Iron and Steel Institute of Japan, 1986, 27 (3): 88–89. |

| [9] | OTSUKA H, YAMADA H, MARUYAMA T, et al. Effects of alloying additions on Fe-Mn-Si shape memory alloys[J]. Transactions of the Iron & Steel Institute of Japan, 1990, 30 (8): 674–679. |

| [10] | MORIYA Y, KIMURA H, ISHIZAKI S, et al. Properties of Fe-Cr-Ni-Mn-Si (-Co) shape memory alloys[J]. Journal De Physique Ⅳ, 1991, 1 (C4): 433–437. |

| [11] |

李建忱, 蒋青, 沈平. 合金元素对铁锰硅系形状记忆合金层错能的影响[J].

功能材料, 1999, 30 (2): 164–165.

LI J C, JIANG Q, SHEN P. Influence of alloy elements on stacking fault energy of Fe-Mn-Si shape memory alloy[J]. Journal of Functional Materials, 1999, 30 (2): 164–165. DOI: 10.3321/j.issn:1001-9731.1999.02.016 |

| [12] |

龙昌柏, 龙霓东. 不同合金成分对Fe-Mn-Si系合金形状记忆效应的影响[J].

热加工工艺, 2008, 37 (24): 117–120.

LONG C B, LONG N D. Effects of different alloy composition on shape memory effect of Fe-Mn-Si alloy[J]. Hot Working Technology, 2008, 37 (24): 117–120. DOI: 10.3969/j.issn.1001-3814.2008.24.038 |

| [13] | LI J C, ZHAO M, JIANG Q. Alloy design of Fe-Mn-Si-Cr-Ni shape-memory alloys related to stacking-fault energy[J]. Meta-llurgical & Materials Transactions A, 2000, 31 (3): 581–584. |

| [14] | SATO A, MORI T. Development of a shape memory alloy Fe-Mn-Si[J]. Materials Science and Engineering:A, 1991, 29 (1/2): 197–204. |

| [15] | BARUJ A, KIKUCHI T, KAJIWARE S, et al. Improvement of shape memory properties of NbC containing Fe-Mn-Si based shape memory alloys by simple thermomechanical treatments[J]. Materials Science & Engineering:A, 2004, 378 (1): 333–336. |

| [16] | PENG H, CHEN J, WANG Y, et al. Key factors achieving large recovery strains in polycrystalline Fe-Mn-Si based shape memory alloys:a review[J]. Advanced Engineering Materials, 2017, 20 (3): 1–18. |

| [17] | PENG H, WANG G, WANG S, et al. Key criterion for achie-ving giant recovery strains in polycrystalline Fe-Mn-Si based shape memory alloys[J]. Materials Science & Engineering:A, 2018, 712 : 37–49. |

| [18] | SMITH A M O, PIERCE J. Effects of the thermodynamic para-meters of the hcp phase on the stacking fault energy calculations in the Fe-Mn and Fe-Mn-C systems[J]. Calphad-computer Cou-pling of Phase Diagrams & Thermochemistry, 2010, 34 (2): 167–175. |

| [19] | MAJI B C, KRISHNAN M, GOUTHAMA, et al. Role of Si in improving the shape recovery of Fe-Mn-Si-Cr-Ni shape memory alloys[J]. Physics Procedia, 2010, 10 (8): 111–116. |

| [20] | MATSUMIYA T. Steelmaking technology for a sustainable soc-iety[J]. Calphad-computer Coupling of Phase Diagrams & Thermochemistry, 2011, 35 (4): 627–635. |

| [21] | KIRINDI T, GVLER E, DIKICI M. Effects of homogenization time on the both martensitic transformations and mechanical properties of Fe-Mn-Si-Cr-Ni shape memory alloy[J]. Journal of Alloys & Compounds, 2007, 433 (1): 202–206. |

| [22] | BERNS H, THEISEN W. Ferrous materials:steel and cast iron[M]. Berlin: Springer, 2008: 190-207. |

| [23] | SAITO T, GASKA K, TAKASAKI A, et al. Fabrication of Fe-Mn-Si alloys by mechanical alloying and direct current sintering[J]. Jurnal Mekanikal, 2010, 30 : 62–67. |

| [24] | TORKAN S, ATAIE A, ABDIZADEH H. Investigation on ph-ase evolution in mechanically alloyed nano-structured Fe-Si system[J]. Advanced Materials Research, 2014, 829 : 703–706. |

| [25] |

邹芹, 黄洪涛, 王明智. 金属基滑动轴承材料研究进展[J].

燕山大学学报, 2016, 40 (1): 1–8.

ZOU Q, HUANG H T, WANG M Z. Research progress of metal-based sliding bearing materials[J]. Journal of Yanshan University, 2016, 40 (1): 1–8. |

| [26] | RAHIMIAN M, PARVIN N, EHSANI N. The effect of prod-uction parameters on microstructure and wear resistance of powder metallurgy Al-AlO composite[J]. Materials & Design, 2011, 32 (2): 1031–1038. |

| [27] |

肖柱, 李周, 龚深, 等.机械合金化制备形状记忆合金的研究[C]//2007高技术新材料产业发展研讨会暨材料导报编委会年会论文集. 2007: 121-131. XIAO Z, LI Z, GONG S, et al. Study on the preparation of shape memory alloy by mechanical alloying[C]//2007 Proceedings of the High-tech New Materials Industry Develo-pment Seminar and Materials Guide Editorial Board. Materials Reports, 2007: 121-131. |

| [28] | BAHADOR A, HAMZAH E, KONDOH K, et al. Mechanical and superelastic properties of disk-laser welded Ti-Ni shape-memory alloys produced by powder metallurgy[J]. Journal of Materials Processing Technology, 2017, 248 (5): 198–206. |

| [29] | MAZZER E M, GARGARELLA P, CAVA R D, et al. Effect of dislocations and residual stresses on the martensitic transfo-rmation of Cu-Al-Ni-Mn shape memory alloy powders[J]. Jour-nal of Alloys & Compounds, 2017, 723 : 841–849. |

| [30] | XU Z, HODGSON M A, CAO P. A comparative study of powder metallurgical (PM) and wrought Fe-Mn-Si alloys[J]. Materials Science & Engineering:A, 2015, 630 : 116–124. |

| [31] | ZHANG Z, SANDSTRÖM R, FRISK K, et al. Characteriza-tion of intermetallic Fe-Mn-Si powders produced by casting and mechanical ball milling[J]. Powder Technology, 2003, 137 (3): 139–147. DOI: 10.1016/j.powtec.2003.08.058 |

| [32] | HE Q, JIA C, MENG J. Influence of iron powder particle size on the microstructure and properties of Fe3Al intermetallics prepared by mechanical alloying and spark plasma sintering[J]. Materials Science & Engineering:A, 2006, 428 (1): 314–318. |

| [33] | LIU T, LIU H Y, ZHAO Z T, et al. Mechanical alloying of Fe-Mn and Fe-Mn-Si[J]. Materials Science & Engineering:A, 1999, 271 (1/2): 8–13. |

| [34] | ORO R, HRYHA E, CAMPOS M, et al. Effect of processing conditions on microstructural features in Mn-Si sintered steels[J]. Materials Characterization, 2014, 95 (3): 105–117. |

| [35] | SAITO T, KAPUSTA C, TAKASAKI A. Synthesis and char-acterization of Fe-Mn-Si shape memory alloy by mechanical allo-ying and subsequent sintering[J]. Materials Science & Engin-eering:A, 2014, 592 (2): 88–94. |

| [36] | XU Z, HODGSON M A, CAO P. Effects of mechanical milling and sintering temperature on the densification, microstructure and tensile properties of the Fe-Mn-Si powder compacts[J]. Journal of Materials Science & Technology, 2016, 32 (11): 1161–1170. |

| [37] | WEN Y H, ZHANG W, LI N, et al. Principle and realization of improving shape memory effect in Fe-Mn-Si-Cr-Ni alloy through aligned precipitations of second-phase particles[J]. Acta Mater-ialia, 2007, 55 (19): 6526–6534. DOI: 10.1016/j.actamat.2007.08.005 |

| [38] | ARRUDA G J, BUONO V T L, ANDRADE M S. The influe-nce of deformation on the microstructure and transformation temperatures of Fe-Mn-Si-Cr-Ni shape memory alloys[J]. Materials Science & Engineering:A, 1999, 273 (3): 528–532. |

| [39] | DOGAN A, ARSLAN H. Effect of ball-milling conditions on microstructure during production of Fe-20Mn-6Si-9Cr shape memory alloy powders by mechanical alloying[J]. Journal of Thermal Analysis & Calorimetry, 2012, 109 (2): 933–938. |

| [40] | PRICOP B, SÖYLER U, ÖZKAL B, et al. A study of marten-site formation in powder metallurgy Fe-Mn-Si-Cr-Ni shape mem-ory alloys[J]. Materials Today Proceedings, 2015, 2 : 789–792. DOI: 10.1016/j.matpr.2015.07.400 |

| [41] | PRICOP B, SÖYLER U, COMČNECI R I, et al. Mechanical cycling effects at Fe-Mn-Si-Cr-Ni SMAs obtained by powder metallurgy[J]. Physics Procedia, 2010, 10 (12): 125–131. |

| [42] | BUJOREANU L G, STANCIU S, ÖZKAL B, et al. Compara-tive study of the structures of Fe-Mn-Si-Cr-Ni shape memory alloys obtained by classical and by powder metallurgy, respec-tively[C]//European Symposium on Martensitic Transforma-tions. Paris: EDP Sciences, 2009: 05003. |

| [43] | PRICOP B, SÖYLER U, LOHAN N M, et al. Thermal beha-vior of mechanically alloyed powders used for producing an Fe-Mn-Si-Cr-Ni shape memory alloy[J]. Journal of Materials Engineering & Performance, 2012, 21 (11): 2407–2416. |

| [44] | PRICOP B, MIHALACHE E, LOHAN M N, et al. Powder metallurgy and mechanical alloying effects on the formation of thermally induced martensite in an FeMnSiCrNi SMA[C]//Matec Web of Conferences. Paris: EDP Sciences, 2015, 33: 04004. |

| [45] | PRICOP B, SÖYLER U, LOHAN N M, et al. Mechanical alloying effects on the thermal behaviour of a Fe-Mn-Si-Cr-Ni shape memory alloy under powder form[J]. Journal of Optoelectronics & Advanced Materials, 2011, 5 (5): 569–575. |

| [46] | MOCANU M, MIHALACHE E, PRICOP B, et al. The Influence of α'(bcc) Martensite on the Dynamic and Magnetic Response of Powder Metallurgy Fe-Mn-Si-Cr-Ni Shape Memory Alloys[C]//Proceedings of the International Conference on Martensitic Transformations: Chicago. Springer, Cham, 2018: 99-108. |

| [47] | PRICOP B, SÖYLER U, ÖZKAL B, et al. Influence of Mech-anical Alloying on the Behavior of Fe-Mn-Si-Cr-Ni Shape Mem-ory Alloys Made by Powder Metallurgy[J]. Materials Science Forum, 2013, 739 (1): 237–241. |

| [48] | AMINI R, SHAMSIPOOR A, GHAFFARI M, et al. Phase transformation during mechano-synthesis of nanocrystalline/amorphous Fe-32Mn-6Si alloys[J]. Materials Characterization, 2013, 84 (10): 169–174. |

| [49] | SPIRIDON I P, PRICOP B, SURU M G, et al. The influence of heat treatment atmosphere and maintaining period on the homogeneity degree of a Fe-Mn-Si-Cr-Ni shape memory alloy obtained through powder metallurgy[J]. Journal of Opto-electronics & Advanced Materials, 2013, 15 (7/8): 730–733. |

| [50] | PRICOP B, ÖZKAL B, SÖYLER U, et al. Structural changes caused by high-temperature holding of powder shape memory alloy Fe-14Mn-6Si-Cr-5Ni[J]. Metal Science & Heat Treatme-nt, 2016, 57 (9/10): 553–558. |

| [51] | SÖYLER A U, ÖZKAL B, BUJOREANU L G. Improved shape memory characteristics of Fe-14Mn-6Si-9Cr-5Ni alloy via mechanical alloying[J]. Journal of Materials Engineering & Performance, 2014, 23 (7): 2357–2361. |

| [52] | PRICOP B, SÖYLER U, LOHAN N M, et al. Thermal beh-avior of mechanically alloyed powders used for producing an Fe-Mn-Si-Cr-Ni shape memory alloy[J]. Journal of Materials Engineering & Performance, 2012, 21 (11): 2407–2416. |

| [53] |

徐飞, 张桢, 申斌, 等. 粉末冶金法制备铁基形状记忆合金工艺研究[J].

科技创新导报, 2010 (1): 58.

XU F, ZHANG Z, SHEN B, et al. Study on preparation of iron-based shape memory alloy by powder metallurgy[J]. Science and Technology Innovation Herald, 2010 (1): 58. DOI: 10.3969/j.issn.1674-098X.2010.01.047 |

| [54] | XU Z, HODGSON M, CHANG K, et al. Effect of sintering time on the densification, microstructure, weight loss and tensile properties of a powder metallurgical Fe-Mn-Si alloy[J]. Metals-Open Access Metallurgy Journal, 2017, 81 (7): 1–16. |

| [55] | CHERDYNTSEV V V, PUSTOV L Y, KALOSHKIN S D, et al. Phase transformations during deformation of Fe-Ni and Fe-Mn alloys produced by mechanical alloying[J]. Physics of Metals & Metallography, 2007, 104 (4): 408–414. |

| [56] | DELLA ROVERE C A, SILVA R, HAMMER P, et al. Corr-osion behavior of Fe-Mn-Si-Cr-Ni-Co shape memory stainless steel in highly oxidizing medium[J]. Materials Science Forum, 2016, 869 : 669–674. DOI: 10.4028/www.scientific.net/MSF.869 |

| [57] |

张存信, 刘洁. 形状记忆不锈钢的研究进展[J].

兵器材料科学与工程, 2003, 26 (4): 47–54.

ZHANG C X, LIU J. Research progress of shape memory stainless steel[J]. Ordnance Material Science and Engineering, 2003, 26 (4): 47–54. DOI: 10.3969/j.issn.1004-244X.2003.04.013 |

| [58] | LI K, DONG Z, LIU Y, et al. A newly developed Fe-based shape memory alloy suitable for smart civil engineering[J]. Smart Materials & Structures, 2013, 22 (4): 045002. |

| [59] | CLADERA A, WEBER B, LEINENBACH C, et al. Iron-based shape memory alloys for civil engineering structures:an over-view[J]. Construction & Building Materials, 2014, 63 (4): 281–293. |

| [60] | SAWAGUCHI T, MARUYAMA T, OTSUKA H, et al. Design concept and applications of Fe-Mn-Si based alloys-from shape-memory to seismic response control[J]. Materials Transactions, 2016, 57 (3): 283–293. DOI: 10.2320/matertrans.MB201510 |

| [61] | LIU B, ZHENG Y F, RUAN L. In vitro investigation of Fe-30Mn-6Si shape memory alloy as potential biodegradable metallic material[J]. Materials Letters, 2011, 65 (3): 540–543. DOI: 10.1016/j.matlet.2010.10.068 |

| [62] | XU Z, HODGSON M A, CAO P. A comparative study of pow-der metallurgical (PM) and wrought Fe-Mn-Si alloys[J]. Materials Science & Engineering:A, 2015, 630 : 116–124. |

| [63] |

周超玉, 林成新, 徐鹏, 等. 不锈钢表面激光熔覆原位生成Fe-Mn-Si记忆合金涂层研究[J].

稀有金属材料与工程, 2014, 43 (12): 3042–3046.

ZHOU C Y, LIN C X, XU P, et al. In situ synthesis of Fe-Mn-Si memory alloy on the surface of stainless steel by laser cladding[J]. Rare Metal Materials and Engineering, 2014, 43 (12): 3042–3046. |

2019, Vol. 47

2019, Vol. 47