文章信息

- 何培, 姚伟志, 吕建明, 张向东

- HE Pei, YAO Wei-zhi, LYU Jian-ming, ZHANG Xiang-dong

- 聚变堆结构材料辐照性能的评价

- Evaluation of Irradiation Properties for Fusion Structural Materials

- 材料工程, 2018, 46(6): 19-26

- Journal of Materials Engineering, 2018, 46(6): 19-26.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2016.001564

-

文章历史

- 收稿日期: 2016-12-29

- 修订日期: 2017-12-01

受控核聚变是人类能源问题的终极解决方式。我国已于2006年加入国际热核聚变实验反应堆(International Thermonuclear Experimental Reactor, ITER)计划,并且建立了自主研发的先进实验超导托卡马克(Experimental Advanced Superconducting Tokamak, EAST)。2013年我国启动了具有完全自主知识产权的中国聚变工程实验堆(China Fusion Engineering Test Reactor,CFETR)重大工程计划(2014~2040年)[1-2]。与ITER相比,CFETR聚变装置的工作温度有大幅度提高(稳态热流通量约为10MW/m2,瞬态热流通量为20MW/m2以上)。真空室中的结构材料将长期承受高热负荷(>5MW/m2)、14MeV高能聚变中子辐照(150~200dpa)交变应力载荷等苛刻的服役环境[3-4]。

随着核反应堆功率的不断提高,结构材料的辐照损伤问题,如辐照肿胀与蠕变现象、辐照硬化与脆化、辐照疲劳与蠕变相互作用、断裂韧度与裂纹生长以及微观结构变化、相稳定性、偏析现象、辐照应力腐蚀/侵蚀等开始显现出来,成为影响反应堆运行安全的重要因素。获得辐照下的材料性能对聚变材料的研发和认证至关重要。在没有可用的14MeV聚变中子源时,材料辐照性能的研究目前依赖于裂变反应堆、双束或三束离子加速器、重离子加速器、散裂中子源等辐照装置[5-10]。为了研究聚变中子辐照条件下的材料性能,国际能源组织于1989年开始着手实施聚变材料研究的大型国际合作项目——国际聚变材料辐照装置(International Fusion Materials Irradiation Facility, IFMIF)[11-13],当时的参与方有欧盟、美国、俄罗斯和日本,计划与ITER并行运行,共同为聚变示范堆(DEMO)工程设计获取必要的数据。

本文针对聚变堆特定的辐照特征参数,对现有的辐照装置进行了比较,评述了不同装置进行聚变堆结构材料辐照效应研究的优势和缺点。

1 聚变中子辐照特征参数表 1总结了聚变堆不同区域的中子辐照特征参数及其候选材料。聚变示范堆(DEMO,CFETR)严苛的服役环境对真空室中的第一壁及结构材料带来了巨大的挑战,从而使抗辐照合金的研发和认证成为制约聚变能应用的严重瓶颈[14-15]。目前抗辐照合金主要有3类,包括铁素体/马氏体(ODS)钢[16-18]、钒合金[19-21]和SiCf/SiC复合材料[22-24]。

| Zone | Material | Irradiation condition |

| High flux | Ferrite/Martensitic(ODS)steel | 250-650℃, 150dpa |

| Vanadium alloy | 350-650℃, 150dpa | |

| SiCf/SiC composite | 600-1100℃, 150dpa | |

| Refractory metal (W alloy) | 650-1100℃, 80dpa | |

| Medium & low flux | Ceramic insulating material | RT-500℃, 0.1-10dpa |

| RF window material | RT-400℃, 0.001-1dpa | |

| Ceramic breeding material | 300-700℃, 1-60dpa | |

| Neutron multiplication (Be alloy) | 300-900℃, 1-60dpa | |

| Superconducting material | 80-100K, < 0.1dpa |

辐照引起的材料微观结构的改变是了解和预测辐照损伤诱发的力学性能下降的关键[25-27]。结构材料的辐照损伤主要是来源于载能粒子引起的原子离位损伤以及核反应产物产生的氦引发的缺陷。中子进入材料后,原子受到直接冲击而形成许多初级离位原子,并形成空位和自间隙原子等缺陷及缺陷团簇。中子辐照也通过(n, p)和(n, α)核反应生成氢(H)和氦(He)。由此引发的氦泡的形成、表面开裂、高温氦脆等对材料的性能有重要影响。辐照参数对材料的辐照现象和辐照机理也有重要影响,主要参数包括初级离位原子(Primary Knock-on Atom,PKA)能谱分布、损伤速率及辐照剂量、核素嬗变引起的氦脆效应[26]。

1.1 初级离位原子能谱分布特征初级离位原子是指从外部入射到固体内的载能粒子直接击出的反冲原子。初级离位原子的能量及其能谱特征与辐照粒子的类型和慢化特征密切相关[28]。氘氚聚变产生的中子能量高达14MeV,极有可能在材料辐照初期产生与裂变中子辐照下显著不同的初始损伤结构,从而导致后续微观组织结构的演化过程的差异。

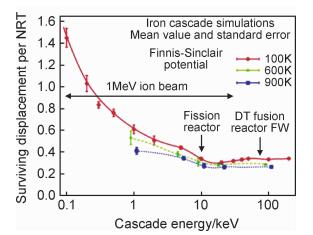

分子动力学模拟了裂变中子、散裂中子源及低强度的14MeV中子实验以及位移级联过程,采用国际通用的NRT(Norgett-Robinson-Torrens[29])模型获得载能粒子在材料中产生的原子位移缺陷损伤。图 1比较了Fe在裂变中子、聚变中子以及离子辐照下,初始离位原子损伤能对辐照损伤缺陷(相比于NRT dpa值)份额的影响[30]。原子离位级联过程中点缺陷的复合导致存活缺陷的份额约为裂变(≈10keV)[30-32]、聚变(50~100keV)[30-32]及散裂中子源(50~200keV)[32-34]的NRT dpa的30%左右。裂变、聚变、散裂中子辐照条件下产生的初级损伤状态,如缺陷团簇的几何结构、空位团簇和自间隙原子团簇的比例都比较相似,因此从裂变和散裂中子源获得的数据能够用于聚变堆候选结构材料的初步筛选。

离子辐照由于长程库仑作用会导致高比例的低角度碰撞,从而造成较高的存活缺陷份额(在1MeV离子辐照条件下存活缺陷份额高达90%)。氘氚聚变中子离位级联反应多产生较大的移动或固定团簇缺陷,而低能碰撞多产生易自由迁移的点缺陷;因此离子辐照中初始缺陷分布的迁移作用动力学与中子辐照有显著差异。离子辐照产生的高份额的可迁移缺陷会加速合金元素偏析及第二相的形成。

综上所述,裂变及散裂中子产生的初始缺陷状态与聚变堆第一壁条件很类似,而离子辐照中初始缺陷分布的迁移作用动力学与中子辐照有显著差异。

1.2 损伤速率材料所处的粒子辐照环境不同,损伤速率也随之变化。离子辐照的优势在于高损伤速率,中子辐照下数月或数年累积的离位损伤在离子辐照条件下数小时或数天就可以达到。实验和理论分析发现,离子辐照具有实验条件可控等独特优势,非常适合用于模拟结构材料辐照效应科学问题的研究。但是要把离子辐照结果与聚变或裂变中子辐照相关联将会涉及不同的温度补偿问题[35]。而温度补偿与缺陷类型和浓度有关,定量较为困难。此外空洞生长速率也与损伤速率呈现出一定的相关性。如果辐照实验的损伤率比特定工况高一个数量级,就需要有成熟可靠的模型对结果进行分析解释,因此离子辐照不能完全模拟特定工况下微观结构演变的特点。

1.3 核素嬗变中子辐照通过(n, p)与(n, α)反应生成氢(H)和氦(He),H的原子半径小,在材料中扩散很快,不易积累;He由于易在材料中积累而对材料影响较大,He的积累速率由He的原子分数与原子平均离位(dpa)之比来表征[36]。在低温时He会导致额外的辐照硬化和脆化,在中温He会加速空洞肿胀,还会进一步造成高温晶界氦脆[37-39]。此外,He还会影响中温溶质偏析和沉淀[40]。当He原子浓度高于0.00001~0.0005时,还会影响空洞肿胀、高温氦脆、相转化以及低温脆化。由于核反应产生的表面活性较高的杂质(如Li, K, S和Ca)将在晶界或内部发生偏析而导致材料脆化。表 2总结了不同环境下He掺杂速率[25]。裂变堆产生的嬗变元素比聚变低1~2个数量级,散裂中子产生的嬗变元素比聚变要高1个数量级。但是裂变堆中含有具有高热中子吸收截面的10B(n, α)7Li, 54Fe(n, α)51Cr, 58Ni(n, γ)59Ni(n, α)56Fe通过两步反应后产生大量的He。常规的离子辐照不会产生嬗变元素,但可以通过He的注入来实现。

| Environment | He transmutation/ implantation rate(atomic) |

| Fast breeder reactor(n, α) | 5×10-6-15×10-6a-1 |

| Fusion reactor(n, α) | 50×10-6-300×10-6a-1 |

| Spallation source(p, α) | ≈100×10-6d-1 |

| Ion implantation α | ≈10-2h-1 |

离子辐照可以造成高损伤速率、高辐照剂量下材料的辐照损伤,由于其实验条件严格可控,尤其适用于研究温度、辐照谱、剂量及剂量率等单一参数对材料的影响[41]。此外还可以增加专用配件在离子辐照的同时进行透射电镜(TEM)原位观察或者同时注入H/He等双束或三束离子[42]。传统离子加速器的缺点在于:(1)辐照体积有限难以获得材料完整的力学性能数据;(2)离子辐照的高损伤率引发与中子辐照显著不同的初始辐照微观结构,影响离子辐照向中子辐照结果的外推;(3)1MeV离子辐照容易在表面引入假象[43]。

高能(10MeV)轻离子加速器如回旋加速器能够将氦均匀注入到块体样品(注入深度≥100μm)中,He的浓度能够达到几千分之一[41, 44]。模拟高温氦脆的最优方式是在施加应力的同时进行热注入[37]。如果在蠕变测试前或者低温段提前注入氦,就会降低氦对材料的影响[44-45]。由于轻离子的弹性散射截面较小,高能轻离子加速器装置的位移损伤速率比裂变和聚变堆只高1个数量级,因此很难达到10dpa以上的位移损伤。

2.2 裂变堆中子辐照目前世界上运行的裂变实验堆约有240个,是研究材料辐照效应的不可或缺的手段。其中用于聚变材料中子辐照研究的反应堆有:EBR-Ⅱ(实验增殖反应堆Ⅱ,美国)、HFIR(高通量同位素反应堆,美国)、FFTF(快通量测试装置,美国)、ARBOR(橡树岭研究反应堆)、JOYO(日本快堆)、BOR60(俄罗斯快堆)、GRR-1(希腊研究反应堆)、PHENIX(凤凰快堆,法国)、BR2(比利时反应堆)、HFR(高通量反应堆,荷兰)和CHOUCA(捷克反应堆)等。表 3总结了现有以及在建的中子辐照装置中铁素体/马氏体钢的辐照条件。相较于离子辐照,中子辐照的体积较大。裂变堆的辐照体积为0.1L到几升之间,有限的辐照空间促进了小样品力学性能的发展。在0.1L的辐照空间内,通过小样品技术可以获得一定温度和辐照剂量下较为全面的力学性能[46]。裂变中子的温度在60~1500℃,经过2~4年,高能混合谱反应堆中的损伤水平约为50dpa,快堆中的损伤水平可以达到约100~150dpa。

| Facility | Displacement damage rate/(dpa/fpy) | He/(10-6/dpa) | H/(10-6/dpa) | Capsule individual volume/L | Totalvolume/L |

| DEMO 1st wall, 3.5MW/m2 | 30 | 11 | 41 | ||

| IFMIF high flux test module | 20-55 | 10-12 | 35-54 | 0.035 | 0.5 |

| HFR fission reactor, position F8 | 2.5 | 0.3 | 0.8 | 2.2 | 37 |

| HFIR fission reactor, target | 24 | 0.35 | 5 | 0.1 | 3.7 |

| BOR60 fast reactor, position D23 | 20 | 0.29 | 0.7 | 0.4 | 5 |

| ESS spallation source, target hull | 20-33 | 25-30 | 250-300 | ||

| SNS spallation source FMITS, 5cm | 5 | 20 | 100 | 0.02 | 0.04 |

| SNS spallation source FMITS, 3cm | 10 | 75 | 310 | 0.02 | 0.04 |

| SINQ spallation source, center rod 1 | ≤10 | ≤70 | ≤470 | 0.006 | 3 |

| MTS spallation, fuel positions, 15cm | 17.5 | 29 | - | 0.001 | 0.04 |

| MTS spallation, fuel positions, 5cm | 32 | 16 | - | 0.001 | 0.04 |

裂变反应堆用于聚变材料辐照研究的主要限制在于:(1)原位测试设备有限,主要受限于测量辐照温度的热电偶和气体管线[47];(2)He/dpa及H/dpa值比氘氚聚变低。利用裂变堆模拟聚变中子辐照材料研究,首先要模拟氦(He)的产生,一般有两种方式:一是利用热中子辐照Ni[48-49]或U[50]等屏蔽层来提高He的产生速率,但是辐照深度仅为几个微米。有限的辐照深度使得这种技术无法获得材料宏观的力学性能,但是可以从中获取不同材料微观结构变化信息。二是通过在材料中掺杂Ni或B也可以提高He的产生速率[51-52],或材料中采用富含铁同位素54Fe,但54Fe在裂变堆中子谱下产生的He仍然低于聚变堆实际工况1个数量级[53],这种方式被用来研究EUROFER97和ODS-EUROFER的辐照效应。利用动态氚衰变[54]技术可以研究中子辐照与He的协同作用,但是需要性能良好的阻氚层防止长期裂变中子辐照中氚的损耗。

2.3 散裂中子源辐照目前世界上运行的散裂中子源主要用于生产同位素及材料的检测(如中子小角散射)。现有和建设中的散裂中子源产生的位移损伤水平大于10~20dpa/a。在散裂源LANSCE[55-57]和SINQ[58-60]进行的辐照研究(He浓度高达0.001)揭示了材料微观结构演变及力学性能下降的原因。位于比利时摩尔的MYRRHA装置利用反应堆乏燃料中少量锕系元素的嬗变反应,每年可达到的损伤水平约为20dpa[61-63],也可用于裂变和聚变材料的研究。与其他散裂源类似,MYRRHA装置中大部分的辐照区域不能提供聚变堆辐照的He/dpa值(偏高),只有较小区域能够满足聚变He/dpa值。位于美国新墨西哥州洛斯阿拉莫斯的材料实验站(Materials Test Station, MTS)采用双束轰击含有裂变燃料的靶材,产生散裂和裂变中子的混合体,相较于纯散裂源其嬗变产物与聚变环境更为接近[64]。

虽然散裂中子实验加深了对聚变材料辐照效应的理解和认识,但是也有一定的局限性,主要表现在以下方面:(1)散裂中子源高能中子将导致较高的初级离位原子能,从而影响高剂量下(>10dpa)材料微观结构演变过程及力学性能的变化。(2)较高的气体和固体嬗变速率所带来的不确定性是目前使用散裂装置进行聚变材料研究最为关注的问题。(3)散裂中子源的脉冲辐照效应将影响辐照温度的控制,其影响程度取决于材料体系。目前大多数散裂中子装置并不能对材料辐照室进行温度控制[65],即使具有温度控制系统的散裂中子装置,由于较高的沉积热,样品与样品之间也存在显著的温度差异。(4)散裂中子源单个辐照室的体积小于裂变堆辐照室,只有充分利用小样品测试技术[46],才能获得关键的力学性能数据。

2.4 氘锂加速器辐照装置(IFMIF)国外从20世纪80年代开始,利用现有的辐照装置对材料进行了广泛深入的研究,但是离子辐照、裂变中子或散裂中子辐照获得的数据能否反映材料在聚变堆中的性能变化情况,还需要在聚变中子辐照条件下加以验证。

目前世界上有多个氘氚聚变加速器式低能中子源(< 1dpa),包括英国奥尔德马斯顿的ASP、日本原子能结构的FNS、德国德累斯顿工业大学、意大利弗拉斯卡蒂的FNG。这些装置能够研究裂变和聚变辐照环境中初始损伤结构的差异性,并获得包层结构中氚增殖、中子屏蔽及衰减等信息。但是传统氘氚聚变中子源(包括在建的ITER)能量和中子通量太低,只能说明聚变中子辐照与其他辐照条件下的差异,因此亟须能产生高通量14MeV中子的装置。

综合考虑造价、技术成熟度、辐照室空间以及聚变中子辐照特征,国际上主要采用加速器驱动的氘锂中子源作为聚变材料辐照装置。其中最具代表性的是IFMIF。IFMIF是由两个串联的40MeV直线加速器加速氘核,冲击一个流动的锂循环靶,产生高达55MeV中子,提供一个高强度的中子源。它的中子通量可达4×1014~1015n/(s·cm2),符合在最大范围内(550±180)cm造成材料辐照损伤20~55dpa/fpy的要求。理论计算气体速率H为(3.5~5)×10-5/dpa,He为(1~1.2)×10-5/dpa。这些材料测试范围分为4个区域:高通量实验区(HFTR)(>20dpa/fpy),中通量实验区(1~20dpa/fpy),低通量实验区(0.1~1dpa/fpy)和非常低的流量实验区(< 0.1dpa/fpy)。IFMIF单个辐照室体积略小于裂变堆辐照室,但是采用成熟的小样品测试技术可以获得全面的力学性能数据[46, 66-67]。在IFMIF中0.5L的高通量区可以容纳超过1000个测试样品[68]。

3 材料辐照损伤数值模拟研究用于聚变堆材料考核的实验堆(如IFMIF)尚未建成,直接采用高通量快中子研究材料的辐照损伤周期长、费用昂贵,公开发表的结果较少,较多的实验研究利用重离子辐照和α粒子注入来进行中子辐照损伤的模拟研究。辐照实验难以直接跟踪和探测原子尺度下材料辐照损伤的演化行为,因此,多尺度的数值模拟研究成为材料辐照性能评价的重要手段。

多尺度数值模拟可针对不同时间/空间尺度的物理现象开展计算模拟,为材料辐照损伤的物理微观图像建立提供解决方案[69-70]。从原子尺度的第一性原理计算、微观尺度的分子动力学模拟和介观尺度的蒙特卡罗方法到宏观尺度的连续介质力学和有限元等方法,可以得到从微观到宏观的物质结构演化信息,如杂质与缺陷或晶界之间的相互作用、初级离位损伤的产生、缺陷和位错的扩散、微结构的演化与宏观力学性能的对应关系,进而评估聚变堆各模块在实际运行环境中的表现。

国内外对铁基结构材料(纯Fe及Fe-Cr合金)的多尺度模拟开展了较为广泛的研究。国内耿文通等系统研究了体心立方铁中的氢、氦在晶界的偏聚和脆化行为以及合金元素对晶界脆化的影响[71-73]。Vincent等采用第一性原理研究了体心立方铁材料的热老化过程中溶质元素(Cu, Ni等)与点缺陷的相互作用情况[74]。Fu和Willaime系统研究了氦在体心立方铁晶格中的溶解与扩散行为,考察了氦-空位复合团簇的稳定性规律[75-76]。

近年来,基于密度泛函理论的第一性原理方法已经成为材料学研究的有力工具,其优点是能够在量子力学水平上精确计算出微观体系的总能量、平衡原子构型和电子结构等重要物理性质。第一性原理计算正在并将继续在材料辐照损伤的微观物理机制研究,特别是杂质、空位、自缺陷原子之间及其与晶格之间的相互作用研究方面发挥较大的作用。

4 结束语聚变能开发走向实际应用已经进入最后的“三步曲”(ITER, DEMO和商用堆),聚变堆材料中子辐照特性的研究是材料研发和认证的关键问题。与裂变中子相比,高能聚变中子碰撞材料原子的级联效应更强,辐照(≥5MeV中子)还会使材料产生氦,从而导致空洞肿胀和氦脆。

在没有可用的14MeV中子源时,离子加速器、裂变堆、散裂中子源以及理论模拟在聚变材料的辐照效应的研究中具有不可替代的作用。离子加速器和裂变堆可用于新材料辐照稳定性的初步筛选,同时能够为辐照模拟提供实验证据。离子加速器的主要缺点在于损伤深度有限、初级离位原子能谱差异大以及在高损伤速率下得到的实验结果外推的可靠性差。裂变反应堆的主要缺点在于较低的H, He产生速率,这将导致在相应聚变条件下材料的空洞肿胀、高温氦脆以及力学性能退化被低估。散裂中子源适于材料的中等辐照损伤(≈10dpa)研究。当>10dpa时,He的产生速率过快,表面活性元素如Ca, K, Cl和S的产生(将导致钢的脆化)以及空洞过度形核效应,导致与聚变辐照条件下结果的偏差。

从离子辐照、裂变中子或散裂中子辐照获得的数据需要与14MeV中子辐照结果进行比较,建立对应关系并证实其与真实聚变中子辐照结果的一致性。2005年后,欧盟与日本双边协作项目IFMIF是功能强大、经济性好的聚变中子辐照装置,是聚变材料走向聚变堆应用的必由之路。

| [1] | LV Z, CHEN H, CHEN C, et al. Preliminary neutronics design and analysis of helium cooled solid breeder blanket for CFETR[J]. Fusion Engineering and Design, 2015, 95 : 79–83. DOI: 10.1016/j.fusengdes.2015.04.038 |

| [2] |

李建刚. 托卡马克研究的现状及发展[J].

物理, 2016, 45 (2): 88–97.

LI J G. The status and progress of tokamak research[J]. Physics, 2016, 45 (2): 88–97. |

| [3] | PENG X, YE M, SONG Y, et al. Engineering conceptual design of CFETR divertor[J]. Fusion Engineering and Design, 2015, 98/99 : 1380–1383. DOI: 10.1016/j.fusengdes.2015.01.017 |

| [4] |

李敏. 中国聚变工程实验堆氦冷固态包层结构设计与热工水力分析研究[D]. 合肥: 中国科学技术大学, 2015. LI M. Structural design and thermal-hydraulic analysis research of helium cooled solid blanket for CFETR[D]. Hefei: University of Science and Technology of China, 2015. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y2806555 |

| [5] | TANAKA T, SHIKAMA T, NARUI M, et al. Evaluation of insulating property of ceramic materials for V/Li blanket system under fission reactor irradiation[J]. Fusion Engineering and Design, 2005, 75/79 : 933–937. DOI: 10.1016/j.fusengdes.2005.06.016 |

| [6] | JIMENEZ-REY D, MOTA F, VILA R, et al. Simulation for evaluation of the multi-ion-irradiation Laboratory of TechnoFusion facility and its relevance for fusion applications[J]. Journal of Nuclear Materials, 2011, 417 (1/3): 1352–1355. |

| [7] | LEE E H, MANSUR L K. Fe-15Ni-13Cr austenitic stainless steels for fission and fusion reactor applications. Ⅲ phase stability during heavy ion irradiation[J]. Journal of Nuclear Materials, 2000, 278 (1): 20–29. DOI: 10.1016/S0022-3115(99)00236-6 |

| [8] | OGOYSKI A I, SOMEYA T, SASAKI T, et al. Heavy ion beam irradiation non-uniformity in inertial fusion[J]. Physics Letters A, 2003, 315 (5): 372–377. DOI: 10.1016/S0375-9601(03)01042-9 |

| [9] | SOMEYA T, MIYAZAWA K, KIKUCHI T, et al. Direct-indirect mixture implosion in heavy ion fusion[J]. Laser and Particle Beams, 2006, 24 (3): 359–369. |

| [10] | NABEREJNEV D G, SALVATORES M. Irradiation of structural materials in spallation neutron sources[J]. Transactions of the American Nuclear Society, 2002, 86 : 425–427. |

| [11] | KNASTER J, CHEL S, FISCHER U, et al. IFMIF, a fusion relevant neutron source for material irradiation current status[J]. Journal of Nuclear Materials, 2014, 453 (1/3): 115–119. |

| [12] | PEREZ M, INTEGRATED I E. The engineering design evolution of IFMIF:from CDR to EDA phase[J]. Fusion Engineering and Design, 2015, 96/97 : 325–328. DOI: 10.1016/j.fusengdes.2015.04.049 |

| [13] | TIAN K, ABOU-SENA A, ARBEITER F, et al. Overview of the IFMIF test facility design in IFMIF/EVEDA phase[J]. Fusion Engineering and Design, 2015, 98/99 : 2085–2088. DOI: 10.1016/j.fusengdes.2015.05.041 |

| [14] | MOSLANG A, ADELHELM C, HEIDINGER R. Innovative materials for energy technology[J]. International Journal of Materials Research, 2008, 99 (10): 1045–1054. DOI: 10.3139/146.101743 |

| [15] | ZINKLE S J, BUSBY J T. Structural materials for fission & fusion energy[J]. Materials Today, 2009, 12 (11): 12–19. DOI: 10.1016/S1369-7021(09)70294-9 |

| [16] | MATHEW M D, VANAJA J, LAHA K, et al. Tensile and creep properties of reduced activation ferritic-martensitic steel for fusion energy application[J]. Journal of Nuclear Materials, 2011, 417 (1/3): 77–80. |

| [17] | SHIBA K, TANIGAWA H, HIROSE T, et al. Long-term properties of reduced activation ferritic/martensitic steels for fusion reactor blanket system[J]. Fusion Engineering and Design, 2011, 86 (12): 2895–2899. DOI: 10.1016/j.fusengdes.2011.06.005 |

| [18] | TAN L, SNEAD L L, KATOH Y. Development of new generation reduced activation ferritic-martensitic steels for advanced fusion reactors[J]. Journal of Nuclear Materials, 2016, 478 : 42–49. DOI: 10.1016/j.jnucmat.2016.05.037 |

| [19] | CHEN J M, CHERNOV V M, KURTZ R J, et al. Overview of the vanadium alloy researches for fusion reactors[J]. Journal of Nuclear Materials, 2011, 417 (1/3): 289–294. |

| [20] | MUROGA T, CHEN J M, CHERNOV V M, et al. Present status of vanadium alloys for fusion applications[J]. Journal of Nuclear Materials, 2014, 455 (1/3): 263–268. |

| [21] | NAGASAKA T, MUROGA T, FUKUMOTO K, et al. Development of fabrication technology for low activation vanadium alloys as fusion blanket structural materials[J]. Nuclear Fusion, 2006, 46 (5): 618–625. DOI: 10.1088/0029-5515/46/5/012 |

| [22] | IVEKOVIC A, NOVAK S, DRAZIC G, et al. Current status and prospects of SiCf/SiC for fusion structural applications[J]. Journal of the European Ceramic Society, 2013, 33 (10): 1577–1589. DOI: 10.1016/j.jeurceramsoc.2013.02.013 |

| [23] | JONES R H, GIANCARLI L, HASEGAWA A, et al. Promise and challenges of SiCf/SiC composites for fusion energy applications[J]. Journal of Nuclear Materials, 2002, 307 : 1057–1072. |

| [24] | RICCARDI B, GIANCARLI L, HASEGAWA A, et al. Issues and advances in SiCf/SiC composites development for fusion reactors[J]. Journal of Nuclear Materials, 2004, 329 : 56–65. |

| [25] |

王志光. 利用高能离子模拟研究反应堆结构材料中的辐照效应[J].

原子核物理评论, 2006, 23 (2): 155–160.

WANG Z G. Simulation of radiation effects in structural materials of reactors using high-energy heavy-ion irradiations[J]. Nuclear Physics Review, 2006, 23 (2): 155–160. DOI: 10.11804/NuclPhysRev.23.02.155 |

| [26] | ZINKLE S J, MOSLANG A. Evaluation of irradiation facility options for fusion materials research and development[J]. Fusion Engineering and Design, 2013, 88 (6/8): 472–482. |

| [27] |

肖厦子, 宋定坤, 楚海建, 等. 金属材料力学性能的辐照硬化效应[J].

力学进展, 2015, 45 : 141–178.

XIAO X Z, SONG D K, CHU H J, et al. Irradiation hardening for metallic materials[J]. Advances in Mechanics, 2015, 45 : 141–178. |

| [28] |

郁金南.

材料辐照效应[M]. 北京: 化学工业出版社, 2007: 155-157.

YU J N. Irradiation effect of reactor material[M]. Beijing: Chemical Industry Press, 2007: 155-157. |

| [29] | NORGETT M J, ROBINSON M T, TORRENS I M. Proposed method of calculating displacement dose-rates[J]. Nuclear Engineering and Design, 1975, 33 (1): 50–54. DOI: 10.1016/0029-5493(75)90035-7 |

| [30] | STOLLER R E, GREENWOOD L R. Subcascade formation in displacement cascade simulations:implications for fusion reactor materials1[J]. Journal of Nuclear Materials, 1999, 271/272 : 57–62. DOI: 10.1016/S0022-3115(98)00730-2 |

| [31] | BRIMBAL D, MESLIN E, HENRY J, et al. He and Cr effects on radiation damage formation in ion-irradiated pure iron and Fe-5.40 wt.% Cr:a transmission electron microscopy study[J]. Acta Materialia, 2013, 61 (13): 4757–4764. DOI: 10.1016/j.actamat.2013.04.070 |

| [32] | VLADIMIROV P, MOSLANG A. Comparison of material irradiation conditions for fusion, spallation, stripping and fission neutron sources[J]. Journal of Nuclear Materials, 2004, 329/333 : 233–237. DOI: 10.1016/j.jnucmat.2004.04.030 |

| [33] | WECHSLER M S, RAMAVARAPU R, DAUGHERTY E L, et al. Calculation of displacement, gas, and transmutation production in stainless-steel irradiated with spallation neutrons[J]. Journal of Nuclear Materials, 1994, 212/215 : 1678–1681. DOI: 10.1016/0022-3115(94)91112-6 |

| [34] | PITCHER E J, KELSEY C T, MALOY S A. The suitability of the materials test station for fusion materials irradiations[J]. Fusion Science and Technology, 2012, 62 (1): 289–294. DOI: 10.13182/FST62-289 |

| [35] | MANSUR L K. Theory and experimental background on dimensional changes in irradiated alloys[J]. Journal of Nuclear Materials, 1994, 216 : 97–123. DOI: 10.1016/0022-3115(94)90009-4 |

| [36] | ODETTE G R, ALINGER M J, WIRTH B D. Recent developments in irradiation-resistant steels[J]. Annual Review of Materials Research, 2008, 38 : 471–503. DOI: 10.1146/annurev.matsci.38.060407.130315 |

| [37] | TRINKAUS H, SINGH B N. Helium accumulation in metals during irradiation-where do we stand?[J]. Journal of Nuclear Materials, 2003, 323 (2/3): 229–242. |

| [38] | KONDO M, SHIBATA T, KAWANOWA H, et al. Influence of helium-ion bombardment on the surface properties of pure and ammonia-adsorbed water thin films[J]. Nuclear Instruments and Methods in Physics Research Section B:Beam Interactions with Materials and Atoms, 2005, 232 (1/4): 140–145. |

| [39] | LINDAU R, MOSLANG A, PREININGER D, et al. Influence of helium on impact properties of reduced-activation ferritic martensitic Cr-steels[J]. Journal of Nuclear Materials, 1999, 271 : 450–454. |

| [40] | MANSUR L K, LEE E H, MAZIASZ P J, et al. Control of helium effects in irradiated materials based on theory and experiment[J]. Journal of Nuclear Materials, 1986, 141/143 : 633–646. DOI: 10.1016/0022-3115(86)90066-8 |

| [41] | MAZEY D J. Fundamental aspects of high-energy ion-beam simulation techniques and their relevance to fusion materials studies[J]. Journal of Nuclear Materials, 1990, 174 (2/3): 196–209. |

| [42] | TROCELLIER P, SERRUYS Y, MIRO S, et al. Application of multi-irradiation facilities[J]. Nuclear Instruments and Methods in Physics Research Section B:Beam Interactions with Materials and Atoms, 2008, 266 (12/13): 3178–3181. |

| [43] | WAS G S. Challenges to the use of ion irradiation for emulating reactor irradiation[J]. Journal of Materials Research, 2015, 30 (9): 1158–1182. DOI: 10.1557/jmr.2015.73 |

| [44] | ULLMAIER H. The influence of helium on the bulk properties of fusion-reactor structural-materials[J]. Nuclear Fusion, 1984, 24 (8): 1039–1083. DOI: 10.1088/0029-5515/24/8/009 |

| [45] | FARRELL K. Experimental effects of helium on cavity formation during irradiation-a review[J]. Radiation Effects and Defects in Solids, 1980, 53 (3/4): 175–194. |

| [46] | LUCAS G E, ODETTE G R, SOKOLOV M, et al. Recent progress in small specimen test technology[J]. Journal of Nuclear Materials, 2002, 307/311 : 1600–1608. DOI: 10.1016/S0022-3115(02)01171-6 |

| [47] | THOMS K R, HICKS G R, MONTGOMERY B H, et al. HFIR irradiation facilities improvements-completion of the HIFI project[J]. Journal of Nuclear Materials, 1988, 155/157 : 1340–1345. DOI: 10.1016/0022-3115(88)90523-5 |

| [48] | MANSUR L K, ROWCLIFFE A F, GROSSBECK M L, et al. Isotopic alloying to tailor helium production rates in mixed-spectrum reactors[J]. Journal of Nuclear Materials, 1986, 139 (3): 228–236. DOI: 10.1016/0022-3115(86)90175-3 |

| [49] | YAMAMOTO T, ODETTE G R, MIAO P, et al. Helium effects on microstructural evolution in tempered martensitic steels:in situ helium implanter studies in HFIR[J]. Journal of Nuclear Materials, 2009, 386/388 : 338–341. DOI: 10.1016/j.jnucmat.2008.12.134 |

| [50] | ODETTE G R. New approaches to simulating fusion damage in fission reactors[J]. Journal of Nuclear Materials, 1986, 141/143 : 1011–1017. DOI: 10.1016/0022-3115(86)90134-0 |

| [51] | GAGANIDZE E, PETERSEN C, AKTAA J. Study of helium embrittlement in boron doped EUROFER97 steels[J]. Journal of Nuclear Materials, 2009, 386/388 : 349–352. DOI: 10.1016/j.jnucmat.2008.12.131 |

| [52] | KLUEH R L, HASHIMOTO N, SOKOLOV M A, et al. Mechanical properties of neutron-irradiated nickel-containing martensitic steels:Ⅱ review and analysis of helium-effects studies[J]. Journal of Nuclear Materials, 2006, 357 (1/3): 169–182. |

| [53] | ROWCLIFFE A F, HISHINUMA A, GROSSBECK M L, et al. Radiation effects at fusion reactor He:dpa ratios:overview of US/Japan spectrally tailored experiments[J]. Journal of Nuclear Materials, 1991, 179/181 : 125–129. DOI: 10.1016/0022-3115(91)90026-4 |

| [54] | SMITH D L, MATSUI H, GREENWOOD L, et al. Experimental method for investigating helium effects in irradiated vanadium[J]. Journal of Nuclear Materials, 1988, 155/157 : 1359–1363. DOI: 10.1016/0022-3115(88)90527-2 |

| [55] | MALOY S A, JAMES M R, WILLCUTT G, et al. The mechanical properties of 316L/304L stainless steels, Alloy 718 and Mod 9Cr-1Mo after irradiation in a spallation environment[J]. Journal of Nuclear Materials, 2001, 296 (1/3): 119–128. |

| [56] | SENCER B H, MALOY S A, HAMILTON M L, et al. Microstructural evolution of both as-irradiated and subsequently deformed microstructures of 316L stainless steel irradiated at 30-160℃ at LANSCE[J]. Journal of Nuclear Materials, 2005, 345 (2/3): 136–145. |

| [57] | GUSSEV M N, McCLINTOCK D A, GARNER F A. Analysis of structure and deformation behavior of AISI 316L tensile specimens from the second operational target module at the Spallation Neutron Source[J]. Journal of Nuclear Materials, 2016, 468 : 210–220. DOI: 10.1016/j.jnucmat.2015.07.013 |

| [58] | SATO K, IKEMURA K, KRSJAK V, et al. Defect structures of F82H irradiated at SINQ using positron annihilation spectroscopy[J]. Journal of Nuclear Materials, 2016, 468 : 281–284. DOI: 10.1016/j.jnucmat.2015.03.055 |

| [59] | DAI Y, FOUCHER Y, JAMES M R, et al. Neutronics calculation, dosimetry analysis and gas measurements of the first SINQ target irradiation experiment, STIP-Ⅰ[J]. Journal of Nuclear Materials, 2003, 318 : 167–175. DOI: 10.1016/S0022-3115(03)00099-0 |

| [60] | ZANINI L, DEMENTJEV S, GRÖESCHEL F, et al. Experience from the post-test analysis of MEGAPIE[J]. Journal of Nuclear Materials, 2011, 415 (3): 367–377. DOI: 10.1016/j.jnucmat.2011.04.037 |

| [61] | ABDERRAHIM H A, BAETEN P, De BRUYN D, et al. MYRRHA-a multi-purpose fast spectrum research reactor[J]. Energy Conversion and Management, 2012, 63 : 4–10. DOI: 10.1016/j.enconman.2012.02.025 |

| [62] | CASTELLITI D, LOMONACO G. A preliminary stability analysis of MYRRHA Primary Heat Exchanger two-phase tube bundle[J]. Nuclear Engineering and Design, 2016, 305 : 179–190. DOI: 10.1016/j.nucengdes.2016.05.019 |

| [63] | ÇELIK Y, STANKOVSKIY A, ENGELEN J, et al. Radiation source terms of MYRRHA reactor components and equipment[J]. International Journal of Hydrogen Energy, 2016, 41 (17): 7213–7220. |

| [64] | PITCHER E J. The materials test station:a fast-spectrum irradiation facility[J]. Journal of Nuclear Materials, 2008, 377 (1): 17–20. DOI: 10.1016/j.jnucmat.2008.02.084 |

| [65] | TONG Z, DAI Y. The microstructure and tensile properties of ferritic/martensitic steels T91, Eurofer-97 and F82H irradiated up to 20 dpa in STIP-Ⅲ[J]. Journal of Nuclear Materials, 2010, 398 (1/3): 43–48. |

| [66] | GARIN P, DIEGELE E, HEIDINGER R, et al. IFMIF specifications from the users point of view[J]. Fusion Engineering and Design, 2011, 86 (6/8): 611–614. |

| [67] | NODA K, EHRLICH K, JITSUKAWA S, et al. Users' requirements for IFMIF[J]. Journal of Nuclear Materials, 1998, 258/263 : 97–105. DOI: 10.1016/S0022-3115(98)00429-2 |

| [68] | MOSLANG A. IFMIF:the intense neutron source to qualify materials for fusion reactors[J]. Comptes Rendus Physique, 2008, 9 (3/4): 457–468. |

| [69] | SAMARAS M, VICTORIA M. Modelling in nuclear energy environments[J]. Materials Today, 2008, 11 (12): 54–62. DOI: 10.1016/S1369-7021(08)70253-0 |

| [70] | BECQUART C, DOMAIN C. Modeling microstructure and irradiation effects[J]. metallurgical and Materials Transactions A, 2011, 42 (4): 852–870. DOI: 10.1007/s11661-010-0460-7 |

| [71] | HAO W, GENG W T. Understanding Cr segregation at the He bubble surface in Fe[J]. Journal of Physics:Condensed Matter, 2012, 24 (9): 095009. DOI: 10.1088/0953-8984/24/9/095009 |

| [72] | ZHANG L, ZHANG Y, GENG W T, et al. Towards theoretical connection between tensile strength of a grain boundary and segregated impurity concentration:helium in iron as an example[J]. Europhysics Letters, 2012, 98 (1): 17001. DOI: 10.1209/0295-5075/98/17001 |

| [73] | HAO W, GENG W T. Impeding effect of Ce on He bubble growth in bcc Fe[J]. Nuclear Instruments and Methods in Physics Research Section B:Beam Interactions with Materials and Atoms, 2012, 280 : 22–25. DOI: 10.1016/j.nimb.2012.02.027 |

| [74] | VINCENT E, BECQUART C, DOMAIN C. Solute interaction with point defects in α Fe during thermal ageing:a combined ab initio and atomic kinetic Monte Carlo approach[J]. Journal of Nuclear Materials, 2006, 351 (1/3): 88–99. |

| [75] | FU C, WILLAIME F. Ab initio study of helium in α-Fe:dissolution, migration, and clustering with vacancies[J]. Physical Review B, 2005, 72 (6): 064117. DOI: 10.1103/PhysRevB.72.064117 |

| [76] | FU C, WILLAIME F. Interaction between helium and self-defects in α-iron from first principles[J]. Journal of Nuclear Materials, 2007, 367/370 : 244–250. DOI: 10.1016/j.jnucmat.2007.03.002 |

2018, Vol. 46

2018, Vol. 46