文章信息

- 刘铭, 李惠曲, 陈军洲, 李国爱, 陈高红

- LIU Ming, LI Hui-qu, CHEN Jun-zhou, LI Guo-ai, CHEN Gao-hong

- 航空用7475-T7351铝合金厚板耐腐蚀性能

- Corrosion Resistance of 7475-T7351 Aluminum Alloy Plate for Aviation

- 材料工程, 2017, 45(9): 129-135

- Journal of Materials Engineering, 2017, 45(9): 129-135.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2016.000714

-

文章历史

- 收稿日期: 2016-06-13

- 修订日期: 2017-04-28

2. 北京市先进铝合金材料及应用工程技术研究中心, 北京 100095

2. Beijing Engineering Research Center of Advanced Aluminum Alloys and Applications, Beijing 100095, China

早在20世纪30年代,人们就开始研究Al-Zn-Mg-Cu系合金,但由于该系合金存在较为严重的腐蚀现象,限制了合金的进一步应用[1-3],因此众多研究者通过微合金化、高纯化、开发新合金以及新的热处理状态等方法,明显改善了合金的腐蚀性能[4-6]。7475合金是1969年美国Alcoa公司在7075合金的基础上通过降低Fe,Si,Mn的含量,同时减少合金化元素Mg和Cu的含量开发出的具有较高的强度,优异的耐腐蚀性能和断裂韧度的新型合金,在F-16,C-58飞机上率先得到应用[7],随后在航空航天领域得到广泛推广,可用于制造机身蒙皮、上下机翼蒙皮、翼梁、中心机翼结构件和舱壁以及子弹壳等[8-10]。国外学者对7475铝合金及其腐蚀性能进行了研究[11-13],Tsai等研究了晶粒大小对7475铝合金板材应力腐蚀开裂的影响[14],同时还研究了超塑成形制造的7475铝合金应力腐蚀开裂敏感性[13],Kong等研究了7475铝合金阳极氧化物的盐雾腐蚀和电化学腐蚀性能[15]。而国内对7475合金的研制起步较晚,“七五”期间,开展了7475合金的预先研究[16],段水亮研究了合金元素和热处理对7475铝合金组织与性能的影响[17],程勇胜等研究了时效制度对7475铝合金组织与性能的影响[18],李海宏等研究了7475铝合金薄壁管时效工艺及应力腐蚀性能[19],但是关于7475铝合金不同厚度方向的腐蚀性能研究报道较少。本工作采用国产7475-T7351铝合金厚板,针对该合金不同厚度方向的晶间腐蚀和剥落腐蚀行为进行了系统研究。

1 实验材料与方法 1.1 实验材料实验材料为东北轻合金有限责任公司生产的厚度17mm的7475-T7351板材,其化学成分见表 1,板材电导率为23.73~23.79MS/m。

| Zn | Mg | Cu | Mn | Cr | Ti | Fe | Si | Al |

| 5.89 | 2.48 | 1.59 | 0.0017 | 0.22 | 0.017 | 0.056 | < 0.03 | Bal |

晶间腐蚀(Intergranular Corrosion, IGC)实验根据GB/T 7998-2005标准进行。在板材的原表面(面Ⅰ),铣去原厚度的1/10表面(面Ⅱ)以及厚度中心1/2表面(面Ⅲ)切取腐蚀试样。腐蚀溶液的体积与试样表面积之比不小于500mL/dm2。溶液恒温水浴加热至(35±1)℃。腐蚀持续时间为24h。经腐蚀后的试样,取出水洗,并在30%HNO3溶液中出光10s,除去表面附着的腐蚀产物,水洗吹干,制备显微观察试片。

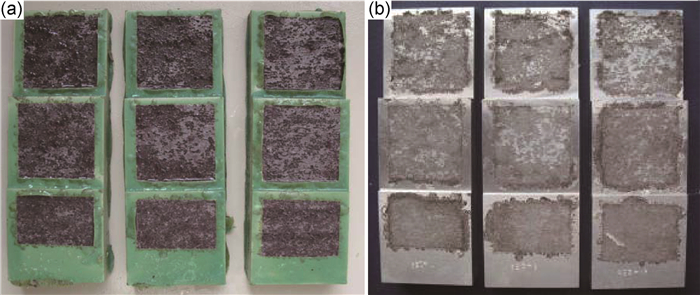

1.2.2 剥落腐蚀剥落腐蚀(Exfoliation Corrosion, EXCO)实验采用浸泡法,按HB 5455-1990标准进行。采用阶梯形试样,面Ⅰ保持原状,面Ⅱ铣去原厚度的1/10,面Ⅲ铣去原厚度的1/2,如图 1所示。厚板试样为147mm×50mm×17mm立方体,非实验面用氯丁橡胶涂封,如图 2所示。腐蚀介质体积与剥蚀面实验面积比为20mL/cm2,实验温度(27±1)℃,实验周期48h。浸泡过程中,观察腐蚀试样的腐蚀情况,记录实验现象,并采用数码相机拍摄试样腐蚀后表面及去除表面腐蚀产物后的宏观形貌。按照GB/T 22639-2008标准,对腐蚀试样进行评级。评级代号:N为腐蚀不严重,表面上有微腐蚀或脱色现象;PA为表面轻微的点蚀;PB为表面点蚀严重;PC为表面呈严重点蚀,出现疱疤、爆皮,并轻微地深入试样表面;EA-EB-EC-ED代表剥落腐蚀程度逐渐加重。

|

图 1 阶梯试样形状示意图 Fig. 1 Sketch map of ladder sample |

|

图 2 试样涂封实物照片 Fig. 2 Photo of sample by japanning |

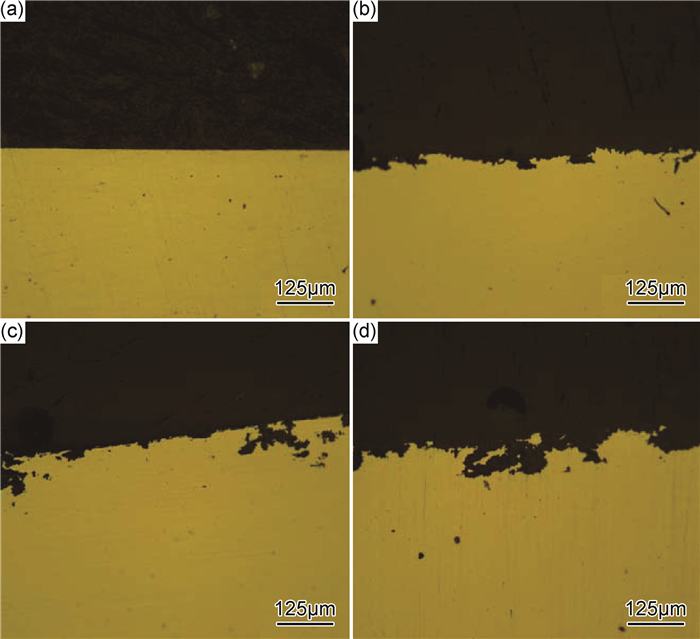

试样晶间腐蚀后用硝酸出光,出光前后的形貌如图 3所示。出光后的试样截取截面进行显微制样,并用金相显微镜进行观察,晶间腐蚀前后的典型金相照片见图 4,不同厚度层腐蚀坑深度及晶间腐蚀等级见表 2。可以看出,试样腐蚀前表面光滑,经晶间腐蚀后表面出现腐蚀坑,均未发现明显的晶间腐蚀。从不同面的腐蚀坑深度可以看出,面Ⅰ腐蚀最轻,面Ⅱ腐蚀较轻,面Ⅲ腐蚀较重。

|

图 3 7475-T7351铝合金晶间腐蚀后的形貌 (a)硝酸出光前的形貌; (b)硝酸出光后的形貌 Fig. 3 Appearances of 7475-T7351 aluminum alloy after intergranular corrosion (a)before rinse by HNO3; (b)after rinse by HNO3 |

|

图 4 7475-T7351铝合金晶间腐蚀前后的金相照片 (a)晶间腐蚀前;(b)表面晶间腐蚀后;(c)D/10表面晶间腐蚀后;(d)D/2表面晶间腐蚀后 Fig. 4 Metallographic photos of 7475-T7351 aluminum alloy before and after intergranular corrosion (a)before intergranular corrosion; (b)after surface intergranular corrosion; (c)after surface intergranular corrosion of D/10;(d)after surface intergranular corrosion of D/2 |

| Sample position | Depth of etch pit/mm | Average depth of etch pit/mm |

| Surface(Ⅰ) | 0.0825, 0.0655, 0.0685 | 0.07217 |

| 1/10 thickness(Ⅱ) | 0.0645, 0.1055, 0.0695 | 0.07983 |

| Center(Ⅲ) | 0.0748, 0.1235, 0.1145 | 0.10430 |

试样放入腐蚀溶液后不久有细小气泡析出,实验记录见表 3,经48h后取出试样,其腐蚀后的宏观剥蚀形貌如图 5所示。试样在未去除腐蚀产物前,原始表面局部金属剥落,有明显点蚀,表面出现较多连续小坑及其连成的鼓泡。按照GB/T 22639-2008评级标准对各试样清除腐蚀产物前后的表面进行评级,剥落腐蚀级别评定结果见表 4。阶梯试样的3个腐蚀面均发生了明显的剥落腐蚀,但不同厚度剥落腐蚀程度有所不同。面Ⅰ腐蚀最轻,均为EA级;面Ⅱ腐蚀较轻,剥蚀级别为EA~EB级;面Ⅲ剥蚀明显,剥蚀程度较重,级别为EB~EC。

| Time of exfoliation corrosion/h | Phenomena of experimentation |

| 1 | Generating number of small bubbles |

| 4 | Generating numerous bubbles on the surface of samples and white foam on the liquid |

| 6 | Bubbles on the surface of samples continued increasing and the surface of samples began to take on the corrosive evidence |

| 10 | The surface of sample changed into black, and the point of corrosion changed into deepness |

| 24 | Bubbles on the surface of sample became large, and the liquid became clarify |

| 48 | The surface of sample became black, and white foam floated on the liquid |

|

图 5 7475-T7351铝合金剥落腐蚀后的表面形貌 (a)未去除腐蚀产物; (b)去除腐蚀产物 Fig. 5 Surface appearances of 7475-T7351 aluminum alloy by exfoliation corrosion (a)before wiping off corrosion products; (b)after wiping off corrosion products |

| Face of experiment | Exfoliation corrosion grade | ||

| Ⅰ | EA | EA | EA |

| Ⅱ | EB | EB | EA |

| Ⅲ | EB | EC | EB |

晶间腐蚀和剥落腐蚀是Al-Zn-Mg-Cu系合金的主要腐蚀形式,且本质都是晶界上优先发生腐蚀,腐蚀程度主要取决于金属的显微组织特征,特别是析出相的性质、尺寸和分布[20, 21]。对7×××系铝合金来说,在腐蚀环境中,晶界上的η析出相和无沉淀析出带与铝基体相比都可能作为阳极相,两者都可优先溶解,但η相作为阳极溶解的趋势更为严重,从而造成腐蚀沿晶界的扩展;因此合金的腐蚀性能与其析出相的尺寸和分布密切相关[22, 23]。当晶界析出相连续时,在腐蚀环境中,很容易造成沿着晶界的连续溶解,从而导致合金的抗晶间腐蚀性能迅速下降。晶界邻近区形成溶质元素贫化区域的无沉淀析出带(Precipitation Free Zone, PFZ),也可造成晶界析出相、无沉淀析出带以及晶粒本体具有不同的电极电位,导致金属晶间腐蚀的发生。剥落腐蚀通常由点蚀开始扩展为晶间腐蚀,是晶间腐蚀的特殊形式,表现为粉化、剥皮、鼓泡等。

图 6所示为7475-T7351合金晶内以及晶界区域的微观组织形貌,可以发现在晶界存在断续粗大析出相,粗大析出相附近没有观察到明显的晶界无析出带,晶内存在均匀分布的细小析出相以及块状Al7Cr相,衍射斑点标示的结果表明晶界析出相为平衡相η相,而晶内为η′相。由于晶间没有形成连续的析出相,在晶间腐蚀过程中不会沿晶界形成连续的电偶腐蚀,从而使合金具有较好的晶间腐蚀抗力。晶间腐蚀过程中晶界粗大平衡相以及部分晶粒内粗大的第二相会使局部区域发生选择腐蚀,形成蚀孔,造成腐蚀离子浓度聚集,腐蚀会进一步加剧,最终导致局部晶粒全部腐蚀,形成边缘凹凸不平的点蚀坑,如图 4所示。此外,由于合金为片状组织,同时晶界存在由电偶腐蚀构成的通路,满足了铝合金剥蚀的两个条件[24, 25],晶界腐蚀产物体积膨胀产生楔入力使晶间腐蚀沿着与表面平行的方向发展并逐步演变为剥落腐蚀。

|

图 6 7475-T7351铝合金透射显微组织 (a)晶粒结构;(b)晶内与晶界析出 Fig. 6 Microstructures of 7475-T7351 aluminum alloy by TEM (a)grain structure; (b)precipitation phase in grain and grain boundary |

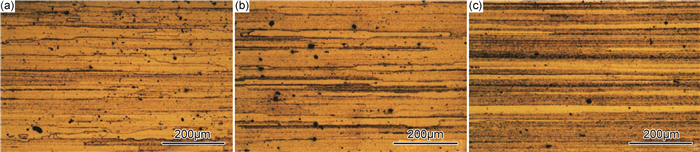

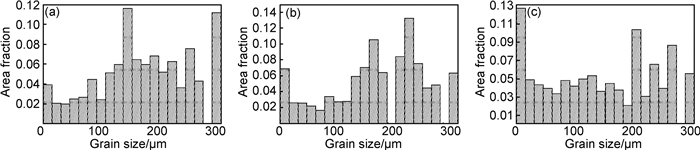

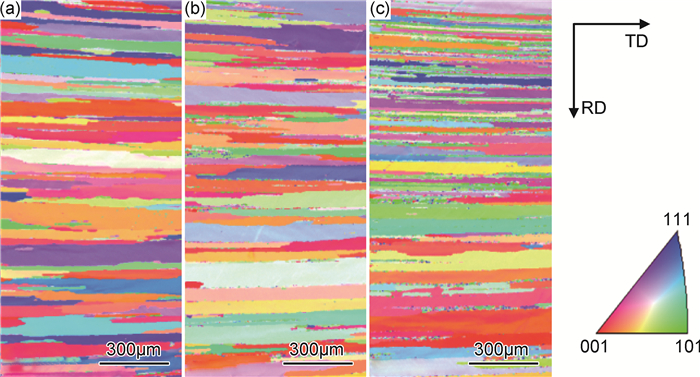

对于航空用7×××系铝合金,剥落腐蚀是一种“局部”的腐蚀行为,主要是由于腐蚀产物大于所消耗金属的体积,对基体产生“楔入效应”,导致表层发生应变引起鼓泡或剥落,而层状组织更容易使表层发生剥落,因此,腐蚀程度不仅与晶界析出相的尺寸及分布密切相关,还主要与板材的晶粒形状和再结晶程度有关[26]。图 7为合金板材不同厚度部位纵截面上的金相组织形貌。图 8和图 9分别为合金板材不同厚度部位晶粒尺寸及取向的EBSD分析。由图 7~9可以看出,从表层到心部合金的组织形貌发生很大变化:表层晶粒厚度较大,绝大多数晶粒边界呈现出明显的锯齿形貌,为典型的部分再结晶组织[27];D/10处再结晶的程度减弱,约有50%左右的晶粒仍然保持轧制后的平直晶界;而在D/2处基本没有发生再结晶,晶粒呈现出平直纤维形貌。由于再结晶程度的不同,导致了晶粒内部位错密度的差异以及晶粒长宽比的变化,再结晶程度越高,晶粒内位错密度越低,晶粒长宽比随之降低。在晶间腐蚀过程中晶内高密度位错会作为腐蚀薄弱区域存在,位错密度越高,越容易发生腐蚀,这也是从表层到心部点蚀坑深度逐渐增加的主要原因。此外,剥蚀过程中扁平状的晶粒结构致使晶界侵蚀成为腐蚀通道,腐蚀产物AlCl3或Al(OH)3的比容均大于基体金属,体积将发生膨胀,随着腐蚀过程的进行和腐蚀产物的积累使晶界受到张力,与未腐蚀部分撕裂,合金成片剥离,发生剥落腐蚀。晶粒长宽比越大,越容易发生剥蚀。由心部到表层再结晶程度增大,晶粒长宽比降低,提高了合金抗剥落腐蚀能力,导致表层的抗剥落腐蚀性能较心部要好。

|

图 7 7475-T7351板材不同厚度部位金相显微组织 (a)表面(Ⅰ);(b)1/10厚度(Ⅱ);(c)心部(Ⅲ) Fig. 7 Microstructures of 7475-T7351 plates with different thicknesses by MA (a)surface(Ⅰ); (b)1/10 thickness(Ⅱ); (c)center(Ⅲ) |

|

图 8 7475-T7351板材不同厚度部位晶粒尺寸分析 (a)表面(Ⅰ);(b)1/10厚度(Ⅱ);(c)心部(Ⅲ) Fig. 8 Grain size distributions of 7475-T7351 plates with different thicknesses by EBSD (a)surface(Ⅰ); (b)1/10 thickness(Ⅱ); (c)center(Ⅲ) |

|

图 9 7475-T7351板材不同厚度部位晶粒取向的EBSD分析 (a)表面(Ⅰ); (b)1/10厚度(Ⅱ); (c)心部(Ⅲ) Fig. 9 Misorientation angle distributions of 7475-T7351 plates with different thicknesses by EBSD (a)surface(Ⅰ); (b)1/10 thickness(Ⅱ); (c)center(Ⅲ) |

(1)7475-T7351铝合金无晶间腐蚀,有剥落腐蚀倾向。不同厚度层板材的剥落腐蚀程度略有不同,表层腐蚀最轻(EA),D/10次之(EB),心部腐蚀较重(EC)。

(2)7475-T7351板材剥落腐蚀主要是由于合金为片状组织,同时晶界存在由电偶腐蚀构成的通路,晶界腐蚀产物体积膨胀产生楔入力使晶间腐蚀沿着与表面平行的方向发展并逐步演变为剥落腐蚀。由心部到表层再结晶程度增大,晶粒长宽比降低,增加了其抗剥落腐蚀能力,导致表层的抗剥落腐蚀性能较心部要好。

| [1] |

王涛, 尹志民. 高强变形铝合金的研究现状和发展趋势[J].

稀有金属, 2006, 30 (2): 197–202.

WANG T, YIN Z M. Research status and development trend of ultra-high strength aluminum alloys[J]. Chinese Journal of Rare Metals, 2006, 30 (2): 197–202. |

| [2] |

王洪斌, 黄进峰, 杨滨, 等. Al-Zn-Mg-Cu系超高强度铝合金的研究现状与发展趋势[J].

材料导报, 2003, 17 (9): 1–4.

WANG H B, HUANG J F, YANG B, et al. Current status and future directions of ultrahigh strength Al-Zn-Mg-Cu aluminum alloys[J]. Materials Review, 2003, 17 (9): 1–4. |

| [3] | HEINZ A, HASZLER A, KEIDEL C, et al. Recent development in aluminum alloys for aerospace applications[J]. Materials Science and Engineering:A, 2000, 280 : 102–107. DOI: 10.1016/S0921-5093(99)00674-7 |

| [4] | ZANG J X, ZHANG K, DAI S L. Precipitation behavior and properties of a new high strength Al-Zn-Mg-Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22 (11): 2638–2644. DOI: 10.1016/S1003-6326(11)61511-2 |

| [5] | HIRSCH J, KAHAUSEN K F, LOHTE L. Advances in industrial aluminum research and development[J]. Materials Science Forum, 2002, 396/402 : 1721–1730. DOI: 10.4028/www.scientific.net/MSF.396-402 |

| [6] | NAUGHTAN D M, WORSFOLD M, ROBINSON M J. Corrosion product force measurements in the study of exfoliation and stress corrosion cracking in high strength aluminum alloys[J]. Corrosion Science, 2003, 45 (10): 2377–2389. DOI: 10.1016/S0010-938X(03)00050-7 |

| [7] | ROBERT E, SANDERS J R. Technology innovation in aluminum products[J]. JOM:Journal of the Minerals, Metals and Materials Society, 2001, 53 (2): 21–25. DOI: 10.1007/s11837-001-0115-7 |

| [8] | WILLIAM C, JOHN L, JAMES S. Aluminum alloys for aircraft structures[J]. Advanced Materials & Processes, 2002, 160 (12): 27–29. |

| [9] | ZUO Y Y, DAO X L, MENG Y, et al. Effects of prior corrosion with and without stress on the mechanical properties of 7475-T761 aluminum alloy[J]. Acta Metallurgica Sinica, 2015, 28 (5): 608–613. DOI: 10.1007/s40195-015-0238-4 |

| [10] | WILLIAMS J C, STARKE Jr E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51 (19): 5775–5799. DOI: 10.1016/j.actamat.2003.08.023 |

| [11] | RAJESH K G, HRISHIKESH D, TAPAN K P. Influence of processing parameters on induced energy, mechanical and corrosion properties of FSW butt joint of 7475 AA[J]. Journal of Materials Engineering and Performance, 2012, 21 (8): 1645–1654. DOI: 10.1007/s11665-011-0074-2 |

| [12] | SOUZA S D, YOSHIKAWA D S, IZALTINO W A S, et al. Nanostructured surface pre-treatment based on self-assembled molecules for corrosion protection of alclad 7475-T761 aluminum alloy[J]. Materials and Corrosion, 2011, 62 (10): 913–919. DOI: 10.1002/maco.v62.10 |

| [13] | TSAI T C, CHANG J C, CHUANG T H. Stress corrosion cracking of superplastically formed 7475 aluminum alloy[J]. Metallurgical and Materials Transactions A, 1997, 28 (10): 2113–2121. DOI: 10.1007/s11661-997-0168-5 |

| [14] | TSAI T C, CHUANG T H. Role of grain size on the stress corrosion cracking of 7475 aluminum alloys[J]. Materials Science and Engineering:A, 1997, 225 (1/2): 135–144. |

| [15] | KONG D J, WANG J C. Salt spray corrosion and electrochemical corrosion properties of anodic oxide film on 7475 aluminum alloy[J]. Journal of Alloys and Compounds, 2015, 632 : 286–290. DOI: 10.1016/j.jallcom.2015.01.175 |

| [16] |

刘铭, 张坤, 黄敏, 等. 7475-T7351铝合金抗疲劳性能研究[J].

稀有金属, 2009, 33 (5): 626–630.

LIU M, ZHANG K, HUANG M, et al. Fatigue damage resistance characteristics of 7475-T7351 aluminum alloy[J]. Chinese Journal of Rare Metals, 2009, 33 (5): 626–630. |

| [17] |

段水亮. 合金元素和热处理对7475铝合金组织与性能的影响[D]. 长沙: 中南大学, 2008. DUAN S L. The effects of alloying elements and various heat treatments process on mechanical properties and microstructural evolution of 7475 aluminum alloys[D].Changsha:Central South University, 2008. http://cdmd.cnki.com.cn/Article/CDMD-10533-2008167712.htm |

| [18] |

程勇胜, 郑子樵, 李秋菊. 时效制度对7475铝合金组织与性能的影响[J].

轻合金加工技术, 2001, 29 (6): 40–44.

CHENG Y S, ZHENG Z Q, LI Q J. Effects of ageing on microstructure and properties of 7475 aluminium alloy[J]. Light Alloy Fabrication Technology, 2001, 29 (6): 40–44. |

| [19] |

李海宏, 刘振伟, 董超芳. 7475铝合金薄壁管时效工艺及应力腐蚀性能研究[J].

轻合金加工技术, 2013, 41 (3): 54–56.

LI H H, LIU Z W, DONG C F. Study on aging technology and stress corrosion of 7475 aluminum alloy with thin-wall tube[J]. Light Alloy Fabrication Technology, 2013, 41 (3): 54–56. |

| [20] | SINYAVSKⅡ V S, UIANOVA V V, KALINLIN V D. On the mechanism of intergranular corrosion of aluminum alloys[J]. Protection of Metals, 2004, 40 (5): 481–490. DOI: 10.1023/B:PROM.0000043067.38199.95 |

| [21] | RAMGOPAL T, GOUMA P I, FRANKEL G S. Role of grain-boundary precipitates and solute-depleted zone on the intergranular corrosion of aluminum alloy 7150[J]. Corrosion, 2002, 58 (8): 687–697. DOI: 10.5006/1.3287699 |

| [22] |

何正林, 高文理, 陆政, 等. 热处理对7A85铝合金组织和性能的影响[J].

材料工程, 2015, 43 (8): 13–18.

HE Z L, GAO W L, LU Z, et al. Effects of heat treatment on microstructure and properties of 7A85 aluminium alloy[J]. Journal of Materials Engineering, 2015, 43 (8): 13–18. DOI: 10.11868/j.issn.1001-4381.2015.08.003 |

| [23] | VALIEV R Z, MURASHKIN Y M, SABIROV I. A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity[J]. Scripta Materialia, 2014, 76 : 13–16. DOI: 10.1016/j.scriptamat.2013.12.002 |

| [24] | ROBINSON M J, JACKSON N C. Exfoliation corrosion of high strength Al-Cu-Mg alloys:effect of grain structure[J]. British Corrosion Journal, 2014, 34 (1): 45–49. |

| [25] | KELLY D J, ROBINSON M J. Influence of heat treatment and grain shape on exfoliation corrosion of Al-Li alloy 8090[J]. Corrosion, 1993, 49 (10): 787–795. DOI: 10.5006/1.3316001 |

| [26] |

赵凤, 鲁法云, 郭富安. 两种7050铝合金厚板的组织与性能[J].

航空材料学报, 2015, 35 (2): 64–71.

ZHAO F, LU F Y, GUO F A. Comparative analysis of microstructures and properties of two kinds of thick plates of 7050-T7451 aluminum alloy[J]. Journal of Aeronautical Materials, 2015, 35 (2): 64–71. DOI: 10.11868/j.issn.1005-5053.2015.2.008 |

| [27] |

宁爱林, 刘志义, 郑青春, 等. 分级固溶对7A04铝合金组织与性能的影响[J].

中国有色金属学报, 2004, 14 (7): 1211–1216.

NING A L, LIU Z Y, ZHENG Q C, et al. Effects of progressive solution treatment on microstructure and mechanical properties of 7A04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14 (7): 1211–1216. |

2017, Vol. 45

2017, Vol. 45