文章信息

- 沈学霖, 朱光明, 杨鹏飞

- SHEN Xue-lin, ZHU Guang-ming, YANG Peng-fei

- 生物医用形状记忆高分子材料

- Biomedical Shape Memory Polymers

- 材料工程, 2017, 45(7): 111-117

- Journal of Materials Engineering, 2017, 45(7): 111-117.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2015.001230

-

文章历史

- 收稿日期: 2015-10-14

- 修订日期: 2016-12-16

形状记忆聚合物(shape memory polymers)是一类具有刺激-响应的新型智能高分子材料,其能感知外界环境变化,并对外界刺激做出响应,从而自发调节自身状态参数恢复到预先设计的状态[1]。兼具生物相容性和生物降解性的SMPs已经在微创外科手术[2, 3]、血管支架[4, 5]、骨组织的固定[6, 7]、可控药物缓释[8, 9]、血栓移除[10]中得到了应用。本文详细讨论了聚乳酸基、聚己内酯基和聚氨酯基三种最常见的生物降解形状记忆聚合物的研究状况。

1 聚乳酸基形状记忆聚合物聚乳酸类材料是一种典型的生物医用材料,具有良好的生物相容性和生物降解性,小分子降解产物能通过体内代谢排出体外[11]。按照形状记忆聚乳酸的分子结构可将其分为聚乳酸共聚物,聚乳酸共混物和聚乳酸基复合材料三类。

1.1 聚乳酸共聚物纯的聚乳酸材料脆而硬,亲水性差,强度高但其韧性较差,极大地限制了其在生物医学领域中的应用[12]。在聚乳酸基体中引入第二单体形成聚乳酸基共聚物,能显著地改善其性能。通过调节PLA与其他单体的比例,可以得到韧性好、降解速率可调,力学性能优异的共聚形状记忆聚乳酸材料[13, 14]。聚己内酯(PCL)[15-17]和聚乙醇酸(PGA)[18]是聚乳酸基形状记忆聚合物常用共聚单元,此外对二氧环酮[19, 20],乙交酯[19]与PLA的共聚物也能表现出形状记忆性能。

Peponi等[15]用聚己内酯和聚乳酸共聚,合成了一种PLLA-PCL-PLLA的三嵌段共聚物。硬段PLLA作为固定相,软段PCL作为转变相(switching segment)。三嵌段共聚物的转变温度(37~40℃)接近于人体温度。Yu等[21]在此基础上用PCLA共聚物(组成比DL-LA/ε-PCL为90/10) 制备了一种生物降解性的食道支架,这种形状记忆支架的转变温度为37℃。在动物体内降解测试中,支架能够保持足够的抗压强度,防止食道狭窄。

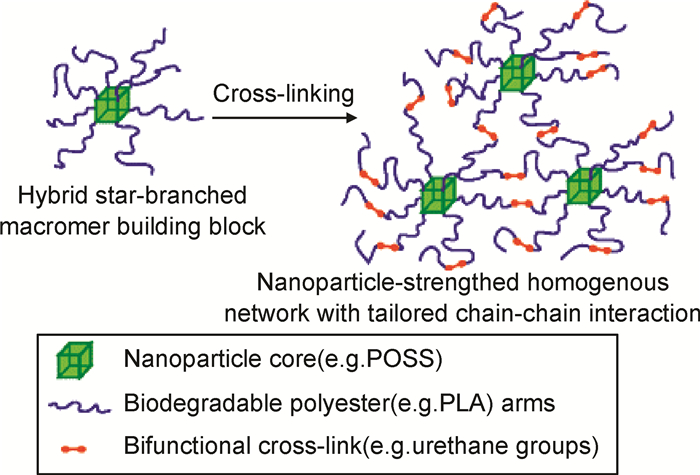

姜继森等[18]用开环聚合的方法合成了一系列组成不同的形状记忆聚(乳酸-乙醇酸)(PLGA)二元共聚物。乙醇酸含量的增加会降低共聚物的结晶度,但PLGA记忆形变的能力大大加强,形状回复率增大,回复力经历了先增大后减小的过程。Knight等[22]在PLGA主链上引入POSS,PLGA端基不饱和改性后(与丙烯酰氯反应)在紫外光作用下聚合得到了一种PLGA-POSS端基交联网络的形状记忆聚合物。其中,POSS不仅作为起始剂开环聚合PLGA,结晶的POSS相还充当了固定相。

聚乳酸多元共聚物也能表现出形状记忆性能,Zini等[3]通过开环聚合的方法制备了一系列不同组成的乳酸-乙交酯-三亚甲基碳酸酯三元共聚物(LA-GA-TMC),形状回复率超过89%(图 1)。共聚物的形状转变温度(玻璃化转变温度)随乳酸含量的变化可调,高乳酸含量的三元共聚物玻璃化转变温度在人体温度附近。

聚乳酸基SMPs共聚物主要是通过共聚单体化学键合形成高分子网络,而聚合物共混物则是通过高分子链段互相缠结形成“互穿聚合物网络”结构(IPN)[23, 24]。基于IPN结构设计SMPs,可以大幅提高其玻璃态模量和橡胶态模量比值,即提高SMP的形状固定率和回复率[25]。聚乳酸基形状记忆聚合物的共混单元有TPU(热塑性弹性体)[26-28],PEG(聚乙二醇)[29],PAE(聚酰胺弹性体)[30, 31],PU(聚氨酯)[32]等。

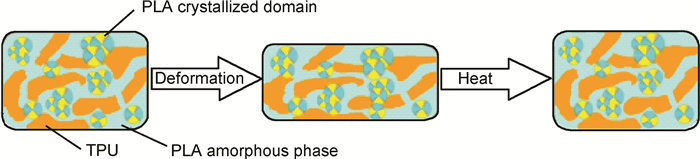

Jing研究小组[33-35]系统地研究了PLA/TPU共混物的微观形貌特征、力学性能、形状记忆效应以及降解性。Jing等将不同组成的PLA和TPU熔融共混物在双螺杆挤出机中热压成型,室温下材料经过弯曲、压缩、拉伸等过程变形,当温度超过PLA玻璃化转变温度(70℃),材料即可回复至初始形状。图 2所示为形变记忆性能的机理,PLA的结晶区作为固定相决定材料的初始形状,可逆相为PLA的无定型部分。

Gu等[32]用溶液浇注的手段制备了PU/PLA-PTMEG共混物,SEM显示这种共混物具有微相分离结构和两个不同的玻璃化转变,材料具有三重形状记忆性能。

1.3 聚乳酸基复合材料形状记忆聚合物的缺陷在于其机械强度低,热稳定性差,回复力小,循环记忆效应不佳。无机纳米粒子与聚乳酸复合制备形状记忆有机/无机复合材料,能使复合材料的力学性能、热稳定性能、降解性等得到明显的改善[36]。

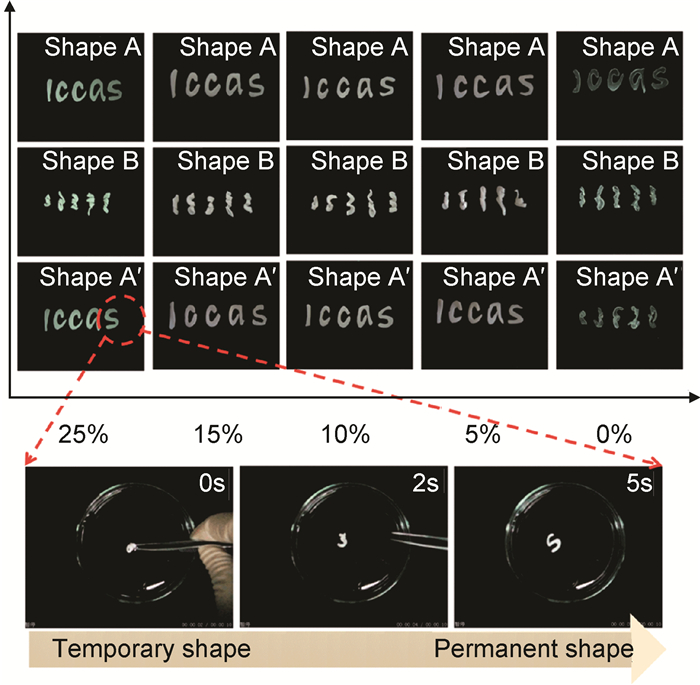

国内西南交通大学周绍兵课题组将聚乳酸与磷酸三钙(β-TCP)[37]、羟基磷灰石(HA)[38]、微晶纤维素[39]等多种纳米填料粒子复合制备了形状记忆材料。磷酸钙盐类是骨科和牙科治疗中常用的生物材料,其骨传导性好,生物降解性和吸收性强。Zheng等[38]用SEM, DSC, DMA分别表征了PDLLA/HA复合物的表面形貌、玻璃化转变、动态力学性能和形状记忆性能,形状回复率和回复时间最佳的组成比在2.0~2.5之间。而Du等[40]用原位聚合制备了不同HA含量的HA-g-PDLA接枝纳米复合材料,形状记忆最优组成比为15%。此外作者研究发现质量分数25%的HA-g-PDLA接枝共聚物比HA/PDLA共混物的形状记忆性能优异,不同含量HA的纳米复合材料形状记忆过程如图 3所示。

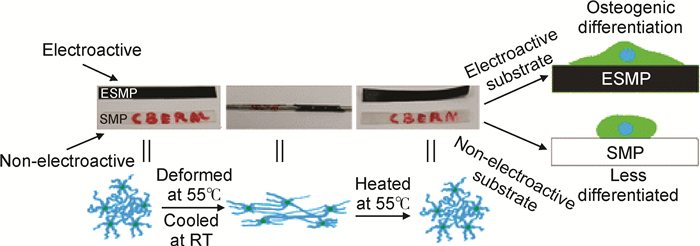

无机填料可作为增强材料提高形状记忆聚合物的性质,另一方面,将聚乳酸与磁性纳米粒子和导电粒子复合,得到的材料不仅对温度具有响应,而且在交变磁场和电场中也能实现形状记忆效应[41, 42]。Alam等[43]用—NH2官能化的碳纳米管(NH2-CNTs)与PLA形成纳米复合材料,5%含量的纳米复合物PLA/NH2-CNTs电阻率最低,导电性能最好,NH2CNTs和PLA交联程度相对较高,材料的形状记忆性能最佳[44]。Xie等[7]也报道了一种导电性SMP,其良好的性能显示了骨再生方面的潜能。他将不同链长度的六臂PLA化学交联起来,之后加入了苯胺二聚体(AT)获得了导电SMP,其形状记忆过程见图 4。

2 聚己内酯基形状记忆聚合物聚己内酯(Polycaprolactone,PCL)是一种半结晶性的脂肪族聚酯,酯基(—COO—)在自然条件下易被微生物或酶分解,生成小分子产物CO2和H2O[45-47]。线形的PCL不具有形状记忆效应,交联呈网络状的PCL耐热性能显著提高,表现出形状记忆行为。PCL的交联固化一般分物理交联型和化学交联型。

2.1 物理交联PCL物理方法主要采用高能射线(如Co60-γ射线,紫外射线等)辐射,将聚己内酯分子链破裂产生自由基,自由基重新结合形成交联的网络结构。本课题组最先开始研究物理交联PCL,Zhu等[48]对不同分子量PCL在不同温度下的辐射交联规律、力学性能、热性能、结晶性和形状记忆性能进行了实验研究。PCL的交联属于无规交联,DMA分析表明,辐射交联PCL的弹性模量和热性能显著的提高。交联改变了PCL的结晶程度和熔点[49]。

辐射交联存在的问题是交联效率较低,因此本课题组将聚己内酯与多官能团单体共混辐射交联,多官能团单体的加入可以显著提高PCL辐射交联的效率。交联后的PCL形状记忆性能优异,回复速率快。Zhu等[50]将PCL和PMVS(聚甲基乙烯基硅烷)共混后辐射交联,实验表明,PMVS的加入会减小PCL/PMVS共混物的裂解/交联(p0/q0)比,提高交联效率,交联后形状回复率超过95%。

2.2 化学交联PCL物理交联得到的PCL交联点随机分布,结构不规整。化学交联用含有多官能团的单体作为交联点,将PCL偶联成化学交联的结构,结构可预先设计。

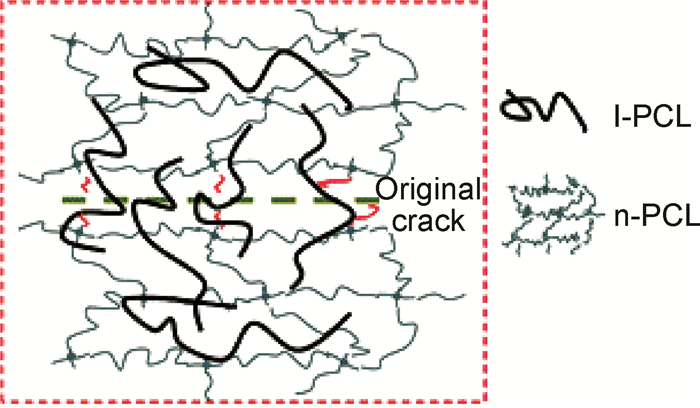

Rodriguez等[46]先将PCL二醇与酰氯制备了端丙烯酸酯基团的预聚物,预聚物和多元醇在紫外光照条件下发生聚合形成网络交联结构。在此基础上,作者将线形PCL和交联PCL共混,线形PCL贯穿整个网络,获得了一种线形/网络聚己内酯共混物(图 5)。Garle等[51]先用1,4-环己二醇和肉桂酰氯合成了肉桂酰基团改性己内酯(CCL),然后CL和CCL开环聚合合成了半结晶型的聚己内酯基共聚物(无规或PCL、PCCL、PCL三嵌段共聚物)。肉桂酸酯可生物降解,降解产物无毒,并且在紫外光作用下,肉桂酸酯中的不饱和键可形成化学交联结构,这样聚合物具有很好的形状记忆效应,PCL链段形成结晶相,PCCL链形成无定型部分。

3 聚氨酯类形状记忆聚合物另外一种重要的医用形状记忆聚合物是聚氨酯类高分子,形状记忆聚氨酯(SMPU)由多异氰酸酯(如TDI,MDI,PDI等)和可降解的多元醇或聚酯类多元醇(如PCL、PGA、聚己二酸丁二醇酯等)反应,再以多元醇(如乙二醇、丁二醇、己二醇等)作为扩链剂制备而成[52-57]。按结构特点可将形状记忆聚氨酯分为热塑性SMPU,热固性SMPU。

3.1 热塑性可降解SMPU热塑性形状记忆聚氨酯,通过氨基甲酸酯基团的聚集(氢键作用)形成物理交联点来实现形状记忆功能。Ping等[58]用分子量为500~10000的PCL二醇,乙二醇和甲苯二异氰酸酯(TDI)制备生物降解性的形状记忆聚氨酯(PCLU),其中PCL作为软段,TDI-EG作为硬段,软硬段比值在1:2到1:6的范围内,材料具有形状记忆效应。Xue等[59]用己内酯在丙三醇的作用下开环聚合生成预聚物(分子量为2700~4200g/mol,熔融温度为45~47℃),1, 6-己二醇作为扩链剂,预聚物和4, 4-二苯基甲烷二异氰酸酯(MDI)反应生成可降解聚氨酯(PCL-PU)。大分子缠结点也可作为物理交联来实现形状记忆效应。

目前对热塑性SMPU的研究主要是针对软段多元醇的种类和相对含量对其形状记忆性能的影响。王小锋等[60]比较了不同软段聚己二酸乙二酯(PEAG)、聚己二酸丁二酯(PBAG)、聚己二酸己二酯(PHAG)、聚己内酯(PCL)形成的超支化SMPU的结晶能力和形状记忆性能。实验发现,聚酯多元醇链段越长,结晶越容易,其中PHAG和PBAG合成的SMPU属于半结晶聚合物,综合性能较好。

3.2 热固性可降解SMPU热塑性形状记忆聚氨酯循环记忆能力较差,形状恢复力不足,热固性SMPU具有体型交联结构,形状记忆性能更好。线形聚氨酯通过多种方式交联成网络结构[61],如图 6。

Chun等[62, 63]用柔性PEG链段将线形PU侧链交联形成网络结构(图 6A),交联后的PU形状固定率和形状回复率都超过了90%。随后Chung等[64]用较硬的聚碳酸酯二醇替代了端羟基聚四氢呋喃,二苯基甲烷二异氰酸酯(MDI)作为交联剂,将相邻两个PU的侧链连接起来(图 6B),改进后的聚合物拉伸强度和形状回复率都有所提高。Xue等[65]设计了一种软段为支化三臂PCL,硬段为微生物聚酯的形状记忆嵌段共聚物,形成了三维网状结构(图 6C),并将这种聚合物用于自膨胀支架。除了用有机基团作为交联点,无机/有机交联SMPU网络结构的报道也越来越多。早在2004年,Cho等[66]通过溶胶-凝胶反应将四乙氧基硅烷引入PU中,合成了PU-silica复合物,结构如图 6D。在此基础上Chung等[67]先通过形成脲基甲酸酯基团在PU侧链上引入3-氨丙基三乙氧基硅烷(ATS),接着利用三乙氧基硅基基团间的溶胶-凝胶反应将线形PU交联起来,如图 6E。改性的二氧化硅纳米粒子也可作为PU的扩链剂形成网络交联结构,Jang等[68]将纳米二氧化硅粒子作为多官能交联剂,通过溶胶-凝胶反应将线形PU聚合在一起,其结构如图 6F。Zhang等[69]制备了SiO2为交联中心的聚氨酯(图 6G),SiO2的引入显著增强了材料的力学性能。多面体低聚倍半硅氧烷(POSS)也可交联PU,形成星型聚氨酯结构(图 6H)[70]。Mya等[71]用羟基官能化的POSS粒子开环聚己内酯,HDMI(六亚甲基二异氰酸酯)作为扩链剂,制备了八臂-星型POSS-PCL聚氨酯,如图 7所示。POSS的引入从分子水平上提高了材料的热稳定性和力学性能,玻璃化温度和存储模量都有所提升。

4 展望生物医用形状记忆聚合物材料不但可以充当现代医疗中的一些临时材料,如药物缓释体系等,而且其独特的形状变化还具有广阔的应用前景。集生物相容性、生物降解性和形状记忆性能的聚合物材料必将是生物领域中最热门的智能材料。生物医用形状记忆聚合物的一些研究趋势概括如下:

(1) 双程形状记忆效应具有单程形状记忆效应不具备的应用优势,而目前报道的双程SMP却很少,因此需要加强对这类形状记忆材料在生物医学方面的研究。

(2) 由于生物医用SMP需应用于人体中,所以将转变温度调整至体温的37℃附近是有必要的。目前具有该转变温度的生物医用SMP的种类尚少,医用选择性少,因此需要研究或开发更多种类的满足上述转变温度的生物医用SMP。

(3) 植入体内的形状记忆聚合物,不仅要研究直接或者间接的热响应,还要考察体液环境,pH值等对形状记忆效应的影响。

| [1] | LENDLEIN A, LANGER R. Biodegradable, elastic shape-memory polymers for potential biomedical applications[J]. Science, 2002, 296 (5573): 1673–1676. DOI: 10.1126/science.1066102 |

| [2] | CHEN M C, TSAI H W, CHANG Y, et al. Rapidly self-expandable polymeric stents with a shape-memory property[J]. Biomacromolecules, 2007, 8 (9): 2774–2780. DOI: 10.1021/bm7004615 |

| [3] | ZINI E, SCANDOLA M, DOBRZYNSKI P, et al. Shape memory behavior of novel (l-lactide-glycolide-trimethylene carbonate) terpolymers[J]. Biomacromolecules, 2007, 8 (11): 3661–3667. DOI: 10.1021/bm700773s |

| [4] | BAER G, WILSON T S, MATTHEWS D L, et al. Shape-memory behavior of thermally stimulated polyurethane for medical applications[J]. Journal of Applied Polymer Science, 2007, 103 (6): 3882–3892. DOI: 10.1002/(ISSN)1097-4628 |

| [5] | LENDLEIN A, BEHL M, HIEBL B, et al. Shape-memory polymers as a technology platform for biomedical applications[J]. Expert Review of Medical Devices, 2010, 7 (3): 357–379. DOI: 10.1586/erd.10.8 |

| [6] | BAO M, LOU X, ZHOU Q, et al. Electrospun biomimetic fibrous scaffold from shape memory polymer of PDLLA-co-TMC for bone tissue engineering[J]. ACS Applied Materials & Interfaces, 2014, 6 (4): 2611–2621. |

| [7] | XIE M, WANG L, GE J, et al. STRONG electroactive biodegradable shape memory polymer networks based on star-shaped polylactide and aniline trimer for bone tissue engineering[J]. ACS Applied Materials & Interfaces, 2015, 7 (12): 6772–6781. |

| [8] | CHEN H, LI Y, LIU Y, et al. Highly pH-sensitive polyurethane exhibiting shape memory and drug release[J]. Polymer Chemistry, 2014, 5 (17): 5168–5174. DOI: 10.1039/C4PY00474D |

| [9] | MVLLER A, ZINK M, HESSLER N, et al. Bacterial nanocellulose with a shape-memory effect as potential drug delivery system[J]. RSC Advances, 2014, 4 : 57173–57184. DOI: 10.1039/C4RA09898F |

| [10] | MUSCHENBORN A, HEARON K, VOLK B, et al. Feasibility of crosslinked acrylic shape memory polymer for a thrombectomy device[J]. Smart Materials Research, 2014, 5 : 971087. |

| [11] | RADJABIAN M, KISH M, MOHAMMADI N. Structure-property relationship for poly (lactic acid)(PLA) filaments: physical, thermomechanical and shape memory characterization[J]. Journal of Polymer Research, 2012, 19 (6): 1–10. |

| [12] | OKAMOTO H, KATAGIRI Y, NAKANO M, et al. A slow shape-recovery polymer based on polylactic acid[J]. Journal of Applied Polymer Science, 2014, 131 (19): 41004–41007. |

| [13] | HUANG Y, PAN P, SHAN G, et al. Polylactide-b-poly (ethylene-co-butylene)-b-polylactide thermoplastic elastomers: role of polylactide crystallization and stereocomplexation on microphase separation, mechanical and shape memory properties[J]. RSC Advances, 2014, 4 : 47965–47976. DOI: 10.1039/C4RA08612K |

| [14] | YANG J, LIU F, YANG L, et al. Hydrolytic and enzymatic degradation of poly (trimethylene carbonate-co-D, L-lactide) random copolymers with shape memory behavior[J]. European Polymer Journal, 2010, 46 (4): 783–791. DOI: 10.1016/j.eurpolymj.2009.12.017 |

| [15] | PEPONI L, NAVARRO-BAENA I, SONSECA A, et al. Synthesis and characterization of PCL-PLLA polyurethane with shape memory behavior[J]. European Polymer Journal, 2013, 49 (4): 893–903. DOI: 10.1016/j.eurpolymj.2012.11.001 |

| [16] | WANG W, PING P, CHEN X, et al. Biodegradable polyurethane based on random copolymer of L-lactide and ∈-caprolactone and its shape-memory property[J]. Journal of Applied Polymer Science, 2007, 104 (6): 4182–4187. DOI: 10.1002/(ISSN)1097-4628 |

| [17] | LU X L, CAI W, GAO Z, et al. Shape memory effects of poly (l-lactide) and its copolymer with poly (ε-caprolactone)[J]. Polymer Bulletin, 2007, 58 (2): 381–391. DOI: 10.1007/s00289-006-0680-6 |

| [18] | 董文进, 姜继森, 谢美然. 形状记忆聚(乳酸-乙醇酸)(PLLGA)的制备及性能研究[J]. 化学学报, 2010, 68 (21): 2243–2249. DONG W J, JIANG J S, XIE M R. Preparation and properties of shape memory poly (l-lactic-co-glycolic acid)(PLLGA)[J]. Acta Chimica Sinica, 2010, 68 (21): 2243–2249. |

| [19] | MIN C, CUI W, BEI J, et al. Effect of comonomer on thermal/mechanical and shape memory property of L-lactide-based shape-memory copolymers[J]. Polymers for Advanced Technologies, 2007, 18 (4): 299–305. DOI: 10.1002/(ISSN)1099-1581 |

| [20] | WANG Y, HUANG M, LUO Y, et al. In vitro degradation of poly (lactide-co-p-dioxanone)-based shape memory poly (urethane-urea)[J]. Polymer Degradation and Stability, 2010, 95 (4): 549–556. DOI: 10.1016/j.polymdegradstab.2009.12.016 |

| [21] | YU X, WANG L, HUANG M, et al. A shape memory stent of poly (ε-caprolactone-co-dl-lactide) copolymer for potential treatment of esophageal stenosis[J]. Journal of Materials Science: Materials in Medicine, 2012, 23 (2): 581–589. DOI: 10.1007/s10856-011-4475-4 |

| [22] | KNIGHT P T, LEE K M, CHUNG T, et al. PLGA-POSS end-linked networks with tailored degradation and shape memory behavior[J]. Macromolecules, 2009, 42 (17): 6596–6605. DOI: 10.1021/ma901237h |

| [23] | SHIBITA A, TAKASE H, SHIBATA M. Semi-interpenetrating polymer networks composed of poly (l-lactide) and diisocyanate-bridged 4-arm star-shaped ε-caprolactone oligomers[J]. Polymer, 2014, 55 (21): 5407–5416. DOI: 10.1016/j.polymer.2014.08.074 |

| [24] | TAKASE H, MORITA K, SHIBITA A, et al. Polymer networks prepared from 4-arm star-shaped L-lactide oligomers with different arm lengths and their semi-interpenetrating polymer networks containing poly (L-lactide)[J]. Journal of Polymer Research, 2014, 21 (11): 1–10. |

| [25] | LIU G, DING X, CAO Y, et al. Shape memory of hydrogen-bonded polymer network/poly (ethylene glycol) complexes[J]. Macromolecules, 2004, 37 (6): 2228–2232. DOI: 10.1021/ma035717w |

| [26] | LAI S, LAN Y. Shape memory properties of melt-blended polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends[J]. Journal of Polymer Research, 2013, 20 (5): 1–8. |

| [27] | SONG J, SRIVASTAVA I, KOWALSKI J, et al. Fabrication and characterization of a foamed polylactic acid (PLA)/thermoplastic polyurethane (TPU) shape memory polymer (SMP) blend for biomedical and clinical applications[C]// Behavior and Mechanics of Multifunctional Materials and Composites. San Diego: SPIE, 2014: 9058. http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=1846694 |

| [28] | SONG J, CHANG H, NAGUIB H. Design and characterization of biocompatible shape memory polymer (SMP) blend foams with a dynamic porous structure[J]. Polymer, 2015, 56 : 82–92. DOI: 10.1016/j.polymer.2014.09.062 |

| [29] | SHEN T, LU M, ZHOU D, et al. Influence of blocked polyisocyanate on thermomechanical, shape memory and biodegradable properties of poly(lactic acid)/poly(ethylene glycol) blends[J]. Iranian Polymer Journal, 2012, 21 (5): 317–323. DOI: 10.1007/s13726-012-0031-4 |

| [30] | LIN Y, ZHANG K, DONG Z, et al. Study of hydrogen-bonded blend of polylactide with biodegradable hyperbranched poly(ester amide)[J]. Macromolecules, 2007, 40 (17): 6257–6267. DOI: 10.1021/ma070989a |

| [31] | ZHANG W, CHEN L, ZHANG Y. Surprising shape-memory effect of polylactide resulted from toughening by polyamide elastomer[J]. Polymer, 2009, 50 (5): 1311–1315. DOI: 10.1016/j.polymer.2009.01.032 |

| [32] | GU S, LIU L, GAO X. Triple-shape memory properties of polyurethane/ polylactide-polytetramethylene ether blends[J]. Polymer International, 2015, 64 (9): 1155–1162. DOI: 10.1002/pi.2015.64.issue-9 |

| [33] | JING X, MI H, PENG X, et al. The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends[J]. Polymer Engineering and Science, 2015, 55 (1): 70–80. DOI: 10.1002/pen.v55.1 |

| [34] | JING X, MI H, SALICK M, et al. Morphology, mechanical properties, and shape memory effects of poly(lactic acid)/thermoplastic polyurethane blend scaffolds prepared by thermally induced phase separation[J]. Journal of Cellular Plastics, 2014, 50 (4): 361–379. DOI: 10.1177/0021955X14525959 |

| [35] | JING X, MI H, TURNG L, et al. Study of biobased shape memory polylactic acid/thermoplastic polyurethane (PLA/TPU) blends[C]// Proceedings of the Asme 8th International Manufacturing Science and Engineering Conference. Madison, Wisconsin: ASME, 2013: 1237. https://www.researchgate.net/publication/267617922_Study_of_Biobased_Shape_Memory_Polylactic_AcidThermoplastic_Polyurethane_(PLATPU)_Blends |

| [36] | MENG Q, HU J, HO K, et al. The shape memory properties of biodegradable chitosan/poly (l-lactide) composites[J]. Journal of Polymers and the Environment, 2009, 17 (3): 212–224. DOI: 10.1007/s10924-009-0141-z |

| [37] | ZHENG X, ZHOU S, YU X, et al. Effect of in vitro degradation of poly(D, L-lactide)/beta-tricalcium composite on its shape-memory properties[J]. Journal of Biomedical Materials Research Part B:Applied Biomaterials, 2008, 86B (1): 170–180. DOI: 10.1002/(ISSN)1552-4981 |

| [38] | ZHENG X, ZHOU S, LI X, et al. Shape memory properties of poly(D, L-lactide)/hydroxyapatite composites[J]. Biomaterials, 2006, 27 (24): 4288–4295. DOI: 10.1016/j.biomaterials.2006.03.043 |

| [39] | LIU Y, LI Y, CHEN H, et al. Water-induced shape-memory poly(D, L-lactide)/microcrystalline cellulose composites[J]. Carbohydrate Polymers, 2014, 104 : 101–108. DOI: 10.1016/j.carbpol.2014.01.031 |

| [40] | DU K, GAN Z. Shape memory behaviour of HA-g-PDLLA nanocomposites prepared via in situ polymerization[J]. Journal of Materials Chemistry B, 2014, 2 (21): 3340–3348. DOI: 10.1039/C3TB21861A |

| [41] | ZHENG X, ZHOU S, XIAO Y, et al. Shape memory effect of poly (d, l-lactide)/Fe3O4 nanocomposites by inductive heating of magnetite particles[J]. Colloids and Surfaces B: Biointerfaces, 2009, 71 (1): 67–72. DOI: 10.1016/j.colsurfb.2009.01.009 |

| [42] | XIAO Y, ZHOU S, WANG L, et al. Electro-active shape memory properties of poly (ε-caprolactone)/functionalized multiwalled carbon nanotube nanocomposite[J]. ACS Applied Materials & Interfaces, 2010, 2 (12): 3506–3514. |

| [43] | ALAM J, ALAM M, RAJA M, et al. MWCNTs-reinforced epoxidized linseed oil plasticized polylactic acid nanocomposite and its electroactive shape memory behaviour[J]. International Journal of Molecular Sciences, 2014, 15 (11): 19924–19937. DOI: 10.3390/ijms151119924 |

| [44] | ALAM J, ALAM M, DASS L, et al. Development of plasticized pla/nh2-cnts nanocomposite: potential of NH2-CNTs to improve electroactive shape memory properties[J]. Polymer Composites, 2014, 35 (11): 2129–2136. DOI: 10.1002/pc.v35.11 |

| [45] | PING P, WANG W, CHEN X, et al. The influence of hard-segments on two-phase structure and shape memory properties of PCL-based segmented polyurethanes[J]. Journal of Polymer Science Part B: Polymer Physics, 2007, 45 (5): 557–570. DOI: 10.1002/(ISSN)1099-0488 |

| [46] | RODRIGUEZ E D, LUO X, MATHER P. Linear/network poly (ε-caprolactone) blends exhibiting shape memory assisted self-healing (SMASH)[J]. ACS Applied Materials & Interfaces, 2011, 3 (2): 152–161. |

| [47] | DEFIZE T, RIVA R, RAQUEZ J, et al. Thermoreversibly crosslinked poly (ε-caprolactone) as recyclable shape-memory polymer network[J]. Macromolecular Rapid Communications, 2011, 32 (16): 1264–1269. DOI: 10.1002/marc.v32.16 |

| [48] | ZHU G M, LIANG G Z, XU Q Y, et al. Shape-memory effects of radiation crosslinked poly (∈-caprolactone)[J]. Journal of Applied Polymer Science, 2003, 90 (6): 1589–1595. DOI: 10.1002/(ISSN)1097-4628 |

| [49] | ZHU G M, XU Q Y, QIN R, et al. Effect of gamma-radiation on crystallization of polycaprolactone[J]. Radiation Physics and Chemistry, 2005, 74 (1): 42–50. DOI: 10.1016/j.radphyschem.2004.11.006 |

| [50] | ZHU G M, XU S G, WANG J H, et al. Shape memory behaviour of radiation-crosslinked PCL/PMVS blends[J]. Radiation Physics and Chemistry, 2006, 75 (3): 443–448. DOI: 10.1016/j.radphyschem.2005.10.004 |

| [51] | GARLE A, KONG S, OJHA U, et al. Thermoresponsive semicrystalline poly(epsilon-caprolactone) networks: exploiting cross-linking with cinnamoyl moieties to design polymers with tunable shape memory[J]. Acs Applied Materials & Interfaces, 2012, 4 (2): 645–657. |

| [52] | FEI G, TUINEA-BOBE C, LI D, et al. Electro-activated surface micropattern tuning for microinjection molded electrically conductive shape memory polyurethane composites[J]. RSC Advances, 2013, 3 (46): 24132–24139. DOI: 10.1039/c3ra43640c |

| [53] | SINGHAL P, SMALL W, COSGRIFF-HERNANDEZ E, et al. Low density biodegradable shape memory polyurethane foams for embolic biomedical applications[J]. Acta Biomaterialia, 2014, 10 (1): 67–76. DOI: 10.1016/j.actbio.2013.09.027 |

| [54] | OH S, OH K, DAO T, et al. The modification of graphene with alcohols and its use in shape memory polyurethane composites[J]. Polymer International, 2013, 62 (1): 54–63. DOI: 10.1002/pi.2013.62.issue-1 |

| [55] | WANG C, ZHAO Y, PURNAWALI H, et al. Chemically induced morphing in polyurethane shape memory polymer micro fibers/springs[J]. Reactive and Functional Polymers, 2012, 72 (10): 757–764. DOI: 10.1016/j.reactfunctpolym.2012.07.013 |

| [56] | WEEMS A, RAYMOND J, WACKER K, et al. Examination of radio-opacity enhancing additives in shape memory polyurethane foams[J]. Journal of Applied Polymer Science, 2015, 132 (23). DOI: 10.1002/app.42054 |

| [57] | SINGHAL P, RODRIGUEZ J, SMALL W, et al. Ultra low density and highly crosslinked biocompatible shape memory polyurethane foams[J]. Journal of Polymer Science Part B: Polymer Physics, 2012, 50 (10): 724–737. DOI: 10.1002/polb.v50.10 |

| [58] | PING P, WANG W, CHEN X, et al. Poly (ε-caprolactone) polyurethane and its shape-memory property[J]. Biomacromolecules, 2005, 6 (2): 587–592. DOI: 10.1021/bm049477j |

| [59] | XUE L, DAI S, LI Z. Synthesis and characterization of three-arm poly (ε-caprolactone)-based poly (esterurethanes) with shape-memory effect at body temperature[J]. Macromolecules, 2009, 42 (4): 964–972. DOI: 10.1021/ma802437f |

| [60] | 王小锋, 廖丽, 曹琪. 软段种类对超支化形状记忆聚氨酯形态结构的影响[J]. 工程塑料应用, 2010, 38 (12): 12–16. WANG X F, LIAO L, CAO Q. Influence of soft segment materials of hyperbranched shape memory polyurethane on morphological structure[J]. Engineering Plastics Application, 2010, 38 (12): 12–16. DOI: 10.3969/j.issn.1001-3539.2010.12.003 |

| [61] | WU C, SHAU S, LIU S, et al. Enhanced shape memory performance of polyurethanes via the incorporation of organic or inorganic networks[J]. RSC Advances, 2015, 5 (22): 16897–16910. DOI: 10.1039/C4RA14277B |

| [62] | CHUN B, CHO T, CHONG M, et al. Structure-property relationship of shape memory polyurethane cross-linked by a polyethyleneglycol spacer between polyurethane chains[J]. Journal of Materials Science, 2007, 42 (21): 9045–9056. DOI: 10.1007/s10853-007-1824-2 |

| [63] | CHUNG Y, CHO T, CHUN B. Flexible cross-linking by both pentaerythritol and polyethyleneglycol spacer and its impact on the mechanical properties and the shape memory effects of polyurethane[J]. Journal of Applied Polymer Science, 2009, 112 (5): 2800–2808. DOI: 10.1002/app.v112:5 |

| [64] | CHUNG Y, CHOI J, SHIN S, et al. Laterally crosslinked polyurethane copolymers with polycarbonate as a soft segment[J]. Fibers and Polymers, 2012, 13 (7): 815–822. DOI: 10.1007/s12221-012-0815-3 |

| [65] | XUE L, DAI S, LI Z. Biodegradable shape-memory block co-polymers for fast self-expandable stents[J]. Biomaterials, 2010, 31 (32): 8132–8140. DOI: 10.1016/j.biomaterials.2010.07.043 |

| [66] | CHO J, LEE S. Influence of silica on shape memory effect and mechanical properties of polyurethane-silica hybrids[J]. European Polymer Journal, 2004, 40 (7): 1343–1348. DOI: 10.1016/j.eurpolymj.2004.01.041 |

| [67] | CHUNG Y, KHIEM N, CHOI J, et al. Application of lateral sol-gel type crosslinking to a polyurethane copolymer[J]. Journal of Sol-gel Science and Technology, 2012, 64 (3): 549–556. DOI: 10.1007/s10971-012-2888-2 |

| [68] | JANG M, HARTWIG A, KIM B. Shape memory polyurethanes cross-linked by surface modified silica particles[J]. Journal of Materials Chemistry, 2009, 19 (8): 1166–1172. DOI: 10.1039/b816691a |

| [69] | ZHANG Y, WANG Q, WANG C, et al. High-strain shape memory polymer networks crosslinked by SiO2[J]. Journal of Materials Chemistry, 2011, 21 : 9073–9078. DOI: 10.1039/c1jm11022e |

| [70] | XU J, SONG J. High performance shape memory polymer networks based on rigid nanoparticle cores[J]. Proceedings of the National Academy of Sciences, 2010, 107 (17): 7652–7657. DOI: 10.1073/pnas.0912481107 |

| [71] | MYA K, GOSE H, PRETSCH T, et al. Star-shaped POSS-polycaprolactone polyurethanes and their shape memory performance[J]. Journal of Materials Chemistry, 2011, 21 (13): 4827–4836. DOI: 10.1039/c0jm04459h |

2017, Vol. 45

2017, Vol. 45