文章信息

- 甘致聪, 王硕, 山圣峰, 张兵, 贾元智, 马明臻

- GAN Zhi-cong, WANG Shuo, SHAN Sheng-feng, ZHANG Bing, JIA Yuan-zhi, MA Ming-zhen

- 微量硼对Ti-Fe-Cu-Sn-Nb合金力学性能的影响

- Effect of minor boron on mechanical properties of Ti-Fe-Cu-Sn-Nb alloys

- 材料工程, 2021, 49(11): 156-162

- Journal of Materials Engineering, 2021, 49(11): 156-162.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2019.001222

-

文章历史

- 收稿日期: 2020-01-02

- 修订日期: 2020-07-01

2. 济宁学院 物理与信息工程系, 山东 曲阜 273155

2. Department of Physics and Information Engineering, Jining College, Qufu 273155, Shandong, China

钛合金具有比强度高[1-5]、抗腐蚀性强[6-8]、生物相容性好[9-11]和绝热性强等特点,凭借这些良好的性能,受到了国内外的广泛关注。Ti-Fe-Cu,Ti-Fe-Sn-Nb,Ti-Fe-Cu-Sn-Nb等近β钛合金具有较高的强度、良好的塑性、低弹性模量和较好的生物相容性等特点,有较好的研究价值和应用前景[11-13]。由于β和部分近β钛合金不存在β-α的相变,不宜基于相变对合金进行热处理强化,须选择其他途径提高这类钛合金的强度,以利于其应用。有报道表明,微量的硼元素对钛合金晶粒细化和第二相强化作用明显,使钛合金的综合力学性能有大幅度改善[14-16]。例如,Zadorozhnyy等[15]和Louzguina-Luzgina等[17]对Ti-Fe-Cu合金添加微量硼元素后的力学性能做过详细的研究,结果表明,添加微量硼元素可以显著提高合金的压缩强度和拉伸强度;国内外学者以TC4,Ti-1023等牌号合金为对象,通过添加硼元素,也进行了改善合金性能的研究工作[18-22]。

关于硼对钛合金性能影响的机理,2003年Zhu等首先发现微量硼元素可以显著细化铸态TC4合金晶粒[23]。近年来,研究者们发现硼元素同样对β型钛合金晶粒可以起到细化作用。而细化晶粒的机理主要有“成分过冷”细化晶粒和“促进形核”细化晶粒两种假说。前者认为在凝固过程中硼元素在固-液界面前沿发生成分过冷,加剧了固-液界面的不稳定,为合金在固-液界面形核提供了驱动力。后者认为凝固过程中硼均匀地分布在熔融溶液中,在温度下降的过程中为合金提供形核质点和合金形核的驱动力,从而细化晶粒。随着研究的深入,人们更倾向于两种假说共同作用的结合[18-19]。在深入理解了晶粒细化机理的基础上,将会在材料具体的力学性能影响上获得更深入的认识。

本工作研究了不同含量硼元素对近β型TiFeCuSnNb钛合金综合力学性能的影响。通过组织观察、力学性能测试及显微结构的分析,研究了硼对合金组织性能的影响,对合金中TiB相对力学性能的影响进行了探讨。

1 实验材料与方法实验材料为高纯度(99.9%以上)的钛丝、铜丝、铌丝、锡块、铁颗粒以及硼铁粉(含硼质量分数18.6%)。以Ti85Fe6Cu5Sn2Nb2为基础加入质量分数分别为0.05%,0.10%,0.15%,0.2%,0.25%的硼,用真空非自耗熔炼炉熔炼,每个铸锭约为80 g,为提高熔炼均匀性,每个铸锭反复熔炼至少5次。熔炼好的铸锭在800 ℃下热轧,道次变形量为0.2 mm,轧制约12次,最终样品厚度约为4 mm。随后将轧后样品在800 ℃保温5 min后水淬。用X射线衍射分析(XRD, D/max-2500pc),设定参数为2 (°)/min进行扫描,范围30°~80°。待测样品表面用细砂纸打磨光滑,用腐蚀液(氢氟酸∶硝酸∶盐酸∶水=1∶4∶3∶7,按体积分数配制)腐蚀,并用光学金相显微镜(Axiovert 200 MAT)观察样品组织。采用万能力学试验机(INSTON5982,含引伸计)测试合金的室温拉伸力学性能,样品测试区尺寸为20 mm×2 mm×3 mm,其截面积为2 mm×3 mm。利用扫描电镜(Hitachi-3400)观察拉伸断口形貌,并对断口表面特征区域进行分析。切取断口附近拉伸样制备透射样,用5000目砂纸打磨到约18 μm厚度,采用离子减薄工艺制备透射样,利用透射电镜(JEOLJEM-2010)分析合金的显微结构,观察合金组织、TiB相形貌,采用衍射花样标定其结构。

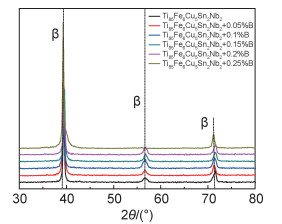

2 结果与分析 2.1 合金组织及金相分析图 1为Ti85Fe6Cu5Sn2Nb2合金加入不同含量硼元素后的X射线衍射图。图中仅出现β相衍射峰,未发现α相和硼化物衍射峰。说明相组成主要为单一β相。值得注意的是随硼含量的提高,38°处衍射峰峰形呈宽化趋势。这可能是由于硼含量提高,进一步细化合金晶粒结果[24]。硼的加入并没有改变合金的相组成。一方面是因为硼的加入量很低,XRD未能检测出相关信号。另外,通过质量分数计算得出合金钼当量(≈19)总值较高。加入少量硼元素不会对合金整体β相和α相的稳定性有明显影响。

|

图 1 不同含硼量Ti85Fe6Cu5Sn2Nb2合金的XRD图谱 Fig. 1 XRD patterns of Ti85Fe6Cu5Sn2Nb2 alloy with different B contents |

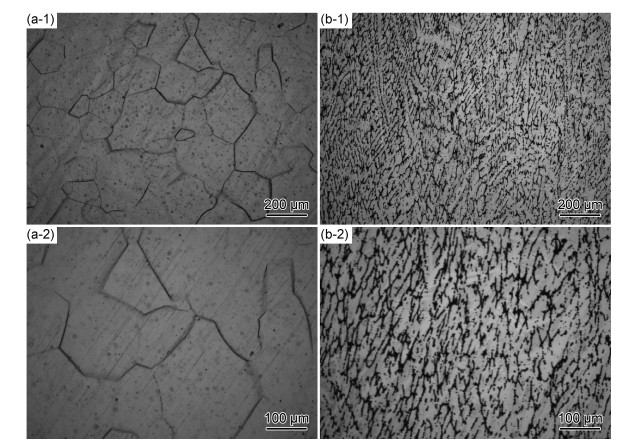

图 2为不同含硼量Ti85Fe6Cu5Sn2Nb2合金的金相组织,其中图 2(a-1)为轧制态的Ti85Fe6Cu5Sn2Nb2合金,晶粒为尺寸约200 μm的等轴晶。图 2(b-1)为含0.15%(质量分数,下同)硼的Ti85Fe6Cu5Sn2Nb2合金,晶粒尺寸约为50 μm,晶粒大多呈宽条状,这是由于轧制形成的一种取向组织。

|

图 2 不同含硼量Ti85Fe6Cu5Sn2Nb2合金金相图 (a)Ti85Fe6Cu5Sn2Nb2; (b)Ti85Fe6Cu5Sn2Nb2+0.15%B;(1)低倍; (2)高倍 Fig. 2 Metallographic images of Ti85Fe6Cu5Sn2Nb2 alloy with different boron contents (a)Ti85Fe6Cu5Sn2Nb2; (b)Ti85Fe6Cu5Sn2Nb2+0.15%B; (1)low magnification; (2)high magnification |

图 2(a-2),(b-2)是对图 2(a-1),(b-1)两合金的金相放大图。对比观察可见,加入0.15%硼的合金晶粒尺寸明显细化。Bermingham等认为这可能是因为在凝固过程中,硼元素在固液界面前沿产生成分过冷,加快形核速率,同时提供形核质点导致晶粒细化[25]。另外,高熔点的硼化物在凝固时首先形成,在晶界处也会对晶粒长大起到阻碍作用。

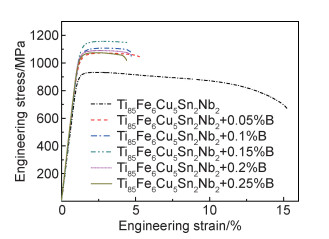

2.2 拉伸力学性能分析图 3为不同含硼量的Ti85Fe6Cu5Sn2Nb2合金拉伸曲线。由图可见,未添加硼元素的Ti85Fe6Cu5Sn2Nb2合金抗拉强度为932 MPa,塑性约为15%。添加少量硼元素后,钛合金的强度明显提高,整体提升150~200 MPa。基于前述组织观察,含硼合金的组织明显细化。根据细晶强化原理,合金晶粒细化,合金塑性和强度均提高。此外,硼元素在合金中形成的间隙固溶加剧了晶格畸变,也提高了合金强度。但随硼含量提高,钛合金整体塑性下降到4%左右。因此,硼元素的加入虽然通过固溶强化和细晶强化方式使合金强化,但是也在一定程度降低了合金塑性。孟瑶等也发现,添加微量硼元素可以细化钛合金晶粒,却显著降低合金塑性[18]。

|

图 3 不同含硼量Ti85Fe6Cu5Sn2Nb2合金的拉伸应力-应变曲线 Fig. 3 Tensile stress-strain curves of Ti85Fe6Cu5Sn2Nb2 alloys with different B contents |

不同成分合金力学性能示于表 1。微量硼元素添加对合金强度影响明显。仅添加0.15%硼的钛合金屈服强度高达1156 MPa。之后随硼元素的增加,合金抗拉强度和塑性均下降。这表明硼含量的升高不会一直有利于合金强度的提升。不同合金成分的最佳含硼量不同。张飞奇等研究发现,TC4合金加入0.05%硼具有良好性能[19]。微量硼元素添加会明显降低合金塑性,如表 1所示。当添加0.25%的硼元素后,合金伸长率由原来15.2%下降到4.3%。初步判断,合金塑性的降低可能是由于合金中的部分硼化物在塑性变形中容易发生脆断,而造成合金内部裂纹萌生与扩展。Anis等也曾提出,硼化物容易产生应力集中导致自身断裂而使合金内部产生裂纹源[26]。

| Sample | E/GPa | σ0.2/MPa | σmax/MPa | δb/% |

| Ti85Fe6Cu5Sn2Nb2 | 85 | 914±73 | 932±72 | 13.2±5 |

| Ti85Fe6Cu5Sn2Nb2+0.05%B | 94 | 1017±92 | 1071±82 | 5.4±3 |

| Ti85Fe6Cu5Sn2Nb2+0.10%B | 92 | 1059±83 | 1107±71 | 4.6±2 |

| Ti85Fe6Cu5Sn2Nb2+0.15%B | 94 | 1105±75 | 1156±70 | 4.5±2 |

| Ti85Fe6Cu5Sn2Nb2+0.20%B | 96 | 1047±50 | 1086±65 | 4.5±2 |

| Ti85Fe6Cu5Sn2Nb2+0.25%B | 94 | 1029±60 | 1075±72 | 4.3±3 |

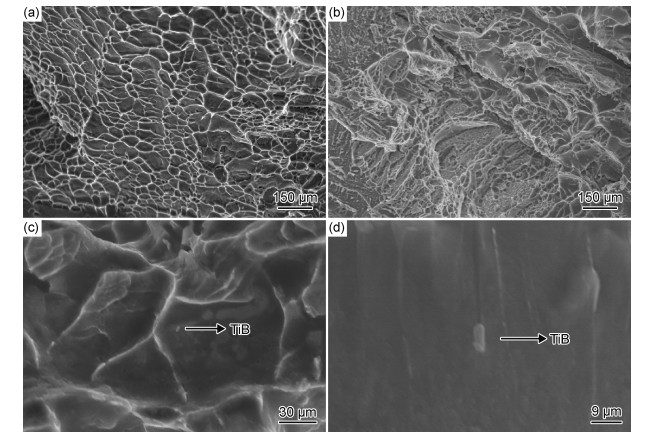

对合金拉伸断口的微观组织形貌进行观察, 结果如图 4所示。未加硼元素的Ti85Fe6Cu5Sn2Nb2合金(图 4(a))断口处显示有较大尺寸的韧窝,且未发现明显的脆性断裂特征。从该图判断,Ti85Fe6Cu5Sn2Nb2合金在拉伸过程中的断裂呈韧性特征。图 4(b)显示,加入硼元素后的Ti85Fe6Cu5Sn2Nb2合金存在数量较多的小韧窝、河流状花样和微观撕裂棱,该合金存在解理断裂和韧性断裂的特征,属于韧-脆混合断裂。对加入硼元素后的Ti85Fe6Cu5Sn2Nb2合金断口进行放大观察,如图 4(c)所示,可看到有些棒状第二相颗粒分布在断口表面裂纹源处且棒状颗粒呈弥散分布,说明在塑性变形过程中,第二相颗粒对位错产生阻碍作用。并且该第二相颗粒数量较少,对合金强化作用明显,与拉伸曲线图 3所示一致。对任一棒状颗粒放大,如图 4(d)所示,发现棒状颗粒端部尖锐,且分布在断口的微观光滑面上。Zhang等认为,这种棒状颗粒为硬度较高的硼化物,在合金变形过程中会割裂基体在尖端处产生裂纹,另外脆性第二相自身的破碎和断裂也可能造成裂纹萌生及扩展,降低合金塑性[27]。以上分析,对拉伸实验中含硼的Ti85Fe6Cu5Sn2Nb2合金虽然晶粒细化但塑性降低的现象做出了一定解释。

|

图 4 不同含硼量Ti85Fe6Cu5Sn2Nb2合金断口扫描图 (a)Ti85Fe6Cu5Sn2Nb2;(b)Ti85Fe6Cu5Sn2Nb2加入0.15%硼;(c)Ti85Fe6Cu5Sn2Nb2加入0.15%硼后的断口放大图;(d)TiB颗粒的放大图 Fig. 4 Fracture scanning images of Ti85Fe6Cu5Sn2Nb2 with different boron contents (a)Ti85Fe6Cu5Sn2Nb2; (b)Ti85Fe6Cu5Sn2Nb2 added with 0.15%B; (c)enlarged fracture image of Ti85Fe6Cu5Sn2Nb2 added with 0.15%B; (d)enlarged image of TiB particles |

对断口中多个棒状颗粒进行分析,可以判定该棒状颗粒为硬度较高的硼化物。高硬度的硼化物弥散分布在合金中, 在合金基体发生塑性变形时,位错主要通过“绕过机制”进行[28]。因此,含硼钛合金的强度极大提高,如图 3, 表 1所示。由于钛合金中硼元素最大固溶度仅为0.05%,添加硼元素的钛合金一般都会形成硼化物。研究者从硼化物动力学和生成焓等角度研究发现,硼化物大多为TiB,Ti2B或TiB2[28-29]。硼化物具有高强度、高硬度及高脆性等特点,这对阻碍晶粒变形、阻挡位错运动、提高合金强度具有重要意义[30]。

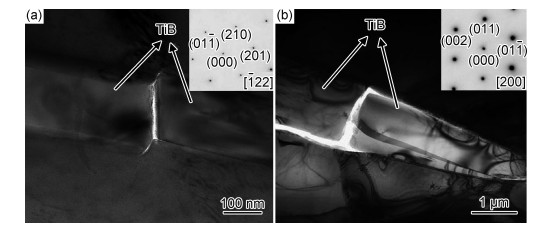

2.4 TEM分析加工工艺和热处理方式不同可以产生不同类别的硼化物[31]。为进一步确定该化合物的种类、结构类型及其对合金的作用,通过透射电镜对断裂试样进行观察(图 5)。

|

图 5 TiB相的透射电镜图 (a)断裂TiB相的形态;(b)界面脱粘和断裂TiB相的形态 Fig. 5 TEM images of TiB phases (a)morphology of fracture TiB phase ; ( b)morphology of interfacial debonding and broken TiB phase |

根据前述的组织性能测试和断口分析,可以认为钛硼相在塑性变形中主要发生脆断而促进了裂纹的萌生与扩展,并进一步导致合金整体的断裂。如图 5(a)所示,该类硼化物在塑性变形中发生脆断。通过对该化合物衍射斑点标定,确定为正交结构的TiB,其杨氏模量为427 GPa,是传统钛合金的3~4倍,硬度远高于SiC[28, 32]。这也是塑性变形过程中TiB相割裂基体的重要原因。通过透射观察,TiB相并非只通过自身脆断、割裂基体来产生裂纹源,如图 5(b)所示,TiB相与基体界面脱粘也为合金断裂提供裂纹源[33-34]。由于TiB相与钛合金基体刚度相差较大,使基体与TiB相发生应变不相容,导致变形中TiB相易与基体分离。此外,微观上TiB相(正交点阵)与β钛基体(体心立方点阵)点阵类型不同,界面处原子错配度高,使得两相界面能较高,导致TiB相与基体界面脱粘。综上所述,TiB相易在合金变形过程中产生大量裂纹源。其宏观表现为:随着硼含量的提高,TiB相增多对合金的变形抗力提高,使合金的强度升高,塑性降低,如图 3所示。当硼含量超过0.15%后,合金塑性的降低也阻碍了强度的进一步提高,如表 1所示。一般认为TiB相的存在会导致合金牺牲塑性增加强度。

如图 5(b)所示,尖锐棒状TiB在靠近尖端处应力集中,促进了TiB相的断裂。TiB相的形状和长径比对合金断裂有重要影响,项娟等发现TiB相长径比过大易导致TiB相断裂[35]。结合TiB相产生裂纹源的方式,如果TiB相以球状颗粒存在,将会降低TiB相的长径比,避免尖端处的应力集中,也避免了合金在塑性变形中高硬度的TiB相对基体的割裂。验证了Lin等提出的类似观点,改变TiB长径比可以优化合金性能,是改善合金力学性能关键因素[36]。

3 结论(1) 加入微量的硼,可以细化Ti85Fe6Cu5Sn2Nb2合金的晶粒,使合金强度提高150~200 MPa,合金的强度达到高强钛合金的标准(σb>1100 MPa),可低成本强化无β-α相变的近β和β钛合金。

(2) 当硼含量增加至0.15%,Ti85Fe6Cu5Sn2Nb2合金具有最高强度(σ0.2=1105 MPa,σmax=1156 MPa)和一定的塑性(δb=4.5%),该成分合金具有良好综合力学性能。

(3) 硼元素在Ti85Fe6Cu5Sn2Nb2合金中,形成正交结构的TiB相,分布于β钛基体中;合金裂纹源不仅通过变形过程中TiB相断裂和TiB相割裂基体产生,还通过TiB相与基体界面脱粘产生,导致合金塑性下降。

| [1] |

CAO G H, SCHNEIDER R, GERTHSEN D, et al. Sn and Nb modified ultrafine Ti-based bulk alloys with high-strength and enhanced ductility[J]. Applied Physics Letters, 2013, 102(6): 061908. DOI:10.1063/1.4792592 |

| [2] |

CHANBI D, ADNANE AMARA L, OGAM E, et al. Microstructural and mechanical properties of binary Ti-rich Fe-Ti, Al-rich Fe-Al, and Ti-Al alloys[J]. Materials (Basel), 2019, 12(3): 433. DOI:10.3390/ma12030433 |

| [3] |

CHOI Y, HONG S I. Apatite deposition and collagen coating effects in Ti-Al-V and Ti-Al-Nb alloys[J]. The Physics of Metals and Metallography, 2014, 115(13): 1307-1312. DOI:10.1134/S0031918X1413002X |

| [4] |

CHU Q, ZHANG M, LI J, et al. Nanoindentation investigation of Ti/Fe bimetallic plate welded by vanadium filler[J]. Metallurgical and Materials Transactions A, 2019, 50(5): 2302-2309. DOI:10.1007/s11661-019-05145-9 |

| [5] |

DAL B M R, SALVADOR C A F, MELLO M G, et al. The effect of Zr and Sn additions on the microstructure of Ti-Nb-Fe gum metals with high elastic admissible strain[J]. Materials & Design, 2018, 160: 1186-1195. |

| [6] |

EHTEMAM-HAGHIGHI S, LIU Y, CAO G, et al. Phase transition, microstructural evolution and mechanical properties of Ti-Nb-Fe alloys induced by Fe addition[J]. Materials & Design, 2016, 97: 279-286. |

| [7] |

EHTEMAM-HAGHIGHI S, LIU Y, CAO G, et al. Influence of Nb on the β→α″ martensitic phase transformation and properties of the newly designed Ti-Fe-Nb alloys[J]. Materials Science and Engineering: C, 2016, 60: 503-510. DOI:10.1016/j.msec.2015.11.072 |

| [8] |

FOWLER L, JANSON O, ENGQVIST H, et al. Antibacterial investigation of titanium-copper alloys using luminescent Staphylococcus epidermidis in a direct contact test[J]. Materials Science and Engineering: C, 2019, 97: 707-714. DOI:10.1016/j.msec.2018.12.050 |

| [9] |

GAO A, HANG R, HUANG X, et al. The effects of titania nanotubes with embedded silver oxide nanoparticles on bacteria and osteoblasts[J]. Biomaterials, 2014, 35(13): 4223-4235. DOI:10.1016/j.biomaterials.2014.01.058 |

| [10] |

HAGHIGHI S E, LU H B, JIAN G Y, et al. Effect of α″ martensite on the microstructure and mechanical properties of beta-type Ti-Fe-Ta alloys[J]. Materials & Design, 2015, 76: 47-54. |

| [11] |

ZHAO G H, KETOV S V, MAO H, et al. Ti-Fe-Sn-Nb hypoeutectic alloys with superb yield strength and significant strain-hardening[J]. Scripta Materialia, 2017, 135: 59-62. DOI:10.1016/j.scriptamat.2017.03.033 |

| [12] |

LOUZGUINE-LUZGIN D V, LOUZGUINA-LUZGINA L V, SAITO T, et al. Structure and properties of high strength and ductile Ti-Fe-Cu-Nb-Sn alloys[J]. Materials Science and Engineering: A, 2008, 497(1/2): 126-131. |

| [13] |

ZHAO G H, KETOV S V, JIANG J, et al. New beta-type Ti-Fe-Sn-Nb alloys with superior mechanical strength[J]. Materials Science and Engineering: A, 2017, 705: 348-351. DOI:10.1016/j.msea.2017.08.060 |

| [14] |

CHANDRAVANSHI V K, SARKAR R, KAMAT S V, et al. Effect of boron on microstructure and mechanical properties of thermomechanically processed near alpha titanium alloy Ti-1100[J]. Journal of Alloys and Compounds, 2011, 509(18): 5506-5514. DOI:10.1016/j.jallcom.2011.02.114 |

| [15] |

LOUZGUINA-LUZGINA L V, LOUZGUINE-LUZGIN D V, INOUE A. Effect of B addition to hypereutectic Ti-based alloys[J]. Journal of Alloys and Compounds, 2009, 474(1/2): 131-133. |

| [16] |

SHIMAGAMI K, ITO T, TODA Y, et al. Effects of Zr and Si addition on high-temperature mechanical properties and microstructure in Ti-10Al-2 Nb-based alloys[J]. Materials Science and Engineering: A, 2019, 756: 46-53. DOI:10.1016/j.msea.2019.04.031 |

| [17] |

ZADOROZHNYY V Y, SHCHETININ I V, CHIRIKOV N V, et al. Tensile properties of a dual-axial forged Ti-Fe-Cu alloy containing boron[J]. Materials Science and Engineering: A, 2014, 614: 238-242. DOI:10.1016/j.msea.2014.07.017 |

| [18] |

孟瑶, 黄利军, 张明杰, 等. 硼对Ti-1023合金组织与性能的影响[J]. 钛工业进展, 2016, 33(4): 26-30. MENG Y, HUANG L J, ZHANG M J, et al. Effect of boron on microstructure and properties of Ti-1023 alloy[J]. Advances in Titanium Industry, 2016, 33(4): 26-30. |

| [19] |

张飞奇, 陈文革, 闫超峰. 微量硼元素添加对Ti6Al4V-xB组织及性能的影响[J]. 稀有金属材料与工程, 2018, 47(3): 932-936. ZHANG F Q, CHEN W G, YAN C F. Effects of trace boron addition on the microstructure and properties of Ti6Al4V-XB[J]. Rare Metal Materials and Engineering, 2018, 47(3): 932-936. |

| [20] |

黄立国, 陈玉勇. 硼对钛合金成形能力和力学性能影响的研究进展[J]. 机械工程材料, 2016, 40(6): 8-13. HUANG L G, CHEN Y Y. Research progress on the effect of Boron on the formability and mechanical properties of titanium alloys[J]. Mechanical Engineering Materials, 2016, 40(6): 8-13. |

| [21] |

BANOTR, CHANDRAVANSHI V, BHATTACHRJEEA, et al. Effect of boron and carbon addition on microstructure and tribological properties of metastable beta titanium alloy, Ti-10V-2Fe-3Al[C]//Materials Today: Proceedings, 9th International Conference of Materials Processing and Characterization. Hyderabad: ICMPC, 2019: 2700-2707.

|

| [22] |

YENER T, ERDO AN A, GÖK M S, et al. Nb and B effect on mechanical properties of Ti-Al based intermetallic materials[J]. Vacuum, 2019, 169: 108867. DOI:10.1016/j.vacuum.2019.108867 |

| [23] |

ZHU J, KAMYA A, YAMADA T, et al. Influence of boron addition on microstructure and mechanical properties of dental cast titanium alloys[J]. Materials Science and Engineering: A, 2003, 339: 53-62. DOI:10.1016/S0921-5093(02)00102-8 |

| [24] |

HE Y, MONTGOMERY C, BEUTH J, et al. Melt pool geometry and microstructure of Ti6Al4V with B additions processed by selective laser melting additive manufacturing[J]. Materials & Design, 2019, 183: 108126. |

| [25] |

BERMINGHAM M J, MCDONALD S D, NOGITA K, et al. Effects of boron on microstructure in cast titanium alloys[J]. Scripta Materialia, 2008, 59(5): 538-541. DOI:10.1016/j.scriptamat.2008.05.002 |

| [26] |

ANIS A L, TALARI M K, KISHORE B N, et al. Grain refinement of Ti-15V-3Cr-3Sn-3Al metastable β titanium alloy welds using boron-modified fillers[J]. Journal of Alloys and Compounds, 2018, 749: 320-328. DOI:10.1016/j.jallcom.2018.03.286 |

| [27] |

ZHANG C J, KONG F T, XU L J, et al. Temperature dependence of tensile properties and fracture behavior of as rolled TiB/Ti composite sheet[J]. Materials Science and Engineering: A, 2012, 556: 962-969. DOI:10.1016/j.msea.2012.07.110 |

| [28] |

ZHOU D, LIU Y, SHEN B, et al. Structural prediction of ultrahard semi-titanium boride (Ti2B) using the frozen-phonon method[J]. Physical Chemistry Chemical Physics, 2016, 18(11): 7927-7931. DOI:10.1039/C6CP00758A |

| [29] |

LI P, ZHOU R, ZENG X C. Computational analysis of stable hard structures in the Ti-B system[J]. ACS Appl Mater Interfaces, 2015, 7(28): 15607-15617. DOI:10.1021/acsami.5b04332 |

| [30] |

HUANG L, QIAN M, WANG L, et al. High-tensile-strength and ductile novel Ti-Fe-N-B alloys reinforced with TiB nanowires[J]. Materials Science and Engineering: A, 2017, 708: 285-290. DOI:10.1016/j.msea.2017.09.136 |

| [31] |

罗皓, 陈志强. 硼改性钛合金研究进展[J]. 材料开发与应用, 2010, 25(4): 77-81. LUO H, CHEN Z Q. Research progress of boron modified titanium alloy[J]. Materials Development and Application, 2010, 25(4): 77-81. |

| [32] |

GORSSE S, PETITCORPS Y L, MATAR S, et al. Investigation of the Young's modulus of TiB needles in situ produced in titanium matrix composite[J]. Materials Science and Engineering: A, 2003, 340(1): 80-87. |

| [33] |

FENG Y, CUI G, ZHANG W, et al. High temperature tensile fracture characteristics of the oriented TiB whisker reinforced TA15 matrix composites fabricated by pre-sintering and canned extrusion[J]. Journal of Alloys and Compounds, 2018, 738: 164-172. DOI:10.1016/j.jallcom.2017.12.132 |

| [34] |

RIELLI V V, AMIGó-BORRáS V, CONTIERI R J. Single step heat treatment for the development of beta titanium composites with in-situ TiB and TiC reinforcement[J]. Materials Characterization, 2020, 163: 110286. DOI:10.1016/j.matchar.2020.110286 |

| [35] |

项娟, 韩远飞, 乐建温, 等. 颗粒增强钛基复合材料大塑性变形组织演变与性能[J]. 稀有金属材料与工程, 2020, 49(3): 901-906. XIANG J, HAN Y F, LE J W, et al. Microstructure evolution and properties of large plastic deformation of particle reinforced titanium matrix composites[J]. Rare Metal Materials and Engineering, 2020, 49(3): 901-906. |

| [36] |

LIN Y, JIANG C, LIN Z, et al. Laser in-situ synthesis of high aspect ratio TiB fiber bundle reinforced titanium matrix composite coating[J]. Optics & Laser Technology, 2019, 115: 364-373. |

2021, Vol. 49

2021, Vol. 49