文章信息

- 马珮珮, 李龙, 吴磊

- MA Pei-pei, LI Long, WU Lei

- 导电纱线的制备及其在智能可穿戴装置中的应用研究进展

- Research progress in preparation of conductive yarn and its application in smart wearable devices

- 材料工程, 2021, 49(10): 31-42

- Journal of Materials Engineering, 2021, 49(10): 31-42.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2020.000460

-

文章历史

- 收稿日期: 2020-05-25

- 修订日期: 2021-03-30

可穿戴装置是指可以直接穿戴在人身上的电子设备或是可以整合到服装上的便携式电子设备[1]。从可穿戴的角度来看,柔韧性是可穿戴的关键参数之一,也是必然的发展趋势。如果材料是刚性的,那么就舒适性而言,它将会大打折扣。一般来说,柔性可穿戴装置经历了从刚性化到柔性化再到智能化的过程,未来也将朝着信息精准化方向迈进。智能可穿戴装置的柔性化需要柔性衬底材料作为依托。目前,通过纺织材料、聚合物薄膜和导电涂层等柔性材料与纳米技术、电气、电子工程和纺织技术融合,可以研发适形、轻量化的柔性电子器件。可穿戴装置的制造一般需要考虑材料的可持续发展、柔性、良好的整体电学性能以及机械和环境的稳定性。与传统的电子器件相比,纺织材料由于柔软、可变形、透气、耐用、耐洗、低成本及高亲肤性等特点,能够满足人体的正常活动,因此非常适合作为未来可穿戴电子产品的开发[2]。纱线作为基本的纺织材料,在智能可穿戴装置中发挥着巨大的作用,而开发具有导电功能的纱线是满足智能可穿戴装置各种需求的突出研究领域之一[3-4]。这些要求包括应变传感器[5]、信号传输[6]、电子产品[7]和微电子中的个人防护以及一些医疗物理健康监测等。其中如何实现普通纱线具有导电性,且如何满足稳定的电学性能和穿着过程中的舒适性,是导电纱线应用于智能可穿戴装置的基础。本文综述了常见的金属基导电纱线、碳基导电纱线、导电聚合物基导电纱线的制备方法,并对导电纱线在智能可穿戴装置中的应用研究进行了阐述。

1 导电纱线及其制备导线纤维是制备导电纱线的重要组成原料,其大致分为两类:一类是天然的导电纤维,如金属纤维、碳纤维、共轭聚合物、光纤等,一般通过拉伸、削切等工艺制备得到[8-9];另一类是通过涂覆、浸渍、混合等方法将具有绝缘性能的材料与高导电材料,如金属基导电材料(银、铜、镍)、碳基导电材料(石墨烯、碳纳米管)、本征型导电高分子聚合物(聚苯胺、聚吡咯、聚噻吩)等结合得到的导电纤维,又称为复合型导电纤维[10-11]。表 1为导电纤维的种类及特点[12-13]。

| Type | Product | Characteristics |

| Conductive metal fiber | Stainless steel fiber, steel fiber | It can be prepared by drawing spinning method, the conductivity is close to metal, and the washing property is good.It is heavy and brittle, and the fiber is easy to break. |

| Conductive carbon fiber | Carbon black fiber, carbon nanotube fiber, graphene fiber | It can be prepared by wet spinning.It has poorer conductivity than metal fibers, good heat resistance, high modulus, lack of toughness, resistance to bending, no heat shrinkage, and limited scope of application. |

| Conductive polymer synthetic fiber | Intrinsically conductive polymers, such as polypyrrole compound | It can be prepared by the melt/dry-wet spinning method, which is soft light, and has relatively low conductivity. |

| Organic coated conductive fiber | Conductive metal/metal oxide coating, metal-plated fiber | It can be prepared by chemical plating, metal coating, chemical bath deposition, etc. It has good conductivity and high manufacturing cost, and is not resistant to water washing. |

| Conductive carbon paint (graphene, carbon nanotube coated fiber) | Simple and easy to use, with good conductivity, the preparation cost is high, the outer layer is easy to fall off. |

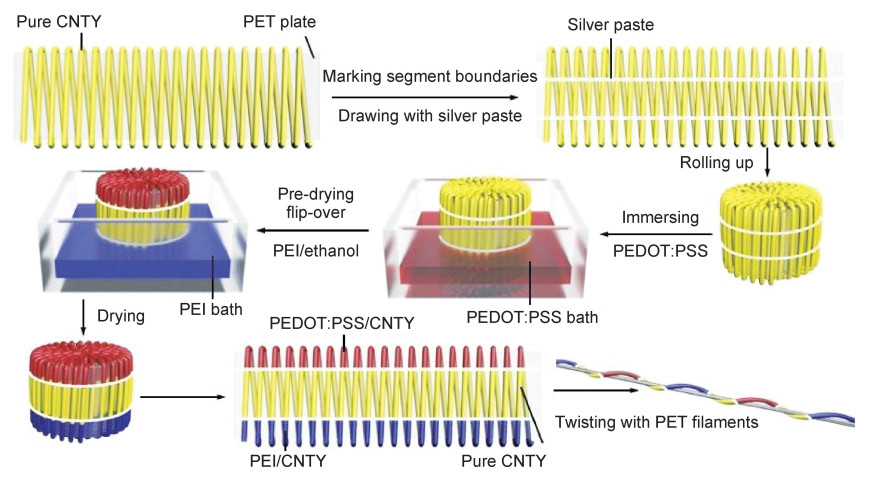

金属材料因具有良好的导电性,在可移动和可穿戴电子器件中应用广泛[14]。金属基导电纱线的制备方式较多,其中将金属丝或纤维通过不同形式加入(如包芯纱、混纺纱),是制备金属基导电纱线方式之一[15]。Shahzad等[16]将不锈钢(SS)纤维分别与聚酯纤维和粘胶纤维按12%和24%的质量比例混纺,在三种不同的捻系数下制备复合导电纱。根据混纺类型、混纺比、捻系数和相对湿度的变化,对纱线的导电性能进行了评价。研究发现,SS纤维含量对导电纱线电阻的影响最大,其次是捻系数和混纺类型。Pei等[17]使用改进的涡流纺纱系统,铜线依次穿过顶部前辊表面上的凹槽和纤维引导件的孔口送入纺丝喷嘴,制造了用于可穿戴电子设备的超细铜线的包芯纱。图 1为金属基导电纱线的制备示意图[17-19]。扫描电子显微镜照片证实,由于涡流纺纱系统的特殊纱线形成机理,铜线位于芯区中,并被包芯纱中外层的螺旋短纤维紧紧包裹,如图 1(a)所示。

|

图 1 金属基导电纱线的制备示意图 (a)含铜线的涡流包芯纱截面显微图[17];(b)通过LbL组件制备MCT基一维ASC的示意图[18];(c)PET/Au/Ni-MOF @碳电极的制备过程及其相应ASYS示意图[19] Fig. 1 Schematic diagrams of the preparation of metal-based conductive yarns (a)microscopic image of the cross-section of the vortex core-spun yarn containing copper wire[17]; (b)schematic illustration of the preparation of the MCT-based 1D ASC via LbL assembly[18]; (c)schematic illustration of the fabricating process of the PET/Au/Ni-MOF@carbon electrode and its corresponding ASYS[19] |

金属混纺纱线具有比导电聚合物基纱线更好的导电性。但金属纤维对皮肤的亲和性较差,且与导电聚合物基纱线相比,金属纱线的缝合相当困难,金属的脆性较大,在使用过程中,裸露的金属纤维容易发生断裂。

此外,金属基导电纱线也可以通过金属化涂层的方法制备得到。金属化涂层方式较多,但金属颗粒沉积在纱线表面可能造成纱线的柔性、舒适度下降。且金属颗粒在纱线表面的负载牢度也是需要考虑的问题。因此, 需要通过对纱线改性处理,提高纱线的电化学性。Shin等[18]使用有机介质中的胺功能化分子将金(Au)纳米颗粒逐层组装在高度多孔的棉纱上,以制备可储存大量电容的金属棉纱。并采用相同的组装方法,将Fe3O4和MnO纳米颗粒沉积在金属棉纱上,以制备非对称超级电容器的阳极和阴极(图 1(b))。此外,将Au纳米颗粒周期性地插入电容多层膜之间,以便于电荷传输。Yang等[19]将聚酯纱线先进行镀金,然后将导电金属有机骨架材料(MOFs)-Ni3(2, 3, 6, 7, 10, 11-六羟基三苯基)2(Ni3HHTP2)完全包覆在镀金涤纶丝(PET/Au)表面,以提高其电化学性能,如图 1(c)所示。采用这种简易浸涂法制备的全固态对称纱线超级电容器,在机械弯曲和拉伸条件下表现出非常稳定的电化学性能。

金属涂层纱线主要是通过一系列反应在纱线表面沉积金属颗粒,从而达到导电的效果。这就要求在纱线表面形成均匀、连续的层。为了满足上述要求,纱线表面要求光滑和高度抛光。因此,在涂层操作过程中需要特别小心,以便在纱线上形成厚度均匀的连续金属层,这一要求使得涂层过程成本很高。金属化涂层纱线的柔韧性比金属混纺纱要好,但金属涂层纱线的金属负载率较低,导电性较纯金属纱线差,且在使用过程中,金属涂层易脱落,导电耐磨性和耐水洗较金属混纺纱差。

1.2 碳基导电纱线随着碳基材料的发展,以石墨烯和碳纳米管为代表的碳材料,因同时具备较优异的导电性和力学性能,成为导电纺织品的重要材料, 在导电纱线的制备中具有广泛的应用[20-23]。

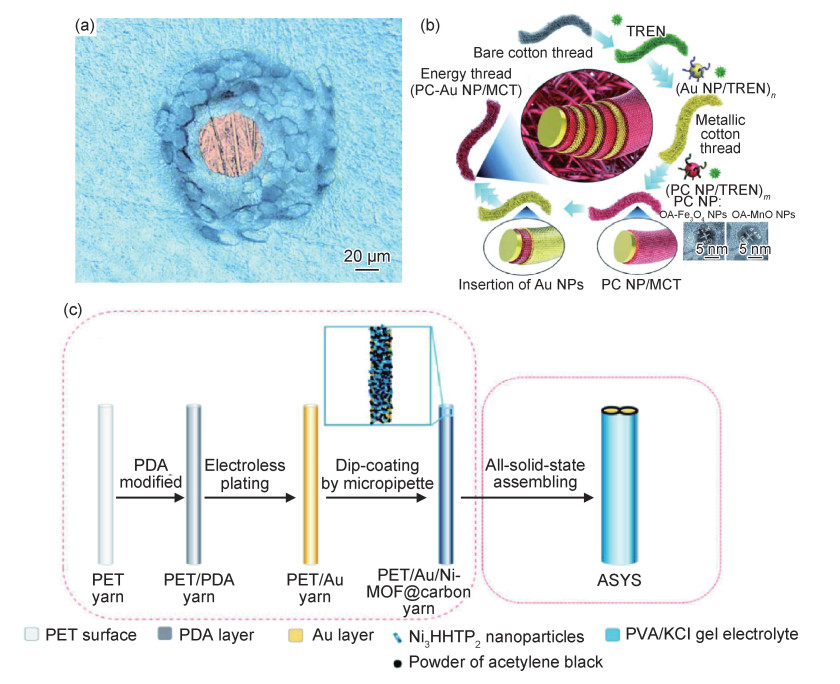

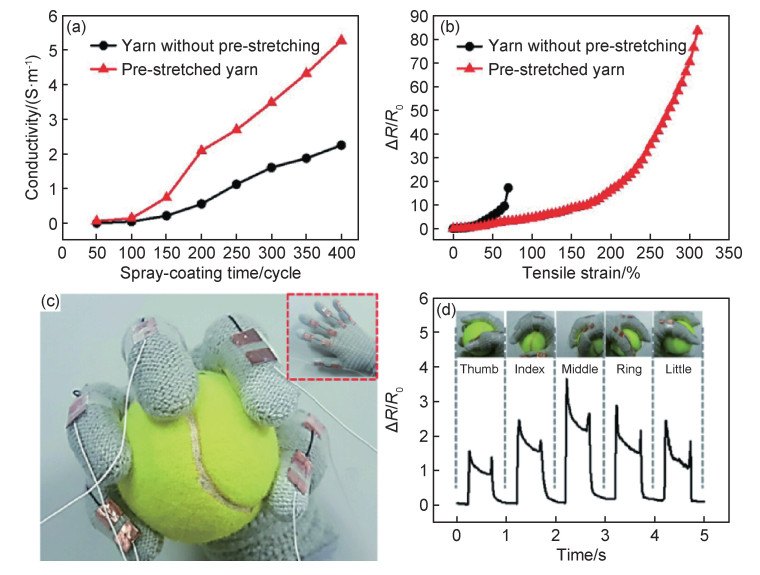

碳纳米管(CNTs)具有高力学性能、低密度以及优异的电学和热学性能[24]。单个碳纳米管具有非常低的电阻,对于直径为9.1 nm的多壁碳纳米管,电阻率低至5.1 μΩ·cm,因此,在航空航天和可穿戴纺织品中使用广泛,而将碳纳米管组装成纱线有望成为金属丝的替代品[25]。当碳纳米管被宏观组装成纱线时,碳纳米管的固有性能限制了由碳纳米管阵列纺成的碳纳米管纱的导电性,因此需要对CNTs纱线进行改性处理[26]。Dini等[27]通过化学掺杂、退火处理(2000 ℃以上)以及两者的结合,大幅度提高了碳纳米管纱线的导电性。并提出了一种新型高效的以氯化铂为基材的碳纳米管p型掺杂剂,将CNTs纱线的电阻率由3.4 mΩ·cm减小到1 mΩ·cm,并且稳定在半年以上。2000 ℃以上的退火处理大幅提高了碳纳米管结构质量。此外,还发现碳纳米管纱线的电阻率随碳纳米管结构质量的提高而线性降低。Tran等[28]利用湿法纺丝技术合成的CNT丝来制备高性能CNT/Au/Cu复合纱线,如图 2(a)所示。经过Au溅射预处理后,由于金属丝表面润湿性和反应性的提高,在碳纳米管丝上沉积的Cu更加均匀,CNT/Au/Cu复合丝的机械强度可达0.74 GPa(约为金属丝的2倍), 导电率可达4.65×105 S/cm(约为铜的80%),如图 2(b)所示。利用湿纺或干纺方法可以开发高性能碳纳米管纺织品[29]。这些方法包括碳纳米管在普通溶剂中的分散、高温退火和化学掺杂[30-32]。此外,由于弯曲、扭曲、拉伸、编织和化学洗涤等不同的机械和化学应力,CNTs用于智能可穿戴的可靠性不高。

|

图 2 碳基导电纱线的制备图 (a)在CNT导线样品上电沉积铜的实验装置[28];(b)CNT/Au/Cu复合导线与几种金属和未经任何后处理的干纺CNT导线制备的CNT/Cu复合导线的拉伸强度和电导率关系[28];(c)CNT-棉复合纱的纺纱工艺[34] Fig. 2 Preparation diagrams of carbon-based conductive yarns (a)experimental setup for electrodeposition of copper on CNT wire samples[28]; (b)relationship of the tensile strength and electrical conductivity of the CNT/Au/Cu composite wires in this work with several metals and the CNT/Cu composite wires fabricated from the dry-spunning CNT wires without any post-treatments[28]; (c)spinning process of CNT-cotton composite yarn[34] |

为了满足人体运动的更大拉伸要求,可将碳纳米管纤维与弹性纤维或普通纤维结合来制备导电纱线。Liu等[33]提出在拉伸的超弹纤维芯材上包裹定向排列的碳纳米管,制备了可拉伸的鞘芯导电纤维。该纤维可织入织物中,使织物作为智能设备的导电基础,这是智能服装最理想的设计状态。Yang等[34]开发了一种简便而原始的方法,制造棉粗纱和CNT相结合的柔性导电纱线。将CNT组装到棉粗纱上,然后在环锭纺纱中通过加捻被纤维包裹,如图 2(c)所示。所得的经CNT处理的棉纱(CNT-CYs)显示出良好的导电性和耐久性能。

CNTs具有较优异的导电性和力学性能,是可以代替金属材料的选择之一,但纯碳纳米管纱线耐磨性和抗弯曲较差,限制了其在纺织领域中的应用。且CNTs原料的价格昂贵,通过涂层方式制备的碳纳米管纱线导电耐久性差。因此,优化工艺是目前需要解决的一个问题。

石墨烯是一种二维同素异形碳原子,自发现以来已在许多行业得到应用[35]。石墨烯因其优异的电学、光学性能,以及易制备等优点,在纺织领域的应用越来越广泛,特别是用于功能纤维的制备及智能纺织品领域[36-37]。而氧化石墨烯(GO)是石墨烯的重要衍生物, 石墨烯经氧化后, 其含氧官能团增多, 性质也较石墨烯更为活跃。与传统碳基材料不同之处在于, 在复合材料纳米填充物中加入少量的氧化石墨烯, 可使其具有良好的导电、力学和导热性能[38]。Bai等[39]将氧化石墨烯涂层工艺与还原聚酯缠绕氨纶丝工艺相结合,建立了一种简便、低成本的石墨烯薄膜纱线传感器(graphene thin film enabled yarn sensors, GYS)的构建方法。通过系统的加工性能关系研究,发现预拉伸处理可以很好控制和调节GYS的电阻恢复程度和厚度灵敏度。Tas等[40]采用浸涂法对3000 tex的聚酰胺单丝纱进行了氧化石墨烯纳米材料的涂覆。然后用绿色化学还原法还原氧化石墨烯层,得到还原氧化石墨烯包覆单丝纱。通过物理、电学、光学和形态学研究,对氧化石墨烯和还原氧化石墨烯包覆聚酰胺单丝纱线的性能进行了表征。

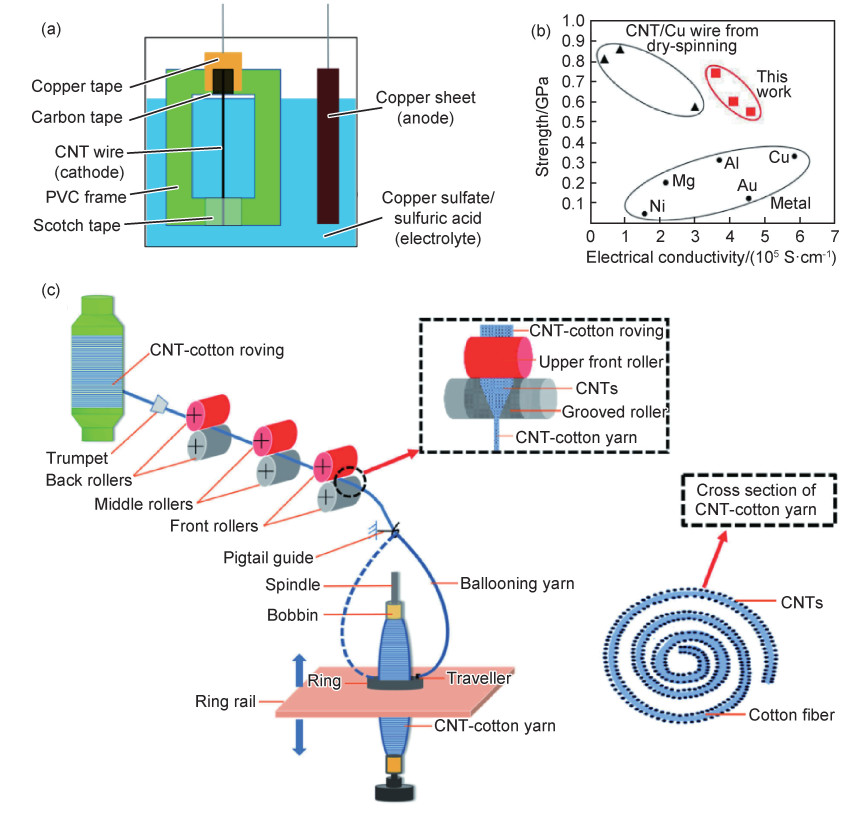

用石墨烯直接涂覆能够拉伸纱线或织物基材,可以为可穿戴设备提供所需的功能。浸涂法是最常用的将石墨烯纳米颗粒嵌入基材的方法,因为它是一种简单且成本低廉的方法,能够产生均匀的涂层。然而,这种方法制备的石墨烯基纺织品表现出相对较低的导电性和较差的机械耐久性,需要额外的处理。Yun等[41]在常规丝光功能化的棉纱(cotton yarns, CYs)上涂覆还原氧化石墨烯(RGO)片。采用拉曼光谱、傅里叶变换红外光谱(FTIR)、扫描电镜(SEM)和高分辨光学显微镜对样品的表面形貌和化学结构进行了表征。通过实验证实,室温丝光处理对制造高柔性和机械稳定性的导电纱是有效的方法。Son等[42]提出了一种基于石墨烯-纱线复合材料(graphene-yarn composite, GYC)的柔性应变传感器,该复合材料通过石墨烯纳米板的喷涂获得。为了提高拉伸性能,将石墨烯纳米片喷涂在预拉伸纱上。与浸涂法相比,喷涂法不仅提高了3.68倍的电导率,而且提高了2.1倍的拉伸性能。该传感器喷涂400次后,具有310%的高拉伸性能,如图 3 (a),(b) 所示。这种传感器可用于监测个人手指的运动,如图 3(c),(d)所示。石墨烯基导电填料具有良好的柔软性和应变敏感性, 可用于智能可穿戴装置中。但纺织品与导电填料之间的附着力差, 在使用过程中容易出现脱落的问题。所以,选择优异的黏合剂或优化工艺方法,提高纱线与填料之间的黏合强度,使纱线固有的拉伸性能得到充分利用是需要解决的问题。

|

图 3 石墨烯-纱线复合材料的柔性应变传感器的表征结果[42] (a)不同喷涂次数预拉伸前后GYC的电导率变化;(b)拉伸应变下GYC的相对电阻变化;(c)附有GYC应变传感器的手套抓取球的照片(插图是手套上每个手指关节附有GYC应变传感器的照片);(d)抓取球时每个手指关节上GYC应变传感器的响应信号(插图是抓取球时每个手指关节(拇指、食指、中指、环指和小指)上GYC应变传感器的照片) Fig. 3 Characterization results of graphene-yarn composite flexible strain sensor[42] (a)conductivity change of the GYC with and without pre-stretching for various numbers of spray coatings; (b)relative resistance change of GYC with and without pre-stretching under tensile strain; (c)photographs of ball being grabbed by glove with GYC strain sensors attached(inset: photograph of the GYC strain sensors attached to each finger joint on the glove); (d)response signals of the GYC strain sensors on each finger joint when the ball is grabbed(inset: photographs of GYC strain sensors on each finger joint(thumb, index, middle, ring and little fingers) when the ball is held) |

导电聚合物是一种柔弹性好、导电性能优异的高分子材料。在导电聚合物中,聚苯胺、聚吡咯因具有良好的环境稳定性和导电性而受到广泛关注[43-45]。聚合物链中的杂原子在独特的导电机制中起着重要作用。由于电子的广泛离域,导电聚合物很难加工成纤维或长丝[46]。因此,通常将导电聚合物与传统绝缘聚合物或材料混合来制备不同的导电复合材料,从而使导电复合材料保持传统聚合物的力学性能和导电聚合物的导电性[47-48]。导电聚合物基导电纺织品可采用原位化学、原位电化学、原位气相聚合、溶液涂覆等方法制备。原位聚合法主要是将纺织品浸渍在导电聚合物单体溶液中,通过溶液中氧化剂的作用发生氧化聚合,使得导电聚合物沉积在纺织品表面,从而赋予纺织品一定的导电性[49]。Pan等[50]报道了利用聚多巴胺功能化处理后在纱线表面原位聚合聚吡咯(PPy),并以编织复合纱线为原料制造高灵敏度耐磨应变传感器。研究了编织复合材料的机电性能和应变传感特性。Mallika等[51]采用原位聚合法将棉纱经23.4%(质量分数,下同)吡咯水溶液处理后,再经40.6%三氯化铁水溶液处理,然后在大气中干燥,纱线的导电性、拉伸强度和伸长率都得到了改善。在环锭纺、转杯纺和摩擦纺这三种纱线中,环锭纱在导电性和强力保持方面表现最好。Yildiz等[52]通过气相聚合技术在各种引发剂浓度下制备聚吡咯(PPy)涂层棉纱,分别以四种不同浓度(0.2,0.4,0.6 mol/L和0.8 mol/L)的氯化铁(FeCl3)用作引发剂,研究引发剂浓度对棉纱拉伸、电学和形态学性能的影响,并将聚吡咯沉积的涤纶纱线织成织物,以研究电磁屏蔽效果。

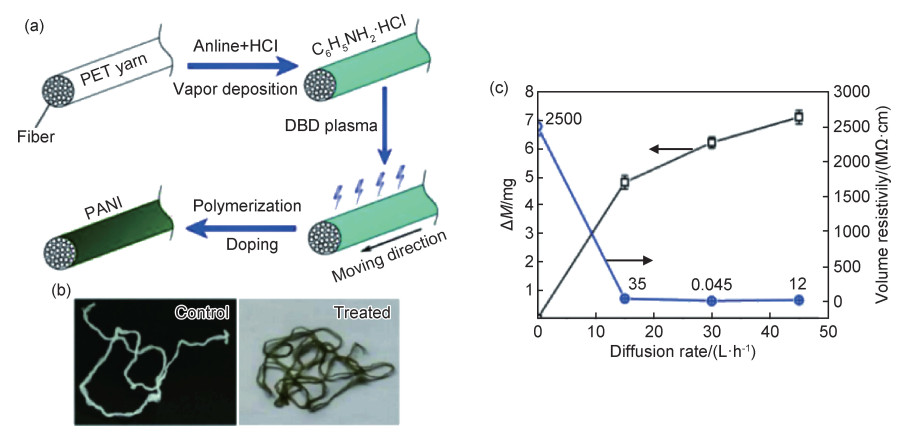

采用原位聚合法制备的导电纤维具有制备方便、纤维导电率较高等优点,但这种方法难以实现导电纤维的连续制备,设备设置也较为复杂。因此,可通过工艺改进降低原料的消耗,提高纱线导电稳定性。Hong等[53]提出了一种基于原位聚合的新方法,并实现了导电纱的连续制备。为了降低制备过程中苯胺、掺杂酸、氧化剂等原料的消耗,提出了进一步的改进措施。采用改进的原位聚合法制备了聚苯胺包覆导电丝素(silk fibroin, SF)纱。结果表明,改进后的方法比原方法降低了能耗,原材料减少90%以上。处理后的纱线具有良好的导电性能。Liu等[54]用一种简单方法制备了聚苯胺(PANI)导电PET丝,即在PET纱表面预先施加苯胺和HCl蒸汽,然后对PET纱进行后续介质阻挡放电等离子体处理。最佳样品的体积电阻率约为对照样品的1.8×105倍,如图 4所示。此外,由于等离子体接枝在PET纱线表面的含氧、含氮极性基因通过与空气射流中的水分子形成H键引起空气阻力上升。研究发现,随着PANI涂层量的增加,PET纱线的空气阻力逐渐改善。导电聚合物基纺织品由于其灵活性、固有的机械刚度、可伸缩电子设备的适应性结构,被认为是可穿戴技术的合适选择。目前遇到的问题是很难加工成纤维或长丝,固有导电聚合物的力学性能较差,不溶于水,呈现非熔融特性。为此,需要将固有导电聚合物与日常使用的聚合物结合起来,以克服预期的力学和物理性能。通过将导电聚合物沉积在纱线表面的方法存在导电聚合物分布不均匀和黏合度不够好的缺点,导致电学稳定性和耐久性较差。因此,可以选择合适的方法对纺织品工艺改进,如采用等离子体和超声波处理。

|

图 4 导电PET纱线的制备过程示意图(a),PANI理想氧化态的化学结构(b),以及PANI包覆量(ΔM)对PET纱线体积电阻率的影响(c)[54] Fig. 4 Schematic diagram of the preparation process of conductive PET yarn(a), chemical structures of idealized oxidation states of PANI(b), and the effect of coating amount(ΔM) of PANI on volume resistivity of PET yarns(c)[54] |

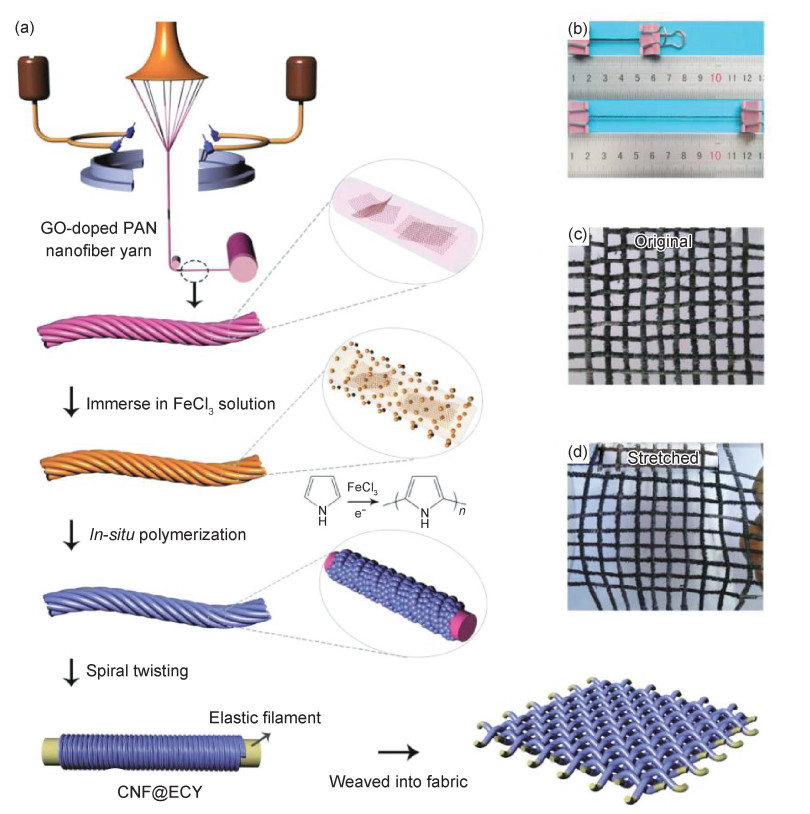

可穿戴应变传感器具有质量轻、舒适性和便携性等独特的优越性能[55-57]。可以实现在连续人体运动检测、体育锻炼、应急救援等各个领域的应用,是下一代电子产品的最佳候选者之一[58]。这些传感器在纺织品上的集成可以通过几种技术来实现,如喷墨打印、丝网印刷、印花转移、静电纺丝和浸涂等。由于市场上的拉伸传感器主要为刚性材料,缺乏柔性,从而降低了传感器的使用范围。利用导电纱线设计和构建基于织物的应变传感器是近年来备受关注的研究领域[59-60]。Nan等[61]设计了一种具有高柔度和可织性的织物传感器,可以检测由压力、应变和弯曲引起的机械力。织物状传感器由在弹性纱线上缠绕氧化石墨烯掺杂聚丙烯腈纳米纤维纱线与原位聚合导电聚吡咯形成的复合纱线(GCNF@ECYs)编织而成,如图 5所示。GCNF@ECY传感器单元灵敏度高(规范因子约68)、压力传感范围宽、循环稳定性和重复性好(超过10000次循环)。该传感器可以检测人体呼吸、面部表情、脉搏监测和全方位的人体运动。Souri等[62]对石墨烯纳米片(GNPs)和炭黑(CB)包覆天然纤维纱线制备导电纱线进行了系统研究。利用高导电纱线制造耐磨、可拉伸和耐用的应变传感器。应变传感器显示出良好的灵敏度,根据施加应变和位移率的大小,规范因子为1.46~5.62。应变传感器对高达60%的应变显示出可靠的机电响应,表明其在人体运动检测中的潜在应用。

|

图 5 电子织物的制造示意图(a),GCNF@ECY的原始和拉伸光学图(b),电子织物和相同材料在双轴拉伸状态下的光学图(c), (d)[61] Fig. 5 Schematic illustration of the fabrication of the electronic fabric(a), optical image of original and stretched GCNF@ECY(b), optical images of the electronic fabric and the same material under biaxial stretched state(c), (d)[61] |

超级电容器(SCs)作为储能器件具有高功率密度、长循环寿命、高倍率性能、环保、易维护、充放电速度快等优点,受到了广泛的关注[63-64]。近年来,可穿戴超级容器正在迅速发展,在能量收集、微型机器人、电子纺织品、表皮和可植入医疗器械等领域都有着巨大的应用潜力[65]。可弯曲和可拉伸电极是制备柔性超级电器的关键。一维柔性纱形超级电容器具有体积小、质量轻、携带方便、可编织等优点,是未来可穿戴电子产品的理想选择[66-70]。Zhang等[71]采用不锈钢/棉混纺纱线作为支撑体和集流器,生产聚吡咯包覆纱电极。在电流密度为0.6 mA·cm-2的条件下,制备的纱线超级电容器(yarn supercapacitor, YSC)具有344 mF·cm-2的比电容和良好的循环稳定性(1000次循环后电容保持率接近93%)。此外,YSC具有优越的柔韧性,可以在不破坏其原有结构和电化学性能的情况下编织到其他织物中,满足可穿戴电子储能器件的要求。Kang等[72]通过分步化学镀、电镀和煅烧工艺,使用商品尼龙纱作为基底,制造了高多孔镍纱(porous nickel yarns, PNY)。PNY由直径为5~10 μm的中空管状结构的多根纤维组成,可通过便捷的毛细管作用过程吸收CNTs溶液。制备的CNTs/PNY电极表现出典型的电化学双层电容性能,具有良好的柔韧性。

2.3 可穿戴电热装置柔性电加热元件是为可穿戴热电服装提供能量的重要部件,由导电材料和基底材料构成。导电纱线作为加热电阻元件应用到加热织物或加热服装中,是近年来智能加热服装的一个重要研究方向[73-75]。Zheng等[76]通过大规模缝制基于碳纳米管纱线的分段热电纱线(thermoelectric yarns, TEYs),制备了有机间隔织物形状的三维热电纺织品(three-dimensional thermoelectric textiles, TETs),如图 6所示。结合有限元分析和实验评价,说明织物结构显著影响发电量。优化设计的TET具有良好的耐磨性和稳定性,在ΔT=47.5时输出功率密度高达51.5 mW/m2,比功率高达171.7 μW/(g·K)。Wang等[77]探讨了不同电压及应变负载下,单一型三组分弹性导电复合纱线(tri-component elastic-conductive composite yarns, t-ECCY)的热响应与稳定性。研究表明,在不同的外加电压和应变变形条件下,纱线的热响应迅速,表面温度分布均匀,纱线的稳定性也通过交流电压开关周期得到证实。纱线在静态和动态两种模式下的性能表明了其在服装上施加特定电压受热均匀的潜力。t-ECCY装饰针织物不仅适用于显示、局部加热等功能,而且具有良好的循环稳定性,经50次循环、膨胀释放应变测试,其功能性能几乎没有退化。纱线的简单加工和优良的多功能特性是进一步设计和开发复杂、可伸缩和可穿戴的加热电子产品的重要步骤。

2.4 其他导电纱线由于可穿戴和电学性能良好,还可以作为信号传输和一些储能装置。锂硫电池具有较高的理论容量和能量密度,被认为是一种很有前途的选择。Yuan等[78]以含氮碳/碳纳米管/硫(NCNT/S)复合阴极和锂金属阳极为基础,研制了电缆型锂硫电池。采用湿法纺丝和炭化工艺制备了导电率高、掺氮量适当的碳纳米管纱线,并将其作为活性材料的自支撑导电骨架。NCNT/S纱线具有高的初始电容和良好的循环稳定性,在0.5 ℃下循环200次后,具有良好的循环稳定性,容量保持率达到87%。Choi等[79]为了给电子纺织品传输信号和能量,提出了一种具有0.01 Ω·m导电性的新型结构弹性杂化纱线,通过对直流电阻、共振频率、S11(反射)、S21(传输)的测量和比较,探讨了其应用于可穿戴纺织品电信号传输的可行性。

3 结束语随着柔性可穿戴产品的发展,智能可穿戴产品不仅需要满足纺织物的基本特性,而且可根据需要添加其他辅助功能性,如紫外线照射、抗菌、阻燃等。对于智能可穿戴产品,除了材料具有良好的电学性能,还需要具备耐洗涤性、柔性、弹性、透气性、可低成本批量加工等性能,以实现较长的生命周期和穿着舒适性。因此,实现智能可穿戴装置的大规模生产仍然是一个具有挑战性的课题。研究导电材料与纺织柔性材料的有机融合方式、纺织技术在柔性智能可穿戴装置加工中的应用,是发展可穿戴智能产品的重要途径。智能可穿戴装置已在不同的领域展现了许多新的可能,并广泛应用于健康监测、智能医疗等各个领域。导电纱线的开发与智能可穿戴产品的发展有着密切关系。研究固有柔性导电纤维材料、固有弹性导电纤维材料的制备技术是智能可穿戴导电纱与可穿戴装置创新发展的关键。碳基导电纱线与高分子导电聚合物基纱线由于其优异的电学性能和柔韧性,得到了越来越多的关注。对于涂覆导电纱线,普通纱线与涂层导电材料的黏合性、均匀分布性以及纱线的导电灵敏性、耐久性、可洗性、柔性、应变性仍是研究的主要问题。

| [1] |

孙悦, 范杰, 王亮, 等. 可穿戴技术在纺织服装中的应用研究进展[J]. 纺织学报, 2018, 39(12): 131-138. SUN Y, FAN J, WANG L, et al. Research progress of wearable technology in textiles and apparels[J]. Journal of Textile Research, 2018, 39(12): 131-138. |

| [2] |

田明伟, 李增庆, 卢韵静, 等. 纺织基柔性力学传感器研究进展[J]. 纺织学报, 2018, 39(5): 170-176. TIAN M W, LI Z Q, LU Y J, et al. Recent progress of textile-based flexible mechanical sensors[J]. Journal of Textile Research, 2018, 39(5): 170-176. |

| [3] |

WU G, YANG X, LI J, et al. Highly stretchable and conductive hybrid fibers for high-performance fibrous electrodes and all-solid-state supercapacitors[J]. Chinese Journal of Polymer Science, 2020, 38(5): 531-539. DOI:10.1007/s10118-020-2381-2 |

| [4] |

ZENG W, SHU L, LI Q, et al. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications[J]. Advanced Materials, 2014, 26(31): 5310-5336. DOI:10.1002/adma.201400633 |

| [5] |

LI X, KOH K H, FARHAN M, et al. An ultraflexible polyurethane yarn-based wearable strain sensor with a polydimethylsilo-xane infiltrated multilayer sheath for smart textiles[J]. Nanoscale, 2020, 12(6): 4110-4118. DOI:10.1039/C9NR09306K |

| [6] |

ATALAY O, KALAOGLU F, KURSUN BAHADIR S. Development of textile-based transmission lines using conductive yarns and ultrasonic welding technology for e-textile applications[J]. Journal of Engineered Fibers and Fabrics, 2019, 14: 1-8. |

| [7] |

CHOI M, KIM J. Electrical characteristics and signal transmission characteristics of hybrid structure yarns for smart wearable devices[J]. Fibers and Polymers, 2016, 17(12): 2055-2061. DOI:10.1007/s12221-016-6478-8 |

| [8] |

马飞祥, 丁晨, 凌忠文, 等. 导电织物制备方法及应用研究进展[J]. 材料导报, 2020, 34(1): 1114-1125. MA F X, DING C, LING Z W, et al. Research progress on preparation and application of conductive fabrics[J]. Materials Reports, 2020, 34(1): 1114-1125. |

| [9] |

黄雅婷. 导电纱线在功能性纺织品中的应用[J]. 印染, 2016, 42(8): 54-55. HUANG Y T. Application of conductive yarn in functional textiles[J]. China Dyeing & Finishing, 2016, 42(8): 54-55. |

| [10] |

吴雨曦, 王朝晖. 柔性导电纤维在智能可穿戴装备中的研究进展[J]. 纺织导报, 2018(9): 61-66. WU Y X, WANG Z H. Application progress of flexible conductive fibers in wearable equipment[J]. China Textile Leader, 2018(9): 61-66. |

| [11] |

丁长坤, 程博闻, 任元林, 等. 导电纤维的发展现状及应用前景[J]. 纺织科学研究, 2006(3): 32-39. DING C K, CHENG B W, REN Y L, et al. Development status and application prospect of conductive fiber[J]. Textile Science Research, 2006(3): 32-39. |

| [12] |

杨晨啸, 李鹂. 柔性智能纺织品与功能纤维的融合[J]. 纺织学报, 2018, 39(5): 160-169. YANG C X, LI L. Integration of soft intelligent textile and functional fiber[J]. Journal of Textile Research, 2018, 39(5): 160-169. |

| [13] |

王晓雷, 缪旭红, 李煜天, 等. 导电纱线在针织柔性应变传感器上的应用进展[J]. 毛纺科技, 2019, 47(3): 81-84. WANG X L, MIAO X H, LI Y T, et al. Progress in application of conductive yarns to knitted flexible strain sensors[J]. Wool Textile Journal, 2019, 47(3): 81-84. |

| [14] |

ZENG W, SHU L, LI Q, et al. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications[J]. Advanced Materials, 2014, 26(31): 5310-5336. DOI:10.1002/adma.201400633 |

| [15] |

WANG Y, GORDON S, BAUM T, et al. Multifunctional stretchable conductive woven fabric containing metal wire with durable structural stability and electromagnetic shielding in the X-band[J]. Polymers, 2020, 12(2): 399. DOI:10.3390/polym12020399 |

| [16] |

SHAHZAD A, ALI Z, ALI U, et al. Development and characte-rization of conductive ring spun hybrid yarns[J]. Journal of the Textile Institute, 2019, 110(1): 141-150. DOI:10.1080/00405000.2018.1507695 |

| [17] |

PEI Z, ZHANG Y, CHEN G. A core-spun yarn containing a metal wire manufactured by a modified vortex spinning system[J]. Textile Research Journal, 2019, 89(1): 113-118. DOI:10.1177/0040517517736477 |

| [18] |

SHIN D, KWON C H, KO Y, et al. Stitchable supercapacitors with high energy density and high rate capability using metal nanoparticle-assembled cotton threads[J]. Journal of Materials Chemistry A, 2018, 6(41): 20421-20432. DOI:10.1039/C8TA06840B |

| [19] |

YANG S, WANG Y, YUE Y, et al. Flexible polyester yarn/Au/conductive metal-organic framework composites for yarn-shaped supercapacitors[J]. Journal of Electroanalytical Chemistry, 2019, 847: 113218. DOI:10.1016/j.jelechem.2019.113218 |

| [20] |

冯亚菲, 曹京宜, 张寒露, 等. 新型碳材料在功能涂料中的应用[J]. 现代涂料与涂装, 2019, 22(12): 31-35. FENG Y F, CAO J Y, ZHANG H L, et al. Application of novel carbon materials on functional coating[J]. Modern Paint & Fini-shing, 2019, 22(12): 31-35. DOI:10.3969/j.issn.1007-9548.2019.12.010 |

| [21] |

宁亮, 王贤明, 韩建军, 等. 碳材料在导电涂料和隐身涂料领域的研究进展[J]. 中国涂料, 2016, 31(6): 40-45. NING L, WANG X M, HAN J J, et al. Research status of carbon material in conducting paint and stealth paint[J]. China Coa-tings, 2016, 31(6): 40-45. |

| [22] |

蔡东荣, 周菁, 段盼盼, 等. 导电织物的制备及应用研究进展[J]. 浙江理工大学学报(自然科学版), 2018, 39(6): 651-658. CAI D R, ZHOU J, DUAN P P, et al. Research progress on preparation and application of conductive fabrics[J]. Journal of Zhengjiang Sci-Tech University(Natural Sciences), 2018, 39(6): 651-658. DOI:10.3969/j.issn.1673-3851(n).2018.06.001 |

| [23] |

贾树生, 万振凯, 杨连贺, 等. 碳纳米线的拉伸应变传感特性[J]. 纺织学报, 2018, 39(3): 14-18. JIA S S, WAN Z K, YANG L H, et al. Tensile strain sensing characteristics of carbon nanoyarns[J]. Journal of Textile Research, 2018, 39(3): 14-18. |

| [24] |

DI J, ZHANG X, YONG Z, et al. Carbon-nanotube fibers for wearable devices and smart textiles[J]. Advanced Materials, 2016, 28(47): 10529-10538. DOI:10.1002/adma.201601186 |

| [25] |

JAROSZ P, SCHAUERMAN C, ALVARENGA J, et al. Carbon nanotube wires and cables: near-term applications and future perspectives[J]. Nanoscale, 2011, 3(11): 4542-4553. DOI:10.1039/c1nr10814j |

| [26] |

DINI Y, FAURE-VINCENT J, DIJON J. How to overcome the electrical conductivity limitation of carbon nanotube yarns drawn from carbon nanotube arrays[J]. Carbon, 2019, 144: 301-311. DOI:10.1016/j.carbon.2018.12.041 |

| [27] |

DINI Y, ROUCHON D, FAURE-VINCENT J Ì R M, et al. Large improvement of CNT yarn electrical conductivity by vary-ing chemical doping and annealing treatment[J]. Carbon, 2020, 156: 38-48. DOI:10.1016/j.carbon.2019.09.022 |

| [28] |

TRAN T Q, LEE J K Y, CHINNAPPAN A, et al. Strong, lightweight, and highly conductive CNT/Au/Cu wires from sputtering and electroplating methods[J]. Journal of Materials Science & Technology, 2020, 40: 99-106. |

| [29] |

XU Z, GAO C. Graphene fiber: a new trend in carbon fibers[J]. Materials Today, 2015, 18(9): 480-492. DOI:10.1016/j.mattod.2015.06.009 |

| [30] |

HIREMATH N, MAYS J, BHAT G. Recent developments in carbon fibers and carbon nanotube-based fibers: a review[J]. Polymer Reviews, 2017, 57(2): 339-368. DOI:10.1080/15583724.2016.1169546 |

| [31] |

YADAV M D, DASGUPTA K, PATWARDHAN A W, et al. High performance fibers from carbon nanotubes: synthesis, characterization, and applications in composites-a review[J]. Indu-strial & Engineering Chemistry Research, 2017, 56(44): 12407-12437. |

| [32] |

DIEZ-PASCUAL A M, NAFFAKH M, MARCO C, et al. Multiscale fiber-reinforced thermoplastic composites incorporating carbon nanotubes: a review[J]. Current Opinion in Solid State & Materials Science, 2014, 18(2): 62-80. |

| [33] |

LIU Z F, FANG S, MOURA F A, et al. Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles[J]. Science, 2015, 349(6246): 400-404. DOI:10.1126/science.aaa7952 |

| [34] |

YANG M, FU C, XIA Z, et al. Conductive and durable CNT-cotton ring spun yarns[J]. Cellulose, 2018, 25(7): 4239-4249. DOI:10.1007/s10570-018-1839-7 |

| [35] |

ALLEN M J, TUNG V C, KANER R B. Honeycomb carbon: a review of graphene[J]. Chemical Reviews, 2010, 110(1): 132-145. DOI:10.1021/cr900070d |

| [36] |

LIU W, YAN X, LANG J, et al. Flexible and conductive nanocomposite electrode based on graphene sheets and cotton cloth for supercapacitor[J]. Journal of Materials Chemistry, 2012, 22(33): 17245-17253. DOI:10.1039/c2jm32659k |

| [37] |

MENG Y, ZHAO Y, HU C, et al. All-graphene core-sheath microfibers for all-solid-state, stretchable fibriform supercapacitors and wearable electronic textiles[J]. Advanced Materials, 2013, 25(16): 2326-2331. DOI:10.1002/adma.201300132 |

| [38] |

姜小强, 刘智波, 田建国. 石墨烯光学性质及其应用研究进展[J]. 物理学进展, 2017, 37(1): 22-36. JIANG X Q, LIU Z B, TIAN J G. Research progress in optical properties and applications of graphene[J]. Progress in Physics, 2017, 37(1): 22-36. |

| [39] |

BAI M, ZHAI Y, LIU F, et al. Stretchable graphene thin film enabled yarn sensors with tunable piezoresistivity for human motion monitoring[J]. Scientific Reports, 2019, 9(1): 18644. DOI:10.1038/s41598-019-55262-z |

| [40] |

TAS M, ALTIN Y, BEDELOGLU A. Graphene and graphene oxide-coated polyamide monofilament yarns for fiber-shaped fle-xible electrodes[J]. Journal of the Textile Institute, 2019, 110(1): 67-73. DOI:10.1080/00405000.2018.1460039 |

| [41] |

YUN Y J, LEE H J, SON T H, et al. Mercerization to enhance flexibility and electromechanical stability of reduced graphene oxide cotton yarns[J]. Composites Science and Technology, 2019, 184(1): 107845. DOI:10.1016/j.compscitech.2019.107845 |

| [42] |

SON W, KIM K, LEE S, et al. Ecoflex-passivated graphene-yarn composite for a highly conductive and stretchable strain sensor[J]. Journal of Nanoscience and Nanotechnology, 2019, 19(10): 6690-6695. DOI:10.1166/jnn.2019.17097 |

| [43] |

OMASTOVA M, MICUSIK M. Polypyrrole coating of inorganic and organic materials by chemical oxidative polymerisation[J]. Chemical Papers, 2012, 66(5): 392-414. |

| [44] |

MAITY S, CHATTERJEE A. Conductive polymer-based electro-conductive textile composites for electromagnetic interference shielding: a review[J]. Journal of Industrial Textiles, 2016, 47(8): 2228-2252. |

| [45] |

MCCONNELL R, MCCONNELL M S, GREEN A, et al. Doped and undoped co-polymers of polyfuran, pyrrole, and thiophene: a chemical synthesis and conductivity studies[J]. Abstracts of Papers of the American Chemical Society, 2005, 229(1): 401. |

| [46] |

MAITY S, CHATTERJEE A. Preparation and characterization of electro-conductive rotor yarn by in situ chemical polymerization of pyrrole[J]. Fibers and Polymers, 2013, 14(8): 1407-1413. DOI:10.1007/s12221-013-1407-6 |

| [47] |

MOLINA J, ESTEVES M F, FERNANDEZ J, et al. Polyaniline coated conducting fabrics. chemical and electrochemical characterization[J]. European Polymer Journal, 2011, 47(10): 2003-2015. |

| [48] |

DAS D, SEN K, MAITY S. Studies on electro-conductive fabrics prepared by in situ chemical polymerization of mixtures of py-rrole and thiophene onto polyester[J]. Fibers and Polymers, 2013, 14(3): 345-351. DOI:10.1007/s12221-013-0345-7 |

| [49] |

洪剑寒, 韩潇, 陈建广, 等. 聚对苯二甲酸丙二醇酯/聚苯胺复合导电纱的电学与力学性能[J]. 纺织学报, 2017, 38(2): 40-46. HONG J H, HAN X, CHEN J G, et al. Electrical and mechanical properties of conductive polytrimethylene terephthalate/polyaniline composite yarns[J]. Journal of Textile Research, 2017, 38(2): 40-46. |

| [50] |

PAN J, YANG M, LUO L, et al. Stretchable and highly sensitive braided composite yarn@polydopamine@polypyrrole for wearable applications[J]. ACS Applied Materials & Interfaces, 2019, 11(7): 7338-7348. |

| [51] |

MALLIKA D, ATIN C, MAINAK M, et al. Development of biodegradable conductive cotton yarns by in-situ polymerisation of pyrrole[J]. Journal of the Textile Institute, 2019, 110(7): 1-6. DOI:10.1080/00405000.2018.1455312 |

| [52] |

YILDIZ Z, USTA I, GUNGOR A. Electrical properties and electromagnetic shielding effectiveness of polyester yarns with polypyrrole deposition[J]. Textile Research Journal, 2012, 82(20): 2137-2148. DOI:10.1177/0040517512449046 |

| [53] |

HONG J, HAN X, SHI H, et al. Preparation of conductive silk fibroin yarns coated with polyaniline using an improved method based on in situ polymerization[J]. Synthetic Metals, 2018, 235: 89-96. DOI:10.1016/j.synthmet.2017.12.002 |

| [54] |

LIU S, LIU D, PAN Z. The effect of polyaniline (PANI) coating via dielectric-barrier discharge (DBD) plasma on conductivity and air drag of polyethylene terephthalate (PET) yarn[J]. Polymers, 2018, 10(4): 351. DOI:10.3390/polym10040351 |

| [55] |

ZHOU Q, JIA C, YE X, et al. A knittable fiber-shaped supercapacitor based on natural cotton thread for wearable electronics[J]. Journal of Power Sources, 2016, 327: 365-373. DOI:10.1016/j.jpowsour.2016.07.048 |

| [56] |

LV T, YAO Y, LI N, et al. Wearable fiber-shaped energy conversion and storage devices based on aligned carbon nanotubes[J]. Nano Today, 2016, 11(5): 644-660. DOI:10.1016/j.nantod.2016.08.010 |

| [57] |

WEN Z, YEH M, GUO H, et al. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors[J]. Science Advances, 2016, 2: e160009710. DOI:10.1126/sciadv.1600097 |

| [58] |

SUSHMITHA V, SHIVAM K, RINKY S, et al. Direct growth of FeS2 on paper: a flexible, multifunctional platform for ultra-low cost, low power memristor and wearable non-contact breath sensor for activity detection[J]. Materials Science in Semiconductor Processing, 2020, 108: 104910. DOI:10.1016/j.mssp.2019.104910 |

| [59] |

彭军, 李津, 李伟, 等. 柔性可穿戴电子应变传感器的研究现状与应用[J]. 化工新型材料, 2020, 48(1): 57-62. PENG J, LI J, LI W, et al. Research progress and application of flexible wearable electronic strain sensor[J]. New Chemical Materials, 2020, 48(1): 57-62. |

| [60] |

吴玉婷, 潘志娟. 柔性可穿戴电子传感器的现状及发展趋势[J]. 现代丝绸科学与技术, 2019, 34(5): 22-25. WU Y T, PAN Z J. Current situation and development trend of flexible wearable electronic sensor[J]. Modern Silk Science & Technology, 2019, 34(5): 22-25. DOI:10.3969/j.issn.1674-8433.2019.05.008 |

| [61] |

NAN N, HE J, YOU X, et al. A Stretchable, highly sensitive, and multimodal mechanical fabric sensor based on electrospun conductive nanofiber yarn for wearable electronics[J]. Advanced Materials Technologies, 2019, 4(3): 1800338. DOI:10.1002/admt.201800338 |

| [62] |

SOURI H, BHATTACHARYYA D. Wearable strain sensors based on electrically conductive natural fiber yarns[J]. Materials & Design, 2018, 154: 217-227. |

| [63] |

CHENG M, MENG Y, MENG Q, et al. A hierarchical porous N-doped carbon electrode with superior rate performance and cycling stability for flexible supercapacitors[J]. Materials Chemistry Frontiers, 2018, 2(5): 986-992. DOI:10.1039/C8QM00023A |

| [64] |

MAO N, CHEN W, MENG J, et al. Enhanced electrochemical properties of hierarchically sheath-core aligned carbon nanofibers coated carbon fiber yarn electrode-based supercapacitor via polyaniline nanowire array modification[J]. Journal of Power Sour-ces, 2018, 399: 406-413. DOI:10.1016/j.jpowsour.2018.07.022 |

| [65] |

YANG S, WANG Y, YUE Y, et al. Flexible polyester yarn/Au/conductive metal-organic framework composites for yarn-shaped supercapacitors[J]. Journal of Electroanalytical Chemistry, 2019, 847: 113218. DOI:10.1016/j.jelechem.2019.113218 |

| [66] |

ULLAH S, YU J, LIU H, et al. Fabrication of MnO2-carbonized cotton yarn derived hierarchical porous active carbon flexible supercapacitor electrodes for potential applications in cable-type devices[J]. Applied Surface Science, 2019, 487: 180-188. DOI:10.1016/j.apsusc.2019.05.054 |

| [67] |

ZHAO P, YE X, ZHU Y, et al. Iodine-steam functionalized reduced graphene oxide/oxidized carbon yarn electrodes for knittable fibriform supercapacitor[J]. Journal of Power Sources, 2019, 442: 227188. DOI:10.1016/j.jpowsour.2019.227188 |

| [68] |

THI S L, THUY K T, VAN NGOC H, et al. Synergetic design of enlarged surface area and pseudo-capacitance for fiber-shaped supercapacitor yarn[J]. Nano Energy, 2020, 67: 104198. DOI:10.1016/j.nanoen.2019.104198 |

| [69] |

LIU M, CONG Z, PU X, et al. High-energy asymmetric supercapacitor yarns for self-charging power textiles[J]. Advanced Functional Materials, 2019, 29: 1806298. DOI:10.1002/adfm.201806298 |

| [70] |

HE N, LIAO J, ZHAO F, et al. Dual-core supercapacitor yarns: an enhanced performance consistency and linear power density[J]. ACS Applied Materials & Interfaces, 2020, 12(13): 15211-15219. |

| [71] |

ZHANG C, CHEN Z, RAO W, et al. A high-performance all-solid-state yarn supercapacitor based on polypyrrole-coated stainless steel/cotton blended yarns[J]. Cellulose, 2019, 26(2): 1169-1181. DOI:10.1007/s10570-018-2126-3 |

| [72] |

KANG C, CAO D, LIU Y, et al. High loading carbon nanotubes deposited onto porous nickel yarns by solution imbibition as fle-xible wire-shaped supercapacitor electrodes[J]. Journal of Energy Chemistry, 2018, 27(3): 836-842. DOI:10.1016/j.jechem.2017.05.009 |

| [73] |

李萍, 蒋晓文. 智能电加热服的研究进展[J]. 棉纺织技术, 2019, 47(9): 79-84. LI P, JIANG X W. Research progress in intelligent electric heating clothing[J]. Cotton Textile Technology, 2019, 47(9): 79-84. DOI:10.3969/j.issn.1001-7415.2019.09.020 |

| [74] |

方纾, 刘皓, 刘莉. 柔性电加热元件与智能加热服装服饰研究进展[J]. 北京服装学院学报(自然科学版), 2019, 39(2): 83-94. FANG S, LIU H, LIU L. Research progress of flexible electric heating element and intelligent heating clothing[J]. Journal of Beijing Institute of Clothing Technology(Natural Science Edition), 2019, 39(2): 83-94. DOI:10.3969/j.issn.1001-0564.2019.02.013 |

| [75] |

李雅芳, 刘皓, 赵义侠. 基于镀银纱线的电加热织物温度场模拟与电热性能[J]. 材料工程, 2019, 47(2): 68-75. LI Y F, LIU H, ZHAO Y X. Electric heating fabrics based on silver yarns and simulation of temperature field[J]. Journal of Materials Engineering, 2019, 47(2): 68-75. |

| [76] |

ZHENG Y, ZHANG Q, JIN W, et al. Carbon nanotube yarn based thermoelectric textiles for harvesting thermal energy and powering electronics[J]. Journal of Materials Chemistry A, 2020, 8(6): 2984-2994. DOI:10.1039/C9TA12494B |

| [77] |

WANG Y, GORDON S, YU W, et al. Structural architecture of wearable materials based on tri-component elastic-conductive composite yarn: toward a Joule heating application[J]. Textile Research Journal, 2019, 89(16): 3303-3311. DOI:10.1177/0040517518811937 |

| [78] |

YUAN H, ZHANG M, YANG C, et al. Cable-shaped lithium-sulfur batteries based on nitrogen-doped carbon/carbon nanotube composite yarns[J]. Macromolecular Materials and Engineering, 2019, 304(8): 1900201. DOI:10.1002/mame.201900201 |

| [79] |

CHOI M, KIM J. Electrical characteristics and signal transmi-ssion characteristics of hybrid structure yarns for smart wearable devices[J]. Fibers and Polymers, 2016, 17(12): 2055-2061. DOI:10.1007/s12221-016-6478-8 |

2021, Vol. 49

2021, Vol. 49