文章信息

- 魏水淼, 马盼, 季鹏程, 马永超, 王灿, 赵健, 于治水

- WEI Shui-miao, MA Pan, JI Peng-cheng, MA Yong-chao, WANG Can, ZHAO Jian, YU Zhi-shui

- 高熵合金增材制造研究进展

- Research progress in high entropy alloys by additive manufacturing

- 材料工程, 2021, 49(10): 1-17

- Journal of Materials Engineering, 2021, 49(10): 1-17.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2020.000820

-

文章历史

- 收稿日期: 2020-08-31

- 修订日期: 2021-06-09

2. 山推工程机械股份有限公司, 山东 济宁 272073

2. Shantui Construction Machinery Co., Ltd., Jining 272073, Shandong, China

高熵合金是含有5种或5种以上的主要元素,且每种元素的原子分数在5%~35%之间的一种新型合金,其概念最早由叶均蔚团队[1]在2004年提出。同年,Cantor等[2]也将其命名为等原子比多组元合金。随着研究的深入,也有研究人员发现了三元、四元等原子比的典型高熵合金[3-4]。高熵合金的设计理念打破了传统单一金属作为主元的设计框架,其特性由各主元集体主导。高熵合金凝固后形成具有BCC, FCC或FCC+BCC等简单晶体结构的固溶体相,无法区分溶质和溶剂组元。同时高熵合金独特的高熵效应、晶格畸变效应、迟滞扩散效应和鸡尾酒效应使其具有传统合金无法比拟的优异性能[5],如高强度、高硬度、高耐磨性及耐腐蚀性、高热阻、高电阻率、抗高温氧化、抗高温软化等。

目前,高熵合金的制备方法大多数是熔铸法(如真空电弧熔炼法)或粉末冶金法[6],并通过后续的轧制、锻造和退火处理等方法来改善合金性能。由于高熵合金具有高强度、高硬度,很难通过机械加工获得复杂的几何形状。而且常规铸态结构中存在疏松、气孔、偏析等典型冶金缺陷也会影响材料的最终性能,这限制了高熵合金的应用潜力。

增材制造技术不同于传统的减材加工,而是将计算机辅助设计(CAD)软件设计的实体三维数据模型用自下而上逐层累加的方式直接制造实体零件。这种工艺缩短了生产周期,并为制造复杂形状的零件提供了一种快捷有效的方法[7]。金属增材制造过程具有大温度梯度、高冷却速率(约106 K/s)等特点,可以获得简单的固溶体相和超细均质组织,并抑制脆性金属间化合物的形成。目前,金属增材制造的方法主要有两种,一种是粉末床熔融技术(powder bed fusion, PBF),如激光选区熔化(selective laser melting, SLM)、电子束选区熔化(electron beam melting, EBM)等;另一种是基于送粉和送丝工艺的直接能量沉积技术(direct energy deposition, DED),如激光近净成形技术(laser engineering net shape, LENS)、电子束熔丝沉积技术(electron beam freeform fabrication, EBF3)、电弧增材制造技术(wire arc additive manufacturing, WAAM)等。由于不同研究人员对送粉工艺(使用激光作为热源,通过喷嘴把粉末送进熔池的工艺)命名不同,下文中将激光熔融沉积(laser melting deposition, LMD)[8], LENS, 激光辅助增材制造(laser aided additive manufacturing, LAAM)[9], 激光3D打印(laser 3D printing)[10], 激光增材制造(laser additive manufacturing, LAM)[11]等技术统称为LMD。在高熵合金增材制造的研究中使用的技术主要有激光选区熔化(SLM)、电子束选区熔化(EBM)和激光熔融沉积(LMD),少数研究人员探索了喷墨挤压(ink-extrusion)和黏结剂喷射(binder jetting)等方式。

本文基于不同高熵合金体系梳理了国内外高熵合金增材制造的研究现状,阐述了不同成分高熵合金增材制造的快速凝固微观组织、偏析和析出及热处理之后的组织演变,重点分析了增材制造高熵合金的力学性能、变形及强化机理。同时提出了目前增材制造高熵合金过程中存在的问题,为综合优异性能(高强度-高塑性)高熵合金的研发以及采用增材制造技术大规模制备该类合金提供一定的参考。

1 高熵合金增材制造技术 1.1 激光选区熔化激光选区熔化也称激光粉末床熔融(laser powder bed fusion,L-PBF)是基于PBF技术的一种增材制造工艺,通过刮刀或铺粉辊将粉末平铺到基板上,高能激光束在每层切片的选定区域进行扫描,将当前零件切片轮廓内的金属粉末完全熔化。加工完一层后,成型平台下降一层高度,该高度即三维模型每层切片的厚度,然后继续下一层铺粉、激光扫描,最终直接成型零件,如图 1所示[12]。成型过程多在惰性气体的保护气氛下进行,防止金属与空气中的氧、氮、水蒸气等发生化学反应。SLM是目前成型精度最高的金属增材制造工艺,对形状复杂零件,可直接由三维模型直接形成最终的零件,无需模具且基本不需要后续机械加工。

高熵合金增材制造所使用的粉末材料主要是通过雾化技术制备的预合金粉末和通过机械合金化方式将各元素单质粉末混合而成的预混元素粉末。对于添加其他元素或增强相的高熵合金增材制造,多是将预合金粉末与其他粉末通过机械合金化方式进行球磨混合。目前的研究中,SLM技术使用的高熵合金粉末多数为雾化法制备的预合金粉末,最近Chen等在SLM制备CoCrFeMnNi高熵合金时使用了预合金CoCrFeNi粉末与Mn粉搅拌的预混合粉末,并将这种方式称为SLM原位合金化[13]。

1.2 激光熔融沉积激光熔融沉积(LMD)通过喷嘴喷射粉末,在成型平台上形成粉末聚集的焦点,同时激光束照射在该焦点处使粉末熔化形成熔池并沉积下来,粉末与激光按照切片层零件信息同步移动,形成熔池轨迹不断熔合,在每一层重复这一过程最终形成层层沉积的零件,如图 2所示[9]。LMD技术通过惰性气体吹粉,一般不需要密闭的加工环境,理论上对成型零件的尺寸没有限制,并且具有较高的成型效率,但成型精度和表面粗糙度较SLM工艺低,成型件还需要进行少量后续机械加工才能应用。

利用LMD工艺制备高熵合金时,除了使用预合金粉末,还可以使用多喷嘴设备对各种元素粉末进行单独送粉。增材制造AlxCoCrFeNi系高熵合金时,为了控制Al的含量,可以采用双喷嘴LMD设备分别送进CoCrFeNi混合粉末和低密度铝粉[14]或使用多喷嘴的LMD设备实现5种元素粉末单独同时送粉[15],这种制备合金的方式称为原位合金化。另外,在加工过程中通过控制送粉率还可以实现合金成分的梯度变化,从而快速制备梯度材料,这种基于LMD制备梯度高熵合金的方式称为高通量(high throughput)筛选技术。

1.3 电子束选区熔化电子束选区熔化(EBM)在成型原理上与SLM工艺基本相似,差别主要是热源不同。电子束在电磁偏转线圈的作用下对粉末层中特定区域进行扫描熔化,一层加工完成后,成型平台下降一层高度,进行下一层铺粉与电子束扫描熔化,经过层层堆积直至加工完成,如图 3所示[16]。与SLM工艺相比,EBM工艺整个成型过程在真空环境中进行,并且具有能量利用率高、无反射、功率密度高等优点。EBM设备中对粉床的预热使EBM过程具有比SLM过程较低的冷却速率和较小的温度梯度,有利于降低残余应力、变形和开裂倾向,尤其适用于成型难熔高熵合金和脆性材料。目前利用EBM工艺制备高熵合金的研究较少,使用的粉末均为预合金粉末。

2 高熵合金增材制造研究现状 2.1 CoCrFeNi系高熵合金在众多的高熵合金体系中,增材制造CoCrFeNi系高熵合金的研究最早且最为广泛,通过添加Mn, Al, Ti, Mo, Zr等元素以及C, N, Si等非金属元素,可以改变其晶体结构从而改善其各项性能,衍生出其他高熵合金体系。表 1汇总了部分增材制造CoCrFeNi系高熵合金研究进展[17-28]。

| Method | Composition | σy/MPa | σuts/MPa | εf/% | Segregation | Remark | Reference |

| SLM | FeCoCrNi | 600 | 745 | 32 | No | [17] | |

| SLM | CoCrFeNi | 572±7.5 | 691.0±15.9 | 17.9±0.9 | No | [18] | |

| SLM | FeCoCrNi | 581.9 | 707.9 | ≈20 | [19] | ||

| Ink-extrusion | CoCrFeNi | 250±5 | 598±8 | 33.8±1.3 | Sintering | [20] | |

| SLM | FeCoCrNiC0.05 | 638 | 797 | 13.5 | No | [21] | |

| SLM | FeCoCrNiC0.05 | 638 | 795 | 13.5 | Cr along dislocation networks | Annealed at 400 ℃ for 3 h followed by water quenching | [22] |

| SLM | FeCoCrNiC0.05 | 787 | 950 | 10.3 | C and Cr on grain boundaries | Nano-scale Cr23C6 type carbides can precipitate under annealing at 1073 K for 0.5 h | [23] |

| SLM | 1.8%(atom fraction) N-doped FeCoNiCr | 650 | 853 | 34 | [24] | ||

| SLM | FeCoCrNiSi0.05 | 701±14 | 907±25 | 30.8±2 | No | By remelting each layer after its initial laser scanning | [25] |

| LMD | CoCrFeNiNbx | ≈410(Nb0.1) | ≈690(Nb0.1) | 55(Nb0.1) | Laves phase was enriched in Nb | As the Nb concentration increased, both yield and fracture strengths increased but tensile ductility decreased | [26] |

| LMD | CoCrFeNiMo0.2 | 500(77 K) | 928(77 K) | 60(77 K) | [27] | ||

| LMD | Ni2.1CoCrFeNb0.2 | 896 | 1127 | 17 | Nb | At 1250 ℃ for 1 h followed by water quenching,then at 650 ℃ aged for 96 h | [28] |

增材制造的CoCrFeNi系高熵合金为单相FCC固溶体结构,化学成分均匀,没有明显的偏析。Brif等[17]首次使用SLM制备的等摩尔FeCoCrNi高熵合金与铸态试样相比力学性能明显提高,证实了增材制造高熵合金的可行性。CoCrFeNi高熵合金在SLM制备时条状扫描路径比棋盘状扫描的性能更好[18]。Lin等[19]发现随着退火温度的升高,试样结构从柱状晶粒再结晶为包含大量退火孪晶的等轴晶粒,并且残余应力几乎被完全消除。Kenel等[20]使用含有混合氧化物纳米粉末(Co3O4+Cr2O3+Fe2O3+NiO)的油墨进行3D喷墨挤压打印,经过共还原、互扩散和烧结形成接近全密度的CoCrFeNi高熵合金并保持稳定的FCC相,在常温和低温下具有优异的力学性能,为使用非束流进行高熵合金增材制造提供了新思路。

目前研究较多的是以CoCrFeNi高熵合金为基础添加其他元素的CoCrFeNi系高熵合金。Zhou等[21]通过SLM工艺制备了含碳的FeCoCrNi高熵合金(FeCoCrNiC0.05)。合金组织是没有碳化物相的单一FCC结构,在较优参数下制备的试样中碳分布均匀,基体中没有偏析。退火后合金中析出纳米级的Cr23C6型碳化物,析出物主要分布在晶界或胞状结构上[23]。Song等[24]利用SLM工艺在氩气和氮气气氛中制备了仍保持单相FCC结构的含氮FeCoNiCr高熵合金,N元素均匀溶解在FCC基质中。这产生了包括双峰晶粒结构、低角度边界和位错网络的异质分层结构,并且实现了强度和延展性的同时提高。Lin等[25]采用由球形Fe, Co, Ni和50CrNi粉末组成的预混合粉末,通过SLM制备了含1.5%(原子分数)Si的FeCoCrNi高熵合金,是目前少见的将预混合粉末用于SLM工艺的研究。试样由柱状晶粒组成,每个柱状晶粒中含有大量单相FCC固溶体的亚晶粒,没有析出或元素偏析现象,在保持较好塑性的同时具有较高的强度。

Zhou等[26]通过LMD制备了CoCrFeNiNbx高熵合金,随着Nb元素的加入,其组织从柱状组织向等轴状组织转变,并倾向于在枝晶间和晶界形成HCP结构的Laves相,最终为FCC-Laves双相结构。CoCrFeNiMo0.2高熵合金呈现单相FCC结构,由柱状晶粒组成。该合金表现出优异的低温力学性能,并且耐腐蚀性高于304不锈钢基材,其腐蚀电流密度甚至低于316L不锈钢[27]。

CoCrFeNi高熵合金增材制造成型质量较好,试样致密度均在99%以上,但晶粒结构多为柱状晶,这与CoCrFeNi高熵合金的FCC基体结构有关,在相似的激光加工条件下,单相FCC结构的高熵合金更容易形成柱状晶[29]。C和Nb的添加可促进等轴晶的形核,而N和Si的添加可以实现强度和塑性的同时提高。

2.2 CoCrFeNiMn高熵合金CoCrFeNiMn高熵合金是目前研究最为广泛的一种高熵合金,而增材制造CoCrFeNiMn合金具有与原始粉末相同的单一FCC相。XRD检测到的(111)峰向更高的2θ角移动并宽化,表明(111)晶面间距减小,原因是在SLM过程中Mn元素的烧损,所以SLM制备的该合金比粉末的晶格常数小[7]。多数情况下,微观组织由外延生长的柱状枝晶和等轴晶组成,制造过程中的快速定向凝固使枝晶的生长方向与激光扫描方向垂直[11]。多数LMD制备的高熵合金具有典型的枝晶结构,原因是LMD的扫描速率明显低于SLM的扫描速率,导致冷却速率低,从而不能实现等轴晶。

增材制造过程中的快速凝固可以抑制元素偏析。在SLM制备的CoCrFeNiMn高熵合金中,Mn在熔池边界处存在轻微偏析,其他元素分布均匀[7, 30]。由于在LMD中倾向于生成柱状晶,Mn和Ni易在晶界偏析[9, 31-32],同样,在EBM中Mn, Ni偏析于枝晶间,Fe, Cr, Co偏析于枝晶[33]。但在合适的工艺参数下,无论是SLM还是LMD制备的试样,各元素均表现出均匀分布无偏析[8, 34-35]。表 2总结了部分增材制造CoCrFeNiMn高熵合金的晶粒尺寸、力学性能、元素偏析、晶体结构和强化机理[7-11, 30-33]。

| Method | Grain size/ μm | σy/MPa | σuts/MPa | εf/% | Segregation | Microstructural evolution | Strengthening mechanism | Reference |

| SLM | ≈1 | 519 | 601 | 35 | Mn is segregated at the boundary of weld pool | After HIP, the Mn segregation disappeared | Grain boundary strengthening | [7] |

| SLM | ≈12.9 | 510 | 609 | 34 | Minor segregation of Mn along the melt pool boundaries | Deformation induced twins | Dislocation strengthening | [30] |

| LMD | 564(77 K) | 891(77 K) | 36(77 K) | Mn, Cr | When the strain increases to 18%, deformation twinning appears | Grain boundary strengthening,dislocation strengthening | [11] | |

| LMD | 3-4 | 710 (-130 ℃) | 850 (-130 ℃) | 40.2 (-130 ℃) | Mn and Ni segregate into grain boundary | Deformation induced twins | Grain boundary strengthening,dislocation strengthening | [9] |

| LMD | 50-200 | 402(77 K) | 878(77 K) | 95(77 K) | No | Grain boundary strengthening,dislocation strengthening | [8] | |

| EBM | ≈65 | 205±3 | 497±2 | 63±1 | Mn and Ni segregate into the interdendrite | Dislocation strengthening | [33] | |

| LMD | 30-150 | 448 | 620 | 57 | Fine BCC phase distributed at the grain boundaries of the FCC matrix | Precipitation strengthening | [10] | |

| LMD | 10 | 346 | 566 | 27.5 | Mn and Ni segregate into grain boundary | BCC phase appears in heat treatment | Residual stress relief by heat treatment | [31] |

| LMD | ≈13 | 517 | 26 | Mn and Ni segregate into grain boundary | Deformation induced twins | Grain boundary strengthening,dislocation strengthening | [32] |

增材制造重复的热循环过程导致合金复杂的组织演变,形成了丰富的初始异质结构。如在FCC基体中同时存在四方σ相和纳米孪晶[7],FCC基体的晶界上分布有细小的BCC相[10]等。制备过程中的大温度梯度和高冷却速率容易引起高热应力并引发裂纹,是影响致密度的主要因素。Zhang等[36]在不同的扫描策略(每层旋转0°, 90°和67°)制备的试样中均观察到了裂纹,并且裂纹周围没有观察到偏析或沉淀。其中0°扫描的裂纹密度和最大裂纹长度均大于其他角度,而67°扫描的裂纹密度和最大长度略小于90°扫描的裂纹密度和最大长度。

CoCrFeNiMn高熵合金增材制造工艺窗口较窄,并且微观组织、元素分布、裂纹和孔隙等对工艺参数和扫描策略比较敏感,后续的热处理和热等静压处理可以改善合金的性能。热等静压处理不仅可以消除偏析,减少合金中的微裂纹、微气孔,还能显著降低合金中的残余应力[7]。Tong等[31]发现合金初始微观组织在熔池边界内部主要是柱状晶粒,而熔池边界外部为等轴晶粒,1100 ℃热处理后组织完全为等轴晶粒结构,且晶粒尺寸与热处理温度成正比。除了后续处理,对工艺参数优化和预测也是调控微观组织、抑制缺陷产生获得高质量成型件的一个重要研究方向。

为进一步提高综合力学性能,研究人员探索了增材制造CoCrFeNiMn高熵合金复合材料,汇总于表 3[37-45]。目前,增材制造高熵合金复合材料所使用的粉末多是预合金CoCrFeNiMn粉末与所添加材料混合制备的预混合粉末。采用LMD制备的添加TiC[37],WC[38],CeO2[41],Al[42]的CoCrFeNiMn高熵合金,其微观组织中均出现了第二相。纳米TiN颗粒改性的CoCrFeNiMn高熵合金在SLM工艺中成型质量比CoCrFeNiMn高熵合金要差,这是因为陶瓷颗粒的表面层需要更多的能量输入和更小的扫描间距以形成致密的微观结构。具有高熔点和高热稳定性的纳米颗粒有助于诱导异质形核促进FCC晶粒为等轴晶,由于陶瓷颗粒在凝固过程中起到钉扎作用,可阻挡FCC晶粒长大,使晶粒更细小[39]。SLM过程中对每一层进行重熔实现了纳米TiN颗粒在高熵合金基体中更均匀的再分配,颗粒越分散越有利于高熵合金晶粒细化[40]。

| Method | Addition | Crystal structure | σy/MPa | σuts/MPa | εf /% | Strengthening mechanism | Reference |

| LMD | TiC | FCC+TiC | 385 | 723 | 32 | Second-phase strengthening | [37] |

| LMD | WC | FCC+Cr23C6 | 800 | 37 | Grain boundary strengthening,precipitation strengthening | [38] | |

| SLM | TiN | FCC+TiN-particles | 1036 | 12 | Grain boundary strengthening,dislocation strengthening | [39] | |

| SLM | TiN | FCC+TiN-particles | 1100 | 18 | [40] | ||

| LMD | CeO2 | FCC+oxides | [41] | ||||

| LMD | Al | FCC+BCC | 506 | 736 | 41.2 | Grain boundary strengthening | [42] |

| SLM | C | FCC+nano precipitate | 829 | 989 | 24.3 | Solution strengthening,dislocation strengthening,precipitation strengthening | [43] |

| SLM | C | γ-austenite | 900 | 30 | Precipitation strengthening | [44] | |

| SLM | C | 741 | 874 | 39.7 | Grain boundary strengthening,dislocation strengthening | [45] |

Park等[43]研究了(CoCrFeMnNi)99C1(原子分数/%,下同)高熵合金,表明SLM工艺可以使碳添加的强化效果最大化,因为纳米碳化物精细分布在凝固胞状结构的边界上。Kim等[44]在较低的扫描速率下制备的C-CoCrFeMnNi高熵合金由γ-奥氏体组成,并且有胞状网络和纳米尺寸的沉淀物广泛分布在γ-奥氏体基体中,在胞状网络中同时发生MnNi偏析和CoCeFe贫化。

总之,在高熵合金中添加其他元素形成的复合材料可改善微观组织,有助于实现强度和塑性的协同增强,添加碳不仅阻止了晶粒的长大,而且还生成了纳米碳化物,添加纳米TiN颗粒有助于生成等轴晶。

2.3 AlxCoCrFeNi系高熵合金相对于等摩尔CoCrFeNiMn系高熵合金,AlxCoCrFeNi系高熵合金具有更多的非等原子比成分设计,使该系高熵合金的微观组织更加复杂。由于Al元素是一种BCC相稳定元素,多数研究人员通过调整Al元素在FCC体系中的含量来控制合金的微观结构。目前对铸态AlxCoCrFeNi系高熵合金的大量研究表明,随着Al含量的增加,AlxCoCrFeNi高熵合金晶体结构会发生改变,x≤0.4时为单相FCC结构,0.5≤x≤0.9时为FCC+BCC结构,x≥1.0时为BCC结构。表 4总结了部分国内外增材制造AlxCoCrFeNi系高熵合金的研究[14-15, 46-62]。

| Method | Composition | Mechanical property | Segregation | Crystal structure | Reference |

| LMD | Al0.3CoCrFeNi | Tension and compression yield strength:194 MPa,tensile elongation 38% | Grain boundary rich in Al | FCC | [14, 46] |

| SLM | Al0.3CoCrFeNi | Tensile strength:896 MPa,yield strength:730 MPa,elongation:29% | FCC | [47] | |

| LMD | Al0.3FeCoCrNi | Tensile yield strength 410 MPa | FCC,precipitation of L12 after HT | [48] | |

| SLM | Al0.5CrFeCoNi | Tensile strength:878 MPa,yield strength:540 MPa,elongation:18% | Al and Ni rich in columnar intergranular | BCC+FCC | [49] |

| SLM | Al0.5FeCoCrNi | Tensile strength:721 MPa,yield strength:579 MPa,elongation:22% | FCC | [50] | |

| LMD | Al0.6CoCrFeNi | Compression yield strength:400 MPa, compressive strength is 1420 MPa, tensile strength is 930 MPa | Grain boundary rich in Al, Ni | FCC/BCC | [14, 46] |

| LMD | AlxCoCrFeNi (0.3 < x < 0.7) | FCC(x=0.3) FCC+B2(x=0.7) | [51] | ||

| LMD | AlxCoCrFeNi (x=0.3, 0.7) | FCC(x=0.3) FCC+BCC(x=0.7) | [52] | ||

| LMD | Al0.85CoCrFeNi | Compression yield strength:1400 MPa,elongation to failure:0.25 | BCC rich in Fe, Cr | BCC+B2 | [14, 46] |

| LMD | AlxCoCrFeNi (0.15 < x < 1.32) | FCC(x≤0.37) BCC/B2(x≥1.16) | [53] | ||

| LMD | AlCoCrFeNi | AlNi-rich matrix,FeCr- rich precipitates | B2+BCC precipitates | [54] | |

| LMD | AlCoCrFeNi | Aged at 1200 ℃/168 h,compression yield strength:1.13 GPa,fracture stress:3.02 GPa,elongation:24.2% | B2 rich in Al-Ni FCC rich in Fe-Cr | B2 matrix+FCC precipitates after aging | [55] |

| EBM | AlCoCrFeNi | Compression yield strength:1015 MPa,fracture strain 26.4%;tensile strength 1073.5 MPa,yield strength 769 MPa,elongation 1.2% | B2 rich in Al-Ni BCC rich in Cr-Fe | B2/BCC matrix+FCC precipitates | [56-57] |

| SLM | AlCoCrFeNi | B2 rich in Al-Ni | B2+A2+Fe-Cr precipitates | [58] | |

| SLM | AlCoCrFeNi | Cr | B2/BCC | [59] | |

| Binder jetting | AlCoCrFeNi | Compression yield strength:(1461±23) MPa, elongation to failure:(31.46±2.1)% | AlNi-rich B2 CrFe-rich BCC | B2/BCC+FCC+σ phase | [60] |

| LMD | AlCoCrFeNi2.1 | Compression yield strength is (711±23) MPa at 400 ℃ | L12 phase is rich in Ni and deficient in Al | L12+BCC | [15] |

| LMD | AlxFeCoCrNi2-x (0.3 < x < 1.7) | γ+B2(x=0.7) A2+B2+L12(x=1) | [61] | ||

| LMD | AlCoxCr1-xFeNi (0 < x < 1) | Ni+Al rich,Fe+Co rich | BCC+B2 | [62] |

基于LMD的原位合金化和高通量成分筛选技术可以快速探索高熵合金的成分,有效筛选新型合金。Li等[53]制备了x=0.15~1.32的AlxCoCrFeNi高熵合金系列,发现随着Al含量的增加,晶体结构由无序FCC结构转变为无序BCC结构和有序B2结构的混合体,并且具有较宽的多相(FCC+BCC/B2)成分范围,如图 4所示[53]。Gwalani等[51]进行了相似的研究。另外,Borkar等[62]在LMD制备的AlCoxCr1-xFeNi(0≤x≤1)高熵合金研究中发现不同Co, Cr含量合金中形成的相变化不大, 均为BCC和B2相,随着Cr含量的增加,BCC晶粒发生明显的调幅分解。Sistla等[61]发现Al还有增加σ相形成的趋势。

Joseph等[14]使用LMD制备的FCC结构Al0.3CoCrFeNi高熵合金中存在细长的柱状晶和横跨打印方向的等轴晶,在晶界处有少量Al偏析和第二相颗粒;FCC/BCC结构的Al0.6CoCrFeNi高熵合金具有Widmanstätten晶粒结构,晶间主要由富集Ni和Al的单相BCC和调幅分解的BCC相组成;BCC结构的Al0.85CoCrFeNi高熵合金也形成了柱状组织,SEM分析表明存在两个亚微米级的离散相:富含Ni-Al的B2相(体积分数为48%)和富含Fe-Cr的无序体心立方相(体积分数为52%)。Mohanty等[52]在1100 ℃下进行了200 h的循环氧化研究,Al0.3CoCrFeNi和Al0.7CoCrFeNi高熵合金氧化后均在表面形成一层Cr2O3氧化膜,并在其内层形成Al2O3亚层,Al0.7CoCrFeNi高熵合金形成了连续的Al2O3氧化膜,其厚度随着氧化时间的延长而增加,从而提高了合金的抗氧化能力。

Peyrouzet等[47]在SLM制备的Al0.3CoCrFeNi高熵合金中发现了的〈110〉纤维织构,而〈001〉织构是增材制造的FCC合金中最常观察到的。原因是在熔池底部,晶粒以〈001〉取向沿打印方向生长,而在熔池的两侧,〈001〉取向的晶粒在相对于打印方向的45°,可形成与打印方向一致的〈110〉的纤维织构。因此,通过合适的扫描策略和激光功率可以形成更强的织构或者改变沿打印方向的择优取向。SLM制备的采用预混合粉末的Al0.5FeCoCrNi高熵合金熔池内存在明显的柱状晶和晶间结构,试样由简单的BCC相与FCC相组成[49],但Zhou等[50]采用预合金粉末制备的Al0.5FeCoCrNi高熵合金中只有FCC相,预合金粉末中的BCC相在SLM过程中转变为FCC相,这表明粉末特性对增材制造合金有一定影响。

在等摩尔AlCoCrFeNi高熵合金的研究中,LMD制备的该合金BCC晶体结构由(富Al, Ni) 有序B2基体和其中的(富Fe, Cr)无序BCC析出物组成[54]。Wang等[55]发现试样中具有接近B2单相的固溶体组织,而800 ℃时效试样中发现B2基体中大量FCC相沿晶界呈片状析出,晶粒内部呈较细的片状和针状析出。B2相富Al-Ni,Fe-Cr偏析于FCC相。Niu等[58]采用SLM制备了等摩尔AlCoCrFeNi高熵合金,试样由无序体心立方相(A2)和有序体心立方相(B2)组成,B2相主要集中在熔池边界,Al和Ni元素结合形成具有BCC超晶格结构的有序Al-Ni固溶体相,其他元素均匀分布在Al-Ni相(B2)周围,形成单一的A2相,且B2相的含量随着体能量密度的增强而增加。Fujieda等[56]首次使用EBM尝试AlCoCrFeNi高熵合金的制备,研究发现铸态和粉末为单相BCC结构,EBM试样同时具有BCC和FCC两种结构,大部分的FCC晶体存在于顶部和底部的晶界处,且底部比顶部高3倍左右,原因是较长的预热过程促进了晶界面心立方相的析出。随后,Shiratori等[57]发现其晶体结构为无序BCC相和有序B2相组成的纳米片层结构,且B2/BCC混合相的晶界也有FCC相析出。Karlsson等[60]使用黏结剂喷射技术制备了AlCoCrFeNi高熵合金,烧结后的试样由BCC/B2相、FCC相和脆性σ相组成。1000~1100 ℃的退火处理可抑制σ相,呈现B2/BCC相和FCC相的混合。升高温度进一步抑制FCC相,1200 ℃和1300 ℃淬火样品只有BCC与B2相组成。因此,等摩尔AlCoCrFeNi高熵合金的相组成与制备工艺、热处理工艺有关,制备时较低的凝固速率和热处理时缓慢冷却都有利于FCC相析出。

SLM制备的AlCoCrFeNi高熵合金致密性较差,密度随着体能量密度的增加而逐渐增大,最大相对密度为98.4%[58];并且易产生裂纹,成形过程中热循环导致热应力和偏析驱动的相变是大范围裂纹形成的一个重要原因,预热和改变合金成分可减少裂纹[59]。因此,对SLM制备高致密度的AlCoCrFeNi高熵合金还需要更深入的研究,仅仅考虑工艺参数有很大局限性,更详细的前处理过程(如制粉方式、粉末预热)、扫描策略和后续处理也应考虑在内。

2.4 难熔高熵合金增材制造难熔高熵合金多使用纯元素粉末或纯元素的预混合粉末,为使化学成分均匀,可在制备过程中增加重熔的扫描策略。

Kunce等[63]采用LMD制备的TiZrNbMoV高熵合金呈现由BCC固溶体和正交NbTi4相组成的两相树枝晶基体以及富Zr析出物。Dobbelstein等[64]通过脉冲激光LMD制备了TiZrNbHfTa高熵合金,结构为单相BCC,细小均匀的等轴晶组织。脉冲激光的动态温度演化影响颗粒附着在表面的概率,未沉积的高熔点颗粒在激光脉冲间隙会弹离并落到工作台之外,通过对粉末混合物的成分调整,使熔点较低的元素以低于等原子浓度的方式加入制备了等原子组成的合金。李青宇等[65]通过LMD制备了NbMoTaTi高熵合金,由于气孔、Ta粉末不完全熔化和裂纹的存在,合金未表现出理想的高温力学性能。Zhang等[66]采用SLM方式制备了WTaMoNb耐高温高熵合金,组织为单一BCC结构,晶界周围出现了微小的树枝晶。为提高试样致密度(不足90%),结合数值模拟对工艺进行了改进,成功抑制了翘曲和裂纹。

由于难熔高熵合金中高熔点元素熔点与低熔点元素沸点接近,导致最终试样的化学成分与初始粉末成分有偏差,在LMD中高熔点元素颗粒易掉落[64],在SLM中低熔点元素易蒸发[66],并且具有脆性断裂或开裂的倾向,难熔高熵合金的增材制造性能并不理想。Dobbelstein等[67]通过LMD制备了成分梯度TiZrNbTa耐火高熵合金,用铌粉逐步取代锆粉,得到Ti25Zr50Nb0Ta25到Ti25Zr0 Nb50Ta25的成分梯度。Ti25Zr0 Nb50Ta25与Ti25Zr25Nb25Ta25之间为单相BCC固溶体,晶粒粗大。当Zr/Nb比超过等原子组成时可获得更细、更硬的多相组织。Melia等[68]制备了多种成分的MoNbTaW高熵合金,基本上在所有情况下,整个试样横截面都存在贯穿厚度的裂纹以及明显的孔隙率和部分未熔化的粉末。每种组合均为无序的BCC固溶体,Nb起到稳定单一无序BCC相的作用,而Ta起到使单一无序BCC相不稳定的作用,导致相分离和有序体心立方第二相的形成[69]。表 5汇总了部分增材制造难熔高熵合金的成分和组织结构[63-69]。

| Method | Composition | Crystal structure | Segregation | Mechanical property | Reference |

| LMD | TiZrNbMoV | BCC | Mo, Zr-rich precipitates | [63] | |

| LMD | TiZrNbHfTa | BCC | [64] | ||

| LMD | NbMoTaTi | BCC | Micro segregation between grain boundaries | Compression strength 1301.83 MPa at 25 ℃ | [65] |

| SLM | WTaMoNb | BCC | [66] | ||

| LMD | TiZrNbTa | BCC | [67] | ||

| LMD | MoNbTaW | BCC | [68-69] |

此外,一些学者还研究了其他的增材制造高熵合金体系,将部分研究成果汇总于表 6[12, 70-88]。无Co的AlCrCuFeNi高熵合金作为一种廉价合金,有利于降低工程制造成本,引起了广泛关注。SLM制备的AlCrCuFeNi高熵合金具有较高的裂纹敏感性,晶体结构为包含B2相和A2相的简单BCC固溶体。纳米级富Cu相在大角度晶界处析出并呈链状分布,而在小角度晶界处呈颗粒状析出[70]。在随后SLM制备AlCrCuFeNix(2.0≤x≤3.0)体系研究[71]中,发现Ni的加入促进柱状晶向近等轴晶的转变,尤其是AlCrCuFeNi3.0高熵合金表现出明显的非均质组织,包括近等轴晶、纳米片层或胞状双相(FCC+B2)结构、大量的小角度晶界和位错堆积以及B2相中大量的共格A2纳米析出物,具有抗拉强度和塑性的最佳组合。另外,AlCrCuFeNi3.0高熵合金近共晶双相纳米结构与近等轴晶的协同作用有效地消除了裂纹[72]。

| Method | Composition | Mechanical property | Crystal structure | Reference |

| SLM | AlCrCuFeNi | Compressive strength 2052.8 MPa, strain of 6.8% | BCC | [70] |

| SLM | AlCrCuFeNix | [71] | ||

| SLM | AlCrCuFeNi3.0 | Yield strength≈775 MPa, tensile strength ≈957 MPa, elongation≈14.3% | B2+FCC | [72] |

| LMD | AlxCrCuFeNi2 (0 < x < 1.5) | FCC+L12+BCC+B2 (x=1) | [73-74] | |

| SLM | AlxCrCuFeNi2 | BCC/B2(x=1) | [75] | |

| LMD | AlxCoFeNiCu1-x (x=0.25, 0.5, 0.75) | FCC(x=0.25, 0.5) FCC+BCC(x=0.75) | [76] | |

| SLM | AlCoCuFeNi | HT at 1000 ℃,compressive fracture strength of 1600 MPa, yield strength of 744 MPa, strain of 13.1% | BCC(B2)+FCC(HT) | [12] |

| SLM | AlCoCrCuFeNi | FCC+BCC | [77] | |

| SLM/EBM | Co1.5CrFeNi1.5Ti0.5Mo0.1 | SLM specimens yield strength:(773.0±4.2) MPa,tensile strength:1178.0 MPa,elongation:(25.8±0.6)% | FCC | [78] |

| LMD | AlCrFeMoVx(x=0-1) | BCC | [79] | |

| SLM | AlCoFeNiSmTiVZr system | FCC | [80] | |

| SLM | Fe49.5Mn30Co10Cr10C0.5 | Yield strength:710 MPa,tensile strength:1 GPa,elongation:28% | FCC | [81] |

| SLM | Fe40Mn20Co20Cr15Si5 | Yield strength of (530±40) MPa,ultimate tensile strength (≈1.1 GPa) and ductility (30%) | ε+γ | [82] |

| SLM | Fe38.5Mn20Co20Cr15Si5Cu1.5 | Ultimate tensile strength ≈1235 MPa, average yield strength is (665±13) MPa,ductility is 17.2% | γ+ε | [83] |

| SLM | AlCrFeNiV | Ultimate tensile strength≈1057.47 MPa and plastic strain≈30.3% | FCC+L12 nano phase | [84] |

| SLM | AlCrFe2Ni2 | Flexural strength is 2051 MPa | BCC+FCC | [85] |

| EBM | Al0.5CrMoNbTa0.5 | BCC | [86] | |

| SLM | C0.12Al0.26CoFeMnNi | Yield strength:500 MPa,tensile strength:800 MPa,elongation:41% | [87] | |

| SLM | Ni6Cr4WFe9Ti | Yield strength:742 MPa,tensile strength:972 MPa,elongation:12% | γ+unknown phase | [88] |

Borkar等[73]利用LMD制备了梯度的AlxCrCuFeNi2(0 < x < 1.5)高熵合金,随着Al含量的增加,显微组织由FCC相(含有序L12相)逐渐转变为BCC相(含有序B2相),当x<0.9时,FCC为首先凝固相,而当Al含量较高时,BCC相首先凝固[74]。在SLM制备AlxCrCuFeNi2研究中[75],随着铝含量的增加,晶体结构同样由FCC向FCC+BCC/B2转变,并伴有柱状晶向等轴晶转变。Al0.75和Al1.0合金形成由片层/胞状FCC基体和嵌入球形BCC纳米析出物的树枝状B2基体组成的类共晶组织。FCC枝晶和BCC纳米沉淀物富Fe和Cr,而枝晶间B2基体富Al和Ni。

Chen等[76]通过LMD制备了AlxCoFeNiCu1-x高熵合金,发现随着Al含量的增加和Cu含量的减少,晶体结构由以FCC为主转变为FCC和BCC相结合。微观组织为柱状树枝晶,树枝晶相均为富Fe, Co相,而基体相为富Cu, Al相。Zhang等[12]经过SLM制备的AlCoCuFeNi高熵合金由单一的有序体心立方(BCC)(B2)固溶体相和细小的柱状亚结构组成,沿层堆积方向有很强的〈001〉织构。1000 ℃热处理后,体心立方(B2)基体中析出细小的富铜FCC相,基体富Al和Ni,Fe和Co在两相中分布均匀。SLM制备的AlCoCrCuFeNi高熵合金晶体结构为FCC和BCC相,具有较高的裂纹敏感性。高角度晶界、Cu元素的偏析以及BCC和FCC相之间的失配是SLM过程中裂纹形成的原因[77]。

Fujieda等[78]比较了SLM和EBM制备Co1.5CrFeNi1.5Ti0.5Mo0.1高熵合金的力学性能与耐腐蚀性能,SLM过程中较高的凝固速率促进生成了没有明显偏析且细小的均匀组织,XRD图像显示出少量的TiCo2或MoFe2金属间化合物,固溶处理后XRD图像显示为单一FCC相,但STEM-EDS图像显示有富Ni-Ti颗粒析出;固溶处理的SLM试样屈服强度和抗点蚀性能明显优于EBM试样,但伸长率低于EBM试样。SLM制备的Fe49.5Mn30Co10Cr10C0.5间隙溶质强化高熵合金(简称iHEA)具有层次化的非均质微结构,其长度范围跨越几个数量级,使合金具有相当高的强度-延性协同效应[81]。亚稳态Fe40Mn20Co20Cr15Si5高熵合金同样具有优异的高强度-延展性组合[82]。SLM制备的Fe38.5Mn20Co20Cr15Si5Cu1.5高熵合金表现出目前最高的抗拉强度(1235 MPa),并且具有较大的极化斜率,因此表现出较高的钝化倾向[83]。

Yao等[84]通过SLM制备了几乎完全致密的AlCrFeNiV高熵合金。微观结构分析表明,由FCC固溶体和L12纳米相组成,并且存在柱状晶、亚晶和位错等层次结构,合金具有高强度和优异塑性的结合。Vogiatzief等[85]通过SLM制备的AlCrFe2Ni2原始组织为亚稳组织,具有纳米级调幅分解的柱状BCC晶粒、B2和A2结构,热处理之后,FCC相以微片的形式析出,从而形成超细且均匀的双相结构,这种结构在传统工艺下是无法获得的。LMD制备的复合梯度AlCrFeMoVx(x=0~1)高熵合金,V含量从0.3%增加到18.5%微观结构未发生变化,为单相BCC固溶体,V的增加使高熵合金的熔点降低,晶粒尺寸增大,但硬度明显增加[79]。Sarswat等[80]采用SLM制备了AlCoFeNiSmTiVZr系高熵合金(AlCoFeNiSm0.1V0.9, AlCoFeNiSm0.1TiV0.9, AlCoFeNiSm0.05TiV0.95Zr和大块金属玻璃AlCoFeNiTiVZr),这些合金大多为单相FCC结构。AlCoFeNiSm0.1V0.9的EDS元素分析表明所有成分分布均匀,但晶界中铝含量不高。AlCoFeNiSm0.05TiV0.95Zr的XRD图谱显示了合金中存在几种金属间化合物,如Al-Sm, Al3V, Al3Zr, V2Zr, (Fe, Al)2Zr, Fe7Sm2Ti, Sm4Ni6Al23和Zr6FeSm2,这些相会导致合金的脆性。Katz-Demyanetz等[86]通过EBM制备了Al0.5CrMoNbTa0.5高熵合金,相组成为体心立方基固溶体和金属间化合物相C14, C36, 6H和C15。

Ewald等[87]使用预混合粉末制备C0.12Al0.26CoFeMnNi高熵合金时发现化学均匀性强烈依赖于能量输入和在SLM过程中形成的熔池的大小。一方面,能量输入不足导致元素分布不均匀,高熔点的粉末只有部分熔化。另一方面,较小的熔池尺寸阻碍了充分的元素混合。Yang等[88]通过SLM制备了自行设计的Ni6Cr4WFe9Ti高熵合金,其显微组织由γ相和未知析出相构成,在γ相的晶界上,析出相以细小的斑点和不连续的网状结构均匀分布,并且在快速凝固的基体内部也发现了析出相,提高了合金的延展性。

3 增材制造高熵合金力学性能强化机理高熵合金本身具有优异的强韧性组合,而增材制造制备的高熵合金更是有可能突破金属材料性能的极限。目前的研究中,通过增材制造制备的高熵合金大多数表现出比铸态同成分高熵合金明显更高的屈服强度和极限抗拉强度,随工艺参数和扫描策略的不同,伸长率呈现与屈服强度协同增加,或者伸长率表现出随强度增加而降低的现象。增材制造高熵合金主要的强化机制主要为传统的四大类:细晶强化,固溶强化,位错强化,沉淀强化,但在传统方式制备的试样中,这些强化方式需要通过锻造、轧制等不同程度的后处理消除原始缺陷后才能被激发。根据Hall-Petch效应,细晶强化(或晶界强化)是目前已发表文献中普遍存在的强化机理,这也是增材制造技术的主要优势之一。

3.1 CoCrFeNi系高熵合金Brif等[17]采用SLM制备的FeCoCrNi高熵合金获得了细小组织,具有很强的Hall-Petch效应,而且没有脆性金属间化合物或第二相,试样同时具有高强度和良好的塑性。退火温度显著影响SLM制备的FeCoCrNi高熵合金的微观结构和力学性能[19],凝固过程中的收缩应变在晶粒内的亚结构边界上形成了大量位错网络,在变形时会阻碍内部位错的定向运动,并在网络内形成位错塞积提高材料强度。在变形过程中,退火孪晶连接并阻止位错运动,从而在晶界处形成位错壁,并在退火后保持较高的屈服强度。

CoCrFeNi高熵合金为单相FCC结构,其可利用的强化方式只有细晶强化和位错强化,在含有析出相的高熵合金中,位错网络还可以与析出相相互作用激发其他强化方式。对于SLM制备的含碳FeCoCrNi高熵合金(FeCoCrNiC0.05),Wu等[22]提出可以简单地将碳作为溶质,将CoCrFeNi作为溶剂。碳溶质在CoCrFeNi高熵合金中产生强烈的间隙固溶强化;另外,热处理后亚晶界布满了高密度的纠缠位错网络,并出现60°全位错和可以显著提高合金加工硬化能力的Lomer位错锁。同时还有一定数量的带有层错的纳米孪生束,纳米孪晶/层错的形成也有助于应变硬化,因为孪晶界可以阻止位错滑移。Zhou等[23]发现退火时合金中析出纳米级Cr23C6型碳化物,碳化物主要形核在晶界和胞状结构上,而高密度缺陷为碳化物提供了形核场所,许多细小的碳化物形成并钉扎在晶界上,使晶粒长大受到抑制,晶粒细化产生了较高的晶界密度,阻碍了位错滑移,位错壁具有与晶界相同的作用。所以,增材制造FeCoCrNiC0.05高熵合金性能的提高是细晶强化、固溶强化、析出强化和位错强化共同作用,相互影响的结果。Park等[43]在SLM制备1%C-CoCrFeMnNi高熵合金研究中也得到相似的结论。

SLM制备的添加N的FeCoNiCr高熵合金在5%的拉伸应变下,形成许多滑移带并穿透了粗晶粒中的位错网络,最终在粗晶粒和细晶粒区域之间的边界堆积,造成高背应力显著促进应变硬化,从而稳定塑性变形提高拉伸伸长率,实现了强度和延展性的同时提高[24]。在中后期变形阶段,由于滑移带细化诱导塑性(slipbands refinement induced plasticity, SRIP)和孪晶诱导塑性(twinning induced plasticity, TWIP)效应的共同激活,背应力持续增加,有助于获得优异的延展性[89]。所以,高背应力和包括滑移带与孪晶的多种变形机制引起的高应变硬化率可同时提高强度和延展性。另外,SLM制备的AlCrCuFeNi3.0高熵合金中也发现了类似于晶界强化的晶间背应力硬化[72]。

在SLM制备的含Si的FeCoCrNi高熵合金中位错和位错环之间发生了两种类型的相互作用,与螺型位错具有相同柏氏矢量的位错环导致螺型位错通过螺旋转弯吸收位错环。如果柏氏矢量不同,位错环起到较强的钉扎点的作用[25]。另外,该合金还具有较大的固溶强化效应,这些因素在不降低塑性的情况下提高了合金的强度。LMD制备的Ni2.1CoCrFeNb0.2高熵合金在650 ℃退火后析出具有D022有序结构的γ″相,其强化作用是通过析出物与位错之间的相互作用实现的。当析出物相对较小且连续时,强化效果以剪切机制为主,而当析出物超过临界值且变得越来越难以剪切时,则会出现Orowan机制[28]。

因此,增材制造CoCrFeNi高熵合金的强化机理主要是细晶强化和位错强化,这也是增材制造高熵合金最普遍的强化机理。添加的元素不同,增材制造CoCrFeNi高熵合金的微观组织略有区别,但固溶强化以及位错与变形孪晶、滑移带的综合强化作用是性能提高的主要原因。另外,在添加不同元素的合金中发现了不同的位错结构,如位错锁、位错环等,并且具有不同的析出相,这些因素均有助于提高强度与塑性。

3.2 CoCrFeNiMn高熵合金增材制造过程中的快速熔化和凝固循环提供了一个非平衡环境,该环境使增材制造的CoCrFeNiMn高熵合金具有丰富的异质结构,包括位错、析出和溶质不均匀性,从而提高了材料的强度。

多数研究均发现,增材制造的CoCrFeNiMn高熵合金具有超细晶粒,根据Hall-Petch理论,随着晶粒尺寸的减小,极限抗拉强度提高,因此,增材制造试样比缓慢凝固的铸态试样具有更高的强度。这是因为晶粒细小提供了丰富的晶界,增强了整体扩散,在重复热循环过程中有利于相析出,Li等[7]在增材制备的试样中观察到σ相,通过快速凝固和σ相细化晶粒可协同改善力学性能,Gao等[10]观察到在FCC基体的晶界处分布着精细的BCC相,激光加工的高冷却速率和晶界BCC相的析出强化的协同作用使增材制造合金具有高强度和出色的延展性。

增材制造CoCrFeNiMn高熵合金具有非常高的初始位错密度[9, 31],这种致密位错的形成可能是由于零件在凝固后迅速冷却到环境温度时内应力的发展以及由此产生的内部应变,增材制造零件中逐渐累积的热应变有一部分由位错来调节[32]。在变形过程中,位错介导的塑性占主导地位,变形后的晶胞内有明显的位错捕获和保留机制,导致胞壁内位错密度明显增加。分层位错活动控制着合金的变形过程,而变形孪晶对塑性流动有额外贡献[30]。Guan等[32]也有相似的发现,屈服点之后纳米级变形孪晶的形成引入了额外的晶粒内界面,这些界面充当了位错滑移的障碍,提高了加工硬化率。CoCrFeNiMn高熵合金在低温下变形时具有相似的变形机理,因此具有良好的低温拉伸性能,并且随实验温度的降低表现出屈服强度和延展性的同时提高[9, 11]。

对于增材制造CoCrFeNiMn高熵合金复合材料,随着TiC添加量的增加,试样的屈服应力增加可归因于TiC相通过阻止和偏转滑移使基体增强[37]。添加WC的CrMnFeCoNi高熵合金基复合材料力学性能的改善归因于LMD时形成更细的等轴晶粒和WC添加实现析出强化的综合作用。制备时的高温还可以使WC或其他具有高熔点的金属间化合物快速熔化。形成的Cr23C6析出物可能在凝固过程中充当异质形核点,导致晶粒尺寸分布更精细[38]。

因此,增材制造CoCrFeNiMn高熵合金的强化机制与CoCrFeNi高熵合金类似,主要是细晶强化、位错强化以及变形孪晶,但Mn作为易偏析元素,纳米级锰氧化物起到析出强化作用。该合金在低温下力学性能优异,但还缺乏高温下拉伸性能的研究。

3.3 AlxCoCrFeNi系高熵合金EBM制备的AlCoCrFeNi高熵合金表现出压缩性能的各向异性,即平行于打印方向的压缩性能优于垂直于打印方向,这种各向异性与垂直于打印方向时沿压缩方向包含微裂纹的大量晶界有关[56]。EBM过程中的预热导致FCC相析出,其拥有比B2/BCC相更低的屈服应力和更好的塑性,使EBM试样在没有明显强度损失的情况下具有较高的塑性[57]。在SLM过程中,随着体能量密度的增加,AlCoCrFeNi高熵合金的显微硬度明显提高,由于B2相为富Ni-Al相(硬脆相),其无序存在会增加其显微硬度[58]。Nartu等[48]研究了LMD制备的Al0.3FeCoCrNi高熵合金,晶粒尺寸与铸态相似,但屈服强度几乎提高了1倍。成型过程中由于沉积层的二次加热,形成了纳米尺度的富Al-Ni溶质团簇,这些团簇在塑性变形过程中与位错相互作用,导致屈服强度的提高。热处理之后进一步提高了屈服强度,可归因于晶内有纳米级L12沉淀,但伸长率降低。因此,增材制造的AlxCoCrFeNi系高熵合金强度随Al元素的增加而提高,但无序BCC相和有序B2相的增加使塑性明显降低。另外,合金表现出力学性能各向异性,可以通过改进增材制造策略来改善合金的性能。

3.4 其他体系高熵合金在含Cu的高熵合金中,SLM制备的AlCoCuFeNi高熵合金具有高强度和高塑性的主要原因是BCC(B2)相和细小FCC相的综合强化作用,同时FCC析出物中的调幅结构抑制了位错的运动[12]。SLM制备的AlCrCuFeNi高熵合金具有明显的压缩性能各向异性,在垂直于打印方向具有优异压缩性能是因为沿压缩方向存在较多的晶粒和富Cu相。另外,SLM过程中超细晶粒和亚晶的形成,使各个方向的塑性都得到了提高。同时交替的纳米A2和B2相之间大量的失配界面产生了巨大的共格内应力,提升了压缩断裂强度[70]。

Zhu等[81]研究了SLM制备的Fe49.5Mn30Co10Cr10C0.5高熵合金,在变形初期FCC基体中发现了变形诱导的少量板条状HCP相,同时在FCC基体中形成了一些孪晶,这表明变形孪晶被激活以适应塑性,随着应变的增加,HCP相和孪晶均增加。这些HCP结构驻留在纳米孪晶中,形成纳米孪晶-HCP片状复合结构,在高应力水平下,变形孪晶和相变对保持稳定的加工硬化能力起着重要的作用。SLM制备的以ε相为主的柱状晶组织促进了Fe40Mn20Co20Cr15Si5高熵合金优异的加工硬化能力,从而在拉伸载荷下产生了非常高的强塑性协同效应。原因是γ/ε相之间应变的均匀分配,这是由于γ晶粒中存在明显的相变诱发塑性,而ε晶粒中存在包括孪晶在内的非基体塑性[82]。孔隙率为1.5%(体积分数)的Fe38.5Mn20Co20Cr15Si5Cu1.5高熵合金[83]比孔隙率仅为0.1%的Fe40Mn20Co20Cr15Si5高熵合金抗拉强度要高得多,表明TRIP效应的激活可以防止在存在裂纹和气孔的情况下力学性能的显著恶化,有助于增材制造损伤容限合金的设计。

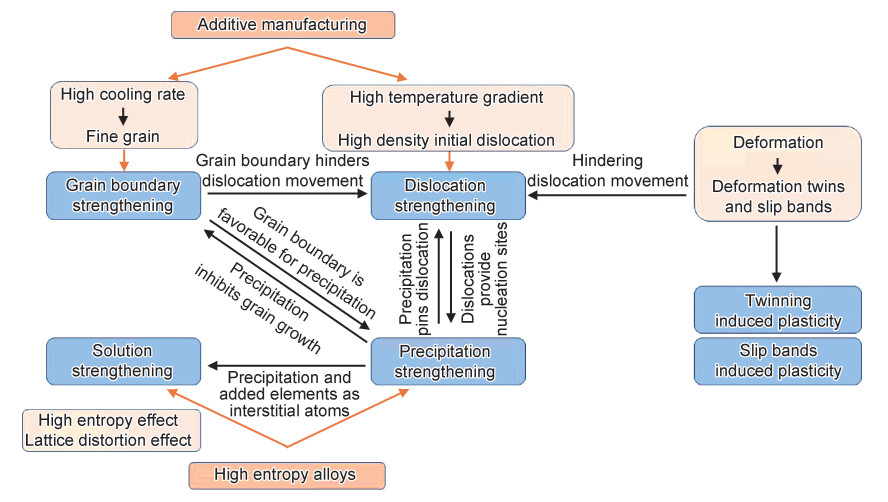

综上所述,增材制造的高熵合金具有细小的晶粒和高密度初始位错为高强韧性提供了组织基础,由于元素偏析或添加其他元素形成的纳米级析出相在成型过程中可以抑制晶粒长大,在变形过程中可以阻碍位错运动,同时变形诱导孪晶也会阻碍位错运动,是提高塑性的重要原因。总之,高熵合金优异的强度-塑性组合是固溶强化、细晶强化、位错强化、析出强化、孪晶诱导塑性、滑移带诱导塑性以及高背应力引起的高应变硬化率共同作用的结果,如图 5所示。

|

图 5 增材制造高熵合金力学性能强化机理 Fig. 5 Strengthening mechanism of mechanical properties of high-entropy alloys prepared by additive manufacturing |

高熵合金作为一种新型材料,打破了基于一种元素为主元的传统合金设计方式,凭借优异的强韧性能、耐高温耐腐蚀性能等有望成为钛基、镍基等贵重金属合金之后的新一代金属材料。增材制造技术作为一种新兴技术,给复杂零件设计、加工制造都带来了无限新的可能。但作为两个新领域的结合,高熵合金增材制造也面临着很多问题。

(1) 增材制造高熵合金面临的问题很多来自增材制造技术本身,在其他合金增材制造过程中也面临同样的问题。不同材料增材制造过程中的球化与飞溅、热应力控制与消除等问题直接影响成型质量,应考虑粉末质量、工艺参数和扫描策略等多个因素,而不仅仅是调整工艺参数。预合金粉末与预混合粉末在相同工艺下制备的合金具有不同的相,需要更深入的熔池热力学研究。此外,除了利用大量增材制造文献数据统计分析,数值模拟和制备过程中对熔池的实时监测也将有助于探索这些影响因素的统一性和规律性。

(2) 高熵合金诞生时间较短,目前关于高熵合金的研究还处于初始阶段,其单固溶体形成机理还不完善。另外,高熵合金一般可含有5~13种元素,其成分设计有巨大的灵活性,通过基于LMD的高通量方式可有效筛选新型高熵合金以及快速制备不同成分的高熵合金,从而提高高熵合金研发速度。同时可以建立不同高熵合金体系的平衡凝固和非平衡凝固相图,以期在增材制造制备时可以获得所需要的组织。

(3) 目前高熵合金的制备多是在实验室中,高熵合金的优异性能使其拥有广泛的应用潜力,但高强度高硬度也限制了其通过传统机械加工方式制备复杂形状,通过增材制造技术可以实现高熵合金的大规模工业化应用。目前的研究表明,多数增材制造的高熵合金具有比铸态试样更优异的拉伸压缩性能、耐腐蚀性能,但普遍缺少疲劳性能的研究。而增材制造试样中大量的微裂纹和孔隙恰好是影响零件疲劳性能的主要因素,因此,增材制造高熵合金的疲劳性能研究对其工程应用将产生一定影响。

(4) SLM或LMD制备的常规高熵合金CoCrFeMnNi具有优异的低温拉伸性能,但耐高温难熔高熵合金的增材制造效果并不理想,需要更深入地研究增材制造策略。另外,EBM制备高熵合金研究较少,但已有的研究表明EBM制备的AlCoCrFeNi高熵合金致密度高,性能优于SLM试样。因此,对于使用SLM方式制备时易开裂的高熵合金,可考虑使用具有较低冷却速率和较小温度梯度的EBM设备制备,从而减少裂纹产生。可以探索不同高熵合金体系对应的最佳增材制造方式(如SLM, LMD, EBM, 喷墨挤出和黏结剂喷射等),建立高熵合金增材制造工艺体系。

(5) 晶粒细小是高强度、高塑性的基础,但不是所有高熵合金都适合利用SLM工艺的高冷却速率和大温度梯度产生细小晶粒,高热应力造成的材料开裂也是影响SLM试样性能的主要因素之一。应根据材料本身的性质和使用目的选择合适的增材制造工艺,如耐高温、耐腐蚀、抗辐照等功能性应用并不需要过高的强韧性组合,制备时应在满足主要需求的基础上提高综合性能或者使用高熵合金涂层材料。此外,C, N, Si等非金属元素以及陶瓷等其他材料的添加,均有助于提高高熵合金的综合力学性能,高熵合金复合材料将是未来重要的研究方向之一。

| [1] |

YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303. DOI:10.1002/adem.200300567 |

| [2] |

CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys[J]. Materials Science and Engineering: A, 2004, 375: 213-218. |

| [3] |

SENKOV O N, WILKS G B, MIRACLE D B, et al. Refractory high-entropy alloys[J]. Intermetallics, 2010, 18(9): 1758-1765. DOI:10.1016/j.intermet.2010.05.014 |

| [4] |

王峰, 郑欣, 张小明, 等. MoNbZr高熵合金微观组织的研究[J]. 热加工工艺, 2012, 41(24): 117-120. WANG F, ZHENG X, ZHANG X M, et al. Study on microstructure of multielement MoNbZr high entropy alloy[J]. Hot Working Technology, 2012, 41(24): 117-120. |

| [5] |

谭雅琴, 王晓明, 朱胜, 等. 高熵合金强韧化的研究进展[J]. 材料导报, 2020, 34(5): 120-126. TAN Y Q, WANG X M, ZHU S, et al. Research progress on strengthening and ductilizing high-entropy alloys[J]. Materials Reports, 2020, 34(5): 120-126. |

| [6] |

陈永星, 朱胜, 王晓明, 等. 高熵合金制备及研究进展[J]. 材料工程, 2017, 45(11): 129-138. CHEN Y X, ZHU S, WANG X M, et al. Research progress in advanced materials of high-entropy alloys[J]. Journal of Materials Engineering, 2017, 45(11): 129-138. DOI:10.11868/j.issn.1001-4381.2015.001124 |

| [7] |

LI R, NIU P, YUAN T, et al. Selective laser melting of an equiatomic CoCrFeMnNi high-entropy alloy: processability, non-equilibrium microstructure and mechanical property[J]. Journal of Alloys and Compounds, 2018, 746: 125-134. DOI:10.1016/j.jallcom.2018.02.298 |

| [8] |

XIANG S, LUAN H, WU J, et al. Microstructures and mechanical properties of CrMnFeCoNi high entropy alloys fabricated using laser metal deposition technique[J]. Journal of Alloys and Compounds, 2019, 773: 387-392. DOI:10.1016/j.jallcom.2018.09.235 |

| [9] |

CHEW Y, BI G J, ZHU Z G, et al. Microstructure and enhanced strength of laser aided additive manufactured CoCrFeNiMn high entropy alloy[J]. Materials Science and Engineering: A, 2019, 744: 137-144. DOI:10.1016/j.msea.2018.12.005 |

| [10] |

GAO X, LU Y. Laser 3D printing of CoCrFeMnNi high-entropy alloy[J]. Materials Letters, 2019, 236: 77-80. DOI:10.1016/j.matlet.2018.10.084 |

| [11] |

QIU Z, YAO C, FENG K, et al. Cryogenic deformation mechanism of CrMnFeCoNi high-entropy alloy fabricated by laser additive manufacturing process[J]. International Journal of Lightweight Materials and Manufacture, 2018, 1(1): 33-39. DOI:10.1016/j.ijlmm.2018.02.001 |

| [12] |

ZHANG M, ZHOU X, WANG D, et al. AlCoCuFeNi high-entropy alloy with tailored microstructure and outstanding compressive properties fabricated via selective laser melting with heat treatment[J]. Materials Science and Engineering: A, 2019, 743: 773-784. DOI:10.1016/j.msea.2018.11.118 |

| [13] |

CHEN P, LI S, ZHOU Y, et al. Fabricating CoCrFeMnNi high entropy alloy via selective laser melting in-situ alloying[J]. Journal of Materials Science and Technology, 2020, 43: 40-43. DOI:10.1016/j.jmst.2020.01.002 |

| [14] |

JOSEPH J, JARVIS T, WU X, et al. Comparative study of the microstructures and mechanical properties of direct laser fabricated and arc-melted AlxCoCrFeNi high entropy alloys[J]. Materials Science and Engineering: A, 2015, 633: 184-193. DOI:10.1016/j.msea.2015.02.072 |

| [15] |

VIKRAM R J, MURTY B S, FABIJANIC D, et al. Insights into micro-mechanical response and texture of the additively manufactured eutectic high entropy alloy AlCoCrFeNi2.1[J]. Journal of Alloys and Compounds, 2020, 827: 154034. DOI:10.1016/j.jallcom.2020.154034 |

| [16] |

GALATI M, IULIANO L. A literature review of powder-based electron beam melting focusing on numerical simulations[J]. Additive Manufacturing, 2018, 19: 1-20. DOI:10.1016/j.addma.2017.11.001 |

| [17] |

BRIF Y, THOMAS M, TODD I. The use of high-entropy alloys in additive manufacturing[J]. Scripta Materialia, 2015, 99: 93-96. DOI:10.1016/j.scriptamat.2014.11.037 |

| [18] |

SUN Z, TAN X P, DESCOINS M, et al. Revealing hot tearing mechanism for an additively manufactured high-entropy alloy via selective laser melting[J]. Scripta Materialia, 2019, 168: 129-133. DOI:10.1016/j.scriptamat.2019.04.036 |

| [19] |

LIN D, XU L, JING H, et al. Effects of annealing on the structure and mechanical properties of FeCoCrNi high-entropy alloy fabricated via selective laser melting[J]. Additive Manufacturing, 2020, 32: 101058. DOI:10.1016/j.addma.2020.101058 |

| [20] |

KENEL C, CASATI N P M, DUNAND D C. 3D ink-extrusion additive manufacturing of CoCrFeNi high-entropy alloy micro-lattices[J]. Nature Communications, 2019, 10(1): 1-8. DOI:10.1038/s41467-018-07882-8 |

| [21] |

ZHOU R, LIU Y, ZHOU C, et al. Microstructures and mechanical properties of C-containing FeCoCrNi high-entropy alloy fabricated by selective laser melting[J]. Intermetallics, 2018, 94: 165-171. DOI:10.1016/j.intermet.2018.01.002 |

| [22] |

WU W, ZHOU R, WEI B, et al. Nanosized precipitates and dislocation networks reinforced C-containing CoCrFeNi high-entropy alloy fabricated by selective laser melting[J]. Materials Characterization, 2018, 144: 605-610. DOI:10.1016/j.matchar.2018.08.019 |

| [23] |

ZHOU R, LIU Y, LIU B, et al. Precipitation behavior of selective laser melted FeCoCrNiC0.05 high entropy alloy[J]. Intermetallics, 2019, 106: 20-25. DOI:10.1016/j.intermet.2018.12.001 |

| [24] |

SONG M, ZHOU R, GU J, et al. Nitrogen induced heterogeneous structures overcome strength-ductility trade-off in an additively manufactured high-entropy alloy[J]. Applied Materials Today, 2020, 18: 100498. DOI:10.1016/j.apmt.2019.100498 |

| [25] |

LIN D, XU L, LI X, et al. A Si-containing FeCoCrNi high-entropy alloy with high strength and ductility synthesized in situ via selective laser melting[J]. Additive Manufacturing, 2020, 35: 101340. DOI:10.1016/j.addma.2020.101340 |

| [26] |

ZHOU K, LI J, WANG L, et al. Direct laser deposited bulk CoCrFeNiNbx high entropy alloys[J]. Intermetallics, 2019, 114: 106592. DOI:10.1016/j.intermet.2019.106592 |

| [27] |

WANG Q, AMAR A, JIANG C, et al. CoCrFeNiMo0.2 high entropy alloy by laser melting deposition: prospective material for low temperature and corrosion resistant applications[J]. Intermetallics, 2020, 119: 106727. DOI:10.1016/j.intermet.2020.106727 |

| [28] |

ZHOU K, WANG Z, HE F, et al. A precipitation-strengthened high-entropy alloy for additive manufacturing[J]. Additive Manufacturing, 2020, 35: 101410. DOI:10.1016/j.addma.2020.101410 |

| [29] |

KIM J, WAKAI A, MORIDI A. Materials and manufacturing renaissance: additive manufacturing of high-entropy alloys[J]. Journal of Materials Research, 2020, 35(15): 1963-1983. DOI:10.1557/jmr.2020.140 |

| [30] |

ZHU Z G, NGUYEN Q B, NG F L, et al. Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting[J]. Scripta Materialia, 2018, 154: 20-24. DOI:10.1016/j.scriptamat.2018.05.015 |

| [31] |

TONG Z, REN X, JIAO J, et al. Laser additive manufacturing of FeCrCoMnNi high-entropy alloy: effect of heat treatment on microstructure, residual stress and mechanical property[J]. Journal of Alloys and Compounds, 2019, 785: 1144-1159. DOI:10.1016/j.jallcom.2019.01.213 |

| [32] |

GUAN S, WAN D, SOLBERG K, et al. Additive manufacturing of fine-grained and dislocation-populated CrMnFeCoNi high entropy alloy by laser engineered net shaping[J]. Materials Science and Engineering: A, 2019, 761: 138056. DOI:10.1016/j.msea.2019.138056 |

| [33] |

WANG P, HUANG P, NG F L, et al. Additively manufactured CoCrFeNiMn high-entropy alloy via pre-alloyed powder[J]. Materials & Design, 2019, 168: 107576. |

| [34] |

XU Z, ZHANG H, LI W, et al. Microstructure and nanoindentation creep behavior of CoCrFeMnNi high-entropy alloy fabricated by selective laser melting[J]. Additive Manufacturing, 2019, 28: 766-771. DOI:10.1016/j.addma.2019.06.012 |

| [35] |

KIM Y K, YANG S, LEE K A. Superior temperature-dependent mechanical properties and deformation behavior of equiatomic CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting[J]. Scientific Reports, 2020, 10(1): 1-13. DOI:10.1038/s41598-019-56847-4 |

| [36] |

ZHANG C, FENG K, KOKAWA H, et al. Cracking mechanism and mechanical properties of selective laser melted CoCrFeMnNi high entropy alloy using different scanning strategies[J]. Materials Science and Engineering: A, 2020, 789: 139672. DOI:10.1016/j.msea.2020.139672 |

| [37] |

AMAR A, LI J, XIANG S, et al. Additive manufacturing of high-strength CrMnFeCoNi-based high entropy alloys with TiC addition[J]. Intermetallics, 2019, 109: 162-166. DOI:10.1016/j.intermet.2019.04.005 |

| [38] |

LI J, XIANG S, LUAN H, et al. Additive manufacturing of high-strength CrMnFeCoNi high-entropy alloys-based composites with WC addition[J]. Journal of Materials Science and Technology, 2019, 35(11): 2430-2434. DOI:10.1016/j.jmst.2019.05.062 |

| [39] |

LI B, ZHANG L, XU Y, et al. Selective laser melting of CoCrFeNiMn high entropy alloy powder modified with nano-TiN particles for additive manufacturing and strength enhancement: process, particle behavior and effects[J]. Powder Technology, 2020, 360: 509-521. DOI:10.1016/j.powtec.2019.10.068 |

| [40] |

LI B, ZHANG L, YANG B. Grain refinement and localized amorphization of additively manufactured high-entropy alloy matrix composites reinforced by nano ceramic particles via selective-laser-melting/remelting[J]. Composites Communications, 2020, 19: 56-60. DOI:10.1016/j.coco.2020.03.001 |

| [41] |

SAVINOV R, WANG Y, SHI J. Microstructure and properties of CeO2-doped CoCrFeMnNi high entropy alloy fabricated by laser metal deposition[J]. Journal of Manufacturing Processes, 2020, 56: 1245-1251. DOI:10.1016/j.jmapro.2020.04.018 |

| [42] |

GAO X, YU Z, HU W, et al. In situ strengthening of CrMnFeCoNi high-entropy alloy with Al realized by laser additive manufacturing[J]. Journal of Alloys and Compounds, 2020, 847: 156563. DOI:10.1016/j.jallcom.2020.156563 |

| [43] |

PARK J M, CHOE J, KIM J G, et al. Superior tensile properties of 1%C-CoCrFeMnNi high-entropy alloy additively manufactured by selective laser melting[J]. Materials Research Letters, 2020, 8(1): 1-7. DOI:10.1080/21663831.2019.1638844 |

| [44] |

KIM J G, PARK J M, SEOL J B, et al. Nano-scale solute heterogeneities in the ultrastrong selectively laser melted carbon-doped CoCrFeMnNi alloy[J]. Materials Science and Engineering: A, 2020, 773: 138726. DOI:10.1016/j.msea.2019.138726 |

| [45] |

PARK J M, CHOE J, PARK H K, et al. Synergetic strengthening of additively manufactured (CoCrFeMnNi)99C1 high-entropy alloy by heterogeneous anisotropic microstructure[J]. Additive Manufacturing, 2020, 35: 101333. DOI:10.1016/j.addma.2020.101333 |

| [46] |

JOSEPH J, STANFORD N, HODGSON P, et al. Understanding the mechanical behaviour and the large strength/ductility differences between FCC and BCC AlxCoCrFeNi high entropy alloys[J]. Journal of Alloys and Compounds, 2017, 726: 885-895. DOI:10.1016/j.jallcom.2017.08.067 |

| [47] |

PEYROUZET F, HACHET D, SOULAS R, et al. Selective laser melting of Al0.3CoCrFeNi high-entropy alloy: printability, microstructure, and mechanical properties[J]. JOM, 2019, 71(10): 3443-3451. DOI:10.1007/s11837-019-03715-1 |

| [48] |

NARTU M S K K Y, ALAM T, DASARI S, et al. Enhanced tensile yield strength in laser additively manufactured Al0.3CoCrFeNi high entropy alloy[J]. Materialia, 2020, 9: 100522. DOI:10.1016/j.mtla.2019.100522 |

| [49] |

徐勇勇, 孙琨, 邹增琪, 等. 选区激光熔化制备Al0. 5CoCrFeNi高熵合金的工艺参数及组织性能[J]. 西安交通大学学报, 2018, 52(1): 151-157. XU Y Y, SUN K, ZOU Z Q, et al. Processing parameters, microstructure and properties of Al0.5CoCrFeNi high entropy alloy prepared by selective laser melting[J]. Journal of Xi'an Jiaotong University, 2018, 52(1): 151-157. |

| [50] |

ZHOU P F, XIAO D H, WU Z, et al. Al0.5FeCoCrNi high entropy alloy prepared by selective laser melting with gas-atomized pre-alloy powders[J]. Materials Science and Engineering: A, 2019, 739: 86-89. DOI:10.1016/j.msea.2018.10.035 |

| [51] |

GWALANI B, GANGIREDDY S, SHUKLA S, et al. Compositionally graded high entropy alloy with a strong front and ductile back[J]. Materials Today Communications, 2019, 20: 100602. DOI:10.1016/j.mtcomm.2019.100602 |

| [52] |

MOHANTY A, SAMPREETH J K, BEMBALGE O, et al. High temperature oxidation study of direct laser deposited AlxCoCrFeNi (x=0.3, 0.7) high entropy alloys[J]. Surface and Coatings Technology, 2019, 380: 125028. DOI:10.1016/j.surfcoat.2019.125028 |

| [53] |

LI M, GAZQUEZ J, BORISEVICH A, et al. Evaluation of microstructure and mechanical property variations in AlxCoCrFeNi high entropy alloys produced by a high-throughput laser deposition method[J]. Intermetallics, 2018, 95: 110-118. DOI:10.1016/j.intermet.2018.01.021 |

| [54] |

KUNCE I, POLANSKI M, KARCZEWSKI K, et al. Microstructural characterisation of high-entropy alloy AlCoCrFeNi fabricated by laser engineered net shaping[J]. Journal of Alloys and Compounds, 2015, 648: 751-758. DOI:10.1016/j.jallcom.2015.05.144 |

| [55] |

WANG R, ZHANG K, DAVIES C, et al. Evolution of microstructure, mechanical and corrosion properties of AlCoCrFeNi high-entropy alloy prepared by direct laser fabrication[J]. Journal of Alloys and Compounds, 2017, 694: 971-981. DOI:10.1016/j.jallcom.2016.10.138 |

| [56] |

FUJIEDA T, SHIRATORI H, KUWABARA K, et al. First demonstration of promising selective electron beam melting method for utilizing high-entropy alloys as engineering materials[J]. Materials Letters, 2015, 159: 12-15. DOI:10.1016/j.matlet.2015.06.046 |

| [57] |

SHIRATORI H, FUJIEDA T, YAMANAKA K, et al. Relationship between the microstructure and mechanical properties of an equiatomic AlCoCrFeNi high-entropy alloy fabricated by selective electron beam melting[J]. Materials Science and Engineering: A, 2016, 656: 39-46. DOI:10.1016/j.msea.2016.01.019 |

| [58] |

NIU P D, LI R D, YUAN T C, et al. Microstructures and properties of an equimolar AlCoCrFeNi high entropy alloy printed by selective laser melting[J]. Intermetallics, 2019, 104: 24-32. DOI:10.1016/j.intermet.2018.10.018 |

| [59] |

KARLSSON D, MARSHAL A, JOHANSSON F, et al. Elemental segregation in an AlCoCrFeNi high-entropy alloy-a comparison between selective laser melting and induction melting[J]. Journal of Alloys and Compounds, 2019, 784: 195-203. DOI:10.1016/j.jallcom.2018.12.267 |

| [60] |

KARLSSON D, LINDWALL G, LUNDBÄCK A, et al. Binder jetting of the AlCoCrFeNi alloy[J]. Additive Manufacturing, 2019, 27: 72-79. DOI:10.1016/j.addma.2019.02.010 |

| [61] |

SISTLA H R, NEWKIRK J W, LIOU F F. Effect of Al/Ni ratio, heat treatment on phase transformations and microstructure of AlxFeCoCrNi2-x (x=0.3, 1) high entropy alloys[J]. Materials & Design, 2015, 81: 113-121. |

| [62] |

BORKAR T, CHAUDHAARY V, GWALANI B, et al. A combinatorial approach for assessing the magnetic properties of high entropy alloys: role of Cr in AlCoxCr1-xFeNi[J]. Advanced Engineering Materials, 2017, 19(8): 1700048. DOI:10.1002/adem.201700048 |

| [63] |

KUNCE I, POLANSKI M, BYSTRZYCKI J. Microstructure and hydrogen storage properties of a TiZrNbMoV high entropy alloy synthesized using laser engineered net shaping (LENS)[J]. International Journal of Hydrogen Energy, 2014, 39(18): 9904-9910. DOI:10.1016/j.ijhydene.2014.02.067 |

| [64] |

DOBBELSTEIN H, GUREVICH E L, GEORGE E P, et al. Laser metal deposition of a refractory TiZrNbHfTa high-entropy alloy[J]. Additive Manufacturing, 2018, 24: 386-390. DOI:10.1016/j.addma.2018.10.008 |

| [65] |

李青宇, 李涤尘, 张航, 等. 激光熔覆沉积成形NbMoTaTi难熔高熵合金的组织与强度研究[J]. 航空制造技术, 2018, 61(10): 61-67. LI Q Y, LI D C, ZHANG H, et al. Study on structure and strength of NbMoTaTi refractory high entropy alloy fabricated by laser cladding deposition[J]. Aeronautical Manufacturing Technology, 2018, 61(10): 61-67. |

| [66] |

ZHANG H, XU W, XU Y, et al. The thermal-mechanical behavior of WTaMoNb high-entropy alloy via selective laser melting (SLM): experiment and simulation[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96(1/4): 461-474. |

| [67] |

DOBBELSTEIN H, GUREVICH E L, GEORGE E P, et al. Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends[J]. Additive Manufacturing, 2019, 25: 252-262. DOI:10.1016/j.addma.2018.10.042 |

| [68] |

MELIA M A, WHETTEN S R, PUCKETT R, et al. High-throughput additive manufacturing and characterization of refractory high entropy alloys[J]. Applied Materials Today, 2020, 19: 100560. DOI:10.1016/j.apmt.2020.100560 |

| [69] |

MOOREHEAD M, BERTSCH K, NIEZGODA M, et al. High-throughput synthesis of Mo-Nb-Ta-W high-entropy alloys via additive manufacturing[J]. Materials & Design, 2020, 187: 108358. |

| [70] |

LUO S, GAO P, YU H, et al. Selective laser melting of an equiatomic AlCrCuFeNi high-entropy alloy: processability, non-equilibrium microstructure and mechanical behavior[J]. Journal of Alloys and Compounds, 2019, 771: 387-397. DOI:10.1016/j.jallcom.2018.08.290 |

| [71] |

LUO S, ZHAO C, SU Y, et al. Selective laser melting of dual phase AlCrCuFeNix high entropy alloys: formability, heterogeneous microstructures and deformation mechanisms[J]. Additive Manufacturing, 2020, 31: 100925. DOI:10.1016/j.addma.2019.100925 |

| [72] |

LUO S, SU Y, WANG Z. Tailored microstructures and strengthening mechanisms in an additively manufactured dual-phase high-entropy alloy via selective laser melting[J]. Science China Materials, 2020, 63(7): 1279-1290. DOI:10.1007/s40843-020-1291-9 |

| [73] |

BORKAR T, GWALANI B, CHOUDHURI D, et al. A combinatorial assessment of AlxCrCuFeNi2 (0 < x < 1.5) complex concentrated alloys: microstructure, microhardness, and magnetic properties[J]. Acta Materialia, 2016, 116: 63-76. DOI:10.1016/j.actamat.2016.06.025 |

| [74] |

CHOUDHURI D, GWALANI B, GORSSE S, et al. Change in the primary solidification phase from fcc to bcc-based B2 in high entropy or complex concentrated alloys[J]. Scripta Materialia, 2017, 127: 186-190. DOI:10.1016/j.scriptamat.2016.09.023 |

| [75] |

SU Y, LUO S, WANG Z. Microstructure evolution and cracking behaviors of additively manufactured AlxCrCuFeNi2 high entropy alloys via selective laser melting[J]. Journal of Alloys and Compounds, 2020, 842: 155823. DOI:10.1016/j.jallcom.2020.155823 |

| [76] |

CHEN X, YAN L, KARNATI S, et al. Fabrication and characterization of AlxCoFeNiCu1-x high entropy alloys by laser metal deposition[J]. Coatings, 2017, 7(4): 47. DOI:10.3390/coatings7040047 |

| [77] |

WANG Y, LI R, NIU P, et al. Microstructures and properties of equimolar AlCoCrCuFeNi high-entropy alloy additively manufactured by selective laser melting[J]. Intermetallics, 2020, 120: 106746. DOI:10.1016/j.intermet.2020.106746 |

| [78] |

FUJIEDA T, CHEN M, SHIRATORI H, et al. Mechanical and corrosion properties of CoCrFeNiTi-based high-entropy alloy additive manufactured using selective laser melting[J]. Additive Manufacturing, 2019, 25: 412-420. DOI:10.1016/j.addma.2018.10.023 |

| [79] |

GWALANI B, SONI V, WASEEM O A, et al. Laser additive manufacturing of compositionally graded AlCrFeMoVx (x=0 to 1) high-entropy alloy system[J]. Optics and Laser Technology, 2019, 113: 330-337. DOI:10.1016/j.optlastec.2019.01.009 |

| [80] |

SARSWAT P K, SARKAR S, MURALI A, et al. Additive manufactured new hybrid high entropy alloys derived from the AlCoFeNiSmTiVZr system[J]. Applied Surface Science, 2019, 476: 242-258. DOI:10.1016/j.apsusc.2018.12.300 |

| [81] |

ZHU Z G, AN X H, LU W J, et al. Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy[J]. Materials Research Letters, 2019, 7(11): 453-459. DOI:10.1080/21663831.2019.1650131 |

| [82] |

AGRAWAL P, THAPLIYAL S, NENE S S, et al. Excellent strength-ductility synergy in metastable high entropy alloy by laser powder bed additive manufacturing[J]. Additive Manufacturing, 2020, 32: 101098. DOI:10.1016/j.addma.2020.101098 |

| [83] |

THAPLIYAL S, NENE S S, AGRAWAL P, et al. Damage-tolerant, corrosion-resistant high entropy alloy with high strength and ductility by laser powder bed fusion additive manufacturing[J]. Additive Manufacturing, 2020, 36: 101455. DOI:10.1016/j.addma.2020.101455 |

| [84] |

YAO H, TAN Z, HE D, et al. High strength and ductility AlCrFeNiV high entropy alloy with hierarchically heterogeneous microstructure prepared by selective laser melting[J]. Journal of Alloys and Compounds, 2020, 813: 152196. DOI:10.1016/j.jallcom.2019.152196 |

| [85] |

VOGIATZIEF D, EVIRGEN A, GEIN S, et al. Laser powder bed fusion and heat treatment of an AlCrFe2Ni2 high entropy alloy[J]. Frontiers in Materials, 2020, 7: 248. DOI:10.3389/fmats.2020.00248 |

| [86] |

KATZ-DEMYANETZ A, GORBACHEV I I, ESHED E, et al. High entropy Al0.5CrMoNbTa0.5 alloy: additive manufacturing vs casting vs CALPHAD approval calculations[J]. Materials Characterization, 2020, 167: 110505. DOI:10.1016/j.matchar.2020.110505 |

| [87] |

EWALD S, KIES F, HERMSEN S, et al. Rapid alloy development of extremely high-alloyed metals using powder blends in laser powder bed fusion[J]. Materials, 2019, 12(10): 1-15. |

| [88] |

YANG X, ZHOU Y, XI S, et al. Additively manufactured fine grained Ni6Cr4WFe9Ti high entropy alloys with high strength and ductility[J]. Materials Science and Engineering: A, 2019, 767: 138394. DOI:10.1016/j.msea.2019.138394 |

| [89] |

WANG Z, GU J, AN D, et al. Characterization of the microstructure and deformation substructure evolution in a hierarchal high-entropy alloy by correlative EBSD and ECCI[J]. Intermetallics, 2020, 121: 106788. DOI:10.1016/j.intermet.2020.106788 |

2021, Vol. 49

2021, Vol. 49