文章信息

- 赵文青, 齐哲, 吕晓旭, 焦健, 马壮, 朱时珍

- ZHAO Wen-qing, QI Zhe, LYU Xiao-xu, JIAO Jian, MA Zhuang, ZHU Shi-zhen

- 界面层对CVI-mini SiCf/SiC复合材料力学性能的影响

- Effects of interphases on mechanical properties of CVI-mini SiCf/SiC composites

- 材料工程, 2021, 49(7): 71-77

- Journal of Materials Engineering, 2021, 49(7): 71-77.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2020.000157

-

文章历史

- 收稿日期: 2020-02-26

- 修订日期: 2020-04-30

2. 冲击环境材料技术国家级重点实验室, 北京 100081;

3. 中国航发北京航空材料研究院 表面工程所, 北京 100095;

4. 中国航发北京航空材料研究院 先进复合材料国防科技重点实验室, 北京 100095

2. National Key Laboratory of Science and Technology on Materials under Shock and Impact, Beijing 100081, China;

3. Surface Engineering Division, AECC Beijing Institute of Aeronautical Materials, Beijing 100095, China;

4. National Key Laboratory of Advanced Composites, AECC Beijing Institute of Aeronautical Materials, Beijing 100095, China

连续碳化硅纤维增强的碳化硅基(SiCf/SiC)复合材料具有高强度、高模量、低密度、耐高温、抗氧化、抗蠕变等优异性能,在航空、航天和核工业等领域具有非常广泛的应用前景[1-3]。SiCf/SiC复合材料由SiC基体、SiC纤维增强体和界面层三部分组成,基体是材料的主体,增强体承担部分载荷并增强材料的韧性,界面层则起到传递载荷、保护增强体和调节增强体与基体之间的结合强度的作用,对复合材料的力学性能有着决定性的影响[4-8]。制备界面层的方法有化学气相渗透(CVI)法、先驱体浸渍裂解(PIP)法、溶胶-凝胶(Sol-Gel)法和原位生长法等[9-11]。CVI法在低压和相对较低的温度下制备界面层,对纤维的损伤较小[12-15];同时可以通过控制反应温度、反应压力、进气量和气体滞留时间等精确调节界面层的厚度,沉积从几十纳米到几微米不等厚度的界面层;通过交替通入不同种类的先驱体并改变温度和压力等其他沉积条件,在同一炉次中实现复合界面层的沉积。

热解炭(PyC)和氮化硼(BN)界面层均为层状结构,可以显著提高陶瓷基复材的力学性能[16-18]。Yang等[19]制备了具有单一PyC或BN界面层的SiCf/SiC复合材料,力学实验的结果显示,单层PyC界面层的SiC纤维具有比原始纤维更大的单丝拉伸强度,其SiCf/SiC复合材料表现出最佳的力学性能。但PyC抗氧化能力差,在450 ℃就开始氧化;相比之下,BN在800 ℃才开始氧化,且氧化生成的氧化硼(B2O3)具有修复裂纹孔隙等作用,因此在高温氧化环境下使用的陶瓷基复合材料采用BN界面层替代PyC界面层。Wang等[4]在石英纤维上制备不同厚度的六方氮化硼(h-BN)界面层以改善石英纤维增强Si-O-C-N复合材料的力学性能。结果表明,h-BN界面层改变了裂纹扩展方向,有效降低了界面剪切强度。不同厚度的h-BN界面层具有不同的结构。当涂层较厚时,六边形颗粒为多层结构,这种多层界面相会消耗更多的断裂功,因此随着h-BN涂层厚度的增加,复合材料的界面剪切强度稳定下降。Yang等[20]研究发现对于SiCf/BN/SiC复合材料,BN界面层被氧化成B2O3,熔融的B2O3可以填充SiC基体中的裂缝和空隙,在高温氧化环境下具有优异的强度保持性。由于BN界面层容易氧化、水解,常在BN界面层的基础上制备SiC界面层,以获得BN/SiC复合界面层[21-25]。

本工作利用CVI工艺在KD-ⅡSiC纤维表面沉积BN和BN/SiC两种界面层,对BN界面层进行1150 ℃惰性气氛处理,再进一步沉积SiC基体制备成mini复合材料。研究界面层成分、结构、表面粗糙度对mini复合材料力学性能的影响,并结合界面层表面形貌和mini复合材料断口形貌研究mini复材的断裂机理。

1 实验材料与方法 1.1 材料制备束丝SiC纤维由国防科技大学提供[26],每束含单丝1 k,单丝平均直径约13 μm。界面层采用CVI法制备,其中BN界面层的沉积以NH3和BCl3为氮源和硼源,NH3/BCl3摩尔比为2.5,N2为载气,沉积温度950 ℃,沉积压力300 Pa;SiC界面层采用H2催化三氯甲基硅烷(MTS)裂解制备,H2/MTS摩尔比为16,沉积温度950 ℃,沉积压力800 Pa,SiC基体同样采用H2催化MTS裂解制备,沉积温度1100 ℃,沉积压力为1800 Pa。CVI制备BN界面层沉积时间为25 min;制备BN/SiC为单一炉次沉积,先沉积BN后沉积SiC,时间分别为15 min和60 min。BN界面层的热处理在石英管管式炉中进行,常压氩气气氛,1150 ℃保温2 h,将此法处理的BN界面层记为HBN。

1.2 分析测试使用INSTRON5567型电子万能拉伸试验机对长150 mm的mini复材进行拉伸性能测试,加载速率为20 mm/min,得到断裂载荷、拉伸强度和应力-应变曲线。每种界面层样品的有效拉伸试样为6个。拉伸强度的公式如下:

|

(1) |

式中:F为断裂载荷,由电子万能拉伸试验机测得,N;ρB为CVI mini复材的体密度,用分析天平利用排水法测得,g/m3;ρL为CVI mini复材的线密度,由分析天平称重结合长度测量计算得到,g/m。

使用S4800型场发射扫描电镜(二次电子模式)表征界面层表面以及界面层和mini复材的断口形貌。沉积了界面层的纤维或mini复材被医用手术刀切断后,用导电胶带粘在长方体铝合金样品基座上。观察表面后将基座翻转90°以观察同一样品的断面。使用原子力显微镜(Dimension Icon型,ScanAsyst模式,OTESPA-R3探针)表征界面层的表面粗糙度。将沉积有界面层的纤维单丝用尖嘴镊挑出,用双面胶粘在载玻片上置于原子力显微镜载物台上观察。使用X射线衍射仪(D8 Advance型)和场发射透射电镜(TECNAI F20型)对BN和HBN界面层进行物相分析。将带有界面层的纤维束丝整齐地排列在玻璃片上进行XRD测试。将带界面层纤维机械破碎后,在无水乙醇中超声分散30 min,用碳膜铜网捞样,制备TEM样品。首先利用SEM寻找厚度较小的样品位置,再利用TEM观测。

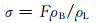

2 结果与分析 2.1 界面层的微观形貌为了解界面层的表面形貌,通过SEM对其表征,结果如图 1所示。从图 1可以看到不同界面层的表面形貌有很大的不同。BN和HBN的表面相对平整,其中BN为“荔枝皮状”,颗粒扁平并且尺寸基本一致,只存在少数尺寸大的颗粒,HBN界面层在BN界面层的基础上通过惰性气氛中的热处理获得,相比BN界面层颗粒尺寸有所增大,表面起伏程度有所增加。BN/SiC的表面则分布有较大的、圆润的SiC颗粒,但是颗粒与颗粒之间紧密排布,没有孔洞等缺陷。

|

图 1 不同界面层表面的SEM照片(a)BN;(b)HBN;(c)BN/SiC Fig. 1 SEM images of the surface of different interphases (a)BN; (b)HBN; (c)BN/SiC |

薄膜生长一般分为三种情况[27-30],即层状生长(Frank-Van der Merwe,F-M),岛状生长(Volmer-Weber,V-W)和介于两者之间的层岛复合生长(Stranski-Krastanov,S-K)。BN界面层为层岛复合生长模式;BN/SiC界面层中的外层SiC亚层为典型的岛状生长模式。根据颗粒尺寸以及起伏程度,推测三种界面层的表面粗糙度大小排序为:BN/SiC > HBN > BN,由此推断制备的mini复材基体与界面层的结合强度最强的为BN/SiC,结合强度最弱的为BN。2.2节将讨论利用原子力显微镜对三种界面层的表面粗糙度进行定量测量的结果。

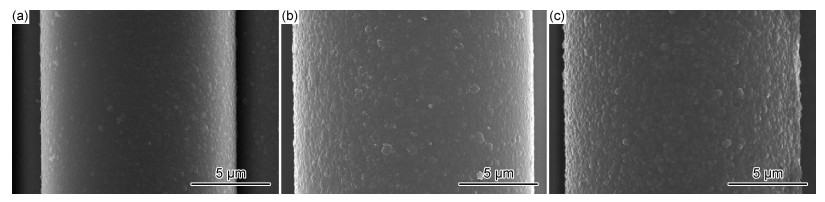

对界面层的断口形貌以及与纤维结合的情况进行表征,结果如图 2所示。从图 2(a), (b)中可以看出BN和HBN界面层厚度约为0.35 μm,与SiC纤维之间的界限清晰,界面层相比纤维断口进一步剥落,导致纤维断口略有突出,说明BN和HBN界面层与纤维之间的结合较弱。此外,图 2(b)显示HBN界面层具有层状结构,而图 2(a)中BN界面层的层状结构并不明显,说明高温处理提高了h-BN的结晶度。图 2(c)显示BN/SiC界面层的BN亚层与SiC亚层厚度均为≈0.18 μm,两者之间界限明显,但是没有缝隙,同时断裂趋势基本一致,说明两个亚层之间的结合较强。

|

图 2 不同界面层断口的SEM照片 (a)BN; (b)HBN; (c)BN/SiC Fig. 2 SEM images of cross-section of different interphases (a)BN; (b)HBN; (c)BN/SiC |

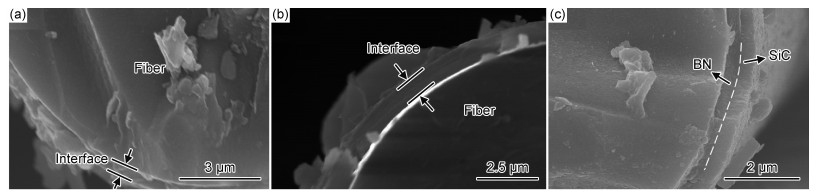

对界面层的表面粗糙度表征结果如图 3所示。由图 3(a)可见,BN界面层表面颗粒较小、尺寸均匀且起伏程度不大,根均方粗糙度为5.3 nm;由图 3(b)可见,HBN界面层表面的颗粒大小不均匀,起伏程度较大,粗糙度为9.8 nm,约为BN界面层表面粗糙度的2倍,说明高温处理使BN的晶粒在一定程度上长大,起伏程度增加,表面粗糙度也相应增大。由图 3(c)可见,BN/SiC界面层表面的颗粒较大,表面起伏程度也较大,表面粗糙度为17.6 nm,约为BN界面层表面粗糙度的3倍。可见,热处理使BN界面层晶粒尺寸增大,也会增加表面粗糙度。岛状生长的BN/SiC界面层表面粗糙度较大。

|

图 3 不同界面层的AFM照片 (a)BN; (b)HBN; (c)BN/SiC Fig. 3 AFM images of different interphases (a)BN; (b)HBN; (c)BN/SiC |

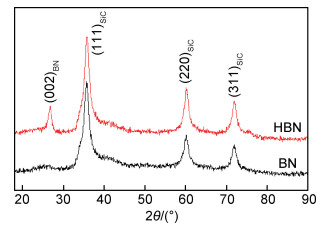

对热处理前后BN界面层的晶体结构进行表征,结果如图 4所示,衍射角2θ为35.6°, 60.0°和71.2°处出现的衍射峰,分别对应β-SiC的(111),(220)和(311)面,皆为SiC纤维的β-SiC晶粒。带有HBN界面层的纤维在衍射角26.7°的位置出现了(002)晶面的BN衍射峰,而BN界面层在相应位置只有一个范围较宽的鼓包,说明中温CVI方法制备的BN界面层结晶性较差,在1150 ℃高温处理后结晶度明显增强。本研究团队对随炉沉积BN/SiC界面层的碳纤维[31]和CVI工艺制备的BN/SiC界面层进行表征[32],与BN和SiC纤维的衍射峰比较,CVI SiC的衍射峰峰型尖锐,半峰宽较窄,说明CVI的SiC晶型更为完整,晶粒尺寸较大。

|

图 4 BN和HBN界面层的XRD谱图 Fig. 4 XRD patterns of BN and HBN interphases |

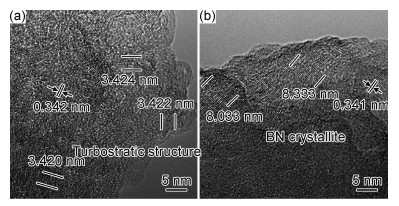

为进一步探究BN和HBN界面层的结构差异,利用高分辨TEM表征BN和HBN界面层的晶格结构,结果如图 5所示。图中可见清晰的六方BN(002)面的晶格条纹。BN界面层(002)面的晶格条纹短并且方向多变呈旋涡状,为乱层结构,即t-BN。BN晶格条纹间距为0.342 nm,晶粒尺寸约为3.5 nm,如图 5(a)所示。由图 5(b)可见,HBN界面层(002)面的晶格条纹较为平直,为长程有序的层状结构。HBN晶格条纹间距为0.341 nm,晶粒尺寸约为8.0 nm。CVI法制备的SiC尺寸较大,大部分为结晶状态,晶格条纹间距为0.251 nm,归属于β-SiC的(111)晶面,晶粒尺寸远远大于h-BN[32]。

|

图 5 BN和HBN界面层的TEM照片 (a)BN; (b)HBN Fig. 5 TEM images of BN and HBN interphases (a)BN; (b)HBN |

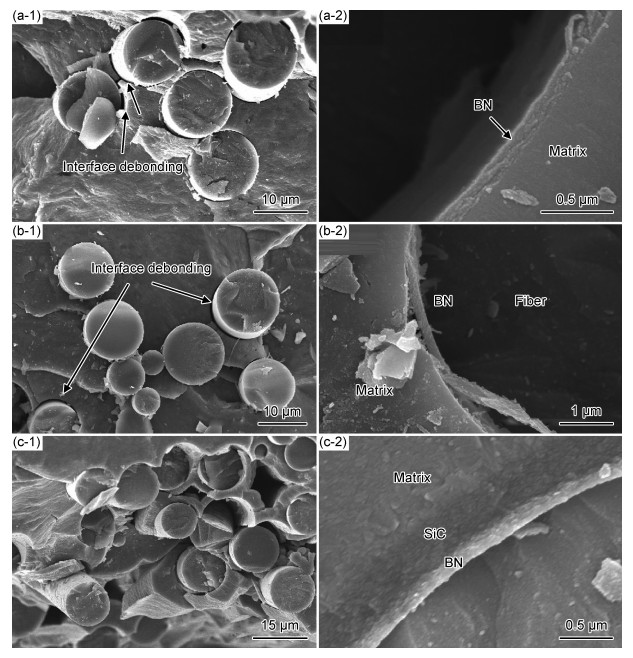

为了解mini复材的断口形貌和纤维拔出情况,应用SEM对mini复材的断口进行了表征,结果如图 6所示。从图中可见,CVI法制备的SiC基体较为致密,大孔洞很少,可以将纤维完全包覆。三种界面层均与纤维发生内脱粘,说明BN界面层、HBN界面层或BN/SiC的内层BN亚层与纤维的结合较弱,而与SiC基体或外层SiC亚层结合较强。图 6(a-1),(b-1)中纤维的拔出长度约为2.0 μm,图 6(c-1)中的纤维拔出长度约为3.9 μm。BN/SiC界面层中SiC亚层的制备温度和制备压力均比SiC基体低。先驱体气体在低温、低压下渗透性更好,从而使SiC亚层的致密性与均匀性优于基体。带BN/SiC的界面层mini复材的纤维拔出长度较长可能是由于SiC亚层对BN亚层的保护,SiC亚层的存在阻碍了空气中的氧气和水蒸气经过CVI SiC基体的细小空隙与BN亚层接触,且减少对BN亚层的氧化和水解,从而最大限度地保留了BN界面层的完整性。

|

图 6 mini复材的断口形貌 (a)BN; (b)HBN; (c)BN/SiC;(1)低倍; (2)高倍 Fig. 6 Fracture profile of mini-composite with different interphases (a)BN; (b)HBN; (c)BN/SiC; (1)low magnification; (2)high magnification |

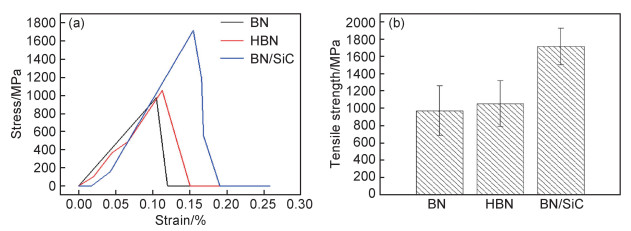

图 7为mini复合材料的力学性能。由图 7可见,mini复合材料的应力-应变曲线经历了三个阶段,第一阶段为非线性阶段,基体开始出现裂纹并不断扩展,直至基体裂纹饱和;第二个阶段为线性阶段,此阶段纤维增强承担载荷,纤维弹性伸长;第三阶段为整体断裂,纤维失效[33-35]。从图 7(a)的应力-应变曲线可以看出,带有BN界面层的mini复材断裂强度最低,仅有约970 MPa,而断裂应变也最小,约0.11%。带有HBN界面层的mini复材断裂强度约为1050 MPa,与BN的相近。具有BN/SiC界面层的mini复材的断裂强度和断裂应变均最大,分别为约1720 MPa和约0.15%。mini复材的拉伸强度与纤维-界面层、界面层-基体结合强度有关。BN界面层与纤维和基体均为异质结合,结合相对较弱,并且低温CVI制备的BN界面层层状结构不明显,为乱层结构,不利于裂纹在界面层处发生偏转,从而导致拉伸强度比较低。HBN界面层较BN界面层粗糙,使得其与基体之间的结合相对强一些,且结晶度也高,层状结构明显,有利于裂纹在界面层处的偏转,拉伸强度略高于BN界面层。BN/SiC界面层的BN亚层与纤维结合较弱,SiC亚层与基体为同质结合,结合相对较强。此外,如2.4节所述,SiC亚层可以减缓BN氧化和水解从而保证了界面层结构的完整性。因此带有BN/SiC界面层的mini复材拉伸强度要比BN和HBN界面层的高很多。由此可得出结论:BN界面层的层状结构对mini复材的拉伸强度有影响,结晶程度越高,层状结构越好,拉伸强度越大。mini复材的拉伸强度也与界面层的组成有关,设计复合界面层,发挥各亚层的优点,有助于提高复合材料的拉伸强度。

|

图 7 mini复材的力学性能 (a)应力-应变;(b)拉伸强度 Fig. 7 Mechanical properties of mini-composite (a)stress-strain; (b)tensile strength |

(1) CVI法制备的BN界面层结晶性不好,经过1150 ℃高温处理后结晶度提高。BN和HBN界面为层状-岛状生长模式,表面粗糙度较小。BN/SiC的SiC亚层为典型的岛状生长模式,表面粗糙度较大。

(2) 具有BN和HBN界面层的mini复材拉伸强度分别为970 MPa和1050 MPa,具有BN/SiC界面层的mini复材拉伸强度明显高于BN和HBN界面层,约为1720 MPa。

(3) BN和HBN界面层与纤维结合较弱;与SiC基体为异质结合,结合力也相对较弱,但是比界面层与纤维的结合强度大。BN/SiC界面层的BN亚层与纤维结合也较弱,SiC亚层与基体为同质结合,结合力较强。

| [1] |

WAN D Q, WU X Z, ZHANG W, et al. Thermal conductivity and thermal expansion of few-layer h-BN/Cu composite[J]. Materials Research Bulletin, 2019, 120: 110606. DOI:10.1016/j.materresbull.2019.110606 |

| [2] |

WING B L, HALLORAN J W. Subsurface oxidation of boron nitride coatings on silicon carbide fibers in SiC/SiC ceramic matrix composites[J]. Ceramics International, 2018, 44(14): 17499-17505. DOI:10.1016/j.ceramint.2018.06.221 |

| [3] |

刘虎, 杨金华, 周怡然, 等. 国外航空发动机用SiCf/SiC复合材料的材料及性能测试研究进展[J]. 材料工程, 2018, 46(11): 1-12. LIU H, YANG J H, ZHOU Y R, et al. Progress in coupon tests of SiCf/SiC ceramic matrix composites used for aero engines[J]. Journal of Materials Engineering, 2018, 46(11): 1-12. DOI:10.11868/j.issn.1001-4381.2018.000503 |

| [4] |

WANG S B, ZHENG Y. Effect of different thickness h-BN coatings on interface shear strength of quartz fiber reinforced SiOCN composite[J]. Applied Surface Science, 2014, 292: 876-879. DOI:10.1016/j.apsusc.2013.12.067 |

| [5] |

卢国锋, 乔生儒, 许艳. 连续纤维增强陶瓷基复合材料界面层研究进展[J]. 材料工程, 2014(11): 107-112. LU G F, QIAO S R, XU Y. Progress in research on interface layer of continuous fiber reinforced ceramic matrix composites[J]. Journal of Materials Engineering, 2014(11): 107-112. DOI:10.11868/j.issn.1001-4381.2014.11.019 |

| [6] |

CHEN S A, ZHANG Y D, ZHANG C R, et al. Effects of SiC interphase by chemical vapor deposition on the properties of C/ZrC composite prepared via precurs or infiltration and pyrolysis route[J]. Materials & Design, 2013, 46: 497-502. |

| [7] |

杨金华, 吕晓旭, 焦健. 碳化硅陶瓷基复合材料界面层技术研究进展[J]. 航空制造技术, 2008, 61(11): 79-87. YANG J H, LV X X, JIAO J. Progress in interphase technology of silicon carbide matrix composites[J]. Aeronautical Manufacturing Technology, 2008, 61(11): 79-87. DOI:10.3969/j.issn.1671-833X.2008.11.016 |

| [8] |

LI S L, QI L, ZHANG T, et al. Interfacial microstructure and mechanical properties of Cf/AZ91D composites with TiO2 and PyC fiber coatings[J]. Micron, 2017, 101: 170-176. DOI:10.1016/j.micron.2017.07.004 |

| [9] |

TANG X Y, LI Y W, CHENG X, et al. In-situ formation of BN layers by nitriding boron powders in BN/Si3N4-based composite ceramics[J]. Ceramics International, 2018, 44(9): 10322-10327. DOI:10.1016/j.ceramint.2018.03.040 |

| [10] |

SONG C K, LIU X F, YE F, et al. Mechanical and dielectric properties of SiCf/BN/SiBCN composites via different synthesis technologies[J]. Journal of the European Ceramic Society, 2019, 39(14): 4417-4423. DOI:10.1016/j.jeurceramsoc.2019.05.033 |

| [11] |

XIAO P, LI Z C, LIU Z Y, et al. Microstructures and mechanical behaviors of CVI-based C/C composites containing h-BN powder additives[J]. Materials Science and Technology, 2019, 35(12): 2824-2831. DOI:10.1016/j.jmst.2019.07.003 |

| [12] |

CHENG Y, YIN X W, LIU Y S, et al. BN coatings prepared by low pressure chemical vapor deposition using boron trichloride-ammonia-hydrogen-argon mixture gases[J]. Surface and Coatings Technology, 2010, 204(16/17): 2797-2802. |

| [13] |

ZHAO S C, ZHOU F, LI Z T, et al. Effect of precursor purity and flow rate on the CVD growth of hexagonal boron nitride[J]. Journal of Alloys and Compounds: Part A, 2016, 688: 1006-1012. DOI:10.1016/j.jallcom.2016.07.117 |

| [14] |

吕晓旭, 齐哲, 赵文青, 等. SiCf/SiC复合材料氮化硼(BN)界面层及其复合界面层研究进展[J]. 航空材料学报, 2019, 39(5): 13-23. LYU X X, QI Z, ZHAO W Q, et al. Research progress of BN interphase and its multilayers in SiC/SiC composites[J]. Journal of Aeronautical Materials, 2019, 39(5): 13-23. |

| [15] |

JACQUES S, VINCENT H, VINCENT C, et al. Multilayered BN coatings processed by a continuous LPCVD treatment onto Hi-Nicalon fibers[J]. Journal of Solid State Chemistry, 2001, 162(2): 358-363. DOI:10.1006/jssc.2001.9387 |

| [16] |

王波, 矫桂琼, 杨成鹏, 等. 陶瓷基复合材料力学行为研究进展[J]. 航空制造技术, 2014(6): 54-57. WANG B, JIAO G Q, YANG C P, et al. Research progress of mechanical behaviors of ceramic matrix composites[J]. Aeronautical Manufacturing Technology, 2014(6): 54-57. DOI:10.3969/j.issn.1671-833X.2014.06.009 |

| [17] |

WANG C H, LIU Y S, YOU Q W, et al. Effect of the pyrolytic carbon (PyC) content on the dielectric and electromagnetic interference shielding properties of layered SiC/PyC porous ceramics[J]. Ceramics International, 2019, 45(5): 5637-5647. DOI:10.1016/j.ceramint.2018.12.028 |

| [18] |

LI S L, QI L H, ZHANG T, et al. Interfacial failure behavior of PyC-Cf/AZ91D composite fabricated by LSEVI[J]. Journal of Materials Science & Technology, 2018, 34(9): 1602-1608. |

| [19] |

YANG B, ZHOU X G, CHAI Y X. Mechanical properties of SiCf/SiC composites with PyC and the BN interface[J]. Ceramics International, 2015, 41(5): 7185-7190. DOI:10.1016/j.ceramint.2015.02.041 |

| [20] |

YANG H T, LU Z Y, BIE B X, et al. Microstructure and damage evolution of SiCf/PyC/SiC and SiCf/BN/SiC mini-composites: a synchrotron X-ray computed microtomography study[J]. Ceramics International, 2019, 45(9): 11395-11402. DOI:10.1016/j.ceramint.2019.03.004 |

| [21] |

NIU Z B, LI Z, XIAO P, et al. Influence of h-BN as an additive on oxidation behaviour and kinetic characteristics of carbon/carbon composites[J]. Corrosion Science, 2019, 160: 108162. DOI:10.1016/j.corsci.2019.108162 |

| [22] |

LU Z L, YUE J L, FU Z Y, et al. Microstructure and mechanical performance of SiCf/BN/SiC mini-composites oxidized at elevated temperature from ambient temperature to 1500℃ in air[J]. Journal of the European Ceramic Society, 2020, 40(8): 2821-2827. DOI:10.1016/j.jeurceramsoc.2019.04.013 |

| [23] |

COONS T P, REUTENAUER J W, MERCADO A, et al. The characterization of an oxide interfacial coating for ceramic matrix composites[J]. Materials Science and Engineering: A, 2013, 573: 190-196. DOI:10.1016/j.msea.2013.02.060 |

| [24] |

GUERRA V, WAN C Y, MANALLY T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers[J]. Progress in Materials Science, 2019, 100: 170-186. DOI:10.1016/j.pmatsci.2018.10.002 |

| [25] |

ZHEN C, LI X, ZHANG B, et al. The improvement of mechanical properties of SiC/SiC composites by in situ introducing vertically aligned carbon nanotubes on the PyC interface[J]. Ceramics International, 2019, 45(3): 3368-3376. DOI:10.1016/j.ceramint.2018.10.251 |

| [26] |

李亮, 简科, 王亦菲. 惰性气氛下低氧碳化硅纤维结构和性能演变[J]. 有机硅材料, 2017, 31(1): 15-18. LI L, JIAN K, WANG Y F. Evolvement of structures and properties of silicon carbide fibers with low oxygen content under inert gas atmosphere[J]. Silicone Material, 2017, 31(1): 15-18. |

| [27] |

IKONOMOV J, STARBOVA K, GIESEN M. Island coalescence and diffusion along kinked steps on Cu(001): evidence for a large kink Ehrlich-Schwoebel barrier[J]. Surface Science, 2007, 601(5): 1403-1408. DOI:10.1016/j.susc.2007.01.004 |

| [28] |

LI K Y, JIANG J, WANG Y G. Fabrication and tensile behaviors of mini-C/SiC composites reinforced by Si3N4 nanowires[J]. Materials Science and Engineering: A, 2015, 627: 241-248. DOI:10.1016/j.msea.2015.01.009 |

| [29] |

FENNIS W M M, KREULEN C M, WOLKE J G C, et al. Fracture resistance of reattached incisor fragments with mini fibre-reinforced composite anchors[J]. Journal of Dentistry, 2009, 37(6): 462-467. DOI:10.1016/j.jdent.2009.03.003 |

| [30] |

HUA Z Z, LOWENGRUB J S, WISE S M, et al. Phase-field modeling of epitaxial growth: applications to step trains and island dynamics[J]. Physica: D, 2012, 241(2): 77-94. DOI:10.1016/j.physd.2011.09.004 |

| [31] |

QI Z, LV X X, ZHAO W Q, et al. BN/SiC coating on SiC tows prepared by chemical vapor infiltration[C]//IOP Conference Series: Materials Science and Engineering of the 11th International Conference on High-Performance Ceramics conference, London, IOP Publishing, 2019: 012062.

|

| [32] |

吕晓旭, 姜卓钰, 周怡然, 等. BN/SiC复合界面层对SiC纤维和PIP-Mini复合材料力学性能的影响[J/OL]. 无机材料学报, 2020, 35(10): 1099-1104. LV X X, JIANG Z Y, ZHOU Y R, et al. Effect of BN/SiC multilayered interphases on mechanical properties of SiC fibers and minicomposites by PIP[J/OL]. Journal of Inorganic Materials, 2020, 35(10): 1099-1104. |

| [33] |

杨平, 张瑞谦, 李月, 等. 含(PyC/SiC)n多层界面SiCf/SiC Mini复合材料的制备与拉伸行为[J]. 粉末冶金材料科学与工程, 2018, 23(6): 553-561. YANG P, ZHANG R Q, LI Y, et al. Preparation and tensile behavior of SiCf/SiC minicomposites with (PyC/SiC)n multilayered interphases[J]. Materials Science and Engineering of Power Metallurgy, 2018, 23(6): 553-561. DOI:10.3969/j.issn.1673-0224.2018.06.002 |

| [34] |

石多奇, 沙景恬, 程震, 等. SiC/SiC mini复合材料拉伸性能分散性的数值仿真方法[J]. 航空动力学报, 2019, 34(5): 971-979. SHI D Q, SHA J T, CHENG Z, et al. Numerical simulation method of the variability in tensile properties of SiC/SiC minicoposites[J]. Journal of Aerospace Power, 2019, 34(5): 971-979. |

| [35] |

孟志新, 常柯, 郭旭, 等. 不同纤维束下SiC陶瓷基复合材料拉伸强度及拉伸行为研究[J]. 西安航空学院学报, 2019, 37(5): 35-42. MENG Z X, CHANG K, GUO X, et al. Study on tensile strength and tensile behavior of SiC ceramic matrix composites under different fiber bundles[J]. Journal of Xi'an Aeronautical University, 2019, 37(5): 35-42. |

2021, Vol. 49

2021, Vol. 49