文章信息

- 刘鹏, 顾晓滨, 赵媛媛, 饶俊, 边亮

- LIU Peng, GU Xiao-bin, ZHAO Yuan-yuan, RAO Jun, BIAN Liang

- 粉煤灰-硅藻土复合相变储能材料制备及导热强化

- Preparation and thermal conductivity enhancement of fly ash-diatomite-based composite phase change materials

- 材料工程, 2021, 49(3): 141-150

- Journal of Materials Engineering, 2021, 49(3): 141-150.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2020.000327

-

文章历史

- 收稿日期: 2020-04-12

- 修订日期: 2020-09-02

2. 河北地质大学 宝石与材料学院, 石家庄 050031;

3. 中国科学院 深圳先进技术研究院, 广东 深圳 518055;

4. 武汉理工大学 资源与环境工程学院, 武汉 430070

2. School of Gems and Materials Technology, Hebei GEO University, Shijiazhuang 050031, China;

3. Shenzhen Institutes of Advanced Technology, Chinese Academy of Sciences, Shenzhen 518055, Guangdong, China;

4. School of Resources and Environmental Engineering, Wuhan University of Technology, Wuhan 430070, China

节能减排及环境保护的客观需要,使得工业固体废弃物资源化循环利用一直是被关注的热点。粉煤灰是燃煤电厂发电过程中产生的固体废弃物,亦会造成生态环境污染,如何实现其无害化、减量化、资源化,越来越受到人们的重视[1-2]。特别是我国作为世界上最大的电力消耗国,所消费电能70%以上来自燃煤电厂,2018年燃煤发电用煤21.8亿吨,占我国煤炭消费总量的50%左右,每年粉煤灰产量高达5亿~7亿吨[3]。而目前粉煤灰的综合利用主要集中在建筑材料,如砖、石膏、水泥、墙板和混凝土、陶粒、微晶玻璃等方面[4],多属于低附加值粗放利用形式,粉煤灰的综合利用水平须需提高。与此同时,传统能源供需存在时间错配失衡,可再生新能源存在利用效率低和稳定性差等问题,而热能储存技术可解决上述问题,提高能源利用效益和效率[5-7]。相变材料(phase change materials,PCMs)作为一种高效热能存储技术实现的主要工作介质,其能量密度高,在能量存储过程中具有近似恒温、热物理性质稳定等诸多优势,成为新能源材料研究领域的活跃前沿之一[8-10]。然而PCMs在工作过程中易产生泄漏问题。因此,实现有效且廉价的封装是PCMs应用中急需解决的关键问题之一[2, 9]。利用粉煤灰等固体废弃物用于PCMs的封装,不但有望为相变储能材料提供一种廉价且来源广、储量大的封装材料,而且可使粉煤灰变废为宝,提高其利用率,有效缓解粉煤灰堆存难处置问题,减少环境污染[2, 11-14]。

为此,国内外一些学者进行了粉煤灰载体封装PCMs的探索性研究[2, 11-32],目前的研究主要集中在:一方面,利用PCMs与粉煤灰进行直接耦合制备复合PCMs[11, 15-20];另一方面对粉煤灰进行高温煅烧[21-25]、酸化预处理[26-27]或高温后再进行酸化处理[28-30],或碱化改性[31-32],然后与不同PCMs进行耦合制备复合PCMs。此外,添加导热剂提高有机相变材料的热传递效率[11, 32]。上述研究中有机PCMs的封装载体基本均为单一粉煤灰载体,主要的制备方法有烧结法、溶液插层法、熔融混合法、真空浸渍法、微胶囊法等[2]。由于PCMs的热物性主要由相变材料、制备方法、封装载体及承载率[33]等多种因素决定,不同设计体系的PCMs具有不同的热物性[34-35]。

目前,为了获得更高的相变潜热,粉煤灰基PCMs多以改性后粉煤灰为封装载体,既有研究虽然表明改性可以改善月桂酸/改性粉煤灰复合PCMs热物性,但存在成本高、制备工艺复杂等问题[2];为了获得较高PCMs承载率,诸多研究虽然考虑了定形,但实际可能仍存在泄漏现象。鉴于天然多孔矿物载体承载率高,将其与粉煤灰进行复合制备二元载体有望具有较好的封装效果,然而相关研究还鲜有报道。为此,本工作选取在我国储量和产量均较大,市场上易获取,吸附性较好的天然多孔矿物——硅藻土,和电厂原始粉煤灰耦合成粉煤灰-硅藻土二元载体为封装材料,以在低温热能储存领域具有较好应用前景的月桂酸为相变材料,碳纳米管为导热剂,采用简单经济的直接熔融法制备月桂酸/粉煤灰-硅藻土/碳纳米管复合无泄漏定形PCMs(form-stable PCMs,FSPCM),并采用傅里叶红外光谱、差示扫描量热仪、热重分析仪、无纸记录仪等实验考察了其结构和热物性。

1 实验材料与方法 1.1 实验材料月桂酸(lauric acid,LA),分析纯,纯度98.5%,国药集团上海公司;原样粉煤灰(raw fly ash,RFA),华北某电厂;硅藻土(diatomite,DT),天津大茂化学试剂厂;碳纳米管(carbon nanotubes,CNTs),苏州碳丰石墨烯科技有限公司。

1.2 实验方法根据前期实验探索,按照一定质量比例分别称取RFA,DT,并放入对应烧杯中充分搅拌混合均匀;接着再称取一定质量LA,放入盛装RFA-DT的烧杯中,亦充分搅拌混合均匀;将各个装有混合物的烧杯分别放入恒温75 ℃的水浴锅中进行加热,并使用玻璃棒不断搅拌,直至LA完全融化,使其充分与RFA-DT二元载体混合。然后冷却至室温,即可得到LA/RFA-DT复合PCMs,将其放在压片机上,采用直径为3 cm的圆柱形模具,在12 MPa下,压制成圆片,并在75 ℃磁力搅拌器上利用热扩散渗透分析测试其封装效果[9, 11]。选用比例及相关测试结果如表 1和图 1所示。根据泄漏情况,即可确定无泄漏LA/RFA-DT复合FSPCM的比例。在第一步的基础上,考虑加入CNT的影响[36],称取1.25%(质量分数,下同),3%的CNT,加入到无泄漏LA/RFA-DT复合FSPCM中,重复上述制备步骤,即可得到进一步优化的定形无泄漏LA/RFA-DT/CNT复合FSPCM。然后对制得的定形无泄漏LA/RFA-DT/CNT复合FSPCM进行相关表征及分析。采用Nicolet5700傅里叶红外光谱仪分析了PCMs的化学兼容性,利用Q600差示扫描量热仪测定PCMs的相变潜热,采用Q600热重分析仪测定PCMs的热重(thermo gravimetry,TG)曲线,使用Phenom ProX扫描电镜来观测PCMs的微观形貌。

| Sample | Composition ratio of the prepared composite/% | Leakage ratio of samples/% | Leakage area of samples/cm2 |

| LA | 100%LA | 45.8 | 122.657 |

| S1-1 | 30%LA +50%RFA+20%DT | 0.367 | 9.075 |

| S1-2 | 25%LA +55%RFA+20%DT | 0 | 0 |

| S1-3 | 28%LA +55%RFA+17%DT | 0.117 | 3.545 |

| S1-4 | 26%LA +57%RFA+17%DT | 0 | 0 |

| S1-5 | 27%LA +56%RFA+17%DT | 0.033 | 0.049 |

| S2-1 | 27%LA +56%RFA+17%DT+1.25%CNT | 0 | 0 |

| S2-2 | 28%LA +55%RFA+17%DT+1.25%CNT | 0.1 | 3.886 |

| S2-3 | 28%LA +55%RFA+17%DT+ 3%CNT | 0 | 0 |

|

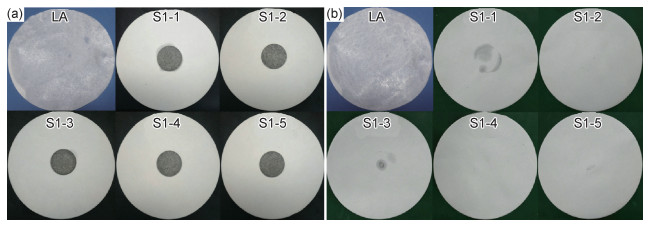

图 1 LA/RFA-DT样品的热扩散渗透测试结果 (a)样品加热后变形情况;(b)样品加热后在滤纸上污迹 Fig. 1 Thermal diffusion and penetration of LA/RFA-DT samples (a)deformation of samples after heating; (b)stain on the filter paper of samples after heating |

第一步所制备样品的热扩散渗透测试结果如图 1所示;同时为量化评价二元载体的封装效果,本工作采用了月桂酸泄漏率和泄漏面积两个参数来评价封装及泄漏结果,测试结果统计参见表 1。表 1中,泄漏率计算根据文献报道的方法而得[37],泄漏面积为污迹4个方向的平均值;利用这两个参数可以定量、客观地描述热扩散渗透情况。

从图 1(a)和表 1可知:在进行加热后,无封装载体时,纯LA发生了严重变形和泄漏;而S1-1至S1-5所对应的复合相变储能材料则均没有发生变形,表现出良好的稳定性,30%LA+50%RFA+20%DT比例样品可观察到明显的泄漏现象。而观察图 1(b)和表 1所对应的各个样品的滤纸污迹结果可发现,纯LA自然泄漏严重,污迹遍布整个滤纸;而30%LA+50%RFA+20%DT在滤纸上污迹亦很显著,这与加热后观察到的现象一致;降低LA含量后的25%LA+55%RFA+ 20%DT样品的滤纸上则无污迹,说明不但实现了定形,且无泄漏。从为提高LA承载率进行的28%LA+55%RFA+17%DT, 26%LA+57%RFA+17%DT和27%LA+56%RFA+17%DT的3个样品的滤纸污迹图可知,28%LA+55%RFA+17% DT在滤纸上污迹明显,说明定形虽好,实际上是发生了泄漏;27%LA+56%RFA+17%DT的滤纸上几乎没有污迹,可忽略不计,可能是发生泄漏的临界范围;26%LA+57%RFA+17%DT滤纸上亦无污迹,说明亦实现了无泄漏及定形。结合表 1可得,当比例为27%LA+56%RFA+17%DT,泄漏率和泄漏面积都很小,接近于0,故粉煤灰-硅藻土二元载体封装月桂酸的最佳比例27%LA+56%RFA+17%DT。

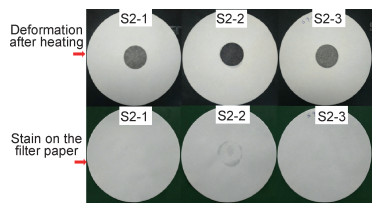

研究证实,具有多孔结构的CNT等导热剂亦对有机脂肪酸有较好的封装作用[36]。为此,在前述配比的基础上,考察了CNT导热剂对LA封装的影响,进行了27%LA+56%RFA+17%DT+1.25%CNT, 28%LA+55%RFA+17%DT+1.25%CNT, 28%LA+55%RFA+17%DT+3%CNT的热扩散渗透测试,结果参见图 2;结果统计亦如表 1所示。从图 2可知,3样品加热后定形均良好,此时均几乎观察不到泄漏;而泄漏之后的滤纸污迹则显示,27%LA+56% RFA+17%DT+1.25%CNT样品未泄漏;28%LA+55% RFA+17%DT+1.25%CNT样品有污迹产生,但可忽略不计,可能是发生泄漏的临界范围;28%LA+55%RFA+17%DT+3%CNT样品亦无泄漏。这说明,CNT在导热作用的同时,亦具有封装防泄漏效果。鉴于CNT主要被用来导热,为进一步提高传热速率,本工作以5%的CNT来制备LA/RFA-DT/CNT复合FSPCM。

|

图 2 LA/RFA-DT/CNT样品的热扩散渗透现象 Fig. 2 Thermal diffusion and penetration of LA/RFA-DT/CNT samples |

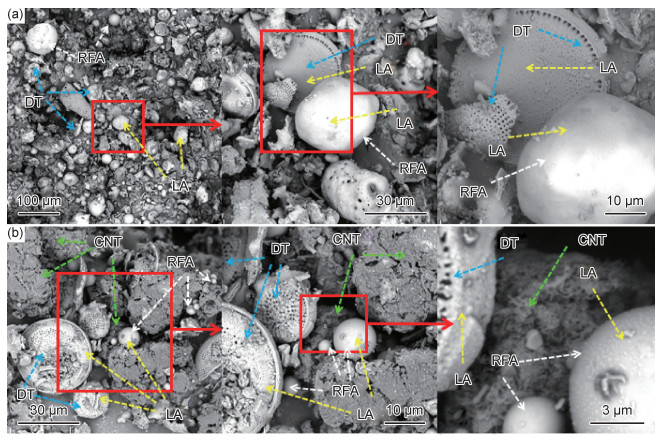

图 3为LA/RFA-DT和LA/RFA-DT/CNT的SEM图。从图 3(a)可看到硅藻土和粉煤灰混合在一起,呈圆盘状的硅藻土孔结构被表面吸附的LA所覆盖,大小各异且呈球形的粉煤灰表面亦被LA所覆盖,硅藻土多孔结构和粉煤灰表面微孔结构共同在LA相变中提供支撑实现LA定形和阻止LA泄漏。从图 3(b)中可观察到,CNT散布在硅藻土和粉煤灰之间,或将粉煤灰包裹或散落在硅藻土圆盘表面,有利于改善LA导热,提高其储/放热效率。

|

图 3 LA/RFA-DT(a)和LA/RFA-DT/CNT(b)的SEM图 Fig. 3 SEM images of LA/RFA-DT(a) and LA/RFA-DT/CNT(b) |

图 4为LA, LA/RFA, LA/RFA-DT及LA/RFA-DT/CNT的FTIR图谱。从图 4可知,在纯LA的图谱中,723 cm-1处代表—OH官能团的平面内摆动振动;1297, 937 cm-1处特征峰分别对应—OH的平面内弯曲振动和平面外弯曲振动;1704 cm-1处特征峰则表示C=O官能团的伸缩振动;而2854 cm-1和2923 cm-1分别代表—CH2和—CH3官能团中的C—H键的对称拉伸振动;3407 cm-1代表O—H伸缩振动[38-41]。将其与LA/RFA-DT及LA/RFA-DT/CNT图谱分别对比可知,纯LA的特征峰均可在定形复合相变材料的FTIR图谱中找到,发生变化的只是位置稍转移或强度强弱,且未出现新特征峰,说明复合材料无新官能团生成。复合相变材料各成分之间是物理吸附,无化学变化发生,它们之间化学相容性良好,LA储能特性未受到影响。

|

图 4 LA, LA/RFA, LA/RFA-DT和LA/RFA-DT/ CNT的FTIR图谱 Fig. 4 FTIR spectra of LA, LA/RFA, LA/RFA-DT and LA/RFA-DT/CNT |

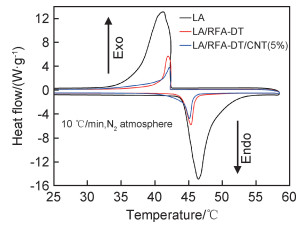

图 5为LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM的DSC曲线,其热物性及粉煤灰承载率对比参见表 2。测试时温升速率为10 ℃/min,N2气氛进行,潜热精度为0.1%,相变温度误差±0.1 ℃。由图 5和表 2可得,LA, LA/RFA-DT和LA/RFA-DT/CNT的吸热熔化相变温度分别为44.29, 45.79 ℃和45.50 ℃;相应相变潜热分别为179.6, 51.06 J/g和44.07 J/g。而在放热凝固时相变温度分别为41.23, 41.71 ℃和41.01 ℃;相应相变潜热分别为177.90, 50.30 J/g和43.44 J/g。LA/RFA-DT/CNT FSPCM的相变温度比纯LA稍有降低,说明RFA, DT和CNT对相变温度影响较小;而相变潜热有所降低,这是由于LA质量分数降低,而RFA, DT和CNT没有相变潜热的缘故[42-43]。

|

图 5 LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM的DSC曲线 Fig. 5 DSC curves of LA, LA/RFA-DT FSPCM and LA/RFA-DT/CNT FSPCM |

| Composition ratio of prepared composite/% | Form-stable, leakage | Melting temperature/ ℃ | Solidifying temperature/ ℃ | Measured latent heat of melting/ (J·g-1) | Measured latent heat of solidifying/ (J·g-1) | Theoretical loading rate of LA/% | Calculated loading rate of LA/% |

| Cetylalcohol-decylic acid (48%)/RFA[17] | 30.2 | 70.51 | 48 | 34.73 | |||

| Camphene-PA/RFA[18] | Form-stable | 68.32 | 60.46 | 37.08 | 34.41 | 55.5 | 18.2 |

| MA/TiO2-RFA[19] | Form-stable | 52.22 | 26.68 | 23.43 | 22.57 | 13.01 | 12.72 |

| LA/RFA[27] | Form-stable | 41.34 | 42.75 | 34.09 | 32.97 | 19.3 | |

| LA/RFA[32] | Both | 42.6 | 40.4 | 43.3 | 38.1 | 21 | 16 |

| MA-PA-SA/modified FA modified FA by weak acid and high temperature[26] | 47.6 | 44.06 | 30 | 35.11 | |||

| MA/modified FA by weak acid and high temperature[29] | 47.6 | 51.18 | 30 | 30.04 | |||

| Al(50%)/modified FA by high temperature[21] | Form-stable | 579 | 35.65 | 50 | 11.88 | ||

| LA(28.5%)/silicon dioxide[38] | Both | 43.84 | 40.09 | 51.47 | 36.22 | 28.5 | |

| LA(30%)/modified sepiolite[40] | Both | 42.4 | 41.5 | 58.4 | 54.3 | 30 | 27.99 |

| LA(44.8%)/CNT[41] | Form-stable | 35.02 | 42.61 | 44.8 | |||

| LA(this study) | Both | 44.29 | 41.23 | 179.6 | 177.9 | 100 | 100 |

| 28% LA +55%RFA+17%DT (this study) | Both | 45.79 | 41.71 | 51.06 | 50.30 | 28 | 28.27 |

| 28% LA +55%RFA+17%DT+ 5%CNT(this study) | Both | 45.50 | 41.01 | 44.07 | 43.44 | 26.67 | 24.59 |

|

式中:μ是FSPCM的相应加载分数,%;ΔHFSPCM和ΔH分别是FSPCM和LA的潜热量,J/g。计算结果亦参见表 2。从表 2中可知,封装在LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM中的LA分别为28.27%和24.59%,与理论值基本一致。

由表 2可知,本工作制得LA/RFA-DT/CNT, LA/RFA-DT/CNT FSPCM的相变潜热、吸附率和粉煤灰利用率均高于未改性粉煤灰基复合FSPCM和部分改性粉煤灰基复合FSPCM。而其相变潜热甚至与部分矿物基LA复合FSPCM的相变潜热相当。更为重要的是,其制备工艺简单、成本低,在保持较高相变潜热的前提下,所制备LA/RFA-DT/CNT FSPCM对原始粉煤灰的利用率为55%,这为粉煤灰的大量综合再利用提供了新的可能。

此外,为考察LA/RFA-DT/CNT定形复合相变储能材料的耐久性,对所制备LA/RFA-DT/CNT定形复合相变储能材料进行了100次的加热-冷却循环测试,并将循环测试加前后的DSC结果进行了比较,如图 6所示。从图 6可看出,LA/RFA-DT/CNT加热-冷却循环前后,其熔化和凝固过程中的相变温度和潜热值没有显著的差异。因此,即使使用寿命长,LA/RFA-DT/CNT定形复合相变储能材料具有良好的可靠性。

|

图 6 LA/RFA-DT/CNT循环前后DSC曲线 Fig. 6 DSC curves of LA/RFA-DT/CNT before and after heating and cooling cycles |

图 7为LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM的TG曲线。从图 7可知,LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM的分解起始温度分别为129, 135 ℃和140 ℃,均高于其工作温度,且LA/RFA-DT/CNT FSPCM分解起始温度较纯月桂酸提高了约10 ℃;三者的分解终止温度分别为255, 250 ℃和227 ℃,此时LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM的失重分别为99.95%, 26.57%和24.93%。这充分说明RFA-DT和CNT提高了LA的热稳定性,使LA/RFA-DT/CNT复合FSPCM具有较好的热稳定性。

|

图 7 LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT FSPCM的TG曲线 Fig. 7 TG curves of LA, LA/RFA-DT FSPCM and LA/RFA-DT/CNT FSPCM |

图 8为LA, LA/RFA-DT FSPCM和LA/RFA-DT/CNT(5%) FSPCM的熔化/凝固曲线。其实验过程按照参考文献[44-45]进行,表 3为各样品熔化/凝固性能参数及热传递速率对比表。从图 8和表 3可知,相同起始温度,LA达到熔化点需要10 min,而LA/RFA-DT FSPCM和LA/RFA-DT/CNT(5%) FSPCM分别需要6,4 min;相同温度开始,LA需要8 min完成凝固过程,LA/RFA-DT FSPCM和LA/RFA-DT/CNT(5%) FSPCM分别需要5,3 min;与纯LA相比,定形复合相变储能材料的热传递速率相对较高,分别提高37.5%, 67.5%。

|

图 8 LA, LA/RFA-DT FSPCM和LA/RFA-DT/ CNT(5%) FSPCM吸热/放热曲线 Fig. 8 Storing and releasing curves of LA, LA/RFA-DT FSPCM and LA/RFA-DT/CNT (5%) FSPCM |

| Sample | Heat time/min | Heat storing time/min | Freezing time/min | Heat releasing time/min | Improved heat rate/% | Improved freezing rate/% |

| LA | 5 | 4 | 10 | 8 | ||

| LA/RFA-DT | 2.5 | 3 | 6 | 5 | 40 | 37.5 |

| LA/RFA-DT/CNT (5%) | 2 | 1.5 | 4 | 3 | 60 | 62.5 |

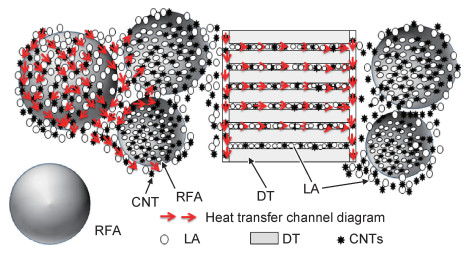

添加碳纳米管主要目的为进一步强化复合相变储能材料的热传递效果,从图 8和表 3可知其的确起到了相应的效果。而碳纳米管进一步强化改善复合相变材料的热传递效率的作用机理,如图 9所示。从图 9可知,碳纳米管在LA/RFA-DT/CNT复合相变储能材料制备过程的充分搅拌,使得碳纳米管与LA, RFA-DT充分混合,并尽可能分散在圆球形粉煤灰表面上或硅藻土多孔微结构中,这样在热导率高的碳纳米管所分散之处可形成连续的高效率导热通道,从而降低了热能在所封装月桂酸分子间的传递界面阻力;同时,碳纳米管在吸收热量后又变成新的热源,使热能从高值区域向低值区域较快传递,改善其周围月桂酸的热传递效果;这样碳纳米管就进一步提高了LA/RFA-DT/CNT复合相变储能材料的热导率。碳纳米管含量越高、分散越均匀连续,形成连续而高效率的导热通道的概率越大,传热面积越大,传热效率越高。

|

图 9 LA/RFA-DT/CNT中碳纳米管强化热传递作用机理 Fig. 9 Mechanism of heat transfer enhanced by CNT in LA/RFA-DT/CNT |

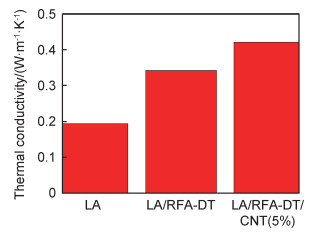

为了验证上述机理,对LA, LA/RFA-DT和LA/RFA-DT/CNT 3个样品的热导率进行了测试,结果如图 10所示。从图 10可得,纯相变材料LA的热导率比较低,只有0.19 W·m-1·K-1;LA/RFA-DT的热导率为0.34 W· m-1·K-1,相比纯LA,热导率得到较大提高,这可能是由于LA与封装载体RFA和DT混合后,粉煤灰中含有可做导热剂的Al2O3等氧化物成分所致。而LA/RFA-DT/CNT的热导率为0.42 W·m-1·K-1,显然加入碳纳米管导热剂之后,LA/RFA-DT/CNT的热导率得到进一步提高;而热导率越高,热传递效率越高。这与融化-凝固曲线的热传递速率结果一致,也证实了LA/RFA-DT/CNT中碳纳米管强化热传递作用机理解释的合理性。

|

图 10 LA, LA/RFA-DT和LA/RFA-DT/CNT的热导率对比 Fig. 10 Thermal conductivity comparison among LA, LA/RFA-DT and LA/RFA-DT/CNT |

(1) 以粉煤灰-硅藻土二元载体来封装月桂酸,添加碳纳米管为传热强化剂,采用直接熔融共混法制备了月桂酸/粉煤灰-硅藻土/碳纳米管定形复合相变材料,当月桂酸、粉煤灰、硅藻土质量分数分别为28%,55%,17%时,可制得无泄漏定形复合相变储能材料;粉煤灰-硅藻土可作为脂肪酸的封装载体材料,且对原样粉煤灰利用率为55%。

(2) 月桂酸、粉煤灰、硅藻土、碳纳米管之间以物理作用为主,所制备定形复合材料化学相容性良好;月桂酸/粉煤灰-硅藻土的熔化/凝固相变温度分别为45.79 ℃和41.71 ℃,相变潜热分别为51.06 J/g和50.30 J/g;月桂酸/粉煤灰-硅藻土/ 碳纳米管的熔化/凝固相变温度分别为45.50 ℃和41.01 ℃,相变潜热分别为44.07 J/g和43.44 J/g;月桂酸/粉煤灰-硅藻土/碳纳米管受热分解的开始温度远高于其工作温度,具有较好的热稳定性。

(3) 碳纳米管的加入可提高月桂酸/粉煤灰-硅藻土复合材料的热传递速率,当加入质量分数为5%的碳纳米管时,复合相变储能材料的熔化与凝固时间分别减少4 min和3 min,即热传递速率分别提高60%和62.5%。LA,LA/RFA-DT,LA/RFA-DT/CNT的热导率分别为0.19,0.34,0.42 W·m-1·K-1;复合相变储能材料中的碳纳米管所分散之处形成连续的高效率导热通道,是碳纳米管进一步改善传热效率的机理所在。

| [1] |

安宁, 马雨威, 刘聚明, 等. 与粉煤灰耦合增强碳掺杂TiO2的可见光催化氧化能力[J]. 催化学报, 2018, 39(12): 1890-1900. AN N, MA Y W, LIU J M, et al. Enhanced visible-light photocatalytic oxidation capability of carbon-doped TiO2 via coupling with fly ash[J]. Chinese Journal of Catalysis, 2018, 39(12): 1890-1900. |

| [2] |

刘鹏, 顾晓滨, 饶俊, 等. 典型固体废弃物制备相变复合材料研究现状及展望[J]. 硅酸盐通报, 2019, 38(2): 380-385. LIU P, GU X B, RAO J, et al. Development and prospects for preparation of composite phase change materials from typical solid waste[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(2): 380-385. |

| [3] |

刘新杰, 王昊, 刘丽丽. 粉煤灰资源开发利用及产业发展[J]. 无机盐工业, 2018, 50(5): 12-14. LIU X J, WANG H, LIU L L. Development and utilization of fly ash resources[J]. Inorganic Chemicals Industry, 2018, 50(5): 12-14. |

| [4] |

王建新, 李晶, 赵仕宝, 等. 中国粉煤灰的资源化利用研究进展与前景[J]. 硅酸盐通报, 2018, 37(12): 3833-3841. WANG J X, LI J, ZHAO S B, et al. Research progress and prospect of resource utilization of fly ash in China[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(12): 3833-3841. |

| [5] |

REDDY K S, MUDGAL V, MALLICK T K. Review of latent heat thermal energy storage for improved material stability and effective load management[J]. Journal of Energy Storage, 2018, 15: 205-227. DOI:10.1016/j.est.2017.11.005 |

| [6] |

JEONA J, PARKA J H, WIA S, et al. Thermal performance enhancement of a phase change material with expanded graphite via ultrasonication[J]. Journal of Industrial and Engineering Chemistry, 2019, 79: 437-442. DOI:10.1016/j.jiec.2019.07.019 |

| [7] |

SARI A, SALEH T, HEKIMOGLU G, et al. Evaluation of carbonized waste tire for development of novel shape stabilized composite phase change material for thermal energy storage[J]. Waste Management, 2020, 103: 352-360. DOI:10.1016/j.wasman.2019.12.051 |

| [8] |

顾晓滨, 秦善, 牛菁菁. 相变储能矿物材料研究现状及其展望[J]. 矿物岩石地球化学通报, 2014, 33(6): 932-940. GU X B, QIN S, NIU J J. Research status and prospect on phase change mineral materials[J]. Bulletin of Mineralogy, Petrology and Geochemistry, 2014, 33(6): 932-940. DOI:10.3969/j.issn.1007-2802.2014.06.023 |

| [9] |

LV P, LIU C, RAO Z. Review on clay mineral-based form-stable phase change materials: preparation, characterization and applications[J]. Renewable and Sustainable Energy Reviews, 2017, 6: 707-726. |

| [10] |

刘鹏, 顾晓滨, 秦善. 相变储能材料系统典型数值模拟研究现状与进展[J]. 储能科学与技术, 2018, 7(2): 221-231. LIU P, GU X B, QIN S. State-of-the-art development of numerical simulations of phase change materials based systems[J]. Energy Storage Science and Technology, 2018, 7(2): 221-231. |

| [11] |

SONG H, YUM W, OH J, et al. Development of fly ash-based aggregate using phase change materials and thermal performance analysis using TGA[J]. Journal of the Korea Concrete Institute, 2018, 30: 147-148. DOI:10.4334/JKCI.2018.30.2.147 |

| [12] |

KHERADMAND M, ABDOLLAHNEJAD Z, PACHECO T F. Alkali-activated cement-based binder mortars containing phase change materials (PCMs): mechanical properties and cost analysis[J]. European Journal of Environmental and Civil Engineering, 2020, 24(8): 1068-1090. DOI:10.1080/19648189.2018.1446362 |

| [13] |

LIU P, GU X B, ZHANG Z, et al. Capric acid hybridizing fly ash and carbon nanotubes as a novel shape-stabilized phase change material for thermal energy storage[J]. ACS Omega, 2019, 4(12): 14962-14969. DOI:10.1021/acsomega.9b01746 |

| [14] |

杨飞. 建筑节能用相变储能材料的热物性研究[D]. 重庆: 重庆大学, 2014. YANG F. Thermal properties of phase change energy storage material for building energy conservation[D]. Chongqing: Chongqing University, 2014. |

| [15] |

董昭. 用于建筑节能的粉煤灰相变储能材料的制备及应用实验[D]. 重庆: 重庆大学, 2013. DONG Z. Preparation and application of fly ash matrix phase change materials for thermal storage in building energy conservation[D]. Chongqing: Chongqing University, 2013. |

| [16] |

韩建辉. 复合相变储能材料: 硬脂酸 & 粉煤灰的配比分析[J]. 山东化工, 2014, 43(3): 28-30. HAN J H. Ratio analysis of phase change energy storage material: stearic acid & coal ash[J]. Shandong Chemical Industry, 2014, 43(3): 28-30. |

| [17] |

杨颖, 董昭, 童明伟, 等. 十六醇-癸酸/粉煤灰定形相变材料的制备及热性能分析[J]. 化工新型材料, 2014, 42(5): 101-104. YANG Y, DONG Z, TONG M W, et al. Preparation and thermal performance characteristics of cetyl alcohol-decylic acid/fly ash shape-stabilized phase change materials[J]. New Chemical Materials, 2014, 42(5): 101-104. |

| [18] |

GENC Z, CANBAY C, ACAR S, et al. Preparation and thermal properties of heterogeneous composite phase change materials based on camphene-palmitic acid[J]. Journal of Thermal Analysis and Calorimetry, 2015, 120: 1679-1688. DOI:10.1007/s10973-015-4478-3 |

| [19] |

GENC M, KARAGOZ GENC Z. Microencapsulated myristic acid-fly ash with TiO2 shell as a novel phase change material for building application[J]. Journal of Thermal Analysis and Calorimetry, 2018, 131(3): 2373-2380. DOI:10.1007/s10973-017-6781-7 |

| [20] |

LIU L, PENG B, YUE C, et al. Low-cost, shape-stabilized fly ash composite phase change material synthesized by using a facile process for building energy efficiency[J]. Materials Chemistry and Physics, 2019, 222: 87-95. DOI:10.1016/j.matchemphys.2018.09.072 |

| [21] |

王建宏. 粉煤灰基高温复合相变蓄热材料的制备与性能研究[D]. 西安: 西安建筑科技大学, 2013. WANG J H. Study on preparation and properties of high temperature fly ash base phase change heat storage composite materials[D]. Xi'an: Xi'an University of Architecture and Technology, 2013. |

| [22] |

华建社, 王建宏, 陈海波, 等. 粉煤灰制备高温复合相变蓄热材料的可行性研究[J]. 热加工工艺, 2013, 42(12): 104-106. HUA J S, WANG J H, CHEN H B, et al. Availability of preparation process of high temperature fly ash based phase change composite[J]. Hot Working Technology, 2013, 42(12): 104-106. |

| [23] |

赵海东, 张咪, 马宏芳, 等. 粉煤灰基高温复合相变蓄热材料的制备[J]. 山西大同大学学报(自然科学版), 2016(5): 38-40. ZHAO H D, ZHANG M, MA H F, et al. The preparation of high temperature composite phase change heat storage material of fly ash[J]. Journal of Shanxi Datong University (Natural Science Edition), 2016(5): 38-40. |

| [24] |

朱桂花, 吕硕, 韩金鹏, 等. 球形粉煤灰基高温定形复合相变蓄热材料的制备与性能[J]. 煤炭转化, 2018, 41(2): 73-79. ZHU G H, LV S, HAN J P, et al. Preparation and properties of spherical fly ash based form-stable composite phase change material for high temperature thermal storage[J]. Coal Conversion, 2018, 41(2): 73-79. |

| [25] |

韩金鹏, 朱桂花, 吕硕, 等. 相变介质粒径对粉煤灰基高温定形复合相变材料蓄热性能的影响[J]. 煤炭转化, 2019, 42(1): 78-86. HAN J P, ZHU G H, LV S, et al. Effects of particle size of phase change medium on thermal storage performance of fly ash-based high temperature form-stable composite phase change material[J]. Coal Conversion, 2019, 42(1): 78-86. |

| [26] |

赖榕永, 王温馨, 谢雯倩, 等. MA-PA-SA/改性粉煤灰复合相变储能材料的制备与性能[J]. 材料导报, 2019, 33(增刊1): 219-222. LAI R Y, WANG W X, XIE W Q, et al. Preparation and properties of composite phase change energy storage material MA-PA-SA/modified fly ash[J]. Materials Review, 2019, 33(Suppl 1): 219-222. |

| [27] |

XU D, YANG H, OUYANG J, et al. Lauric acid hybridizing fly ash composite for thermal energy storage[J]. Minerals, 2018, 8: 161-169. |

| [28] |

赵亮, 王海洋, 方向晨, 等. 改性粉煤灰相变储能材料在余热回收中的应用[J]. 储能科学与技术, 2013, 2(6): 598-602. ZHAO L, WANG H Y, FANG X C, et al. Modification of fly ash as a carrier of paraffin wax based phase change energy storage material for waste heat recovery[J]. Energy Storage Science and Technology, 2013, 2(6): 598-602. |

| [29] |

黄平, 丁益民, 李宣瑶. 肉豆蔻酸/改性粉煤灰复合相变储能材料的制备及性能研究[J]. 材料导报, 2016, 30(增刊1): 214-216. HUANG P, DING Y M, LI X Y. Preparation and properties of myristic acid-stearic acid/modified fly ash composite phase change energy storage materials[J]. Materials Review, 2016, 30(Suppl 1): 214-216. |

| [30] |

黄平, 丁益民, 胡婷, 等. 肉豆蔻酸-硬脂酸/改性粉煤灰复合相变储能材料的制备及性能研究[J]. 功能材料, 2017, 48(5): 5154-5158. HUANG P, DING Y M, HU T, et al. Study on preparation and properties of myristic-stearic acid/modified fly ash composite phase change energy storage materials[J]. Journal of Functional Materials, 2017, 48(5): 5154-5158. |

| [31] |

PILEHVAR S, CAO V, SZCZOTOK A, et al. Physical and mechanical properties of fly ash and slag geopolymer concrete containing different types of micro-encapsulated phase change materials[J]. Construction and Building Materials, 2018, 173: 28-39. |

| [32] |

QIU F, SONG S K, LI D N, et al. Experimental investigation on improvement of latent heat and thermal conductivity of shape-stable phase-change materials using modified fly ash[J]. Journal of Cleaner Production, 2020, 246: 118952-118961. |

| [33] |

SARI A, BICER A, AL-SULAIMAN F A, et al. Diatomite/CNTs/PEG composite PCMs with shape-stabilized and improved thermal conductivity: preparation and thermal energy storage properties[J]. Energy and Buildings, 2018, 164: 166-175. |

| [34] |

LI M, GUO Q, NUTT S. Carbon nanotube/paraffin/montmorillonite composite phase change material for thermal energy storage[J]. Solar Energy, 2017, 146: 1-7. |

| [35] |

LIU P, GU X B, BIAN L, et al. Thermal properties and enhanced thermal conductivity of capric acid/diatomite/carbon nanotubes composite as form-stable phase change materials for thermal energy storage[J]. ACS Omega, 2019, 4(2): 2964-2972. |

| [36] |

SARI A, BICER A, HEKIMOGLU G. Effects of carbon nanotubes additive on thermal conductivity and thermal energy storage properties of a novel composite phase change material[J]. Journal of Composite Materials, 2018, 52: 1-14. |

| [37] |

RAMAKRISHNAN S, WANG X, SANJAYAN J, et al. Assessing the feasibility of integrating form-stable phase change material composites with cementitious composites and prevention of PCM leakage[J]. Materials Letters, 2017, 192: 88-91. |

| [38] |

FANG G, LI H, LIU X. Preparation and properties of lauric acid/silicon dioxide composites as form-stable phase change materials for thermal energy storage[J]. Materials Chemistry and Physics, 2010, 122(2/3): 533-536. |

| [39] |

CHEN Z, SHAN F, CAO L, et al. Synthesis and thermal properties of shape-stabilized lauric acid/activated carbon composites as phase change materials for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2012, 102: 131-136. |

| [40] |

SHEN Q, OUYANG J, ZHANG Y, et al. Lauric acid/modified sepiolite composite as a form-stable phase change material for thermal energy storage[J]. Applied Clay Science, 2017, 146: 14-22. |

| [41] |

FENG Y, WEI R, HUANG Z, et al. Thermal properties of lauric acid filled in carbon nanotubes as shape-stabilized phase change materials[J]. Physical Chemistry Chemical Physics, 2018, 20: 7772-7780. |

| [42] |

RAO Z H, ZHANG G T, XU T T, et al. Experimental study on a novel form-stable phase change materials based on diatomite for solar energy storage[J]. Solar Energy Materials and Solar Cells, 2018, 182: 52-60. |

| [43] |

MA L Y, WANG Q W, LI L P. Delignified wood/capric acid-palmitic acid mixture stable-form phase change material for thermal storage[J]. Solar Energy Materials and Solar Cells, 2019, 194: 215-221. |

| [44] |

LIU P, GU X B, BIAN L, et al. Capric acid/intercalated diatomite as form-stable composite phase change material for thermal energy storage[J]. Journal of Thermal Analysis and Calorimetry, 2019, 138: 359-368. DOI:10.1007/s10973-019-08230-8 |

| [45] |

GU X B, LIU P, BIN L, et al. Enhanced thermal conductivity of palmitic acid/mullite phase change composite with graphite powder for thermal energy storage[J]. Renewable Energy, 2019, 138: 833-841. |

2021, Vol. 49

2021, Vol. 49