文章信息

- 董亚光, 陈尚, 王俊升, 靳柯

- DONG Ya-guang, CHEN Shang, WANG Jun-sheng, JIN Ke

- 含BCC/B2共格结构多主元合金研究进展

- Research progress in multi-principal element alloys containing coherent BCC/B2 structure

- 材料工程, 2021, 49(2): 1-9

- Journal of Materials Engineering, 2021, 49(2): 1-9.

- http://dx.doi.org/10.11868/j.issn.1001-4381.2020.000351

-

文章历史

- 收稿日期: 2020-04-20

- 修订日期: 2020-10-15

2. 北京理工大学 前沿交叉科学研究院, 北京 100081

2. Advanced Research Institute of Multidisciplinary Science, Beijing Institute of Technology, Beijing 100081, China

通过引入第二相阻碍位错运动是合金常见的强化方式之一[1-5], 其中共格析出相稳定性较高, 且在起强化作用的同时可较好地保持材料的塑性[3-8]。例如, 在马氏体时效钢中引入与BCC(体心立方)基体共格的B2相可获得高达2.2 GPa的抗拉强度, 并保持8%的塑性[6]。Yeh等[9]和Cantor等[10]于2004年提出高熵合金和多主元合金概念。与传统合金单一主元的成分特点不同[6-12], 这类新型合金由多种合金元素按照等原子比或近似等原子比方式混合而成[13-17], 因其独特的合金设计理念与优异的性能而得到国内外的广泛关注[18-21]。早期多主元合金的研究主要针对单相固溶体合金[22-25]。随着研究的深入和拓展, 发现在多主元合金中引入共格析出相可以大幅度提升力学性能, 例如在FCC(面心立方)结构的Ni-Co-Fe-Cr-Ti-Al[23-24]和Al-Cr-Fe-Ni-V多主元合金[25]中, 通过引入共格L12相进行强化。近年来, BCC结构多主元合金表现出了优异的强度、硬度及较好的耐磨性能, 具有良好的应用前景[26-27]。在此基础上, 研究人员发现通过在BCC固溶体中引入共格B2相, 获得含BCC/B2共格结构多主元合金, 如Al-3d金属体系[28]与Al-难熔金属体系等[29-30], 合金强度得到进一步提高。

本文归纳了含BCC/B2共格结构多主元合金的研究进展, 分析了多主元合金中BCC/B2共格结构的成分与组织形貌, 剖析了BCC/B2共格结构的稳定性, 总结了这类合金的组成元素及力学性能等特征, 并展望了含BCC/B2共格结构多主元合金的发展方向。

1 成分与组织形貌尽管在铁基、镍基等传统合金中已经发现多种B2结构的第二相, 如Fe-Ti, Fe-Al, Ni-Ti, Ni-Al相, 但是目前在BCC结构多主元合金中发现的B2相主要为二元Ni-Al相和三元Ti-Al-M(M=Zr, Mo, Cr等)相, 这些B2相的成分与镍基合金和钛基合金中的B2相类似[31-34]。从合金成分看, 现有含BCC/B2共格结构的多主元合金可大致分为2类: (1)Al-3d金属体系, 通常在由3d过渡元素组成的FCC结构多主元合金中添加Al元素而获得; (2)Al-难熔金属体系, 通常在由难熔金属组成的BCC结构多主元合金中添加Al元素后发生有序化而形成。这2类合金中BCC/B2共格结构的形成可能是由Al元素与其他元素之间高的负混合焓所致[35]。

1.1 Al-3d金属体系此类合金主要由Ni, Co, Fe, Cr, Mn等3d过渡元素和Al元素组成[36-39], 其中Al与Ni原子之间有较低的混合焓(-22 kJ/mol)[35], 易于形成B2结构的富(Al, Ni)相。

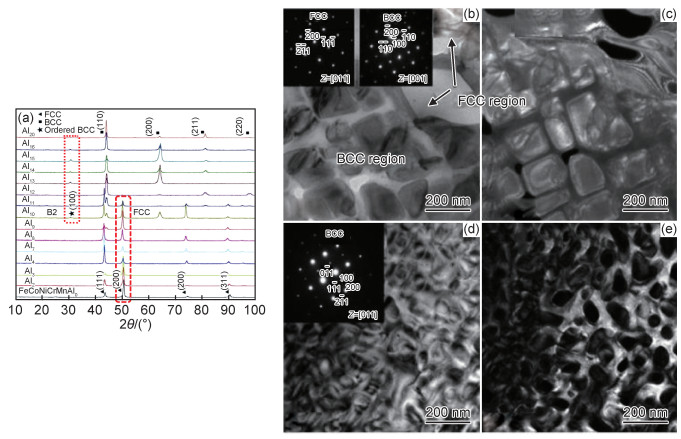

等原子比NiCoFeCrMn合金是典型的FCC结构单相多主元合金, 具有良好的强度与塑性匹配。He等[36]研究了Al含量对(NiCoFeCrMn)100-xAlx合金结构的影响(图 1), 发现随着Al含量的增加, FCC结构逐渐向BCC结构转变, 而当Al元素含量较高时会进一步形成B2相, 如图 1(e)所示。类似的结构演变现象在NiCoFeCrAlx[37], NiFeCrAlx[38]等合金中也能够发现。此外, 合金的组织大都是由无序BCC相和有序B2基体相组成, 只有少数合金中的B2相弥散分布于BCC基体中, 而对于合金中BCC/B2结构的相变顺序, 还未有统一的定论。Santodonato等[40]通过模拟研究发现, NiCoFeCrAl合金在凝固过程中的相变顺序为BCC固溶体→部分有序B2相(作者称之为B2'相)→BCC+B2双相。

|

图 1 (NiCoFeCrMn) 100-xAlx合金的XRD谱图和TEM图[36] (a)XRD图; (b), (c)(NiCoFeCrMn)89Al11合金TEM图; (d), (e)(NiCoFeCrMn)80Al20合金TEM图 Fig. 1 XRD patterns and TEM images of (NiCoFeCrMn)100-xAlx alloys[36] (a)XRD patterns; (b), (c)TEM images of (NiCoFeCrMn)89Al11 alloys; (d), (e)TEM images of (NiCoFeCrMn)80Al20 alloys |

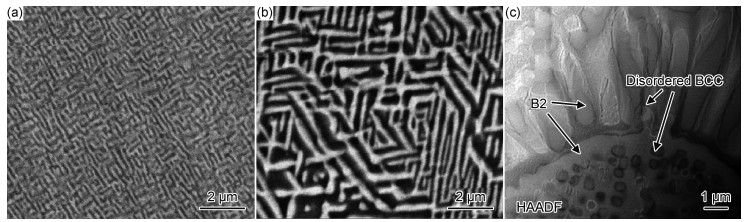

在Al-3d金属体系中, B2相均为富(Al, Ni)相, 而BCC/B2共格结构的形貌随成分的变化而变化。例如, 在(NiCoFeCrMn)89Al11合金中, B2相呈方格状, BCC相分布于B2相之间(图 1(b), (c))。在(NiCoFeCrMn)80Al20合金中, BCC相呈立方状分布于B2基体上(图 1(d), (e))。在NiCoFeCrAl和NiFeCrAl合金中, BCC/B2双相呈编织网状的调幅组织(图 2(a), (b)), 然而, Ni35Fe21.67Cr21.67Al21.67合金具有独特的花瓣状BCC/B2共格结构[41](图 2(c)), 核心由B2基体相和球形颗粒状BCC相组成, 花瓣处由BCC基体相和向外发散的条纹状B2相组成, 且富(Fe, Cr)的BCC相是由初生富(Al, Ni)-B2基体相发生调幅分解而形成。可见, 通过成分设计能够调控并优化多主元合金中BCC/B2共格结构的相组成及其组织形貌。

|

图 2 不同元素含量的NiFeCrAl多主元合金中BCC/B2共格结构的组织形貌 (a)NiFeCrAl合金[38]; (b)NiFeCrAl1.3合金[38]; (c)Ni35Fe21.67Cr21.67Al21.67合金[41] Fig. 2 Microstructures of the coherent BCC/B2 structure of NiFeCrAl alloys with different compositions (a)NiFeCrAl alloy[38]; (b)NiFeCrAl1.3 alloy[38]; (c)Ni35Fe21.67Cr21.67Al21.67 alloy[41] |

合金主要由Ti, V, Zr, Mo, Ta等高熔点金属元素和Al元素组成[42-44], 其中B2相与钛基合金中的B2型Ti-Al-M(M=Zr, Mo, Cr等)相成分类似。

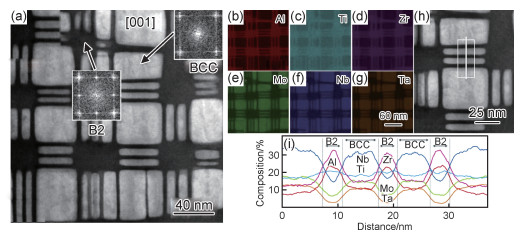

难熔多主元合金多为BCC固溶体结构[42-45], 而一定含量Al元素的添加可促使共格富(Ti, Al, M)-B2相的形成。Whitfield等[46]发现Mo0.5NbTa0.5TiZr合金由BCC固溶体相和形状不同的HCP相组成, 而Jensen等[30]研究发现Al元素的添加使AlMo0.5NbTa0.5TiZr合金在晶粒内部形成周期性排列的方格形或板条形BCC/B2共格结构(图 3), 其中B2相为富(Ti, Al, Zr)相[47]。类似的方格形或板条形BCC/B2共格结构在其他Al-难熔金属体系中也可以观察到, 如Al10(Ti45Ta27.5Zr27.5)[48], Al0.25NbTaTiZr[49]和Al0.5NbTa0.8Ti1.5V0.2Zr[50]合金。除了方格形或板条形BCC/B2共格结构外, Jensen等[49]通过降低Al含量获得含有球状BCC相的Al0.5Mo0.5NbTa0.5TiZr合金。Schliephake等[51]在Al0.5MoTaTi合金中发现立方形和环形混合的BCC/B2共格结构。Zhang等[52]在AlTiV合金中发现纳米B2相弥散分布于BCC基体中。Soni等[50]通过特殊的热处理方式(热等静压+1200 ℃/24 h均匀化+1200 ℃/2 h退火处理)在Al0.5NbTa0.8Ti1.5V0.2Zr合金中也发现了在BCC基体中弥散分布的纳米级B2相。对于Al-难熔金属体系中BCC/B2共格结构的相变顺序, Schliephake等[51]根据Al0.5MoTaTi合金中反相畴界的形成、组织形貌等特征, 推测出该合金在凝固或热处理过程中的相变顺序为BCC相→B2相→B2+BCC双相, 且这一推测与Al-3d金属体系中NiCoFeCrAl合金的模拟结果相似, 但应用范围仍需进一步研究。

|

图 3 AlMo0.5NbTa0.5TiZr合金中BCC/B2共格结构的STEM-HAADF图和XEDS图[30] (a)STEM-HAADF图; (b)~(g)XEDS图; (h)高倍数下的STEM-HAADF图; (i)图 3(h)中沿白色线分布的元素含量 Fig. 3 STEM-HAADF images and XEDS elemental maps of AlMo0.5NbTa0.5TiZr alloys[30] (a)STEM-HAADF image; (b)-(g)XEDS maps; (h)STEM-HAADF image under high magnification; (i)composition of elements along with white line in fig. 3(h) |

Al-难熔金属体系中的BCC/B2结构通常是在铸态、均匀化或固溶态下形成, 而Körmann等[53]基于第一性原理计算预测不含Al元素的NbMoTaW合金会在750 K时由无序BCC结构向有序B2结构转变, 有序化温度为508 K[54]。实验结果表明[55-56], NbMoTaW合金无论是在铸态还是经1800 ℃/168 h热处理后均未形成B2相, 因此通过中等温度下长时间时效是否可以得到新的含BCC/B2共格结构多主元合金尚待验证。

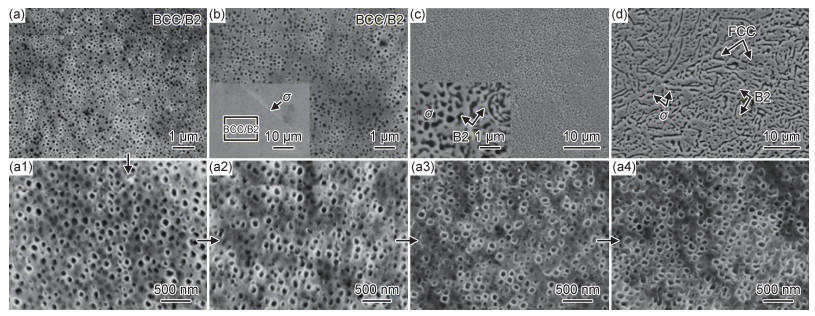

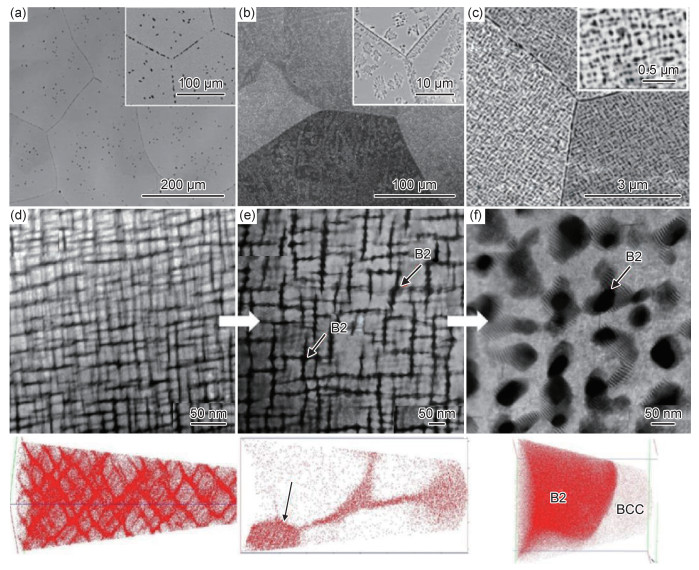

2 结构稳定性合金在高温下的结构稳定性是其在高温应用时需要重点考量的因素之一。Al-3d金属体系的BCC/B2共格结构在300~500 ℃范围内表现出较高的稳定性, 例如NiCoFeCr2Al0.7合金在500 ℃以下热处理2 h时, BCC/B2共格结构稳定, B2相呈立方形均匀分布在BCC基体中; 而当热处理温度升高到600 ℃时, BCC相逐渐被σ相取代, 且B2相不再保持立方形形貌; 当温度继续升高至1000 ℃时, 合金则以FCC固溶体为主要物相(图 4(a)~(d))[57]。可见, 在600 ℃以上进行热处理时, BCC/B2共格结构会逐渐消失。这种结构和形貌的变化在NiCoFeCrAlx[58]和Ni15Fe36Cr18Mn21Al10[59]等合金中也被发现。图 4(a1)~(a4)为NiCoFeCr2Al0.7合金在500 ℃下热处理不同时间的SEM图, 颗粒状B2相的尺寸并没有随热处理时间的延长而发生明显粗化, 平均尺寸在100~120 nm之间, 表明合金在500 ℃以下BCC/B2共格结构的确具有较高的稳定性。

|

图 4 NiCoFeCr2Al0.7合金经不同工艺热处理后的SEM图[57] (a)500 ℃/2 h; (a1)500 ℃/24 h; (a2)500 ℃/240 h; (a3)500 ℃/720 h; (a4)500 ℃/1080 h; (b)600 ℃/2 h; (c)800 ℃/2 h; (d)1000 ℃/2 h Fig. 4 SEM images of NiCoFeCr2Al0.7 alloy annealed at 500 ℃ for 2 h(a), 24 h(a1), 240 h(a2), 720 h(a3), 1080 h(a4), and at 600 ℃(b), 800 ℃(c), 1000 ℃(d) for 2 h[57] |

对于Al-难熔金属体系, 较高温度下的长时间热处理会使合金在晶界或晶内形成新的金属间化合物。例如, Al10Nb15Ta5Ti30Zr40合金经600 ℃/72 h和750 ℃/24 h热处理后, 在晶界处形成大量的颗粒状ω相[60]; Al0.5NbTa0.8Ti1.5V0.2Zr合金经1000 ℃/20 h热处理后, 在晶界处出现不连续分布的富(Al, Zr)-HCP相, 在晶粒内部呈颗粒状分布(图 5(a)), 而经800 ℃/20 h热处理后, 富(Al, Zr)-HCP相尺寸明显缩小, 聚集在一起并呈片状或面状分布在晶界一侧, 在晶内由片状聚集形成(图 5(b))[50, 61]。除了金属间化合物的形成, 一种特殊的相反转(phase inversion)现象发生在Al0.5NbTa0.8Ti1.5V0.2Zr合金中, 该合金经600 ℃/0.5 h热处理后, 形成与AlMo0.5NbTa0.5TiZr[30], Al0.25NbTaTiZr[49]合金相似的方格状或板条状BCC/B2共格结构, 而在该温度下延长热处理时间使B2相逐渐聚集长大, 直至热处理120 h时形成以BCC基体相和分离的B2相组成的双相组织(图 5(c)~(f))。在相反转后的组织中, BCC与B2相的晶格错配度由600 ℃/0.5 h热处理后的0.93%增加到600 ℃/120 h热处理后的3.8%[29], 然而这种现象还未在其他含BCC/B2共格结构多主元合金中观察到。

|

图 5 Al0.5NbTa0.8Ti1.5V0.2Zr合金经1000 ℃/20 h(a), 800 ℃/20 h(b), 600 ℃/120 h(c)热处理后的SEM图[29], 600 ℃/0.5 h(d), 600 ℃/24 h(e), 600 ℃/120 h(f)的STEM-HAADF图和APT结果[61] Fig. 5 SEM images of Al0.5NbTa0.8Ti1.5V0.2Zr alloys annealed at 1000 ℃ for 20 h(a), 800 ℃ for 20 h(b) and 600 ℃ for 120 h(c)[29], STEM-HAADF images and APT results of the alloys annealed at 600 ℃ for 0.5 h(d), 600 ℃ for 24 h(e) and 600 ℃ for 120 h(f)[61] |

共格析出相通过阻碍位错运动从而强化合金, 获得较高强度[57-60]。与非共格相相比, 具有可变形性(位错可切过粒子)的共格相对合金塑性的影响较小[62]。

表 1总结了含BCC/B2共格结构多主元合金的形貌、B2相组成及室温压缩力学性能, 其中σ0.2 为屈服强度, ε为断裂应变。与Al-3d金属体系相比, Al-难熔金属体系表现出较高的屈服强度和更低的塑性。通过对比表 1中各合金的BCC/B2结构形貌, 可以发现, 基体为B2相的合金的强度普遍较高, 而塑性明显更低。值得注意的是, 等原子比多主元合金的力学性能并非是最好的, 例如, 在Ni-Fe-Cr-Al体系中, Ni35Fe21.67Cr21.67Al21.67合金的室温屈服强度为1471 MPa, 塑性为40%, 优于等原子比NiFeCrAl合金的843.2 MPa和34.6%, 与Melnick等[63]对难熔多主元合金的研究结果类似。此外, 通过热处理调控析出相的尺寸/体积分数会显著影响力学性能。例如, NiCoFeCr2Al0.7合金在铸态时的室温屈服强度和塑性分别为1727 MPa和约22.5%, 经过500 ℃/2 h热处理后, 立方状B2相的尺寸由铸态时的100 nm增加到120 nm, B2相的体积分数从铸态时的55%增加到62%, 这种相体积分数和尺寸优化后的组织使屈服强度提高到2190 MPa, 而塑性仅降低了约1%[57]。

| Alloy | Morphology of coherent BCC/B2 structures | Element of B2 phase | σ0.2/MPa | ε/% |

| (NiCoFeCrMn)89Al11[36] | Cubic-shaped B2 and interconnected BCC | Al, Ni | — | — |

| (NiCoFeCrMn)80Al20[36] | BCC-spherical phases, B2-matrix phase | Al, Ni | — | — |

| NiCoFeCrAl0.74[37] | Weave-like spinodal structure (BCC+B2) | Al, Ni | 1394 | 24 |

| NiCoFeCrAl1.12[37] | BCC-spherical particles, B2-matrix phase | Al, Ni | 1366 | 17 |

| NiCoFeCrAl1.33[37] | BCC-spherical particles, B2-matrix phase | Al, Ni | 1348 | 14 |

| NiFeCrAl[38] | Maze-shaped spinodal structure (BCC+B2) | Al, Ni | 843.2 | 34.6 |

| NiFeCrAl1.3[38] | Maze-shaped spinodal structure (BCC+B2) | Al, Ni | 1122.8 | 24.7 |

| Ni35Fe21.67Cr21.67Al21.67[41] | Sunflower-like structure (BCC+B2) | Al, Ni | 1471 | 40 |

| Ni14Co4Fe34Cr34Al14[64] | BCC-matrix, B2-cuboidal particles | Al, Ni | 1353 | 40.6 |

| NiCoFeCr2Al0.7[55] | BCC-matrix, B2-cuboidal particles | Al, Ni | 1727 | 22.5 |

| NiCoFe2CrAl0.7[65] | BCC-matrix, B2-cuboidal particles | Al, Ni | 1166 | 30.2 |

| Ni15Fe36Cr18Mn21Al10[57] | BCC-matrix, B2-cuboidal particles | Al, Ni | 990 | >50 |

| (Ni15Fe40Cr20Mn25)90Al10[66] | BCC-matrix, B2-cuboidal particles | Al, Ni | 987 | >50 |

| (Ni15Fe40Cr20Mn25)86Al14[66] | BCC-matrix, B2-cuboidal particles | Al, Ni | 941 | >50 |

| AlMo0.5NbTa0.5TiZr[30, 49] | BCC-cuboidal and plate-like precipitates, B2-matrix phase | Ti, Al, Zr | 2197 | 4 |

| Al0.25NbTaTiZr[49] | BCC-cuboidal and plate-like precipitates, B2-matrix phase | Ti, Al, Zr | 1745 | 3.8 |

| Al0.5NbTa0.8Ti1.5V0.2Zr[50] | BCC-cuboidal precipitates, B2-matrix phase | Ti, Al, Zr | 2032 | 4.7 |

| Al0.5MoTaTi[51] | BCC-cuboidal and loop morphology, B2-matrix phase | — | 1085 | 4.6 |

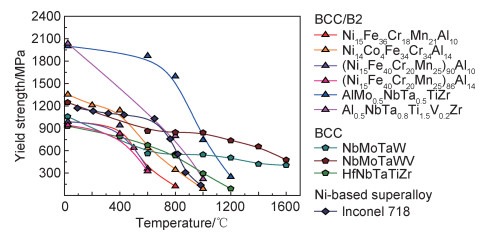

图 6对比了部分含BCC/B2共格结构或单相BCC结构多主元合金与镍基合金的高温屈服强度[42-43, 59, 64-68]。根据变化趋势可知, Inconel 718合金的高温屈服强度高于目前所报道的Al-3d金属体系, 而低于Al-难熔金属体系。Al-3d金属体系在高于400 ℃时的屈服强度呈现明显的下降趋势, Inconel 718合金在高于700 ℃时呈现该趋势, 而Al-难熔金属体系在高于800 ℃时才会出现。与单相BCC结构难熔多主元合金相比, Al-难熔金属体系在低于800 ℃时表现出更高的屈服强度, 但高于1000 ℃时的屈服强度较低。

含BCC/B2共格结构多主元合金在成分上主要包括Al-3d金属和Al-难熔金属2类体系, 合金组织形貌多样, 结构稳定性和力学性能也存在较大差异。当前已发现的含BCC/B2共格结构多主元合金在300~500 ℃下具有较好的结构稳定性, 而更高温度/长时间热处理会导致相变、相反转等现象的发生。在力学性能方面, 室温下Al-3d金属体系的室温屈服强度低于Al-难熔金属体系的, 而塑性则相反; 高温下Al-难熔金属体系表现出较高的屈服强度, 而高于800 ℃时呈现明显下降的趋势。

尽管含BCC/B2共格结构多主元合金的研究取得了一定的进展和成果, 但进一步实现在工程上的应用仍然面临一系列挑战, 如强塑性匹配、结构稳定性等问题。在此类合金中, Al元素与其他元素之间较低的混合焓易于形成金属间化合物, 且编织状的BCC/B2共格结构造成位错缠结和应力集中, 使得合金塑性较差。随着多主元合金的发展, 模拟计算方法使多主元合金相形成、相转变以及结构稳定性的研究过程更加便利, 因此可将第一性原理、相场模拟和其他热力学计算方法结合起来, 通过成分设计与热处理的双重优化, 开发新型低Al、含BCC/B2共格结构的多主元合金是推动其工程应用的一种重要途径。

| [1] |

WERINOS M, ANTREKOWITSCH H, EBNER T, et al. Design strategy for controlled natural aging in Al-Mg-Si alloys[J]. Acta Materialia, 2016, 118: 296-305. DOI:10.1016/j.actamat.2016.07.048 |

| [2] |

KIM S H, KIM H, KIM N J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility[J]. Nature, 2015, 518(7537): 77-79. DOI:10.1038/nature14144 |

| [3] |

吕昭平, 雷智锋, 黄海龙, 等. 高熵合金的变形行为及强韧化[J]. 金属学报, 2018, 54(11): 1553-1566. LU Z P, LEI Z F, HUANG H L, et al. Deformation behavior and toughening of high-entropy alloys[J]. Acta Metallurgica Sinica, 2018, 54(11): 1553-1566. |

| [4] |

ZHAO H L, DONG Y G, DONG X L, et al. Effects of trace alloy-ing elements Fe and Cr on the microstructure and aging properties of Cu-3Ti alloy foils[J]. Metals, 2018, 8(11): 881. DOI:10.3390/met8110881 |

| [5] |

信思树, 王镇华, 李春玲, 等. 体心立方BCC基多主元合金中的共格析出及强化[J]. 材料导报, 2020, 34(7): 7130-7137. XIN S S, WANG Z H, LI C L, et al. Coherent precipitation and strengthening in body-centered-cubic-based multi-component alloys[J]. Materials Reports, 2020, 34(7): 7130-7137. |

| [6] |

JIANG S H, WANG H, WU Y, et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation[J]. Nature, 2017, 544(7651): 460-464. DOI:10.1038/nature22032 |

| [7] |

DORIN T, RAMAJAYAM M, LAMB J, et al. Effect of Sc and Zr addition on the microstructure/strength of Al-Cu binary alloys[J]. Materials Science and Engineering: A, 2017, 707: 58-64. DOI:10.1016/j.msea.2017.09.032 |

| [8] |

MOCHUGOVSKIY A G, MIKHAYLOVSKAYA A V, TABACH- KOVA N Y, et al. The mechanism of L12 phase precipitation, microstructure and tensile properties of Al-Mg-Er-Zr alloy[J]. Materials Science and Engineering: A, 2019, 744: 195-205. DOI:10.1016/j.msea.2018.11.135 |

| [9] |

YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303. DOI:10.1002/adem.200300567 |

| [10] |

CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys[J]. Materials Science and Engineering: A, 2004, 375/377: 213-218. DOI:10.1016/j.msea.2003.10.257 |

| [11] |

ZHANG K, GAO X L, DONG Y G, et al. Effect of annealing on the microstructure, microhardness, and corrosion resistance of Ni62Nb33Zr5 metallic glass and its composites[J]. Journal of Non-Crystalline Solids, 2015, 425: 46-51. DOI:10.1016/j.jnoncrysol.2015.05.027 |

| [12] |

GUO S, HU Q, NG C, et al. More than entropy in high-entropy alloys: forming solid solutions or amorphous phase[J]. Intermetallics, 2013, 41: 96-103. DOI:10.1016/j.intermet.2013.05.002 |

| [13] |

ZHANG Y, LU Z P, MA S G, et al. Guidelines in predicting phase formation of high-entropy alloys[J]. MRS Communications, 2014, 4(2): 57-62. DOI:10.1557/mrc.2014.11 |

| [14] |

GUO S, NG C, LU J, et al. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys[J]. Journal of Applied Physics, 2011, 109: 103505. DOI:10.1063/1.3587228 |

| [15] |

YANG X, ZHANG Y. Prediction of high-entropy stabilized so-lid-solution in multi-component alloys[J]. Materials Chemistry and Physics, 2012, 132: 233-238. DOI:10.1016/j.matchemphys.2011.11.021 |

| [16] |

SINGH A K, KUMAR N, DWIVEDI A, et al. A geometrical parameter for the formation of disordered solid solutions in multi-component alloys[J]. Intermetallics, 2014, 53: 112-119. DOI:10.1016/j.intermet.2014.04.019 |

| [17] |

TODA-CARABALLO I, RIVERA-DÍAZ-DEL-CASTILLO P E J. A criterion for the formation of high entropy alloys based on lattice distortion[J]. Intermetallics, 2016, 71: 76-87. DOI:10.1016/j.intermet.2015.12.011 |

| [18] |

LU Y P, GAO X Z, LI J, et al. Directly cast bulk eutectic and near-eutectic high enropy alloys with balanced strength and ductility in a wide temperature range[J]. Acta Materialia, 2017, 124: 143-150. DOI:10.1016/j.actamat.2016.11.016 |

| [19] |

LU Y P, DONG Y, GUO S, et al. A promising new class of high-temperature alloys: eutectic high-entropy alloys[J]. Scientific Reports, 2014, 4: 6200. |

| [20] |

WU Z, BEI H B, PHARR G M, et al. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures[J]. Acta Materialia, 2014, 81: 428-441. DOI:10.1016/j.actamat.2014.08.026 |

| [21] |

LU C Y, NIU L L, CHEN N J, et al. Enhancing radiation tole-rance by controlling defect mobility and migration pathways in multicomponent single-phase alloys[J]. Nature Communications, 2016, 7: 13564. DOI:10.1038/ncomms13564 |

| [22] |

ZHANG Y, ZUO T, TANG Z, et al. Microstructures and pro-perties of high-entropy alloys[J]. Progress in Materials Science, 2014, 61: 1-93. DOI:10.1016/j.pmatsci.2013.10.001 |

| [23] |

HE J Y, WANG H, HUANG H L, et al. A precipitation-hardened high-entropy alloy with outstanding tensile properties[J]. Acta Materialia, 2016, 102: 187-196. DOI:10.1016/j.actamat.2015.08.076 |

| [24] |

ZHENG Y, JIA N N, QIAN F, et al. Thermal stability of (CoCrFeNi)94Ti2Al4 alloy containing coherent nanoprecipitates at intermediate temperatures[J]. Materialia, 2020, 12: 100775. DOI:10.1016/j.mtla.2020.100775 |

| [25] |

LIANG Y J, WANG L J, WANG Y R, et al. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys[J]. Nature Communications, 2018, 9: 4063. DOI:10.1038/s41467-018-06600-8 |

| [26] |

FEUERBACHER M, LIENIG T, THOMAS C. A single-phase bcc high-entropy alloy in the refractory Zr-Nb-Ti-V-Hf system[J]. Scripta Materialia, 2018, 152: 40-43. DOI:10.1016/j.scriptamat.2018.04.009 |

| [27] |

WU Y D, CAI Y H, CAI X H, et al. Phase composition and solid solution strengthening effect in TiZrNbMoV high-entropy alloys[J]. Materials & Design, 2015, 83: 651-660. |

| [28] |

MA Y, WANG Q, JIANG B B, et al. Controlled formation of coherent cuboidal nanoprecipitates in body-centered cubic high-entropy alloys based on Al2(Ni, Co, Fe, Cr)14 compositions[J]. Acta Materialia, 2018, 147: 213-225. DOI:10.1016/j.actamat.2018.01.050 |

| [29] |

SONI V, GWALANI B, ALAM T, et al. Phase inversion in a two-phase, BCC+B2, refractory high entropy alloy[J]. Acta Materialia, 2020, 185: 89-97. DOI:10.1016/j.actamat.2019.12.004 |

| [30] |

JENSEN J K, WELK B A, WILLIAMS R E A, et al. Characte-rization of the microstructure of the compositionally complex alloy Al1Mo0.5Nb1Ta0.5Ti1Zr1[J]. Scripta Materialia, 2016, 121: 1-4. DOI:10.1016/j.scriptamat.2016.04.017 |

| [31] |

OVRUTSKY A, PROKHODA A. Particularities of nucleation and growth of the B2-phase: results of simulations for the Al50Ni50 alloy[J]. Computational Materials Science, 2013, 79: 193-200. DOI:10.1016/j.commatsci.2013.05.045 |

| [32] |

PREMKUMAR M, SINGH A K. Deformation behavior of an ordered B2 phase in Ti-25Al-25Zr alloy[J]. Intermetallics, 2010, 18: 199-201. DOI:10.1016/j.intermet.2009.07.015 |

| [33] |

DAS K, DAS S. Order-disorder transformation of the body centered cubic phase in the Ti-Al-X (X=Ta, Nb, or Mo) system[J]. Journal of Materials Science, 2003, 38: 3995-4002. DOI:10.1023/A:1026262616194 |

| [34] |

SINGH A K, BANUMATHY S, SOWJANYA D, et al. On the structure of the B2 phase in Ti-Al-Mo alloys[J]. Journal of App-lied Physics, 2008, 103: 103519. DOI:10.1063/1.2931004 |

| [35] |

TAKEUCHI A, INOUE A. Classification of bulk metallic gla-sses by atomic size difference, heat of mixing and period of consi-tuent elements and its application to characterization of the main alloying element[J]. Materials Transactions, 2005, 46: 2817-2829. DOI:10.2320/matertrans.46.2817 |

| [36] |

HE J Y, LIU W H, WANG H, et al. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system[J]. Acta Materialia, 2014, 62: 105-113. DOI:10.1016/j.actamat.2013.09.037 |

| [37] |

MA Y, JIANG B B, LI C L, et al. The BCC/B2 morphologies in AlxNiCoFeCr high-entropy alloys[J]. Metals, 2017, 7: 57. DOI:10.3390/met7020057 |

| [38] |

CHEN X, QI J Q, SUI Y W, et al. Effects of aluminum on microstructure and compressive properties of Al-Cr-Fe-Ni eutectic multi-component alloys[J]. Materials Science and Engineering: A, 2017, 681: 25-31. DOI:10.1016/j.msea.2016.11.019 |

| [39] |

WANG W R, WANG W L, WANG S C, et al. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys[J]. Intermetallics, 2012, 26: 44-51. DOI:10.1016/j.intermet.2012.03.005 |

| [40] |

SANTODONATO L J, LIAW P K, UNOCIC R R, et al. Predictive multiphase evolution in Al-containing high-entropy alloys[J]. Nature Communications, 2018, 9: 4520. DOI:10.1038/s41467-018-06757-2 |

| [41] |

ZHANG L, ZHOU D, LI B S. Anomalous microstructure and excellent mechanical properties of Ni35Al21.67Cr21.67Fe21.67 high-entropy alloy with BCC and B2 structure[J]. Materials Letters, 2018, 216: 252-255. DOI:10.1016/j.matlet.2018.01.124 |

| [42] |

SENKOV O N, ILKS G B, SCOTT J M, et al. Mechanical pro-perties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloy[J]. Intermetallics, 2011, 19: 698-706. DOI:10.1016/j.intermet.2011.01.004 |

| [43] |

SENKOV O N, SCOTT J M, SENKOVA S V, et al. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy[J]. Journal of Alloys and Compounds, 2011, 509: 6043-6048. DOI:10.1016/j.jallcom.2011.02.171 |

| [44] |

JIA N N, LI Y K, LIU X, et al. Thermal stability and mechanical properties of low-activation single-phase Ti-V-Ta medium entropy alloys[J]. JOM, 2019, 71: 3490-3498. DOI:10.1007/s11837-019-03713-3 |

| [45] |

陈永星, 朱胜, 王晓明, 等. 高熵合金制备及研究进展[J]. 材料工程, 2017, 45(11): 129-138. CHEN Y X, ZHU S, WANG X M, et al. Progress in preparation and research of high entropy alloys[J]. Journal of Materials Engineering, 2017, 45(11): 129-138. |

| [46] |

WHITFIELD T E, PICKERING E J, TALBOT C E, et al. Observation of a refractory metal matrix containing Zr-Ti-rich precipitates in a Mo0.5NbTa0.5TiZr high entropy alloy[J]. Scripta Materialia, 2020, 180: 71-76. DOI:10.1016/j.scriptamat.2020.01.028 |

| [47] |

SENKOV O N, ISHEIM D, SEIDMAN D N, et al. Development of a refractory high entropy superalloy[J]. Entropy, 2016, 18: 102. DOI:10.3390/e18030102 |

| [48] |

WHITFIELD T E, PICKERING E J, OWEN L R, et al. The effect of Al on the formation and stability of a BCC-B2 microstructure in a refractory metal high entropy superalloy system[J]. Materialia, 2020, 13: 100858. DOI:10.1016/j.mtla.2020.100858 |

| [49] |

SENKOV O N, JENSEN J K, PILCHAK A L, et al. Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0.5TiZr[J]. Materials & Design, 2018, 139: 498-511. |

| [50] |

SONI V, SENKOV O N, GWALANI B, et al. Microstructural design for improving ductility of an initially brittle refractory high entropy alloy[J]. Scientific Reports, 2018, 8: 8816. DOI:10.1038/s41598-018-27144-3 |

| [51] |

SCHLIEPHAKE D, MEDVEDEV A E, IMRAN M K, et al. Precipitation behaviour and mechanical properties of novel Al0.5MoTaTi complex concentrated alloy[J]. Scripta Materialia, 2019, 173: 16-20. DOI:10.1016/j.scriptamat.2019.07.033 |

| [52] |

ZHANG X K, YE H T, HUANG J C, et al. Nano-scaled creep response of TiAlV low density medium entropy alloy at elevated temperatures[J]. Materials, 2020, 13: 36. |

| [53] |

KÖRMANN F, RUBAN A V, SLUITER M H F. Long-ranged interactions in bcc NbMoTaW high-entropy alloys[J]. Materials Research Letters, 2017, 5: 35-40. DOI:10.1080/21663831.2016.1198837 |

| [54] |

KÖRMANN F, SLUITER M H F. Interplay between lattice distortions, vibrations and phase stability in NbMoTaW high entropy alloys[J]. Entropy, 2016, 18(8): 403. DOI:10.3390/e18080403 |

| [55] |

SENKOV O N, WILKS G B, MIRACLE D B, et al. Refractory high-entropy alloys[J]. Intermetallics, 2010, 18: 1758-1765. DOI:10.1016/j.intermet.2010.05.014 |

| [56] |

ZOU Y, MAITI S, STEURER W, et al. Size-dependent plasticity in an Nb25Mo25Ta25 W25 refractory high-entropy alloy[J]. Acta Materialia, 2014, 65: 85-97. DOI:10.1016/j.actamat.2013.11.049 |

| [57] |

MA Y, HAO J M, WANG Q, et al. Temperature-affected microstructural stability of coherent cuboidal B2 particles in precipitation-strengthened body-centered-cubic Al0.7CoCr2FeNi high-entropy alloy[J]. Journal of Materials Science, 2019, 54: 8696-8710. DOI:10.1007/s10853-019-03459-y |

| [58] |

WANG W R, WANG W L, YEH J W. Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures[J]. Journal of Alloys and Compounds, 2014, 589: 143-152. DOI:10.1016/j.jallcom.2013.11.084 |

| [59] |

SHAYSULTANOV D G, SALISHCHEV G A, IVANISENKO Y V, et al. Novel Fe36Mn21Cr18Ni15Al10 high entropy alloy with bcc/B2 dual-phase structure[J]. Journal of Alloys and Compounds, 2017, 705: 756-763. DOI:10.1016/j.jallcom.2017.02.211 |

| [60] |

SONI V, SENKOV O N, COUZINIE J P, et al. Phase stability and microstructure evolution in a ductile refractory high entropy alloy Al10Nb15Ta5Ti30Zr40[J]. Materialia, 2020, 9: 100569. DOI:10.1016/j.mtla.2019.100569 |

| [61] |

SONI V, GWALANI B, SENKOV O N, et al. Phase stability as a function of temperature in a refractory entropy alloy[J]. Journal of Materials Research, 2018, 33: 3235-3246. DOI:10.1557/jmr.2018.223 |

| [62] |

ARDELL A J. Precipitation hardening[J]. Metallurgical and Materials Transactions A, 1985, 16(12): 2131-2165. DOI:10.1007/BF02670416 |

| [63] |

MELNICK A B, SOOLSHENKO V K. Thermodynamic design of high-entropy refractory alloys[J]. Journal of Alloys and Compounds, 2017, 694: 223-227. DOI:10.1016/j.jallcom.2016.09.189 |

| [64] |

ZHOU Y, JIN X, ZHANG L, et al. A hierarchical nanostructured Fe34Cr34Ni14Al14Co4 high-entropy alloy with good compressive mechanical properties[J]. Materials Sicence and Engineering: A, 2018, 716: 235-239. DOI:10.1016/j.msea.2018.01.034 |

| [65] |

WANG Q, MA Y, JIANG B B, et al. A cuboidal B2 nanoprecipitation-enhanced body-centered-cubic alloy Al0.7CoCrFe2Ni with prominent tensile properties[J]. Scripta Materialia, 2016, 120: 85-89. DOI:10.1016/j.scriptamat.2016.04.014 |

| [66] |

STEPANOV N D, SHAYSULTANOV D G, CHERNICHENKO R S, et al. Effect of Al on structure and mechanical properties of Fe-Mn-Cr-Ni-Al non-equiatomic high entropy alloys with high Fe content[J]. Journal of Alloys and Compounds, 2019, 770: 194-203. DOI:10.1016/j.jallcom.2018.08.093 |

| [67] |

SENKOV O N, WOODWARD C, MIRACLE D B. Microstructure and properties of aluminum-containing refractory high-entropy alloys[J]. JOM, 2014, 66: 2030-2042. DOI:10.1007/s11837-014-1066-0 |

| [68] |

SENKOV O N, SCOTT J M, SENKOVA S V, et al. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy[J]. Journal of Materials Science, 2012, 47: 4062-2074. DOI:10.1007/s10853-012-6260-2 |

2021, Vol. 49

2021, Vol. 49