The article information

- Bin-Shi Xu

- Technology of self-repairing and reinforcement of metal worn surface

- Advances in Manufacturing, 2013, 1(1): 102-105

- http://dx.doi.org/10.1007/s40436-013-0009-2

-

Article history

- Received: 2012-09-08

- Accepted: 2012-11-15

- Published online: 2013-03-13

Friction and wear,as one of the main causes of materials failure,has attracted more and more attention all over the world [1, 2]. In recent years,micro-nano scale phyllosilicate composition (the main component is serpentine) developed by Russian researchers exposed favorable self-repairing performance at practical application [3]. Jin et al. [4] studied the tribological performance of serpentine by using the serpentine additive in diesel engine of locomotive,and the results indicated that certain thickness of self-repairing protective layer can be formed on the iron worn surface. Moreover,the self-repairing protective layer possesses lower surface roughness,higher microhardness and very low frictional coefficient. Zhang et al. [5] indicated that the tribological performance of metallic tribo-couples was improved and the friction temperature was reduced by adding micro-nano scale natural serpentine powder (SP) into base oil. The self-repairing technology for the metal worn surface of mechanical equipments under the running conditions, by using lubricating oil as carrier to transport the micro-nano scale into the interface of tribo-couples,could accelerate the formation of self-repairing protective layer with a dynamical thickness on the worn surface. Thereby,the formation of self-repairing protective layer on worn surface could reduce worn and prolong remarkably the service life of equipments [2]. It is notable that there are numerous research reports on the tribological performance of phyllosilicate selfrepairing material,but the self-repairing mechanism in the frictional course did not get to a common view.

Our research team has been hammering at research works about serpentine (a kind of phyllosilicate) in the past few years,such as surface modification,tribological properties,self-repairing mechanism,and so on. In this paper,some research work was introduced summarily. 2 Experimental

Friction and wear tests were performed on a RFT-III tribometer with a pin-on-block configuration at room temperature [6, 7]. The upper sample was a pin with a diameter of 8 mm and a height of 30 mm,and the lower sample was sectioned into 70 nm 9 14 nm 9 14 mm block. The pin makes oscillating movement (50 mm in amplitude) on the top of block. Both pin and block were made of 45# steel. The tribological testswere conducted with a load of 50 Nand a sliding speed of 1.0 m/s. All the specimens were ultrasonically cleaned in an acetone bath prior to the tribological tests. A MicroXAM 3D profiler was used to measure the worn volumes of the disks after friction and wear testing. All wear rates were calculated based on the worn volumes and the sliding distance. The morphology and composition of worn surfaces were investigated by using scanning electron microscopy (SEM),X-ray energy dispersive spectroscopy (EDS),laser Raman spectroscopy and X-ray photoelectron spectroscopy (XPS). 3 Results and discussion 3.1 Tribological properties

The tribological properties of serpentine powder as additive in lubricant oil was investigated. The result shows that the tribological properties of base oil can be remarkably improved by addition of serpentine powder under different sliding conditions [6, 7, 8, 9, 10, 11, 12]. Figure 1 shows the tribological properties of lubricant oil before and after addition of serpentine powder [8]. Compared with base oil,friction coefficient of lubricant oil containing 0.5 % serpentine powder by weight was reduced to one-half (see Fig. 1a), and wear rate was reduced by 80 % (see Fig. 1b).

|

| Fig. 1 a Friction coefficient and b wear rate of lubricant oil with and without addition of serpentine powder [7] |

Figure 2 shows the SEM morphologies of worn surface under lubricating condition of base oil and oil including serpentine powder [8]. The typical characteristics of abrasive wear and plastic deformation were exhibited on worn surface in base oil,as shown in Fig. 2a. After adding serpentine powder in base oil,a smooth surface morphology is presented on worn surface shown in Fig. 2b. Moreover, many black dots could be observed on the worn surface. The non-black areas around black dots are analyzed to be made from the elements of C,O,Fe,and Si by using EDS. There is higher content of element Si on black dot area than non-black area.

|

| Fig. 2 Micrograph of worn surface lubricated in a base oil,and b oil including serpentine powder [7] |

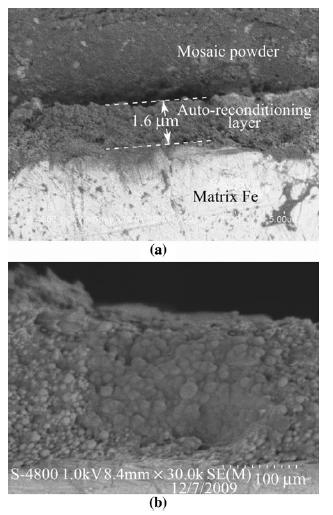

The SEM photographs of cross section of worn block surface under lubricating condition of base oil containing serpentine powder are shown in Fig. 3 [6]. Upper black mosaic powder,middle auto-reconditioning layer (selfrepairing layer) and lower matrix Fe can be observed in Fig. 3a,and the thickness of self-repairing layer is about 1.6 lm. The self-repairing layer was made of an amount of nano-scale particles with different particle sizes (60-180 nm),as shown in Fig. 3b. The self-repairing layer was compacted closely on matrix Fe,which means that there might be a transition layer for structure and composition on the interface between the self-repairing layer and matrix Fe.

|

| Fig. 3 SEM photograph of cross section of worn block surface under lubricating condition of base oil containing serpentine powder [6] |

The composition of self-repairing layer on worn surface was characterized by using EDS,laser Raman spectroscopy and XPS [6]. The results show that the self-repairing layer was made of Fe,Fe2O3,non-crystalline graphite,organic fragment,silicon organic substance and SiO2. The noncrystalline graphite was due to the fracture of carbon chains of lubricant oil,and could reduce friction coefficient of tribo-couples. Fe2O3 was the oxide of matrix Fe. Organic fragment,silicon organic substance and SiO2 might come from decomposition production or secondary reaction production of natural serpentine powder.

By addition of natural serpentine powder in lubricant oil,a self-repairing layer with a certain thickness could be formed on iron worn surface under certain tribological conditions. Due to the formation of self-repairing layer on worn surface,friction coefficient and wear rate of working parts could be decreased obviously. So the service life of machines could be prolonged effectively by using the dynamic self-repairing technology. 4 Conclusions

Serpentine powder as additive in lubricant oil shows the excellent tribological properties and self-repairing performance for metal tribo-couples. The technology of selfrepairing and reinforcement of metal worn surface had been used widely in friction fields of gear-box,bearing, gear driving parts,engine. The service life of these mechanical equipments could be prolonged remarkably. However,the self-repairing mechanism of serpentine had not been clear and needs to be studied in further.

In the future research work,the following aspects need to be noticed: (i) self-repairing mechanism of serpentine, (ii) the online detection of worn surface in the sliding process,and (iii) effect of rare earth metal on self-repairing performance of phyllosilicate serpentine.

Acknowledgments The paper is financially supported by the National Key Basic Research Program of China (973) (Grant No. 2011CB013405), Young Scientist Fund of NSFC (Grant Nos. 50904072, 50805146), China Postdoctoral Science Foundation (Grant Nos. 20090461452), and China Postdoctoral Science Special Foundation (Grant No. 201003796).| 1. | Shu SJ (1992) Wear of metals. Metallurgy Industrial Press,Beijing |

| 2. | Xu BS (2004) Nano surface engineering. Chemical Industry Press, Beijing |

| 3. | Yang H, Li SH, Jin YS (2005) Study on tribological behavior of Mg6Si4O10(OH)8 additive package with steel tribo-pair. Tribology 25(4):308–311 |

| 4. | Jin YS, Li SH, Zhang ZY et al (2004) In situ mechanochemical reconditioning of worn ferrous surfaces. Tribol Int 37(7):561–567 |

| 5. | Zhang B, Xu Y, Zhang BS et al (2011) Tribological performance research of micro-nano serpentine powders addictive to lubricant oil. Adv Mater Res 154(155):220–225 |

| 6. | Gao F, Xu Y, Xu BS et al (2011) Study on self-repairing performance and formation mechanism of self-repairing layer of natural serpentine powder as a lubricating oil additive. Tribology 31:431–438 |

| 7. | Zhang BS, Xu Y, Gao F et al (2011) Sliding friction and wear behaviors of surface-coated natural serpentine mineral powders as lubricant additive. Appl Surf Sci 257:2540–2549 |

| 8. | Zhang BS, Xu Y, Xu BS et al (2011) The self-reconditioning effect of the phyllosilicate lubricating material on Fe-based tribopairs. J Funct Mater 42(7):1301–1308 |

| 9. | Zhang BS (2011) Preparation of self-reconditioning materials based on metastable serpentine mineral and investigation on their tribology mechanisms. Dissertation, Shanghai Jiao Tong University |

| 10. | Zhang BS, Xu BS, Xu Y et al (2011) Cu nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribol Int 44:878–886 |

| 11. | Xu Y, Zhang BS, Xu BS et al (2011) Thermodynamic characteristics and tribological properties of lanthanum/serpentine composite lubricating material. Mater Sci Eng Powder Metall 16(3):349–354 |

| 12. | Zhang B, Xu Y, Gao F et al (2011) Tribological characteristics and self-repairing effect of hydroxy-magnesium silicate on various surface roughness friction pairs. J Cent South Univ Technol 18(5):1326–1333 |

2013, Vol. 1

2013, Vol. 1