The article information

- Varaprasad Bhemuni, Srinivasa Rao Chalamalasetti, Pavan Kumar Konchada, Venkata Vinay Pragada

- Analysis of hard turning process: thermal aspects

- Advances in Manufacturing, 2015, 3(4): 323-330

- http://dx.doi.org/10.1007/s40436-015-0124-3

-

Article history

- Received: 22 January 2015

- Accepted: 14 October 2015

- Published online: 13 November 2015

2 Department of Mechanical Engineering, College of Engineering (A), Andhra University, Visakhapatnam, India

Machining is a popular manufacturing process to produce high precision distinct metal parts. With the advent of new kind of tools such as cubic boron nitride (CBN), polycrystalline cubic boron nitride (PCBN),poly-crystalline diamond (PCD),coated,chemical vapor deposition (CVD),physical vapor deposition (PVD) and ceramic tools,better surface finish can be accessible without any finishing and complementary operations such as grinding, turning of hardened steels into finished parts by eliminating intermediate machining and reducing grinding operations. This has been a cost effective method for manufacturing high quality automotive components [1]. Besides,hard turning is flexible,environment friendly and higher output substitute to cylindrical grinding. However,surface quality and process reliability is still considered not on par with grinding process,due to issues related to different geometrically defined cutting tools [2].

The manufacturing sector is still hesitant to implement fast and economically hard turning technology compared to slow and costly grinding. Ceramic cutting tools can withstand high temperatures but not thermal and mechanical shocks. To optimize the tooling cost,ceramic cutting tools are the right choice for light and continuous cutting. The geometry of the insert also has a major influence upon the surface integrity. Single point cutting tool gives uniform micro structural changes compared to grinding as this will increase functional performance of the product. Hence correct tool geometry must be selected for a given application or it may produce subsurface damage and high tensile residual stresses on the surface of the machined workpiece [2, 3, 4, 5]. Generation of heat during hard turning and heat dissipation along the insert corner is also affected by geometry due to change in work material flow around the cutting edge [3].

Al2O3/TiN-coated tungsten carbide tools for finishturning of NiCr20TiAl nickel-based alloy under various cutting conditions,cutting forces,surface integrity and tool wear are investigated and the inter-diffusing and transferring of elements between Al2O3/TiN-coated tungsten carbide tool and NiCr20TiAl nickel-based alloy are studied [6]. The cutting performance of tungsten carbide tools with restricted contact length and multilayer chemical vapor deposition coatings,TiCN/Al2O3/TiN and TiCN/Al2O3- TiN in dry turning of AISI 4140 and the results show that coating layouts and cutting tool edge geometry can significantly affect the heat distribution in the cutting tool [7].

The machinability of hardened steel using grey relational approach and ANOVA to obtain optimum process parameters considering metal remove rate,surface finish, tool wear and tool life for both rough and finish machining is performed by Gopalsamy et al. [8]. Multi-response optimization of turning parameters and nose radius over surface roughness and power consumed using Taguchi based grey relational approach was conducted,and it reported that the main influencing parameter was cutting speed followed by feed rate and depth of cut [9]. In turning operations,for multi-response optimization Taguchi based grey relational approach was used to identify the optimum conditions to obtain better results [10, 11]. Prediction of flank wear and surface roughness during hard turning was performed using uncoated carbide inserts of various tool geometries by Senthilkumar et al. [12].

Mechanics and dynamics of machining hard metals using mixed ceramic tool has been investigated experimentally and analytically in few studies. In addition, studies of finite element (FE) modelling and orthogonal two dimensional (2D) cutting are also used to determine the influence of process parameters on performance characteristic such as formation of chips,cutting forces,temperatures and effective stresses [13, 14, 15, 16, 17]. Serrated formation of chip is seen with growing cutting speed and rate of feed in most FE experimental studies in hard turning [17, 18]. On the other hand,FE analysis on three dimensional (3D) hard turning is insufficient to appreciate the process completely. Ceretti et al. [19] established a 3D FE model for turning to predict forces of cutting,temperature and distribution of stresses for the machining of aluminium alloys and low-carbon steels under orthogonal and oblique cutting configurations were analyzed. A 3D FE model for hard turning of AISI 52100 steel PCBN tools was proposed by Guo and Liu [20]. Aurich and Bil [21] offered 3D FE modelling for segmented chip formation.

It is found from the literature that there is a scope for comparing CAE analysis with experimental results. The main advantage of CAE analysis over experimentation is that simulation can be performed for wider range of input parameters to enumerate their behavior on the performance characteristics. Rosochowska et al. [22] experimentally compared the heat contact conductance ‘‘h’’ with the theoretical formulation at various contact pressures and different interface temperatures.

Nusselt number is related to Reynolds number and Prandtl number. The convective heat transfer coefficient ‘‘h’’ is found using the Nusselt number,where ‘‘h’’ is proportional to Nusselt number [23]. The formulated value of ‘‘h’’,the workpiece and tool properties and the conditions selected are taken as an input for analysis using DEFORM 3D. The same conditions with the materials are experimented upon for comparison of the results with the outputs from the software DEFORM 3D.

2 ExperimentalThe workpiece materials used for experimentation are AISI D3 and AISI H13. Bars of diameter 70 mm 9 360 mm long are prepared. Test sample is trued,centered and cleaned by removing a 2 mm layer prior to actual machining tests. The chemical composition of the work specimens are presented in Table 1. AISI D3 is oil-quenched from 980 ℃ for hardening,followed by tempering at 200 ℃ to attain 62 HRC. The AISI H13 is hardened by oil quenching from 1 050 ℃ and tempered at 600 ℃ to attain 62 HRC.

Experimental setup is shown in Fig. 1. The lathe used for machining operations is Kirloskar (model Turn Master- 35,spindle power 6.6 kW). The cutting forces are measured by Kistler piezoelectric dynamometer (model 9257B). The dynamometer can measure forces in three mutually perpendicular directions,i.e.,feed force (Fx), thrust force (Fy) and cutting force (Fz). The charge generated at the dynamometer is amplified by a Kistler charge amplifier (model 5070A). The signal is acquired by a data acquisition system consisting of a personal computer, controller cable and charge amplifier. The Dynoware software installed in the personal computer is used to acquire the force data in all three directions. The average value of this force data is used for further analysis.

|

| Fig. 1 Experimental setup |

Surface roughness is measured using Mitutoyo Surftest SJ 210 with a measuring range of 17.5 mm and skid force less than 400 mN. Four readings with a sample length of 0.8 mm are recorded after each experiment and the average value is taken as the surface roughness.

The surface roughness values are obtained without disturbing the assembly of the workpiece in order to reduce uncertainties. The used cutting insert is SNGA 120408 T01020. The insert is a mixed ceramic grade (Sandvik CC6050),having an alumina base with an addition of titanium carbide. The high hot-hardness,good level of toughness make the grade suitable as the first choice for machining hardened steels (50-65 HRC). The inserts are mounted on a commercial tool holder of designation PSBNR 2525 M 12 (ISO) with the geometry of active part characterized by the following angles: χ = 75°; α = 6°; γ =-6°; λ =-6°.

The temperatures of the machined samples are measured by keeping the infrared thermometer (IR) at a distance of 15 cm from the workpiece and tool interface. The IR thermometer (Amprobe IR750) has a measuring temperature range of-50 ℃ to 1 500 ℃ and with an optical resolution of 10:1 and emissivity 0.1-1 (adjustable). Temperature measurements can be obtained online by using the software supplied along with the instrument.

Three levels are defined for each cutting process parameter (see Table 2). The cutting process parameter levels are chosen within the intervals according to recommendations made by the cutting tool manufacturer. Three selected cutting process parameters at three levels led to a total of 20 tests as per the response surface methodology (RSM) based central composite design (CCD),was applied as an experimental design employed to accomplish 20 tests with 6 center points. The 6 axial runs have the same input parameters and therefore the design matrix has 6 repeated runs.

In the present work,the CAE software DEFORM 3D is used. DEFORM 3D uses an implicit Lagrangian computational routine with continuous adaptive re-meshing. The workpiece is modelled as perfectly plastic. The material constitutive model of this deformable body is represented with Johnson-Cook material model [24]

where σ is flow stress,ε the plastic strain,ε the plastic strain rate,ε0 the reference plastic strain rate (0.001 s-1),T the tempature of the workpiece,Tmelt the melting temperature of the workpiece material and T0 the roomtemperature;material constant A is the yield strength,B the hardening modulus, C the strain rate sensitivity,n the strain-hardening exponent and m the thermal softening exponent. Although a more realistic simulation model for the machining process should also take A = 1491 MPa,B = 570 MPa,n = 0.24,C = 0.002 7,m = 0.6,Tmelt = 1 450 ℃. For AISI D3 and values for AISI H13 steel are A = 715 MPa,B = 329 MPa, C = 0.03,n = 0.28 and m = 1.5 and Tmelt = 1 475 ℃. The workpiece is represented by a straightmodel of 10 mmwhere the cutting tool ismodelled as a rigid body whichmoves at the specified cutting speed.A finemesh density is defined with an input size of 0.075 mm and size ratio 2 for workpiece. Thermal boundary conditions are defined keeping in view that it will allow heat transfer from workpiece to cutting tool. Heat transfer between the workpiece and the tool is dependent on the pressure developed during machining.

The values of thermal and mechanical properties,taken from the literature sources,used in this present paper are mentioned in Table 3. Workpiece model includes 100 000 elements of tetrahedron shape. The bottom surface of the workpiece is fixed in all directions. The cutting tool is modelled as a rigid body using 25 000 (tetrahedron) elements which moves at the specified cutting speed. A fine mesh density is defined at the tip of the tool and at the cutting zone to obtain a good process output distribution. 3D computational modelling is utilized to predict chip formation,forces,temperatures and tool wear on uniform honed tool of 80 lm nose radius. All simulations are run at the same cutting condition (Vc = 155 m/min,f = 0.075 mm/r,αp = 0.6 mm) for machining of AISI D3 and AISI H13 steel at a hardness of 62 HRC.

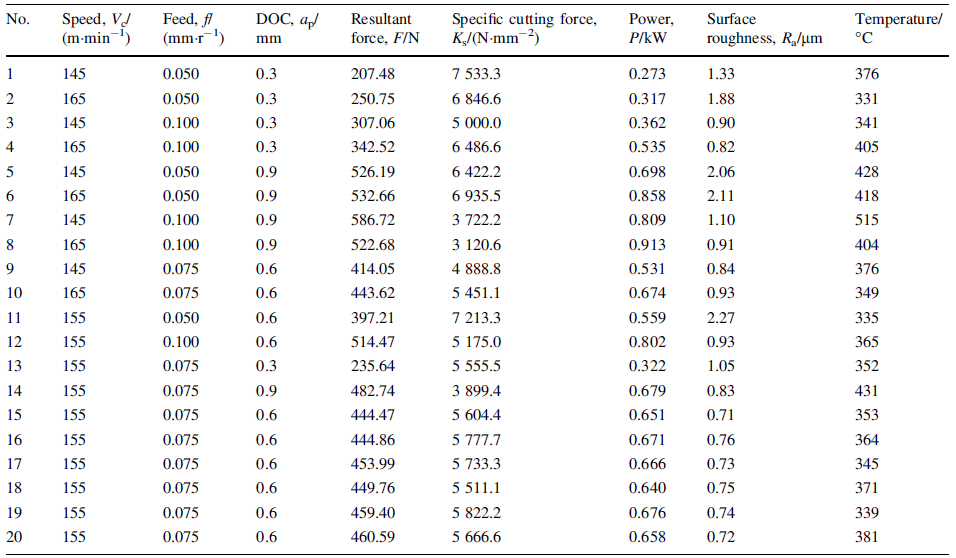

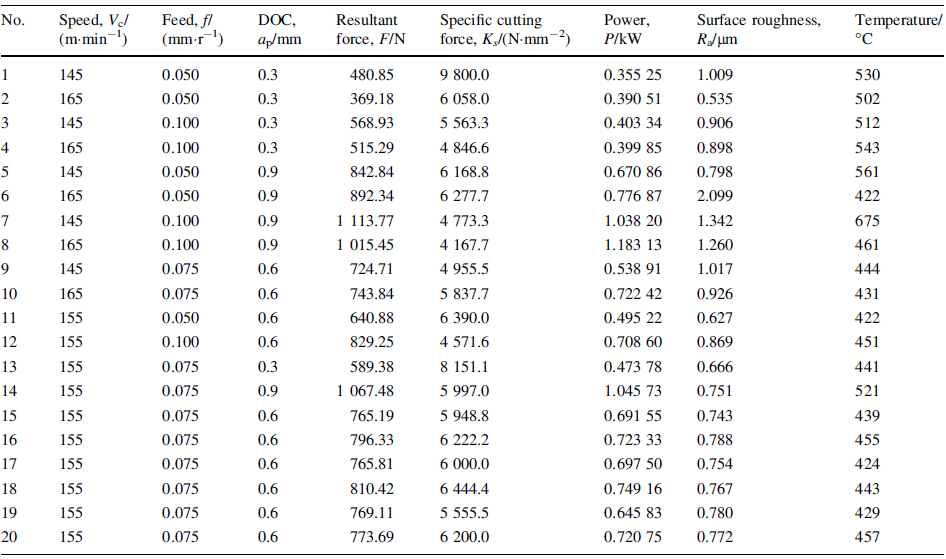

The experimental results obtained from the various measuring equipment’s as mentioned in the earlier section are shown in Tables 4 and 5. The obtained data from experimentation are compared with the simulation results from DEFORM 3D software for both the materials AISI D3 and AISI H13. These results have shown similar trends mostly and analysis performed in Section 5.

|

|

The insert (CC6050) used for the present research is selected due to its utilization in the local metal cutting industry for its high material removal rate and realization of good surface finish. Friction in metal cutting is found to be complex due to the varying level of contact conditions along the tool-chip contact area. In 3D FE modelling, constant shear friction factor m,Coulomb friction μ,and pressure-dependent shear friction factor m(p),have been benchmarked to identify the friction between tool and workpiece. The pressure dependent friction factor for the conditions (Vc = 155 m/min,f = 0.075 mm/r,αp = 0.6 mm) is evaluated from experimentation and is used in the modelling. A simple trial-and-error approach is used during fine-tuning friction models for calibrating FE simulation outputs.

From the results obtained,it may be concluded that the maximum temperature of workpiece and tool increase the cutting speed,which are 353 ℃ from Table 4 when machining AISI D3 and 439 ℃from Table 5 for AISI H13 at constant cutting speed (155 m/min) considered. Figures 2a, b show simulated values obtained during the machining of AISI D3 workpiece as 582 ℃ and 910 ℃ while machining AISI H13. Therefore it is possible,besides the cutting and thrust forces,to be extracted from the proposed model predictions. Obtaining these values of temperature from experimentation is laborious and sometimes impossible.

|

| Fig. 2 a Workpiece temperature profile of AISI D3, b workpiece temperature profile of AISI H13 |

As it can be observed from the simulations of the tools, temperatures are 254 ℃ when machining AISI D3 and 291 ℃ for AISI H13 presented in Figs. 3a,b. Examples of such cases are: the temperature distribution in the workpiece and tool in the form of isothermal bands and the effective stresses developed during cutting. This explains that the thrust force decreases for higher cutting speed,since softening of the material at higher temperature takes place. The regions thermally loaded are the chip and the rake face of the tool. In the chip-tool interface close to tool tip,due to the plastic deformation of the chip and the frictional forces,the part of the chip that is curled away from the rake face is progressively cooled down. The stress has an almost constant value along the center of the shear zone,while near the tool tip lower values of stress are observed. This can be explained due to the temperature rise of this area which softens the material.

|

| Fig. 3 a Tool temperature profile while cutting AISI D3, b tool temperature profile while cutting AISI H13 |

Figures 4a,b show the details of workpiece-tool interface temperatures. Simulated results from DEFORM 3D for temperature values are in the range of 30-592 ℃ when machining AISI D3 and 30-903 ℃,when machining AISI H13 are presented and experimental results recorded using infrared thermometer that can record the temperature values on to a computer are found to be in the same range as mentioned above. With the numerical results provided by the model,it is possible to minimize unwanted effects and choose suitable cutting conditions in order to optimize the process.

|

| Fig. 4 a Interface temperature profile while cutting AISI D3, b interface temperature profile while cutting AISI H13 |

The values of temperatures experimentally obtained are found (see Tables 4 and 5) to be correlating with the values observed from DEFORM 3D simulation for the inputs of cutting velocity of 155 m/min,feed rate of 0.075 mm/r and depth of cut 0.6 mm. Figures 5a,b show the variations in the maximum temperature attained by workpiece along the length for a given velocity with respect to time. The stresses calculated by considering resultant forces from experimentation and the results obtained by simulations are found to be correlating. Effective stress profiles are presented in Figs. 6a,b.

|

| Fig. 5 a Temperature vs time while cutting AISI D3, b temperature vs time while cutting AISI H13 |

|

| Fig. 6 a Stress distribution curve AISI D3, b stress distribution curve AISI H13 |

In the present study,experimental and FE modelling investigations using DEFORM 3D turning with mixed ceramic inserts are presented. Cutting experiments and 3D finite element simulations are performed on uniform honed tool. 3D finite element modelling is utilized to predict forces,temperature and stresses.

(i) The surface roughness values of 0.71 lm (as minimum) for AISI D3 and 0.743 lm for AISI H13 materials are obtained at cutting velocity of 155 m/min,feed rate of 0.075 mm/r and depth of cut 0.6 mm from the experimental results while machining. These machining results are the inputs considered for the analysis using DEFORM 3D software.

(ii) From the experimental results,surface roughness of 0.535 lm for AISI H13 material is observed at cutting velocity of 165 m/min,feed rate of 0.050 mm/r and depth of cut 0.3 mm are found to be minimum.

(iii) The heat generation and stress concentration along the tool cutting edge are more significant and this can affect tool life. Extensive experimentation has to be performed for analysis and this is a costly process. In the case of CAE large data are generated that can be utilised to predict performance characteristics at a low cost.

(iv) Good agreement has been shown in the case of tool temperature in both the experimentation and CAE simulated results for both AISI D3 and AISI H13 materials.

(v) The outcome may be seen as favourable for many performance characteristics experimented and analysed. Further investigations on performance characteristics by using other factors like shape of the insert,nose radius and micro geometry may be carried out to access the damage to the machined surfaces.

| 1. | Byrne G, Dornfeld D, Denkena B (2003) Advanced cutting technology. Ann CIRP 52(2):483-507 |

| 2. | Klocke F, Brinksmeier E, Weinert K (2005) Capability profile of hard cutting and grinding processes. Ann CIRP 54(2):557-580 |

| 3. | Klocke F, Kratz H (2005) Advanced tool edge geometry for high precision hard turning. Ann CIRP 54(1):47-50 |

| 4. | Denkena B, Becker JC, de Leon-Garcia L (2005) Study of the influence of the cutting edge micro geometry on the cutting forces and wear behavior in turning operations. In: Proceedings of the 8th CIRP, international workshop on modelling of machining operations, Chemnitz, pp 503-507 |

| 5. | Özel T, Hsu TK, Zeren E (2005) Effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and forces in finish turning of hardened AISI H13 steel. Int J Adv Manuf Technol 25:262-269 |

| 6. | Zou B, Chen M, Li S (2011) Study on finish-turning of NiCr20TiAl nickel-based alloy using Al2O3/TiN-coated carbide tools. Int J Adv Manuf Technol 53:81-92 |

| 7. | Fahad M, Mativenga PT, Sheikh MA (2012) A comparative study of multilayer and functionally graded coated tools in high-speed machining. Int J Adv Manuf Technol 62:43-57 |

| 8. | Gopalsamy BM, Mondal B, Ghosh S (2009) Optimisation of machining parameters for hard machining: grey relational theory approach and ANOVA. Int J Adv Manuf Technol 45:1068-1086 |

| 9. | Ahilan C, Kumanan S, Sivakumaran N (2010) Application of grey based taguchi method in multi response optimization of turning process. Adv Prod Eng Manag 5(3):171-180 |

| 10. | Tzeng CJ, Lin YH, Yang YK et al (2009) Optimization of turning operations with multiple performance characteristics using the taguchi method and grey relational analysis. J Mater Process Technol 209:2753-2759 |

| 11. | Kazancoglu Y, Esme U, Bayramoglu M et al (2011) Multi-objective optimization of the cutting forces in turning operations using the grey-based taguchi method. Mater Technol 45(2):105-110 |

| 12. | Senthilkumar N, Tamizharasan T, Anandakrishnan V (2013) An ANN approach for predicting the cutting inserts performances of different geometries in hard turning. Adv Prod Eng Manag 8(4):231-241 |

| 13. | Özel T (2003) Modeling of hard part machining: effect of insert edge preparation for CBN cutting tools. J Mater Process Technol 141:284-293 |

| 14. | Yen YC, Jain A, Altan T (2004) A finite element analysis of orthogonal machining using different tool edge geometry. J Mater Process Technol 146:72-81 |

| 15. | Hua J, Shivpuri R, Cheng X et al (2005) Effect of feed rate, workpiece hardness and cutting edge on subsurface residual stress in hard turning of bearing steel using chamfer and hone edge geometry. Mater Sci Eng, A 394:238-248 |

| 16. | Chen L, ElWardany TI, Nasr M et al (2006) Effects of edge preparation and feed when hard turning a hotwork die steel with polycrystalline cubic boron nitride tools. Ann CIRP 55(1):88-92 |

| 17. | Umbrello D, Rizzuti S, Outeiro JC (2008) Hardnessbased flowstress for numerical simulation of hardmachining AISI H13 tool steel. J Mater Process Technol 199(1-3):64-73 |

| 18. | Karpat Y, Özel T (2008) Mechanics of high speed machining with curvilinear tools. Int J Mach Tools Manuf 49:195-208 |

| 19. | Ceretti E, Lazzaroni C, Menegardo L et al (2000) Turning simulations using a three-dimensional FEM code. J Mater Process Technol 98:99-103 |

| 20. | Guo Y, Liu CR (2002) 3D FEA modeling of hard turning. ASME J Manuf Sci Eng 124:189-199 |

| 21. | Aurich JC, Bil H (2006) 3D finite element modelling of segmented chip formation. Ann CIRP 55(1):47-50 |

| 22. | Rosochowska M, Balendra R, Chodnikiewicz K (2003) Measurements of thermal conductance. J Mater Process Technol 135:204-210 |

| 23. | Incropera FP, DeWitt DP (2001) Fundamentals of heat and mass transfer. Willey, New York |

| 24. | Johnson GR, Cook WH (1985) Fracture characteristic of three metals subjected to various strains. Eng Fract Mech 21:3 |

2015, Vol. 3

2015, Vol. 3